Lime calcining rotary furnace

A converter and lime technology, applied in the field of calcined lime rotary furnace, can solve the problems of low efficiency, poor firing quality, pollution, etc., and achieve the effect of uniform heating and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

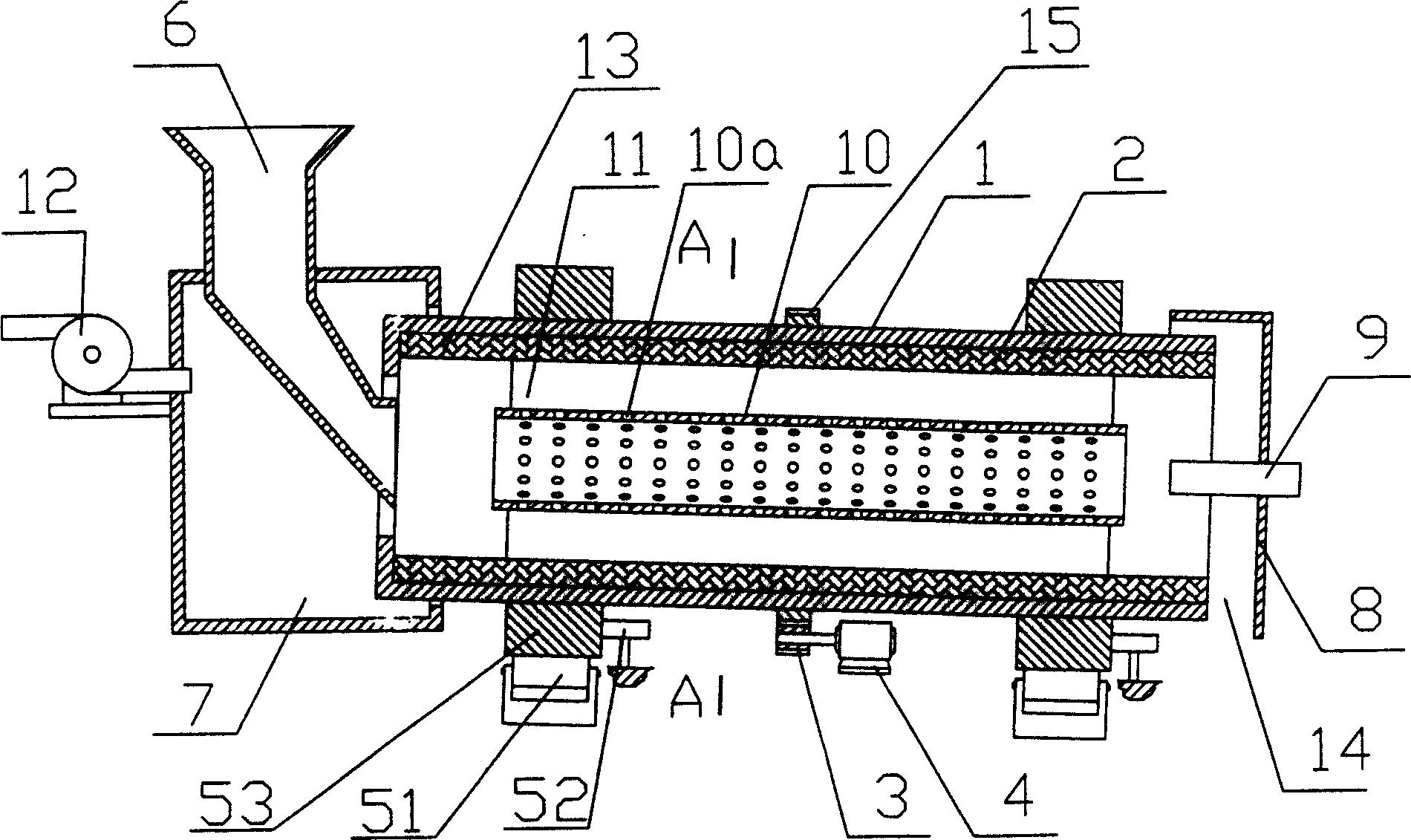

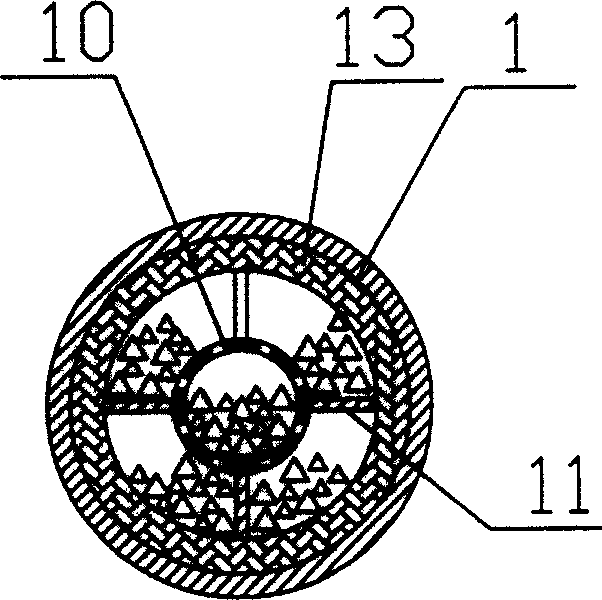

[0008] Such as figure 1 , figure 2 As shown, a lime calcining rotary furnace includes a cylindrical furnace body 1 installed in an inclined shape with a high front and a low rear. This installation method can ensure that the furnace material flows to the cylindrical furnace by its own gravity during the rotation of the furnace body 1. The discharge port at the lower end of the body 1; the inner wall of the cylindrical furnace body 1 is provided with a refractory layer 13, and the high end of the cylindrical furnace body 1 is provided with a feed hopper 6, and the lower end of the cylindrical furnace body 1 is located One end of the cylinder is provided with a discharge port 14, and a pulverized coal combustion injector 9 is installed at the lower end of the cylindrical furnace body 1. The outer side of the cylindrical furnace body 1 is provided with a driving device for driving the furnace body to rotate and The supporting wheel device supporting the furnace body is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com