Coal powder burning organic heat carrier boiler

A waste heat boiler, an organic technology, applied in the boiler field, can solve the problems of uneven flue gas flow, insufficient stability of the body frame, and insufficient flame combustion of the waste heat boiler, and achieve the effects of reducing the length of the furnace, compact structure, and stretching the furnace volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

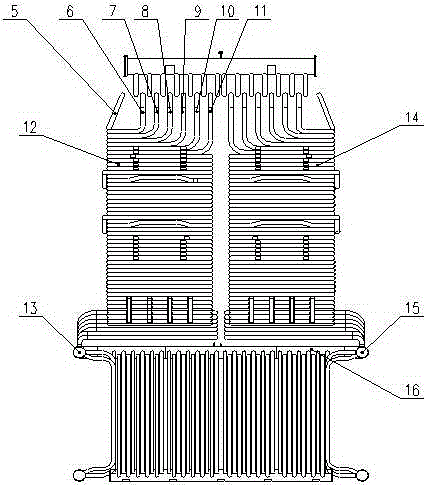

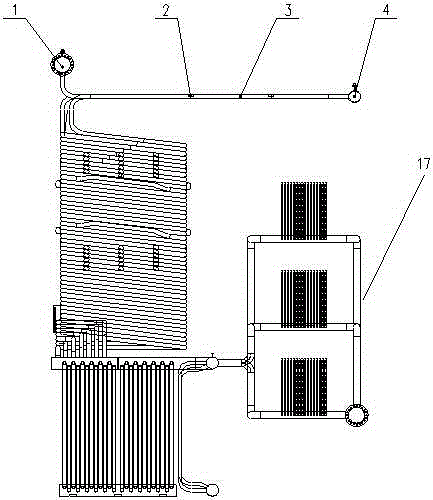

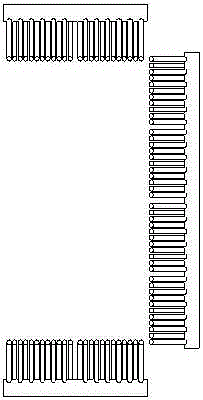

[0028] A pulverized coal-fired organic heat carrier boiler of the present invention comprises a lower furnace, an upper furnace, a convection zone, and a waste heat boiler. Such as Image 6 As shown, the length of the lower furnace is less than the length of the flame in the combustion zone, and an air supply device is arranged on one side of the lower furnace, so that the flame in the combustion zone is bent into an L shape, which reduces the length of the furnace and reduces the floor space; the volume of the furnace is stretched, and the flame burns full. Such as image 3 As shown, the cross-section of the heat exchange area of the lower furnace is U-shaped, and the pipelines in the heat exchange area of the lower furnace are densely distributed, which makes full use of the space, strengthens the radiation heat transfer, and reduces the furnace outlet temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com