An environmentally friendly aluminum processing system with good energy saving

A processing system and environmentally friendly technology, applied in metal processing equipment, furnace types, manufacturing tools, etc., can solve problems such as unsatisfactory energy saving, unsatisfactory fusion effect of molten aluminum and ingredients, poor product quality, etc., to improve the thermal insulation effect. and product quality, avoid direct contact with aluminum surfaces, and improve the effect of burning damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

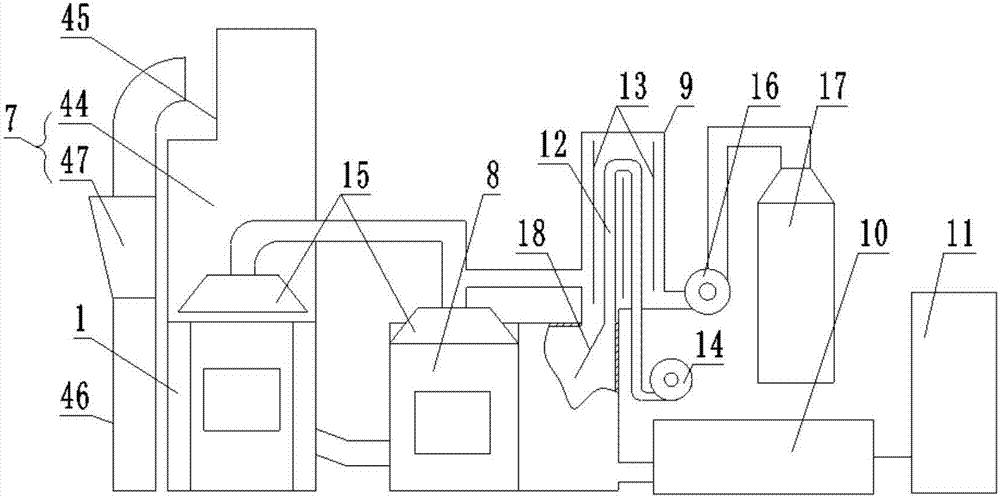

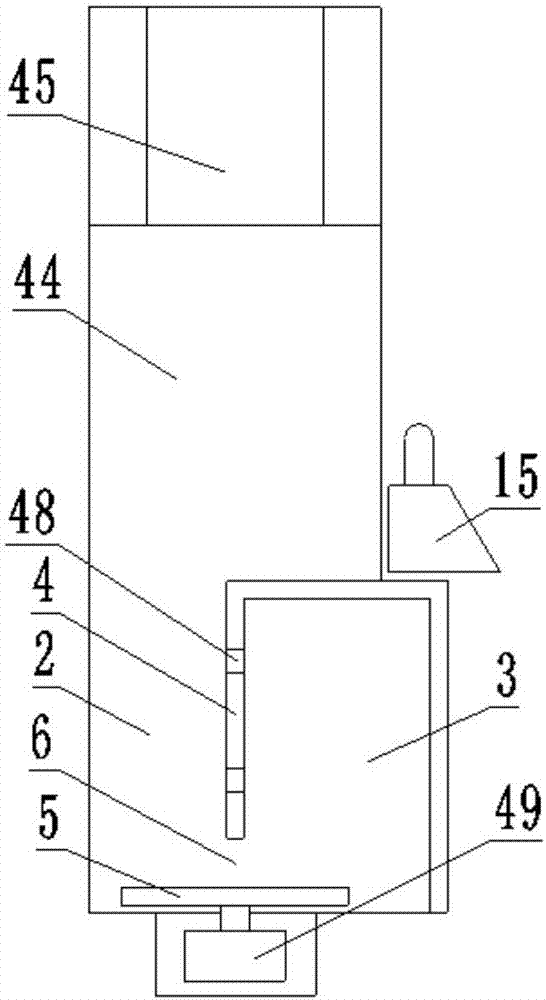

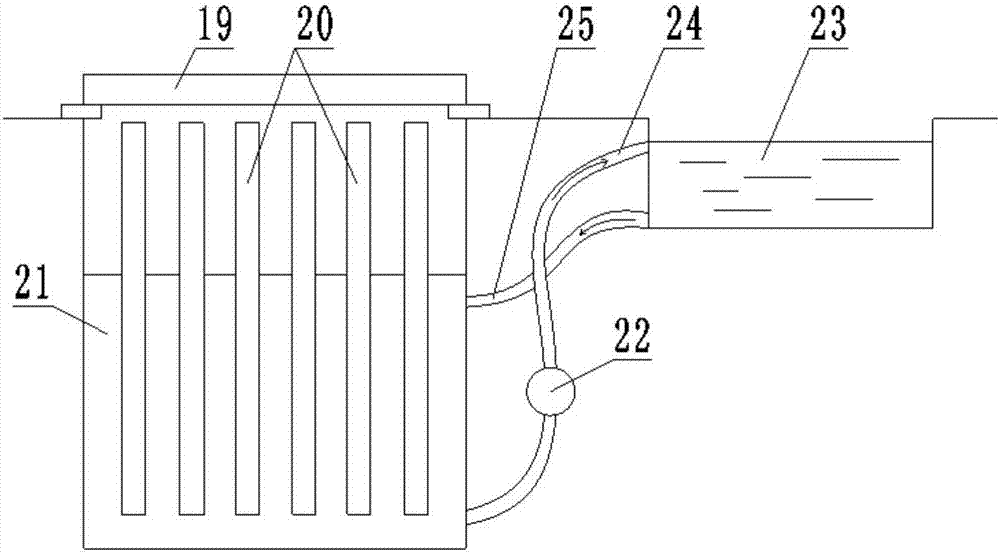

[0029] Example. An environment-friendly aluminum material processing system with good energy saving, which is composed of Figures 1 to 7As shown, a melting furnace 1 is included, and a melting chamber 2 and a heating chamber 3 arranged side by side are arranged in the melting furnace 1, and a partition 4 is arranged between the melting chamber 2 and the heating chamber 3; a stirrer 5 is arranged below the partition 4 A gap 6 is provided between the agitator 5 and the partition 4; a feeding mechanism 7 and a holding furnace 8 are respectively arranged on both sides of the melting furnace 1, and a discharge pipe is connected between the melting furnace 1 and the holding furnace 8; A heat collecting furnace 9 is connected to the top of the holding furnace 8 , a hot top casting unit 10 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com