Powder burning furnace

A combustion furnace and powder technology, applied in the field of preparation of spherical silicon micropowder particles, can solve the problems of narrow particle size distribution, inability to uniformly disperse silicon micropowder particles, particle bonding, etc., and achieve high filling rate, simple structure and high fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

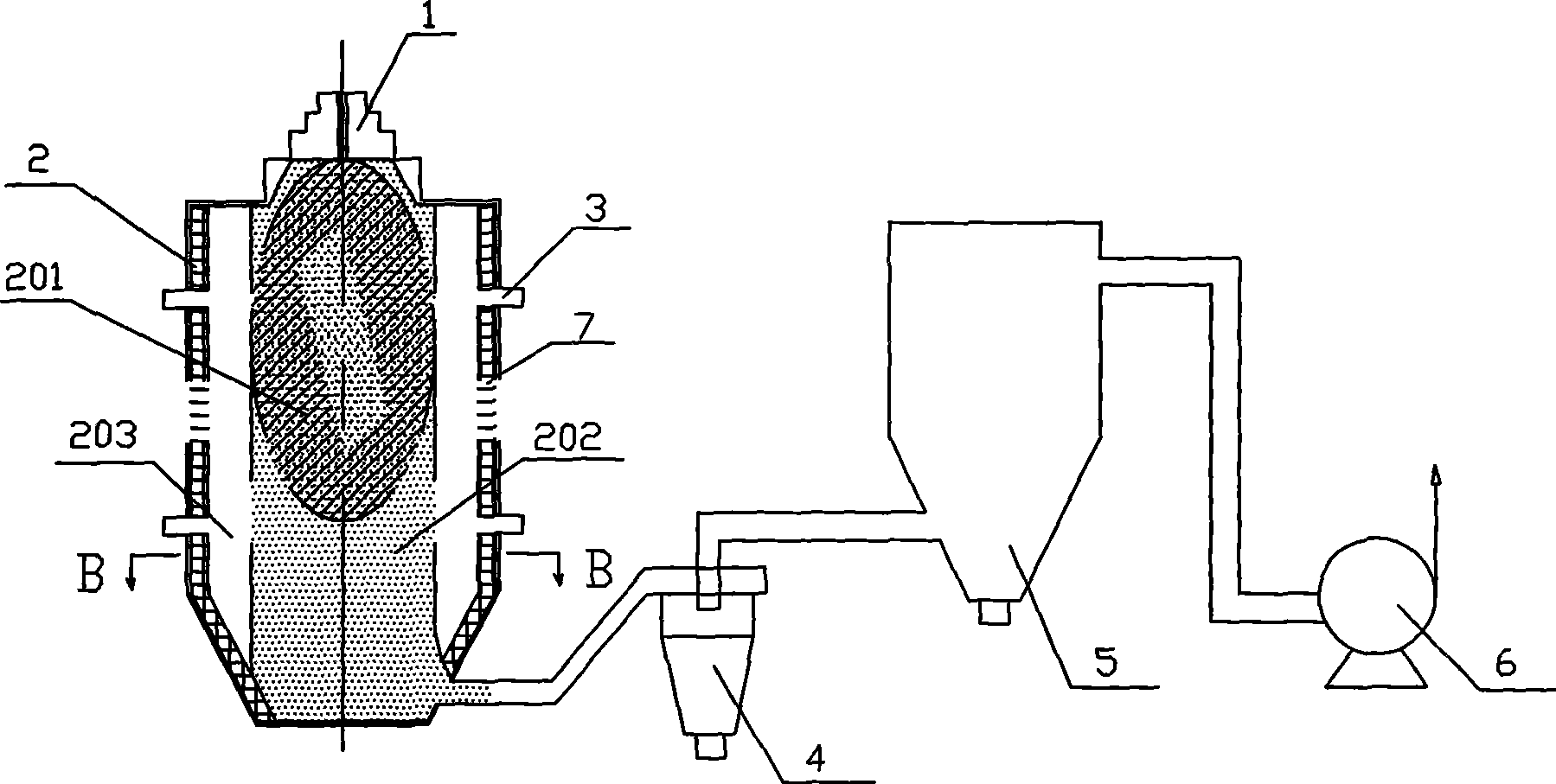

[0020] Such as figure 1 As shown, a powder combustion furnace provided by the present invention includes a burner 1 and a spheroidizing furnace 2, and the bottom of the spheroidizing furnace 2 is sequentially connected to a cyclone separator 4, a bag filter 5, and an induced draft fan 6.

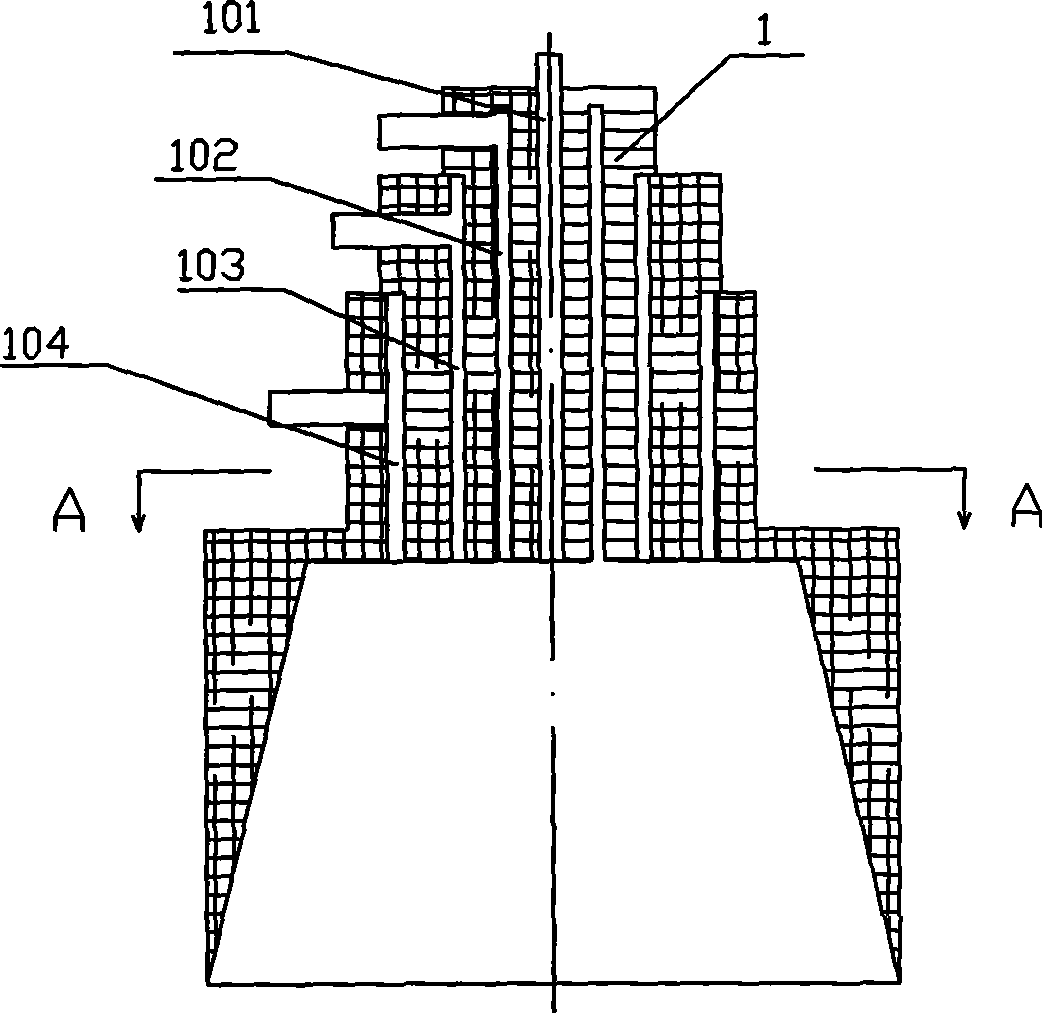

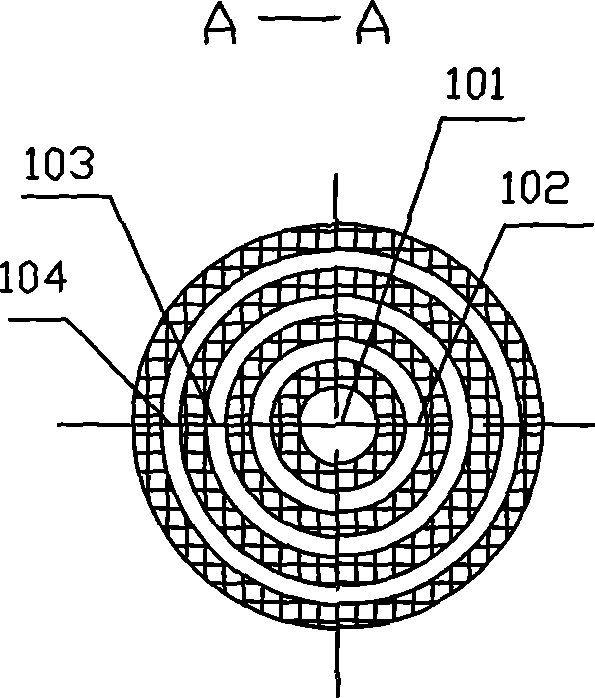

[0021] Such as figure 2 , image 3 As shown, the center of the burner 1 is provided with an inner epoxy central gas injection hole 101, and three layers of annular gas injection channels 102, 103, 104 arranged around the center of the burner.

[0022] Such as figure 1 , Figure 4 As shown, a group of two layers of cooling air inlets 3 are provided on the furnace wall of the spheroidizing furnace 2, and each layer has four cooling air inlets 3, which enter the spheroidizing furnace along the tangential direction of the furnace body.

[0023] The burner 1 is placed on the upper part of the spheroidizing furnace 2 with a vertical cylinder structure, and the center of the burner 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com