Graded air-feed dual-swirled pulverized coal industrial furnace combustor

A technology for industrial boilers and burners, which is applied in the direction of burners, burners for burning powder fuel, and combustion methods, etc. It can solve problems such as difficulties and small furnace space, so as to suppress the formation of NOX, improve the burnout rate, and prevent slagging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

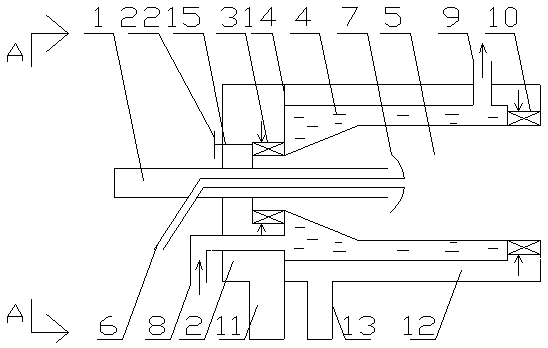

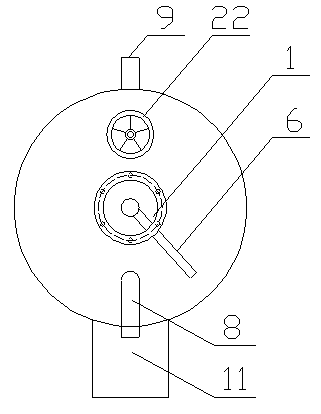

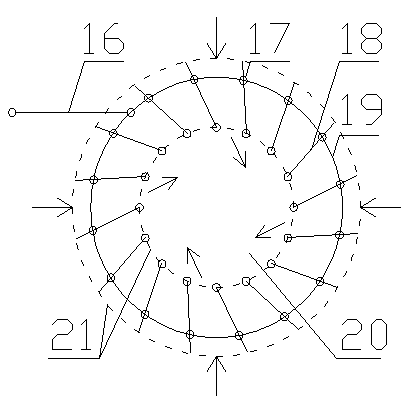

[0029] Such as figure 1 , figure 2 As shown, an annular baffle plate 14 of the air chamber of the present invention is divided into two parts, the secondary air box 2 and the classification air box 12. In the area surrounded by the secondary wind box 2 and the classification wind box 12, a pre-combustion chamber 5 is arranged. The front section of the chamber 5 is surrounded by the secondary air box 2, and communicates with the secondary air box 2 through the secondary air cyclone 3; the middle section and the rear section of the pre-combustion chamber 5 are surrounded by the grading air box 12, and are connected by an annular water cooling jacket 4 and The grading bellows 12 are separated. The lower side of the water cooling jacket 4 is provided with a cooling water inlet pipe 8, and the cooling water inlet pipe 8 passes through the secondary air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com