High-efficiency low-NOx staged coupling combustion method for inferior coal

A combustion method and low-quality coal technology, applied in the direction of combustion method, graded combustion, combustion type, etc., can solve the problems that low NOx emissions and high combustion efficiency cannot be achieved at the same time, and achieve the effect of no slagging load response and low NOx combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

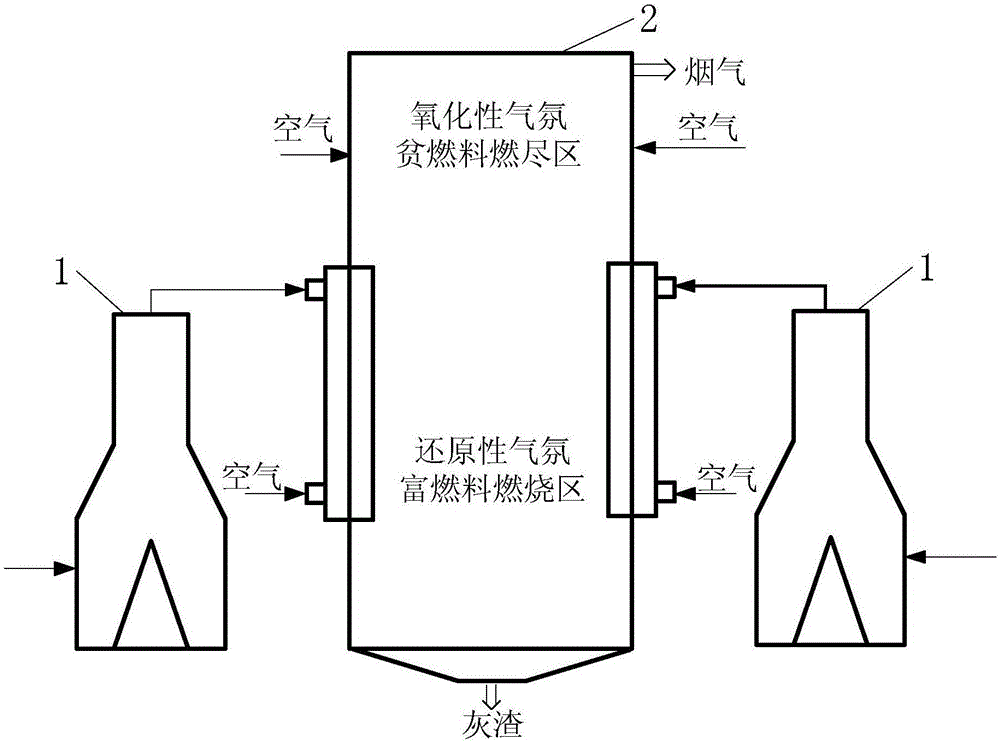

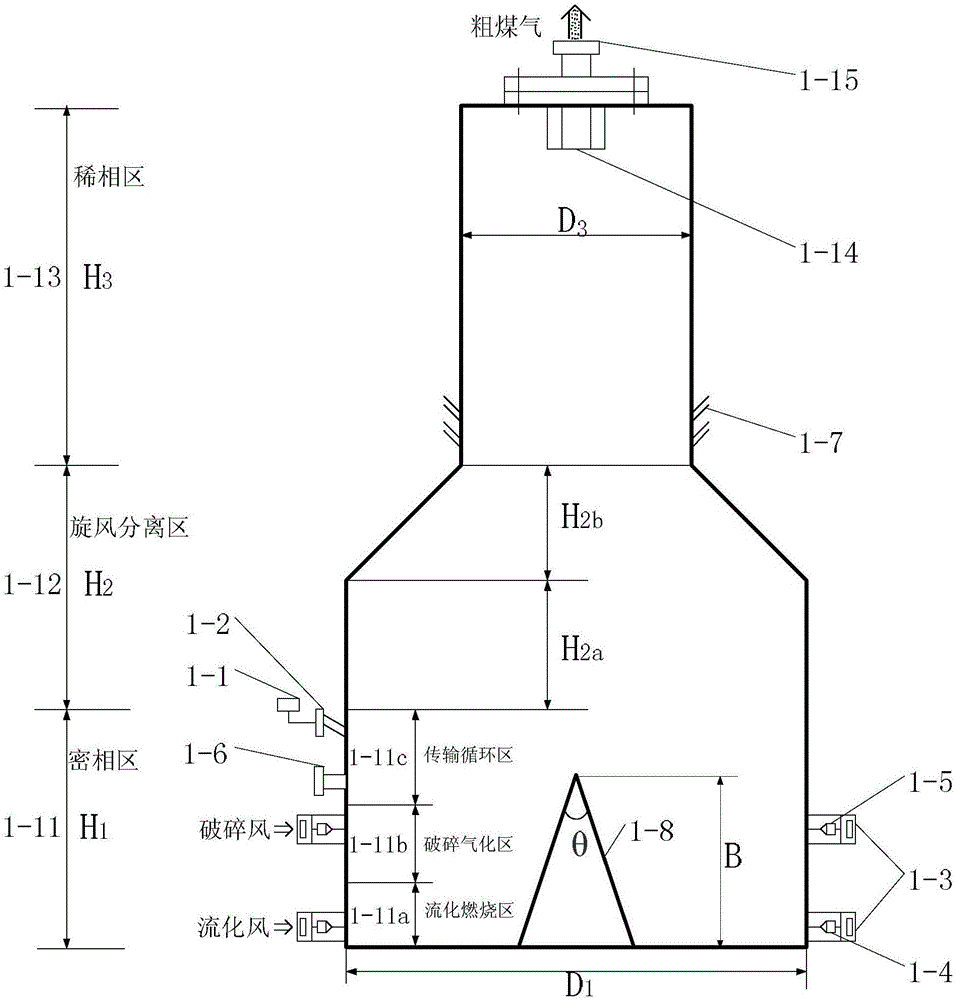

[0047] Specific implementation mode one: see figure 1 , figure 2 with Figure 4 Describe this embodiment, a high-efficiency and low-NOx segmented coupling combustion method for inferior coal described in this embodiment is realized by a high-efficiency and low-NOx segmental coupling combustion device for inferior coal, and the high-efficiency and low-NOx segmental coupling of the inferior coal The combustion device includes N fluidized beds 1 and a pulverized coal furnace 2, and the raw gas output pipes 1-15 of the N fluidized beds 1 are all communicated with the crude gas burner 2-4 of the pulverized coal furnace 2, and N is greater than or an integer equal to 1,

[0048] The fluidized bed 1 includes three reaction zones, which are dense phase zone 1-11, cyclone separation zone 1-12 and dilute phase zone 1-13 from bottom to top,

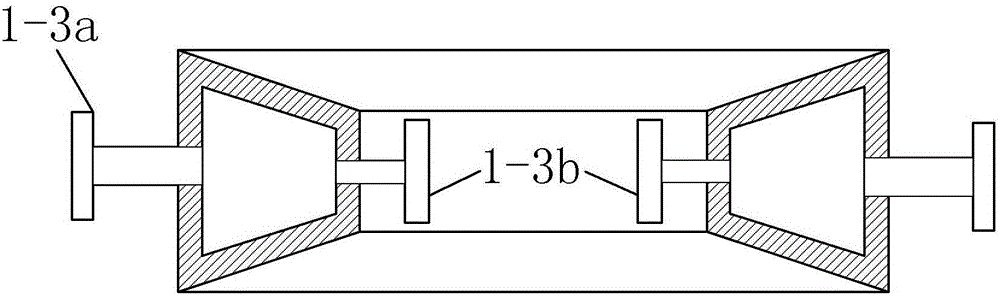

[0049] A central cone 1-8 is provided at the bottom of the fluidized bed 1, and a louver 1-14 is provided at the top, and both the central cone...

specific Embodiment approach 2

[0070] Specific implementation mode two: see figure 1 , figure 2 with Figure 4 To illustrate this embodiment, the difference between this embodiment and the high-efficiency, low-NOx staged coupling combustion method for low-quality coal described in Embodiment 1 is that the area where the crude gas burner 2-4 is located is a reducing atmosphere rich The fuel combustion zone 2-2, the area above where the crude gas burner 2-4 is located is the oxidizing atmosphere lean fuel burnout zone 2-3.

[0071] In this embodiment, the crude gas nozzle 2-5a of the pulverized coal furnace 2 communicates with the crude gas outlet pipe 1-15 of the fluidized bed 1, and multiple groups of crude gas burners 2-4 need to be configured. Gas burners 2-4 are configured in 4 groups.

[0072]4 groups of crude gas burners 2-4 are arranged in a reducing atmosphere fuel-rich combustion area 2-2 in a tangential manner, and are used for the combustion of crude gas 1100°C in a reducing atmosphere rich in...

specific Embodiment approach 3

[0075] Specific implementation mode three: see figure 1 , figure 2 with Figure 4 This embodiment is described. The difference between this embodiment and the high-efficiency, low-NOx staged coupled combustion method for low-quality coal described in Embodiment 1 is that:

[0076] In step 1, the air distribution method of injecting the fluidizing air nozzles 1-4 into the fluidizing air is as follows: the fluidizing air is arranged tangentially around the bed bottom of the fluidized bed 1, and the adjacent two fluidizing air in the same layer Air flow nozzle 1-4 jet cross;

[0077] In step 1, the air distribution method of the crushing air nozzles 1-5 injected into the crushing wind is: the jet direction of all the crushing air nozzles 1-5 in the same layer is perpendicular to the symmetry axis of the central cone 1-8, and the same The jets of two opposing crushing air nozzles 1 - 5 in a layer collide with each other.

[0078] In Step 1, the Mach number Ma of the outlet ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com