200 MW grade high-efficiency subcritical boiler

A grade, boiler technology, applied in steam boilers, boiler water pipes, steam boiler accessories, etc., can solve the problems of low main steam pressure, low reheat steam temperature, low main steam temperature, etc., to reduce coal consumption, improve efficiency, improve The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

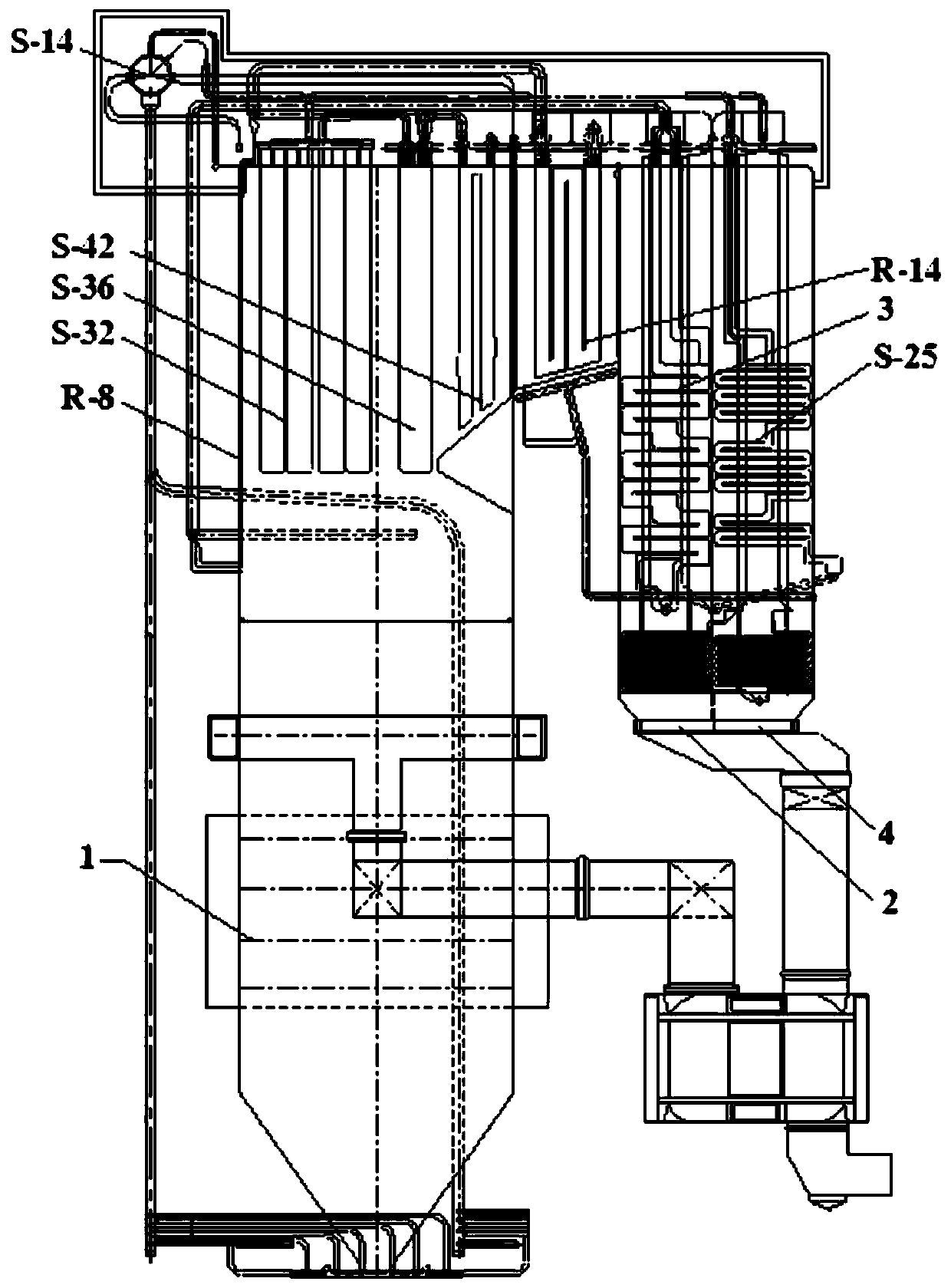

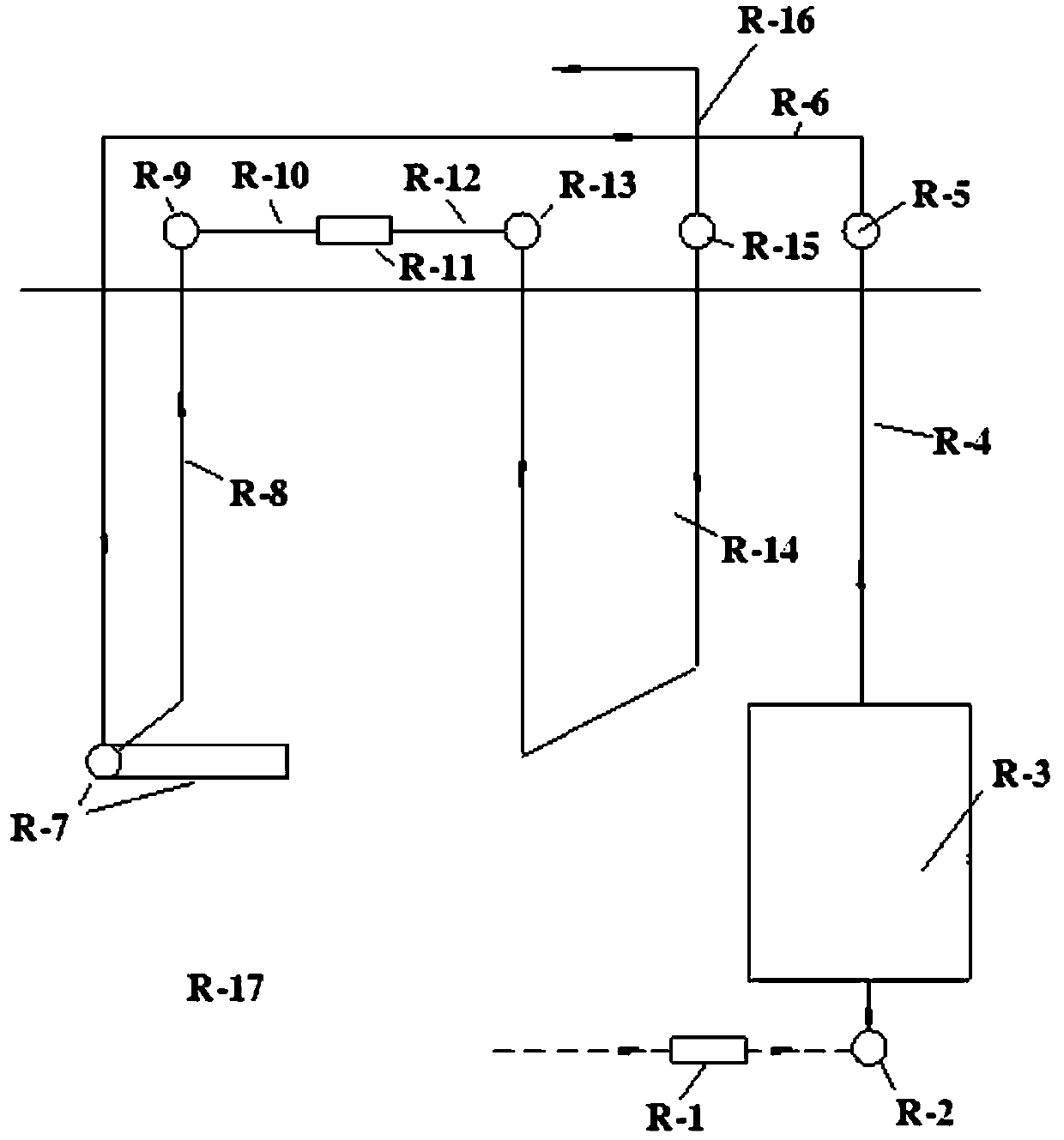

[0014] Specific embodiment 1: This embodiment is a high-efficiency subcritical boiler of 200MW level, which includes a drum S-14, a water wall, a cladding wall, a superheater, a reheater, an economizer, and a desuperheater; the furnace The outer ring is equipped with a water-cooled wall and a cladding wall, and the cladding wall is equipped with a superheater, a reheater, an economizer and a desuperheater, and the water-cooled wall is connected to the drum; a unit with double flue at the tail is adopted, and The radiation reheater R-8 is arranged on the unit with double flue at the tail; the swing burner 1 is installed in the middle of the water wall; the reheater side temperature regulation baffle 2 and the superheater side temperature regulation baffle 4 are arranged;

[0015] The steam parameters of the 200MW high-efficiency subcritical boiler are as follows: the main steam pressure is 17.5MPa·g, the main steam temperature is 571°C, and the reheat steam temperature is 569°C....

specific Embodiment approach 2

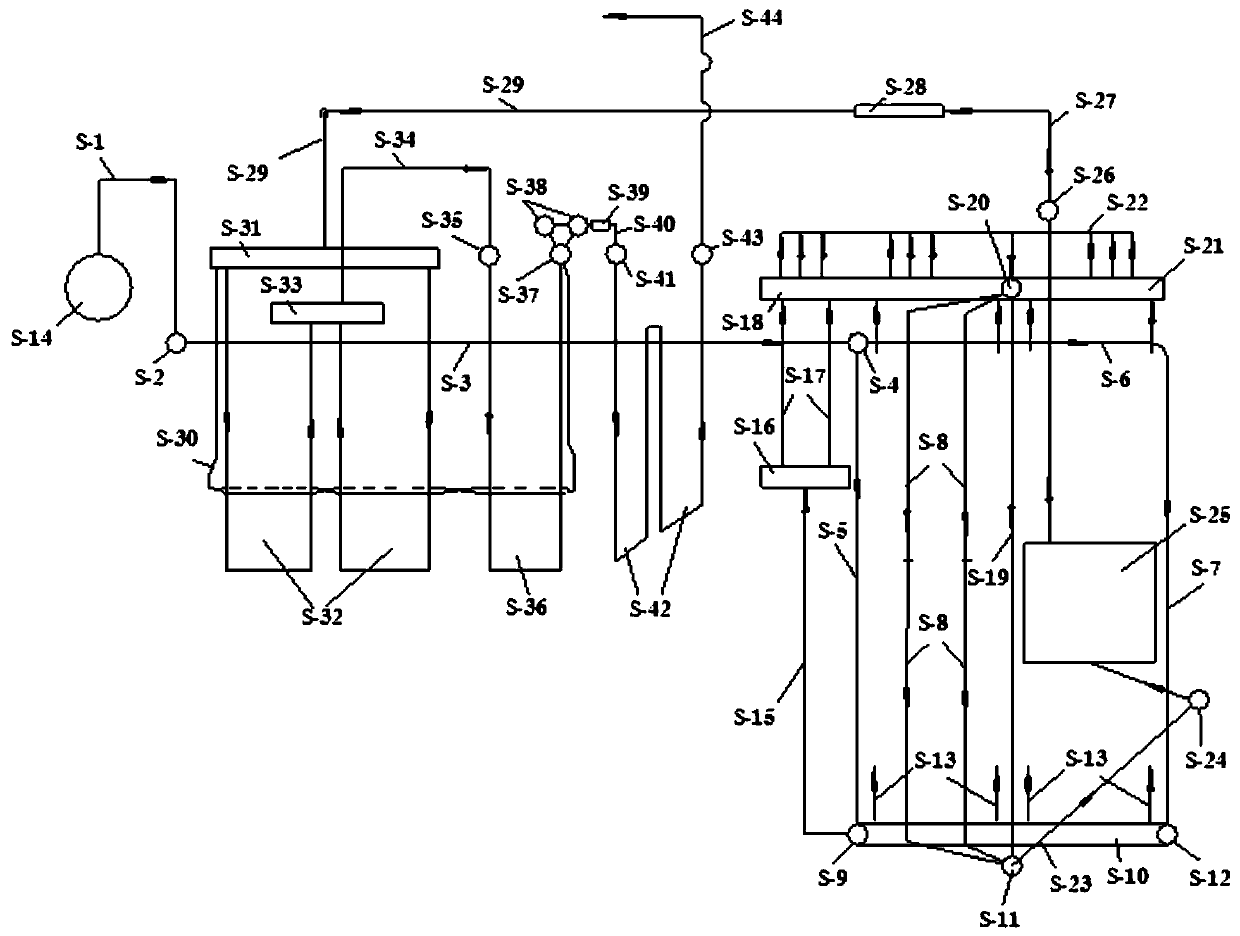

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the composition and connection of the superheater are as follows:

[0018] The ceiling inlet header S-2 is connected to the drum S-14 through the steam outlet pipe S-1, and the ceiling inlet header S-2 is connected to the ceiling outlet header S-4 through the ceiling pipe S-3. The ceiling outlet header S-4 is connected to the lower header S-9 of the rear flue front wall through the rear flue front wall S-5, and the ceiling outlet header S-4 is connected to the lower header S-9 of the rear flue rear wall. The header S-12 is connected through the roof pipe S-6 of the rear flue and the rear wall of the rear flue S-7, the lower header S-9 of the front wall of the rear flue and the lower header S-12 of the rear wall of the rear flue are respectively Connect with the lower header S-10 of the side wall of the rear flue, the lower header of the side wall of the rear flue S-10 and the...

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the lower header S-9 on the front wall of the rear flue and the header S-18 on the side wall of the horizontal flue pass through the lower header of the horizontal flue. The box connecting pipe S-15, the lower header box S-16 of the side wall of the horizontal flue and the pipe S-17 of the wall of the horizontal flue are connected. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com