Steam sterilization method and steam sterilizer utilizing contact type downward eccentric pipeline

A disinfection method and eccentric tube technology, applied in heating and other directions, can solve the problems of short service life of steam sterilizer, poor use effect, and influence on heating plate, etc., and achieve the effect of improving steam disinfection performance, simple structure, and reducing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

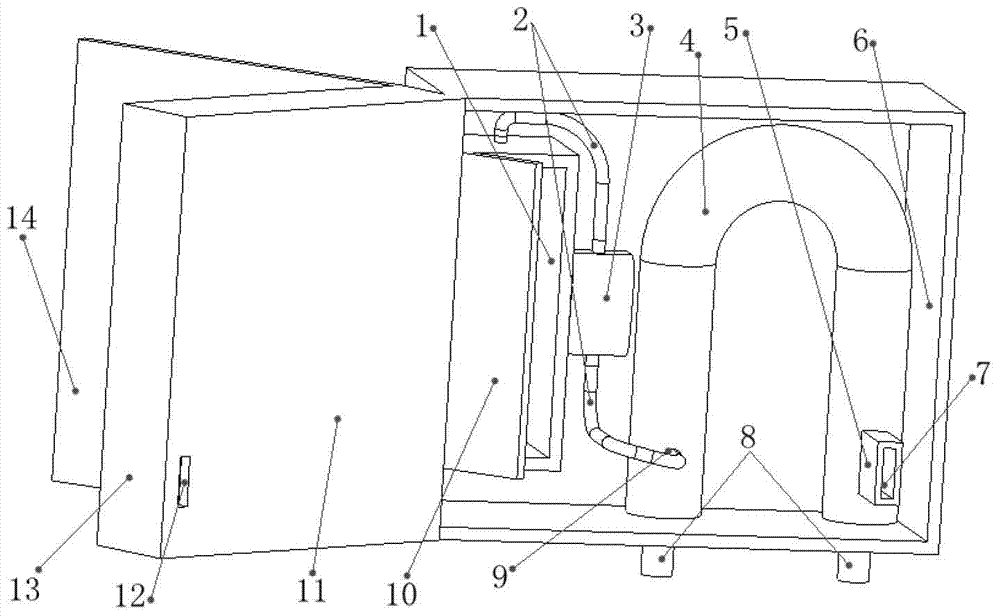

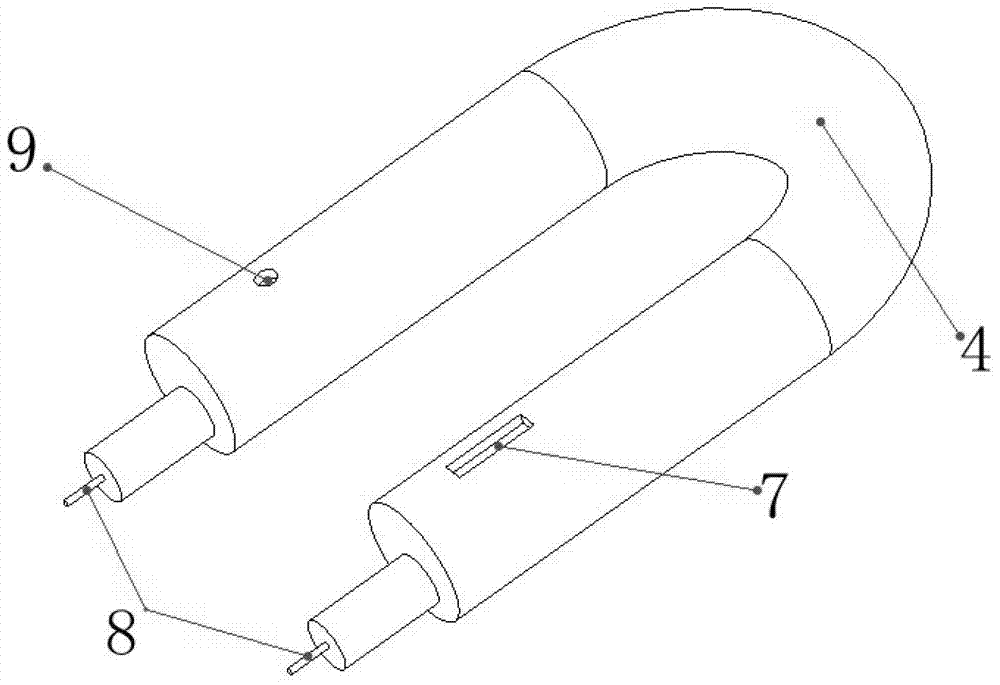

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0020] Example. The steam disinfection method using the contact downward eccentric pipeline is characterized in that: the water supply flow is controlled by the pump, and the water supply enters the eccentric pipeline, and the eccentric pipeline not only makes the water directly contact with the heater installed in the eccentric pipeline, but also increases The contact area is enlarged, so as to obtain a higher evaporation rate and a shorter preheating time, and reduce the amount of fouling and reaction time, so as to achieve the purpose of reducing fouling. The eccentricity of the eccentric pipeline is 20%-30% of the radius of the circular tube of the eccentric pipeline. The flow rate of the water supply is controlled at 10-30g / min. The evaporation rate is 10-30g / min. The power of the heater 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com