Anti-cracking surface-grinded brick and preparation method thereof

A technology for surface grinding and anti-cracking of bricks, which can be applied to clay products, other household utensils, applications, etc., and can solve the problems of fine grains in finished products, dry cracks in adobes, high drying shrinkage and sintering shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

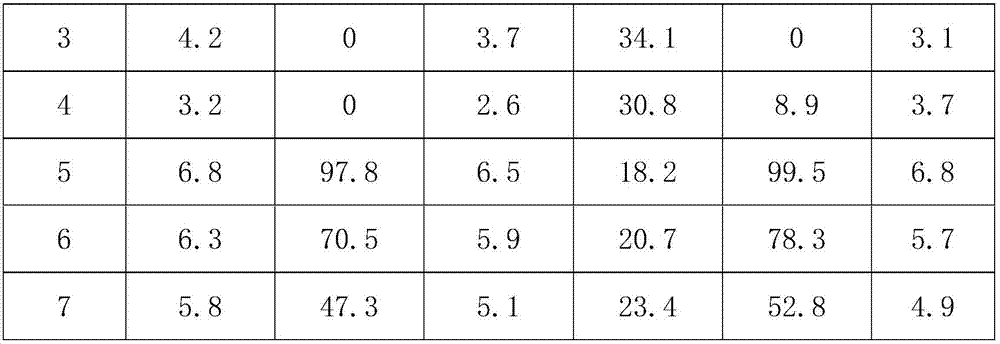

Examples

Embodiment 1

[0024] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 20% of alkylketene modified cellulose, 5% of phosphate, 5% of polyvinyl alcohol, 15% of bentonite, 5% of polyacrylic acid emulsion and 15% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0025] Step B, according to weight percentage, mix 20% of plastic mud, 30% of whole body brick clinker particles of 10-15 mesh, 15% of vitrified brick clinker particles of 20-30 mesh, 32% of feldspar solvent and the anti-cracking 3% agent, add water and knead evenly to make mud;

[0026] In step C, the uniformly mixed mud in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into wet bricks, wherein the relative vacuum degree of the vacuum extruder is - 0.08~-0.1MPa, the moisture content of mud particles is 20%;

[0027] Step D, placing the extruded wet adobe o...

Embodiment 2

[0032] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 10% of alkyl ketene modified cellulose, 2% of phosphate, 3% of polyvinyl alcohol, 10% of bentonite, 5% of polyacrylic acid emulsion and 35% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0033] Step B, according to weight percentage, mix 20% of plastic mud, 30% of whole body brick clinker particles of 10-15 mesh, 15% of vitrified brick clinker particles of 20-30 mesh, 32% of feldspar solvent and the anti-cracking 3% agent, add water and knead evenly to make mud;

[0034] In step C, the uniformly mixed mud in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into wet bricks, wherein the relative vacuum degree of the vacuum extruder is - 0.08~-0.1MPa, the moisture content of mud particles is 20%;

[0035] Step D, placing the extruded wet adobe ...

Embodiment 3

[0040] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 20% of alkylketene modified cellulose, 5% of phosphate, 5% of polyvinyl alcohol, 15% of bentonite, 5% of polyacrylic acid emulsion and 15% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0041] Step B, according to weight percentage, mix 20% of plastic mud, 30% of whole body brick clinker particles of 10-15 mesh, 15% of vitrified brick clinker particles of 20-30 mesh, 32% of feldspar solvent and the anti-cracking 1% agent, add water and knead evenly to make mud;

[0042] In step C, the uniform mud mixed in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into wet bricks, wherein the relative vacuum degree of the vacuum extruder is - 0.08~-0.1MPa, the moisture content of mud particles is 20%;

[0043] Step D, placing the extruded wet adobe on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com