An entrained-flow gasifier with solidification of slag in swirl

A technology of gasifier and entrained flow bed, which is applied in the field of coal chemical industry, and can solve problems such as the difficulty of hanging slag on the water-cooled wall, unfavorable structure of the cooling spiral tube, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

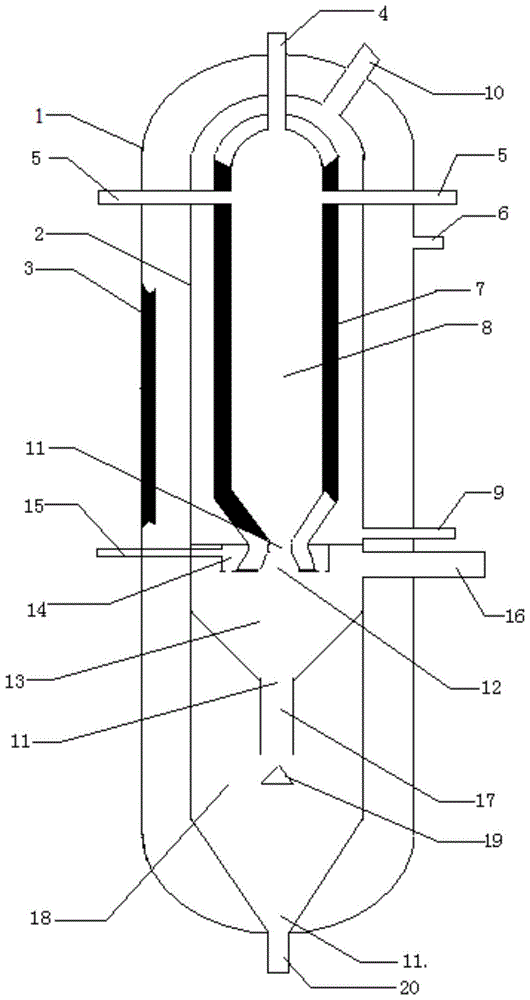

[0015] Below in conjunction with accompanying drawing, the present invention is described in detail: figure 1 As shown, a kind of entrained bed gasification furnace solidified by swirling liquid slag according to the present invention is composed of a gasification furnace pressure-resistant jacket 1, a high-pressure inert gas filling hole 6, a heat insulating material layer 3, a cooling jacket 2, a wear-resistant Material layer 7, top nozzle 4, side nozzle 5, gasification chamber 8, cooling water inlet 9, saturated steam outlet 10, segmented conical head 11, gasification product outlet 12, swirl cooling chamber 13, atomization Water cooling jacket 14, atomized water inlet 15, gas outlet 16, solidified slag discharge port 17, solid slag cooling chamber 18, anti-shock plate 19, water-cooled slag discharge port 20, characterized in that the gasifier is divided into gas The gasification furnace pressure jacket 1 and the gasifier liner, a gap of 50-500 mm is maintained between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com