Fan coal mill with both coal groove angle and motor rotating speed being capable of being adjusted

A technology of fan coal pulverizer and motor speed, applied in grain processing and other directions, can solve the problems of narrow fineness range, difficult impact and crushing effect, coarse particle size, etc., to meet the requirements of fine adjustment and reduce equipment operating costs , the effect of improving the adaptability of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

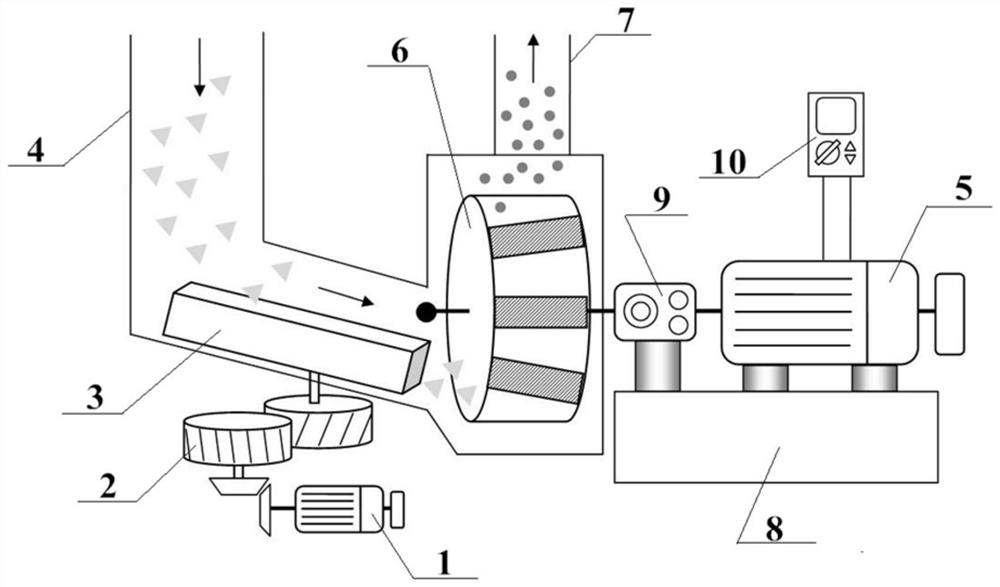

[0019] refer to figure 1 , the fan coal mill with double adjustable coal tank angle and motor speed according to the present invention includes a coal drop pipe 4, a raw coal conveying pipeline, a blow chamber, a coal mill motor 5, a coal tank motor 1 and a powder outlet pipe 7; The bottom outlet of the coal pipe 4 is connected with the entrance of the raw coal conveying pipeline, and the raw coal conveying pipeline is connected with the entrance of the percussion chamber, and the percussion wheel 6 is arranged in the percussion chamber, and the coal groove 3 is arranged inside the raw coal conveying pipeline, and the coal mill motor 5 The output shaft of the coal tank motor 1 is connected to the beating wheel 6, the output shaft of the coal tank motor 1 is connected to the coal tank 3, the outlet of the percussion chamber is connected to the powder outlet pipe 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com