Stain-resistant additive for boiler as well as preparation method and application of stain-resistant additive

An additive and anti-contamination technology, which is applied in the boiler field, can solve the problems of lower boiler efficiency, difficulty in promotion, high cost of raw materials, etc., and achieve good anti-contamination effect, good coal type adaptability, and great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

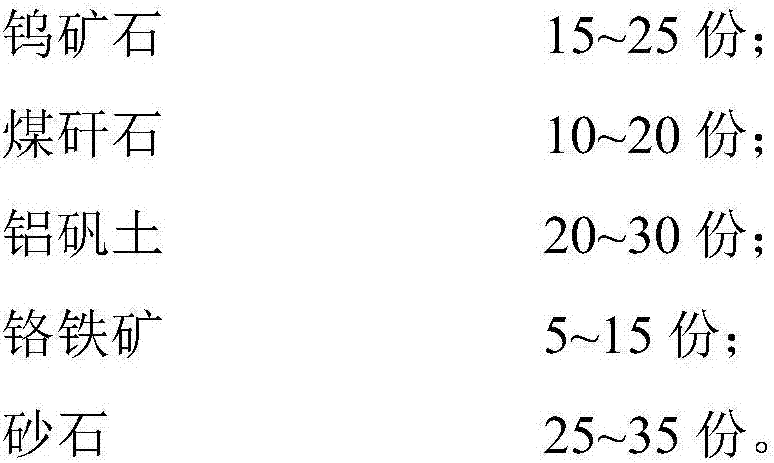

[0021] Prepare boiler anti-contamination additive of the present invention: the anti-contamination additive of the present embodiment comprises 20 parts of tungsten ore, 15 parts of coal gangue, 25 parts of bauxite, 10 parts of chromite, 20 parts of gneiss, and 10 parts of desert sand , 3 parts by mass of pyrolusite.

[0022] The preparation method: first crush each component until the maximum particle size is less than 200 μm, and then mix the components uniformly according to the parts by mass.

[0023] The usage method of this anti-fouling additive is as follows:

[0024] The prepared additive is mixed with the desulfurizer powder and stored in the desulfurizer silo, and finally sent to the fluidized bed under the action of conveying wind.

[0025] The dosage of the boiler antifouling additive of the present invention is: the mass ratio of the additive to the boiler fuel is 0.3:100.

[0026] The boiler anti-contamination additive provided in this example was applied to a ...

Embodiment 2

[0028] Adopt similar formula and preparation method and application method with embodiment 1, difference is:

[0029] (1) The parts by weight of each component are as follows: 25 parts of tungsten ore, 10 parts of coal gangue, 30 parts of bauxite, 15 parts of chromite, 35 parts of sea sand, and 5 parts of pyrolusite.

[0030] (2) The mass ratio of additives to boiler fuel is 3:100.

[0031] According to actual tests, the proportion of ash in the form of alkali metal aluminosilicate is 92%, and the measured ash melting point is 1501°C, which also reduces the problems of ash deposition, slagging and heat exchange surface corrosion caused by alkali vapor, and improves Improve equipment utilization efficiency and extend boiler life. The continuous operation time of the boiler reached 269 days, during which the various operating data of the boiler were normal and stable.

Embodiment 3

[0033] Adopt similar formula and preparation method with embodiment 1, difference is:

[0034] (1) The parts by weight of each component are as follows: 15 parts of tungsten ore, 20 parts of coal gangue, 20 parts of bauxite, 5 parts of chromite, 25 parts of river sand, and 1 part of pyrolusite.

[0035] (2) The additive obtained in this example is used in a 350MW lignite boiler, and the mass ratio of the additive to the boiler fuel is 0.1:100.

[0036] (3) Application method: Send the prepared additives and coal into the coal mill for crushing and mixing, and the obtained mixture is separated by a coarse powder separator and a fine powder separator, and then stored in a coal storage bin. When in use, it is sent into the pulverized coal boiler through the powder feeding fan.

[0037] According to actual tests, the proportion of ash in the form of alkali metal aluminosilicate is 88%, and the measured ash melting point is 1463°C, which also reduces the problems of ash deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com