Eddy flow powdered coal burner lit up by tiny oil

A pulverized coal burner and micro-oil ignition technology, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of difficult placement of an external gas-solid separator, limited adjustment capability, complex system, etc. Achieve the effect of enhancing operating safety, enhancing regulation function and low NOx emission function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

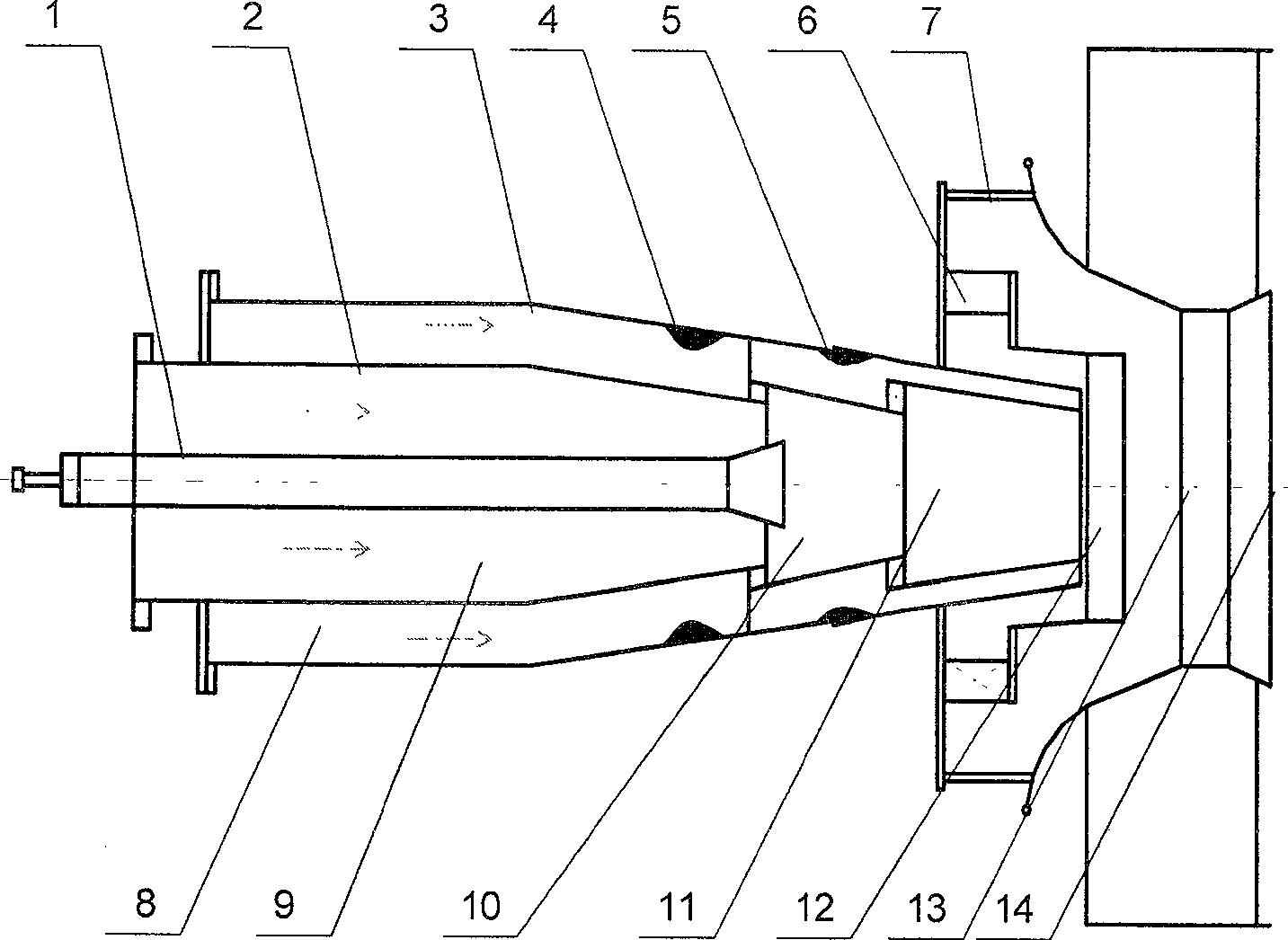

[0016] The micro-oil ignition swirl pulverized coal burner provided by the present invention includes a primary air duct, a central air duct arranged in the primary air duct, a high-energy oil gun horizontally arranged in the central air duct, an inner secondary air inlet, and an outer secondary air inlet , primary air and internal secondary air nozzles and burner nozzles; one or more stages of diversion and concentration rings are arranged on the inner wall of the primary air pipe, and one or more stages of pre-combustion rings are correspondingly arranged at the front end of the central air pipe The adjacent pre-chambers are connected to each other, and there is a radial gap between the outlet of the previous pre-chamber and the entrance of the rear pre-chamber; the nozzle of the high-energy oil gun extends into the first pre-chamber combustion chamber. The primary air pipe can be a straight pipe or a tapered tapered pipe.

[0017] figure 1 Schematic diagram of the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com