Multistage separation center backflow axial cyclone burner

An axial swirl, multi-stage separation technology, applied in burners, burners for burning powder fuel, combustion methods, etc., to reduce the generation of NOx, promote the ignition of pulverized coal, and have strong adaptability to coal types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

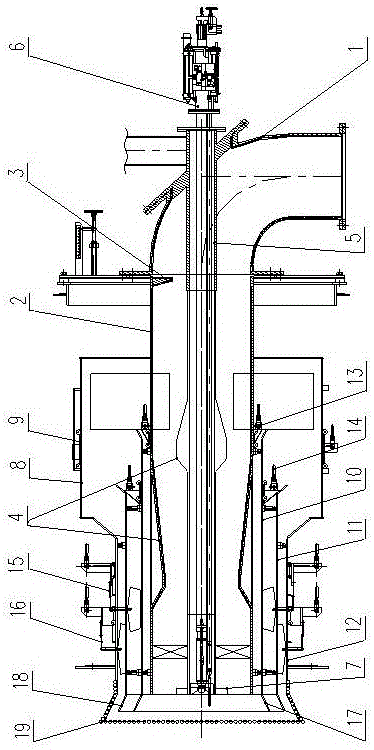

[0027] A multi-stage separation center return type axial swirl burner, its composition includes: a primary air powder system, a total secondary air system, the primary air powder system includes a primary air pipe elbow 1, the primary air The pipe elbow is connected to the horizontal section 2 of the primary air pipe through the flange, and the secondary air pipe 10 is installed on the outside of the horizontal section of the primary air pipe. Angle secondary air duct flaring 17, this flaring is connected with the secondary air duct by welding and reinforcing plate, the outside of the secondary air duct is equipped with a tertiary air duct 11, and the outlet end of the tertiary air duct is set There is a tertiary air duct flaring 18 with a certain angle with the axial direction. This flaring is connected with the tertiary air duct by welding and reinforcing plate. The tertiary air duct 12 is installed outside the tertiary air duct. The horizontal section of the primary air duc...

Embodiment 2

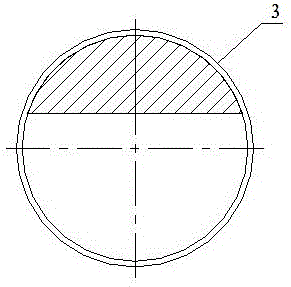

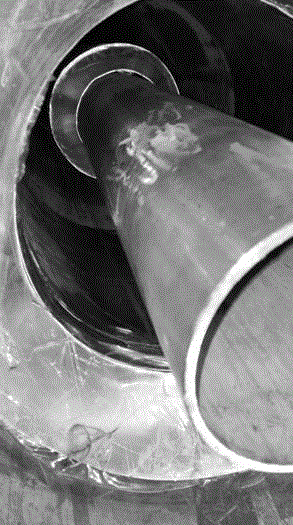

[0029] According to the multi-stage separation center return type axial swirl burner described in embodiment 1, a crescent-shaped pulverized coal distributor 3 is installed on the upper part of the inlet end of the horizontal section of the primary air duct, and the horizontal section of the primary air duct is A Venturi pulverized coal concentrator 4 is installed near the outlet end of the section, and a central air duct assembly 5 is installed at the center of the horizontal section of the primary air duct, and the outlet end of the central air duct assembly is connected to the horizontal section of the primary air duct through a bracket , the inlet end is connected to the elbow of the primary air duct through an inclined flange, the outlet end of the central air duct assembly is welded to the combustion-stabilizing ring 7, and an oil gun assembly 6 is installed at the center of the central air duct assembly , the outlet end of the oil gun assembly is supported in the central...

Embodiment 3

[0031]According to the multi-stage separation center return type axial swirl burner described in embodiment 1 or 2, the total secondary air system includes an air box 8, and the air box is welded with the horizontal section of the primary air pipe and the four The air ducts are connected, and the main air brake assembly 9 is installed on the outside of the air box, and the general air brake assembly is a coaxial cylinder located outside the air box, which can move axially through its pulleys, guide rails and connecting rods. To adjust the opening of the damper, a tertiary air swirl adjustment mechanism 15 is arranged near the outlet end of the tertiary air duct. This adjustment mechanism is to install a group of axial swirl blades arranged at equal intervals on the circumference of the tertiary air duct passage. Each blade is connected to a ring plate installed on the outside of the quaternary air duct through its positioning shaft and drive link. The quaternary air swirl adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com