Method capable of improving coating film uniformity and graphite carrier

A graphite carrier and uniformity technology, which is applied in climate sustainability, photovoltaic power generation, electrical components, etc., can solve problems such as short temperature stabilization time and large film thickness span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

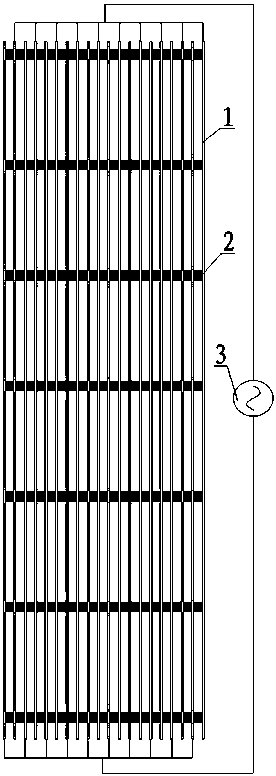

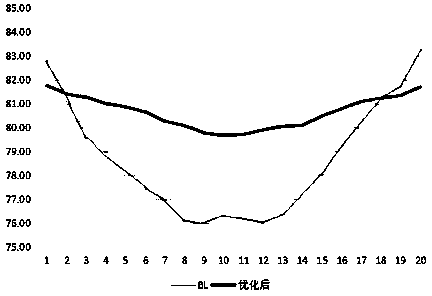

[0036] The present invention relates to a kind of method that can improve coating uniformity, comprises the following steps:

[0037] a) Number the solar cell carriers loaded on the graphite carrier in the deposition furnace sequentially from the outside to the inside with the solar cell carrier numbers C1, C2, C3...Cn;

[0038] b) The distance between C1 and C2 is denoted as D1, the distance between C2 and C3 is denoted as D2, ... the distance between Cn-1 and Cn is denoted as Dn-1;

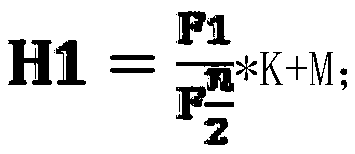

[0039] c) The length of the ceramic support sleeve between C1 and C2 is denoted as H1, the length of the ceramic support sleeve between C2 and C3 is denoted as H2, ... the length of the ceramic support sleeve between Cn-1 and Cn is denoted as Hn-1;

[0040] d) The graphite carriers in the deposition furnace are evenly arranged at equal distances, so that the spacing between the solar cells loaded on each graphite carrier is equal, that is, each D1=D2=D3=...=Dn-1=H1=H2=H3 =…=Hn-1;

[0041] e) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com