A method and equipment for multi-stage entrained entrained bed coal gasification coupled with high temperature shift

A high-temperature conversion and entrained bed technology, which is applied in the gasification of granular/powdered fuels, chemical industry, and the manufacture of combustible gases, can solve the problems of high-temperature sensible heat utilization, large CO conversion load, and large sensible heat loss of gas. , to achieve the effects of improving the adaptability of coal types, reducing the system switching load, reducing system investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

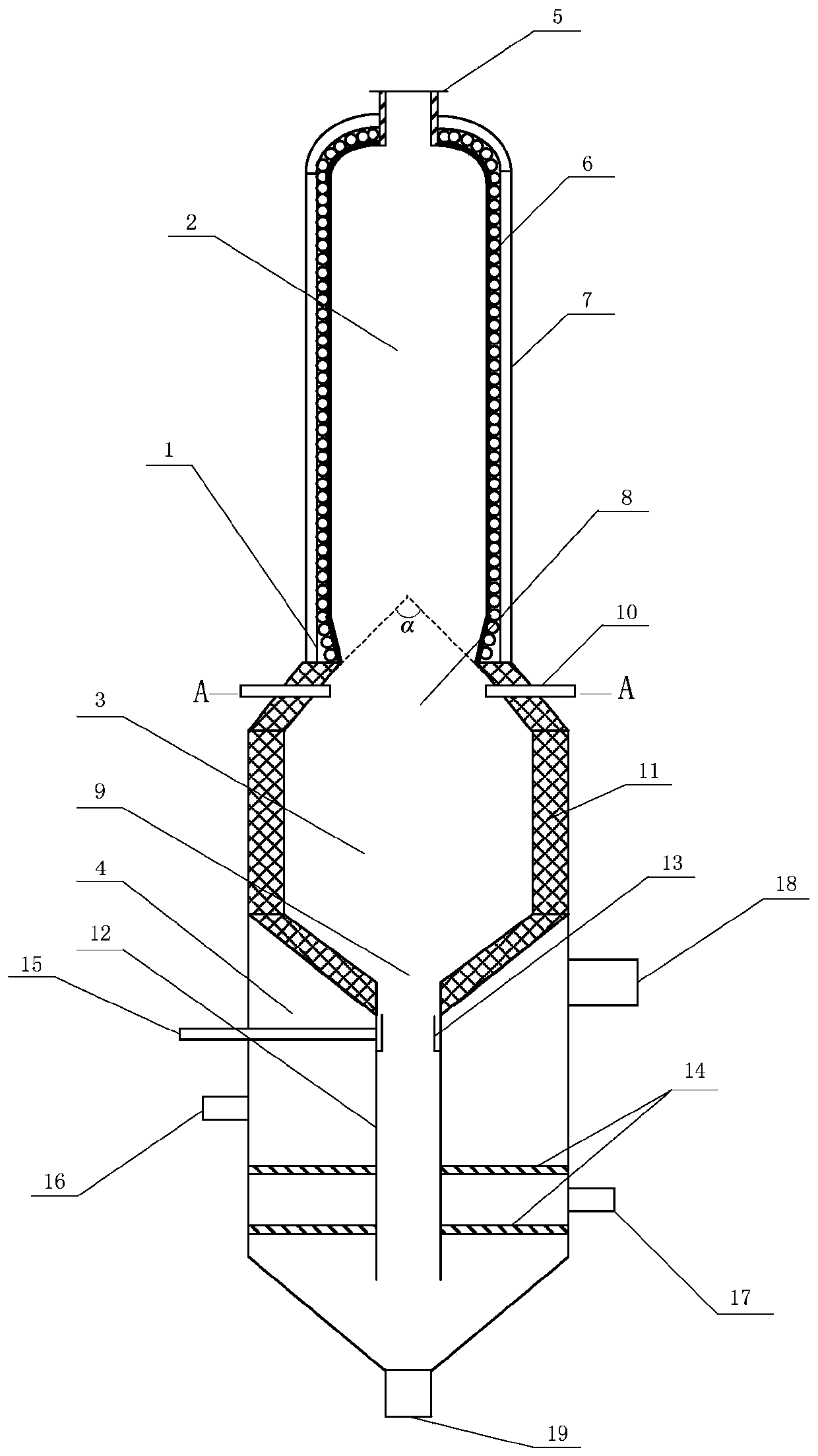

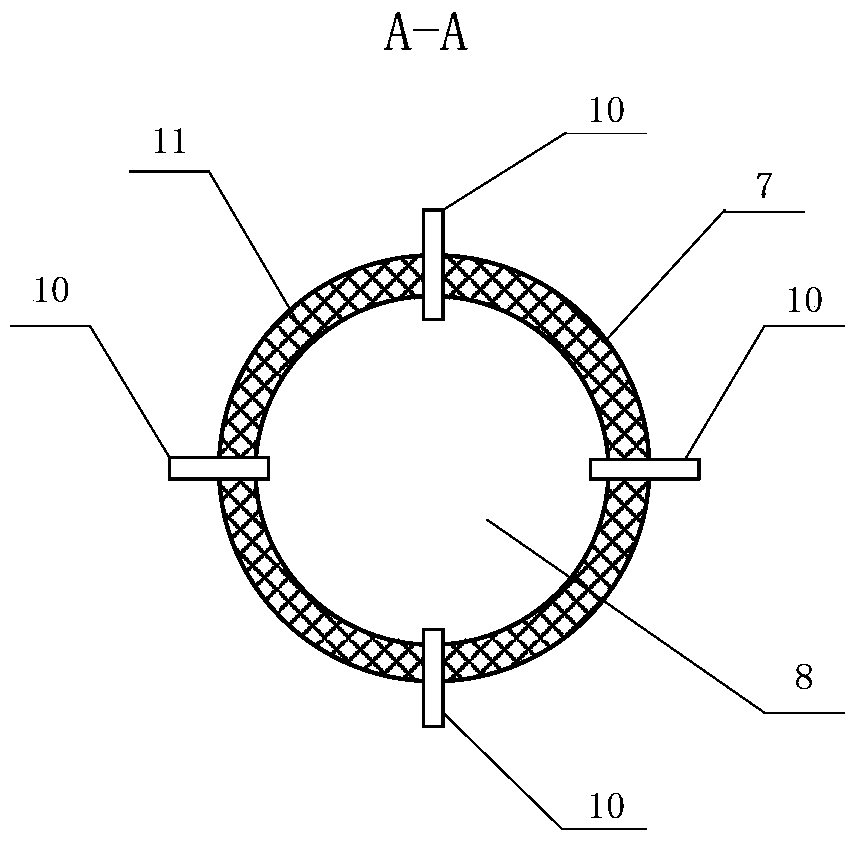

[0032]A multi-stage entrained entrained gasifier, which includes a furnace body 1, a high-temperature gasification section 2, a high-temperature transformation section 3 and a quenching section 4, and is characterized in that the furnace body 1 is divided into a high-temperature gasification section 2, a high-temperature transformation section 3 and a quenching section. Section 4, the inner wall of the high-temperature gasification section 2 is a water-cooled wall 6, the outer wall is a cylindrical shell 7, the top of the high-temperature gasification section 2 has coal powder and gasification agent inlet 5, and the lower part of the high-temperature gasification section 2 passes through the flaring section 8 and The high-temperature conversion section 3 is connected, and the conical surface of the flared section 8 is evenly distributed to change the atomizing nozzle 10 for spraying water or low-temperature steam. It is a refractory lining 11, the outer wall is a cylindrical sh...

Embodiment 2

[0042] The total height of the multi-stage entrained-bed coal gasifier is 13800mm. Among them, the height of the high-temperature gasification section is 5200mm, the inner diameter is 450mm, and the wall is a coiled water-cooled wall structure; the height of the high-temperature transformation section is 4100mm, the inner diameter is 900mm, and the wall is a corundum refractory lining structure; the height of the chilling section is 4500mm, and the inner diameter is 900mm; The apex angle α of the section cone is 60°, and 8 nozzles are evenly distributed along the circumference of the conical surface of the flaring section, and are arranged opposite to each other at 45° horizontally downward; 10 layers of baffles are arranged in the chilling section, The included angle between the plate blade and the horizontal plane is 60°, and the rest of the multi-stage entrained-bed coal gasifier is the same as that in Embodiment 1.

[0043] The properties of the experimental coal are as de...

Embodiment 3

[0049] The total height of the multi-stage entrained bed coal gasifier is 14300mm. Among them, the height of the high-temperature gasification section is 5500mm, the inner diameter is 800mm, and the wall is a coiled water-cooled wall structure; the height of the high-temperature transformation section is 3700mm, the inner diameter is 1200mm, and the wall is a corundum refractory lining structure; the height of the chilling section is 5100mm, and the inner diameter is 1200mm; The apex angle α of the section cone is 150°, and there are 12 spray water atomization nozzles evenly distributed along the circumference of the cone surface of the flaring section, which are arranged opposite to each other at 60° horizontally downward; 15 layers of baffles are arranged in the chilling section, The included angle between the plate blade and the horizontal plane is 75°, and the rest of the multi-stage entrained-bed coal gasifier is the same as that in Embodiment 1.

[0050] The experimental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com