Low-load stable-combustion boiler combustor and combustion method and application thereof

A technology of stable combustion and boiler combustion, applied in the combustion method, combustion air/fuel supply, combustion using multiple fuels, etc., can solve the problems of increased incomplete combustion loss, low-load stable combustion characteristics, unsafe and reliable operation, etc. , to achieve the effect of good calorific value, avoid waste, reduce environmental pollution and greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

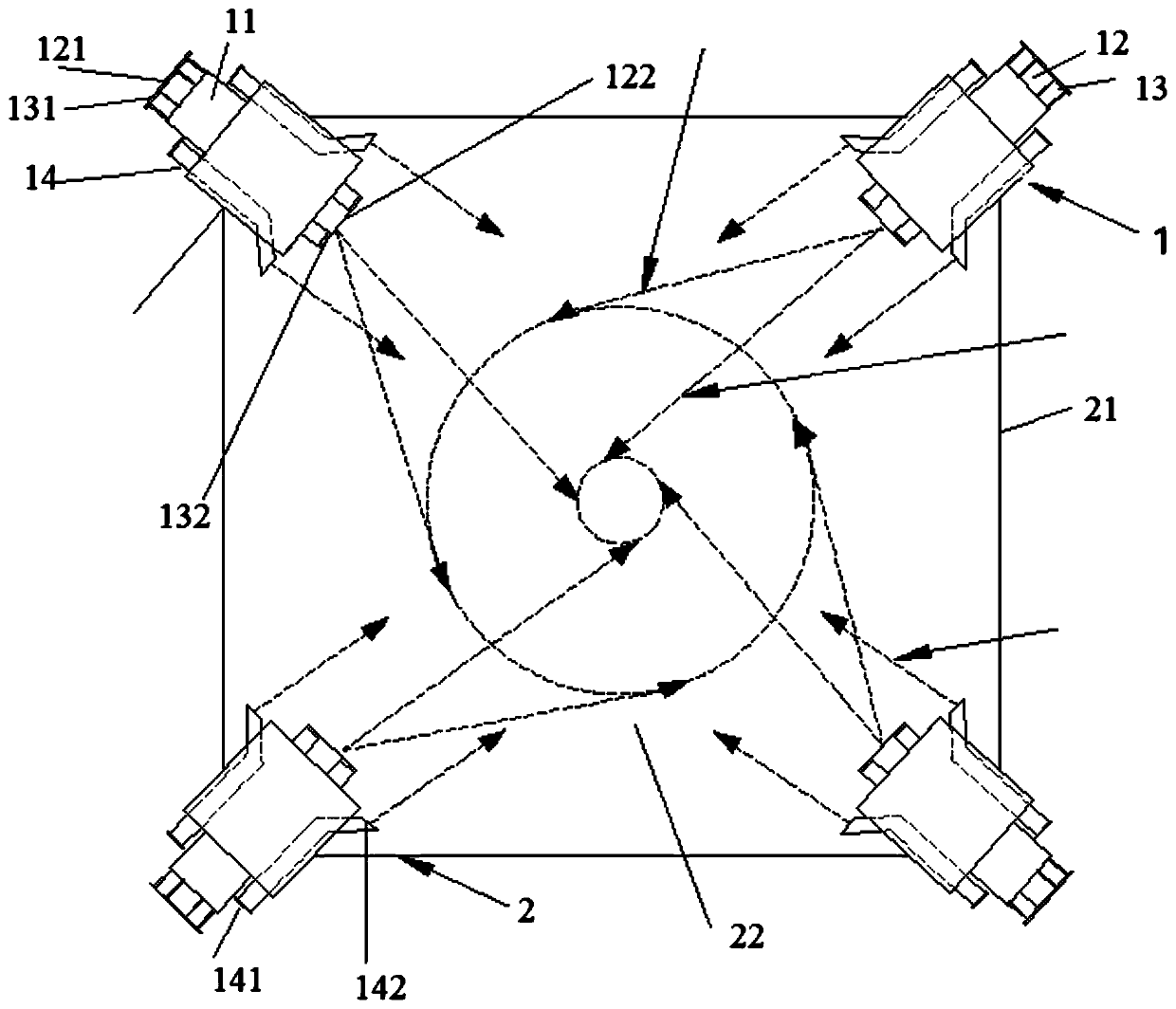

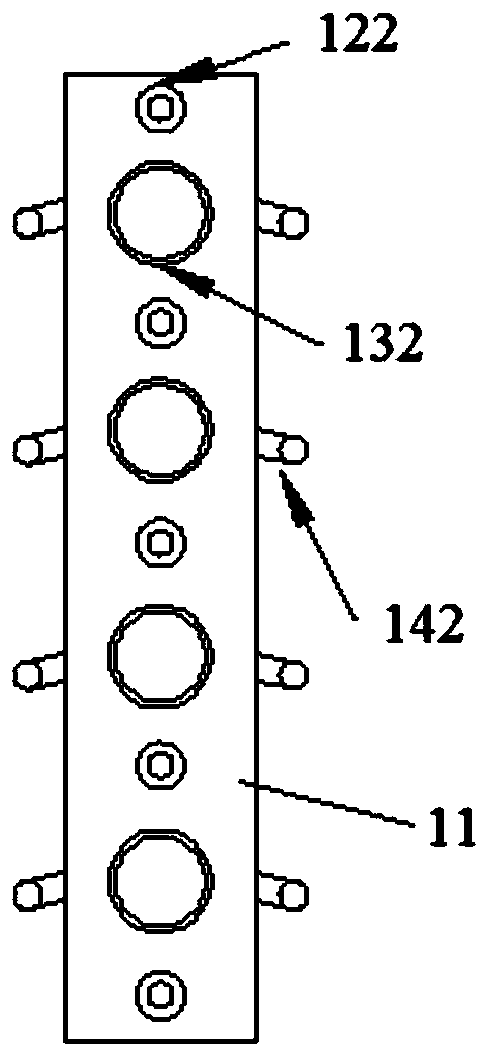

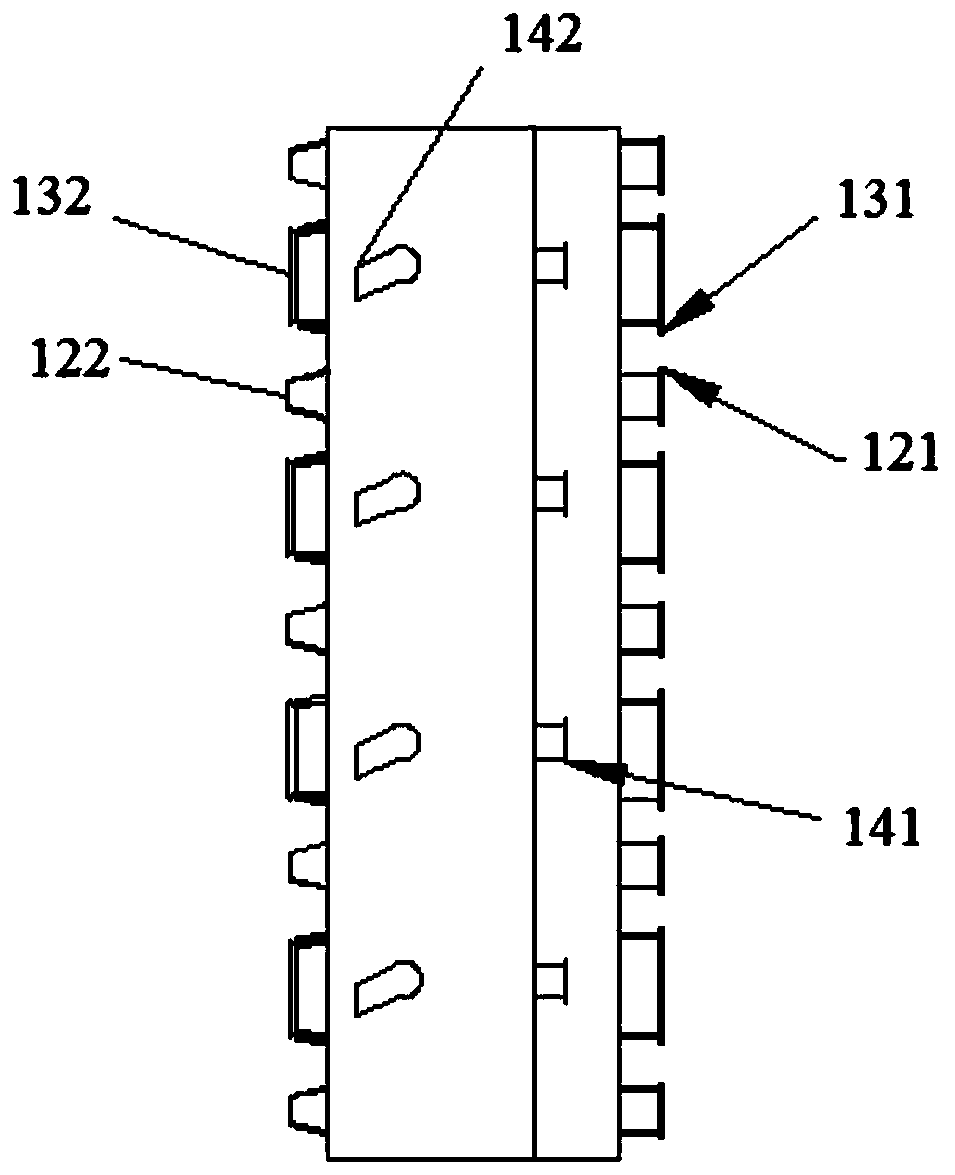

[0034] Such as Figure 1-4 as shown, figure 1 The middle arrows indicate the direction of air flow respectively. A boiler burner with low load and stable combustion includes a burner 1 and a furnace 2. The primary air pipe 13 surrounding both sides of the secondary air pipe 12, the biomass fuel pipe 14 arranged close to the inner wall of the casing 11, and the burner 1 is arranged at the four corners of the furnace 2, wherein:

[0035] The secondary air nozzle 122 of the secondary air pipe 12 is arranged along the circular tangent direction of the furnace 2; the secondary air is ejected from the secondary air nozzle 122 to form tangential combustion.

[0036] The primary air nozzle 132 of the primary air pipe 13 is arranged along the radial direction of the furnace 2; the primary air is ejected from the primary air nozzle 132, carrying coal powder into the furnace for combustion.

[0037] The biomass fuel nozzle 142 of the biomass fuel pipe 14 is arranged along the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com