Bottom plate liquid cooling battery module with honeycomb-shaped heat dissipation channels

A heat dissipation channel, liquid-cooled battery technology, applied in secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of reduced battery efficiency, less heat, insufficient battery thermal management, etc., to achieve good heat, The effect of increasing the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below the present invention is further described:

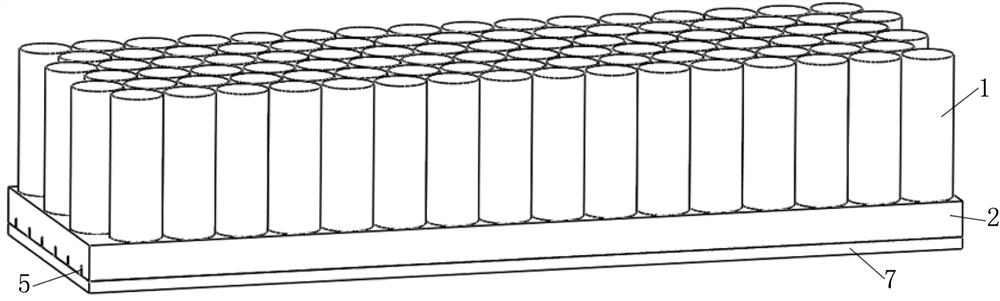

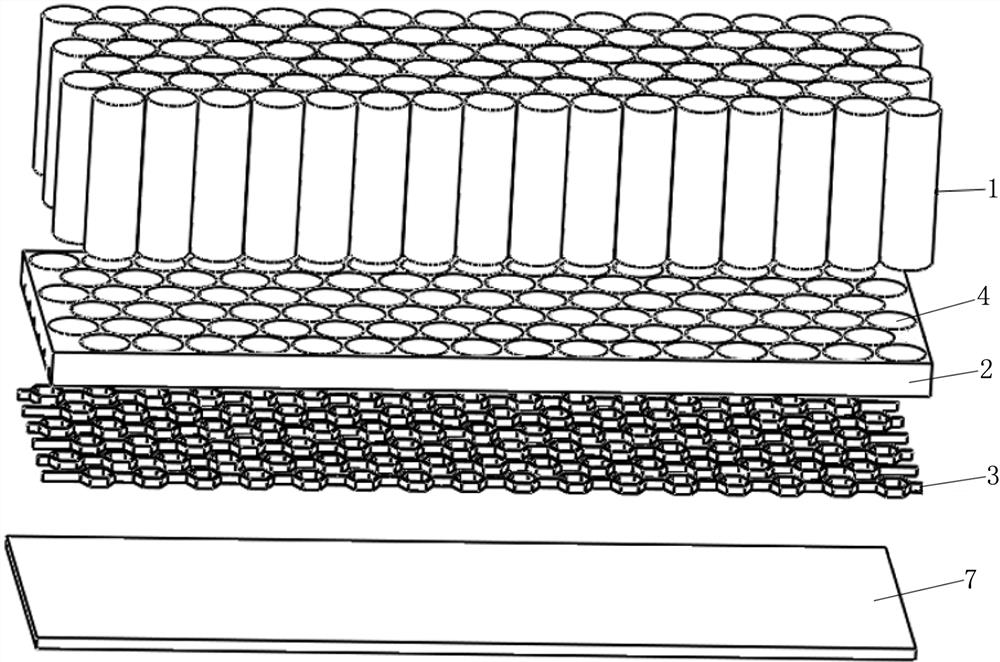

[0023] see Figure 1-6 ,

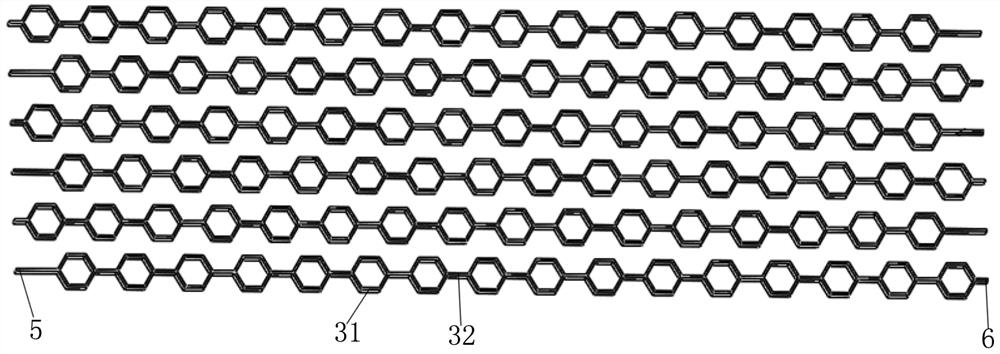

[0024] The invention discloses a base plate liquid-cooled battery module with a honeycomb heat dissipation channel, which includes a cylindrical battery 1, a liquid cooling plate 2 and a honeycomb liquid cooling heat dissipation channel 3. The liquid cooling plate 2 has a square structure, and its upper surface is provided with A number of circular grooves 4 for the insertion of the bottom of the cylindrical battery 1; a number of honeycomb liquid-cooled heat dissipation channels 3 are fixed inside the liquid-cooled plate 2, with coolant inlets 5 and coolant outlets 6 at both ends Pass through the two end walls of the liquid cold plate 2 to communicate with the outside; the bottom of the liquid cold plate 2 is provided with a cooling bottom plate 7 matching its shape, which skillfully utilizes the characteristics of the honeycomb hexagon, and the fluid in the The flow in this channel is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com