Multi-pass industrial pulverized coal boiler with flue gas recirculation technology and swirl pulverized coal burner on top

A pulverized coal burner and flue gas recirculation technology, which is applied to the burners, burners, and combustion air/fuel supply of powder fuels, etc., can solve the problems of poor burnout and high NOx emissions, and achieve extended residence time. Time, NOx production reduction, NOx production reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

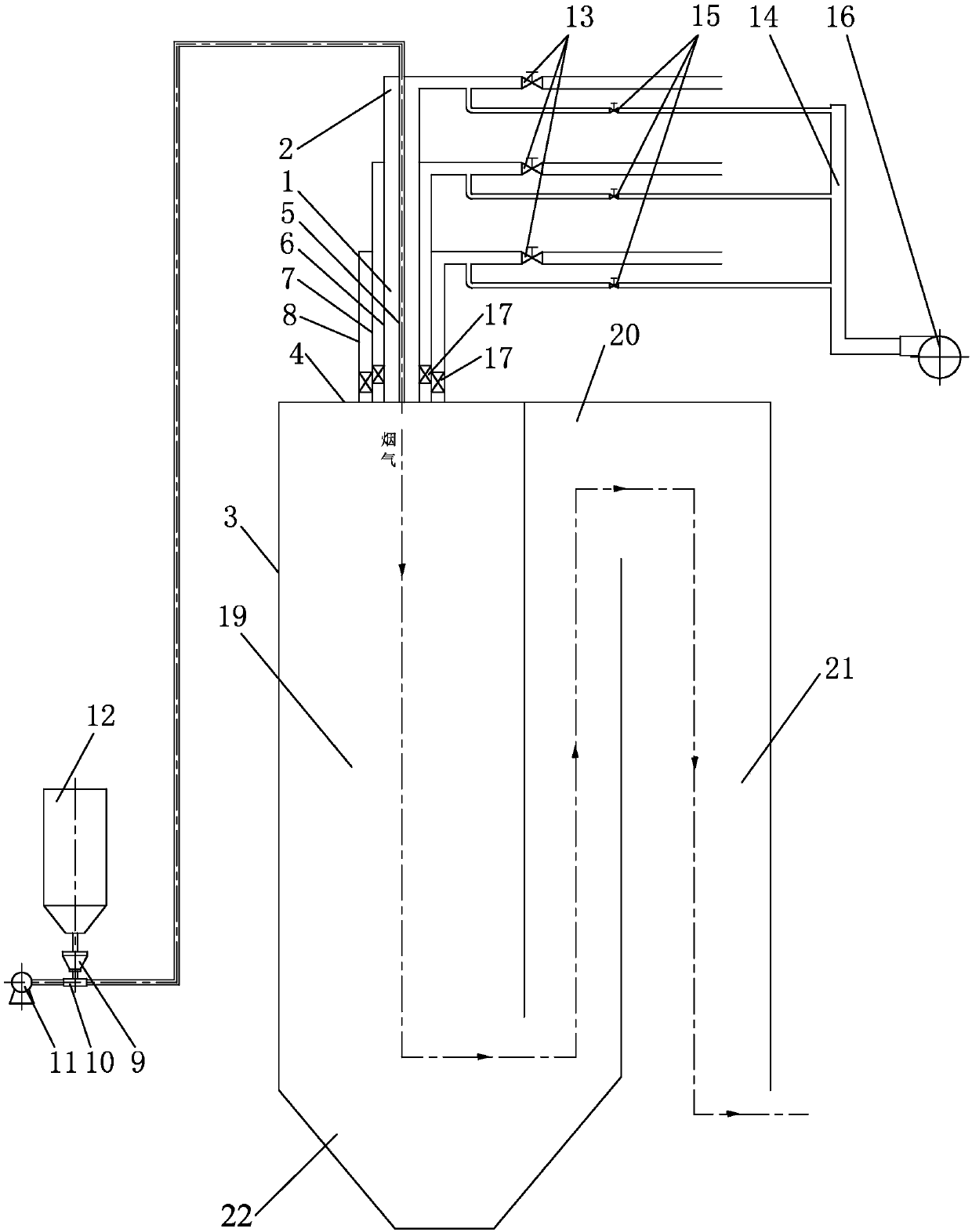

[0027] like figure 1 As shown, the multi-stroke industrial pulverized coal boiler with flue gas recirculation and swirl pulverized coal burner on the top includes swirl pulverized coal burner 1, air powder system 2, boiler body 3 and flue gas recirculation system 4;

[0028] The swirling pulverized coal burner 1 includes a primary air duct 5, a direct current secondary air duct 6, a swirling inner secondary air duct 7 and a swirling outer secondary air duct 8, and the boiler body 3 has a zigzag channel with three flue gas strokes ; The primary air duct 5 is located in the DC secondary air duct 6, the DC secondary air duct 6 is located in the secondary air duct 7 inside the swirl flow, and the secondary air duct 7 inside the swirl flow is located in the secondary air duct outside the swirl flow 8, primary air duct 5, DC second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com