Catalytic coal gasifaction furnace of differential speed bed, and method of catalytic gasification

A technology of coal catalytic gasification and differential speed, which is applied in the field of coal gasification, can solve the problems of dry powder drying, complex preparation system, complex furnace structure and control system, and poor amplification capacity of fluidized bed gasifier, so as to avoid coal gasification. Poor coal type adaptability, strong coal type adaptability, and the effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

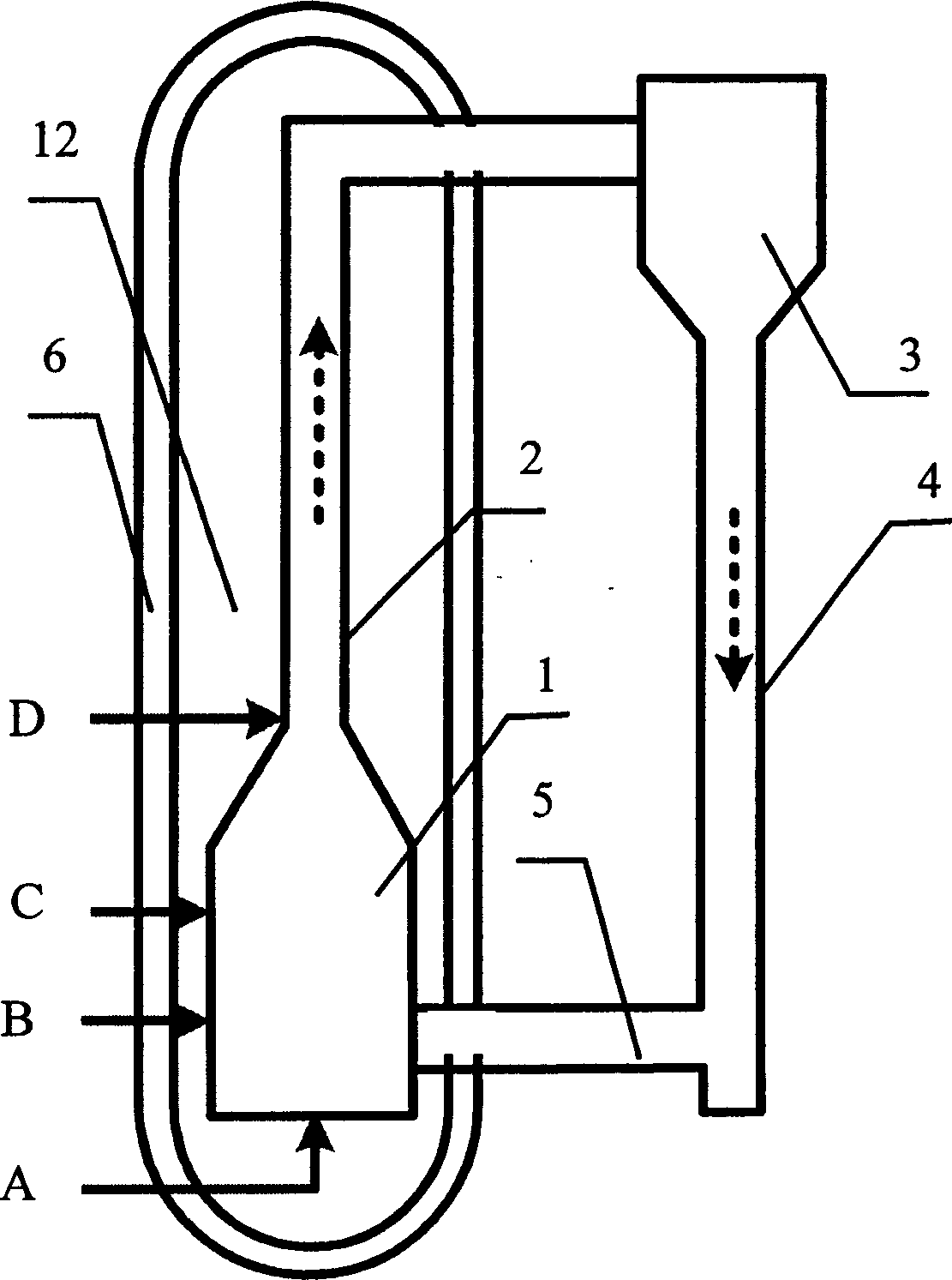

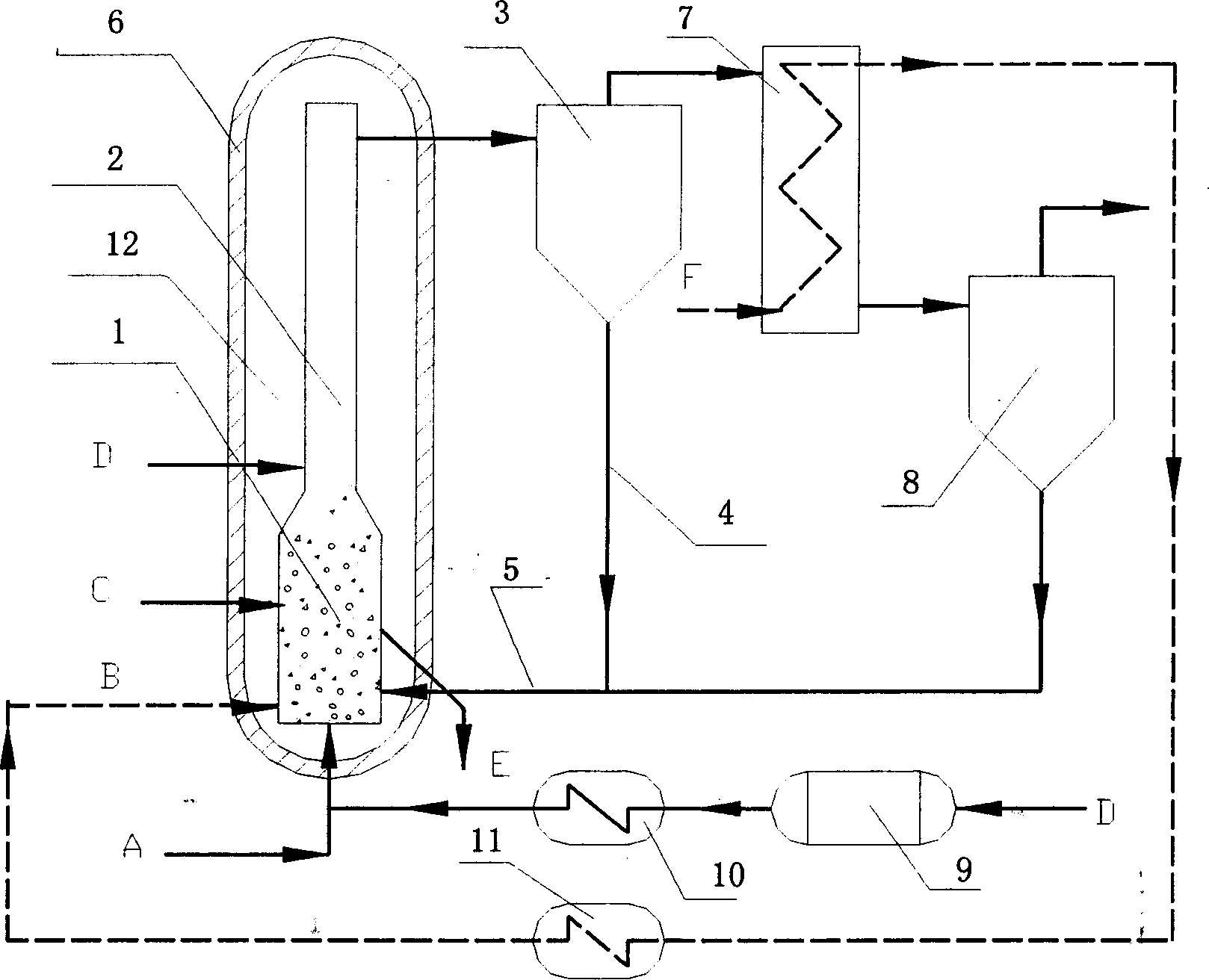

[0012] See attached figure 1 , the gasifier hearth is divided into two sections, the lower hearth 1 and the upper hearth 2 . The lower furnace 1 is a chamber body with a wide bed diameter. The gas flow rate in this bed is low (3-4m / s), and the gas-solid contact mode is a turbulent bed. In this operating mode, the gas-solid contact is good and no large bubbles are generated. Coal, limestone, catalyst and gasification agent (air / oxygen and steam) inlets and slag outlets are arranged around and at the bottom of the bed, and the operating temperature in the bed is low (850-950°C), which is conducive to the partial coal gasification and limestone desulfurization reactions. conduct. At the upper part of the lower furnace 1, the surrounding area of the bed will shrink inward to form a reaction tube with a smaller area to form the upper furnace 2. After the area shrinks, the gas flow rate will increase. Under the upper furnace 2, air or oxygen will be introduced to burn part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com