A heating equipment for coal chemical deep processing

A heating equipment and deep processing technology, which is applied in the field of coal chemical deep processing heating equipment, can solve the problems of large area occupied by external air ducts of coal-fired machinery, inconvenient coal addition and slag removal, and small operating space for firemen, so as to achieve environmental protection and energy saving Remarkable effect, solve the problem of large coal consumption and unique air distribution method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

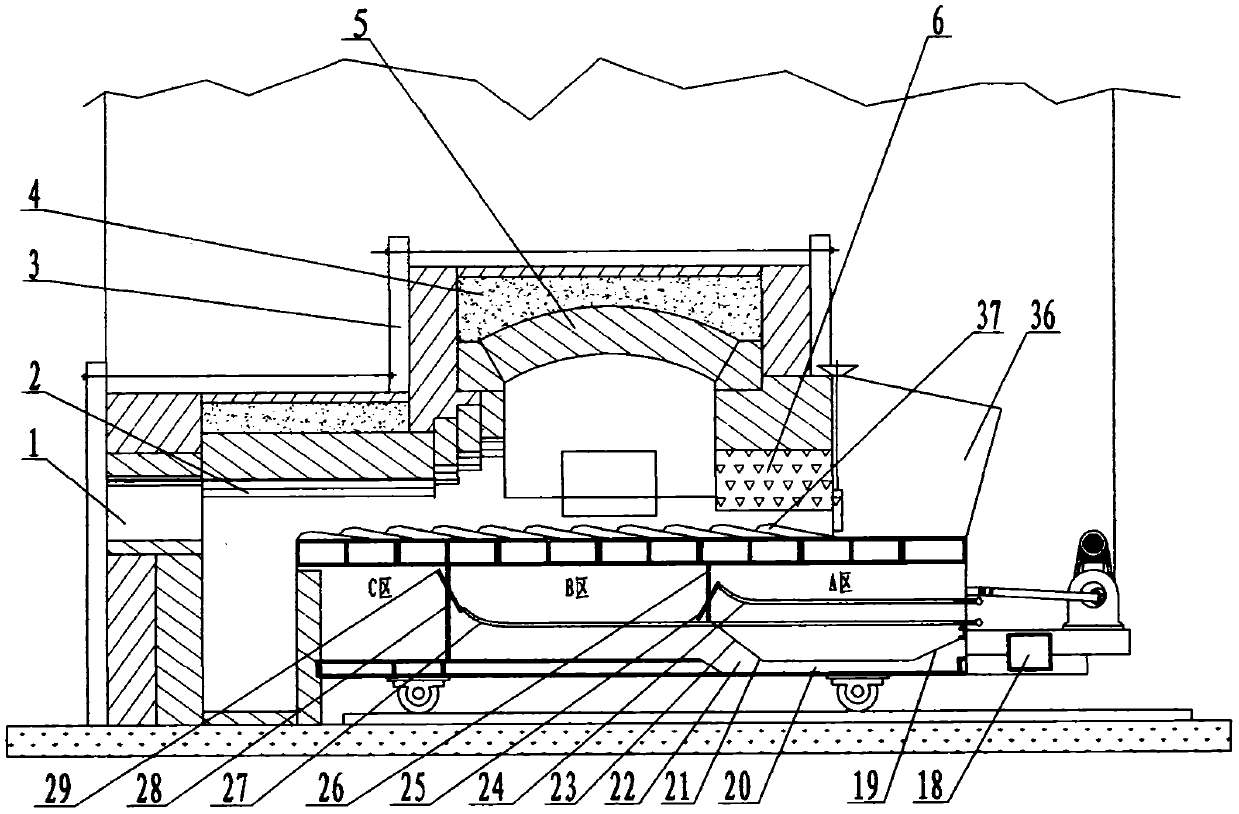

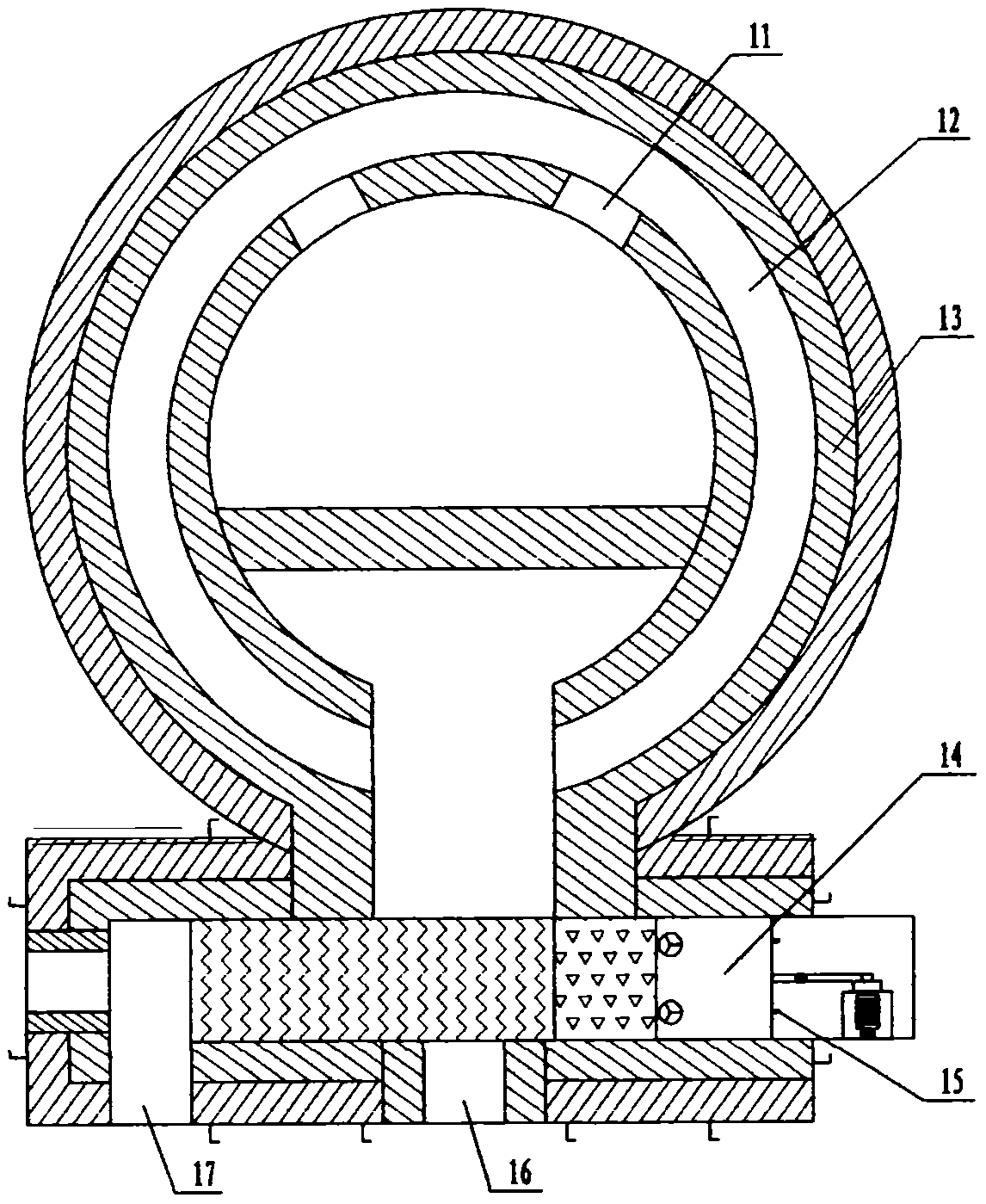

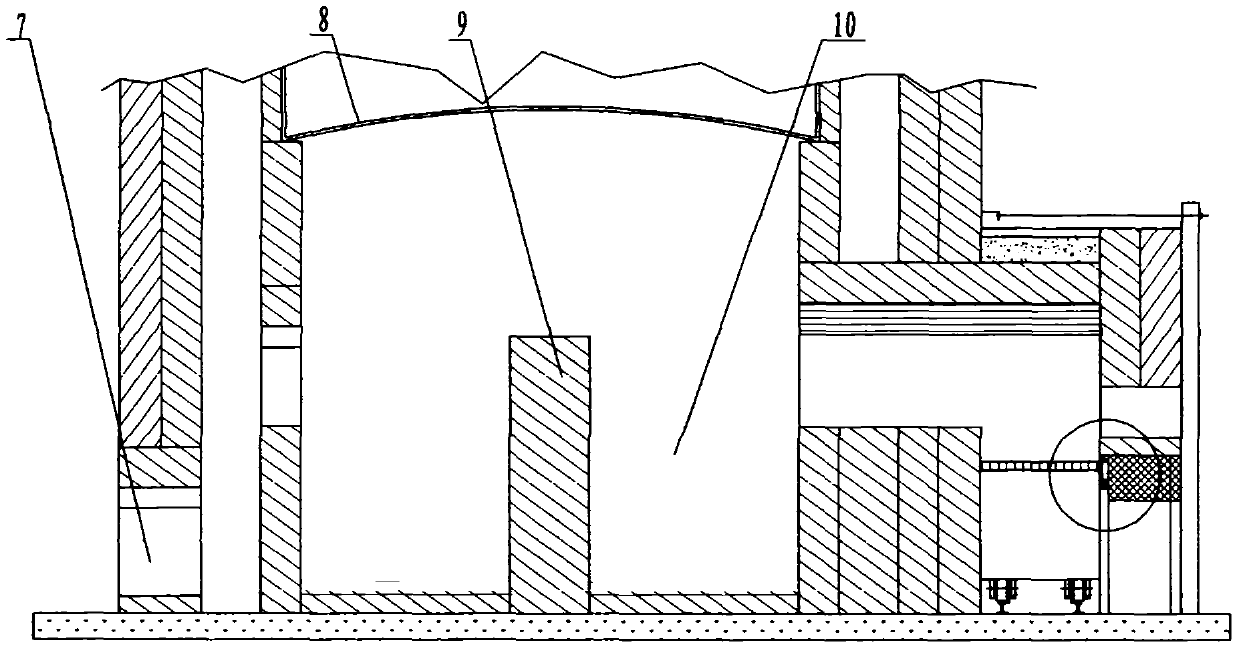

[0013] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the accompanying drawings, the structure of the present invention includes observation furnace door 1, furnace back arch 2, shell 3, heat preservation material 4, furnace middle arch 5, furnace front arch 6, ash removal port 7, and coal chemical still 8. Fire wall 9, clean room 10, fire outlet 11, fire passage 12, still wall 13, coal burner 14, air regulating device 15, ignition door 16, slag outlet 17, fan interface 18, upper bottom 19, Double-layer bottom air duct 20, 45° lower bottom 21, air duct opening 22, 45° upper bottom 23, area A air adjustment push-pull rod 24, A area damper 25, AB area partition 26, C area air adjustment push-pull rod 27, Partition plate 28 in BC area, damper in area C 29, wearing parts of heating equipment 30, refractory fiber felt 31, furnace wall support plate 32, side baffle device 33, furnace outer wall lightweight sealing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com