Laser projection light source

A laser projection and light source technology, applied in optics, instruments, projection devices, etc., can solve the problems of high light energy density, affecting the reliability of laser projection light machine, etc., achieve uniform energy, simple and effective powder burning risk, and solve the problem of powder burning risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

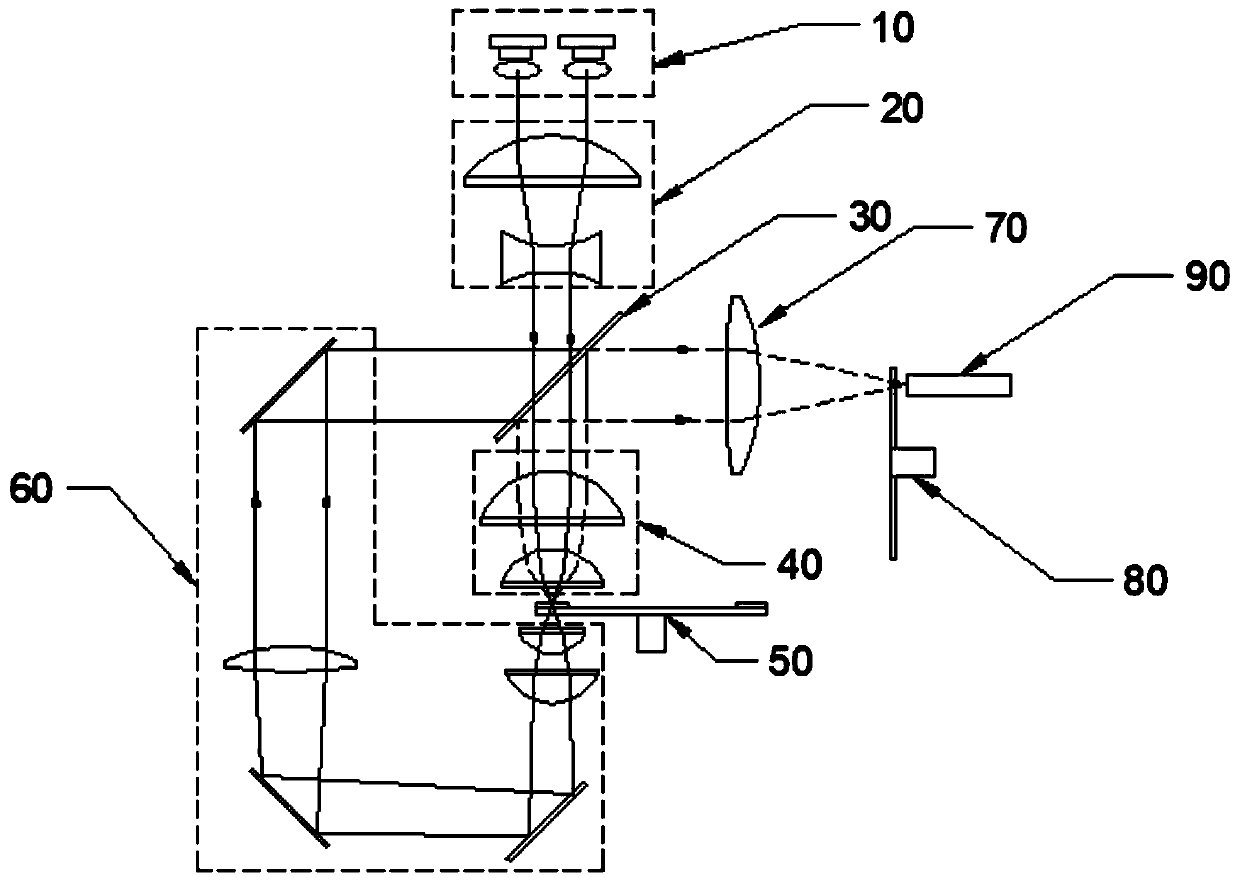

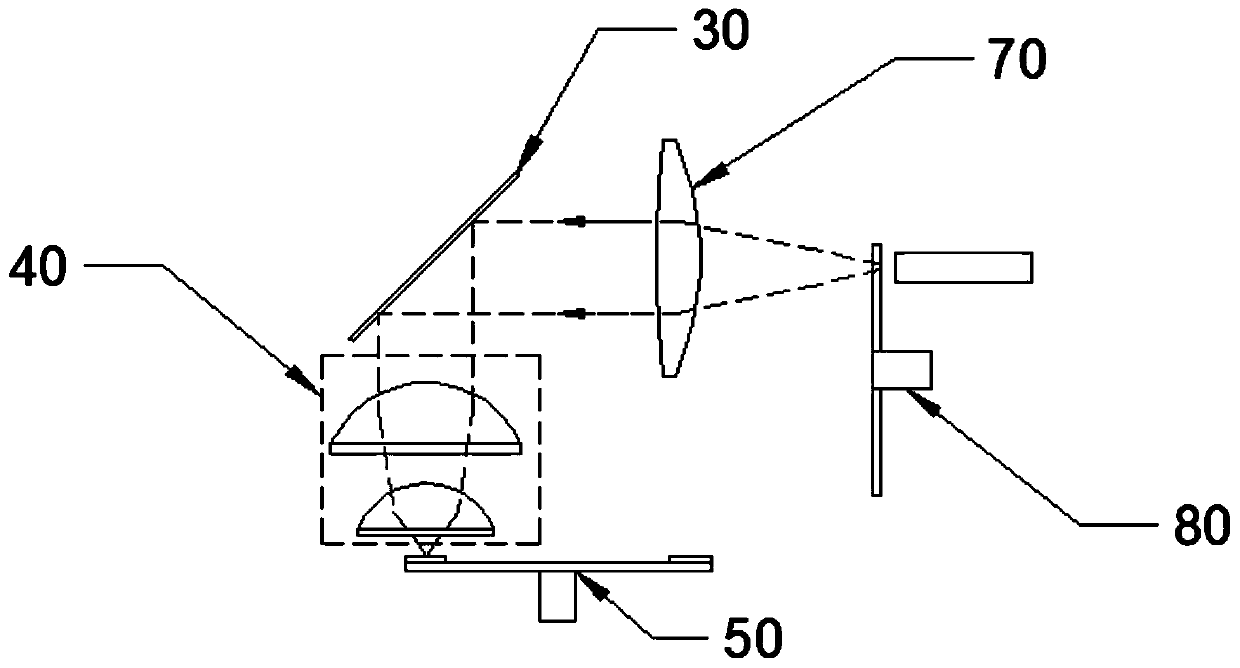

[0033] Such as figure 1 As shown, this embodiment provides a laser projection light source, including a laser array 10, a telephoto component 20, a dichroic color separation component 30, a light receiving component 40, a phosphor wheel device 50, a blue light path 60, a light concentrating component 70, Color wheel assembly 80 and light bar assembly 90. The laser beam emitted by the laser array 10 is focused on the surface of the phosphor wheel 50 after passing through the telescopic assembly 20 , the dichroic separation assembly 30 and the light collection assembly 40 .

[0034] Such as Figure 5 As shown, the fluorescent powder wheel device 50 in this embodiment includes a substrate and a motor, and the two are coaxially connected, and the motor drives the substrate to rotate at a high speed. The substrate is a reflective metal substrate, including a first fluorescent area 50a, a second The fluorescent area 50b and the first hollow area 50c.

[0035] Wherein, the first p...

Embodiment 2

[0045] This embodiment is the same as the optical path structure and basic principle of Embodiment 1, such as Figure 7 As shown, the difference is that the technical solutions of the color filter wheel device 70 are different.

[0046] Such as Figure 7 As shown, in this embodiment, the substrate of the first filter area 80a is composed of a diffuser 803 and a color filter 804, with a gap of 0-0.2 mm in between. In this embodiment, two combined substrates are used instead of one integral substrate, which increases the degree of freedom of setting the diffuse scattering surface, and technicians can flexibly set the number or position of the diffuse scattering surface according to the effect.

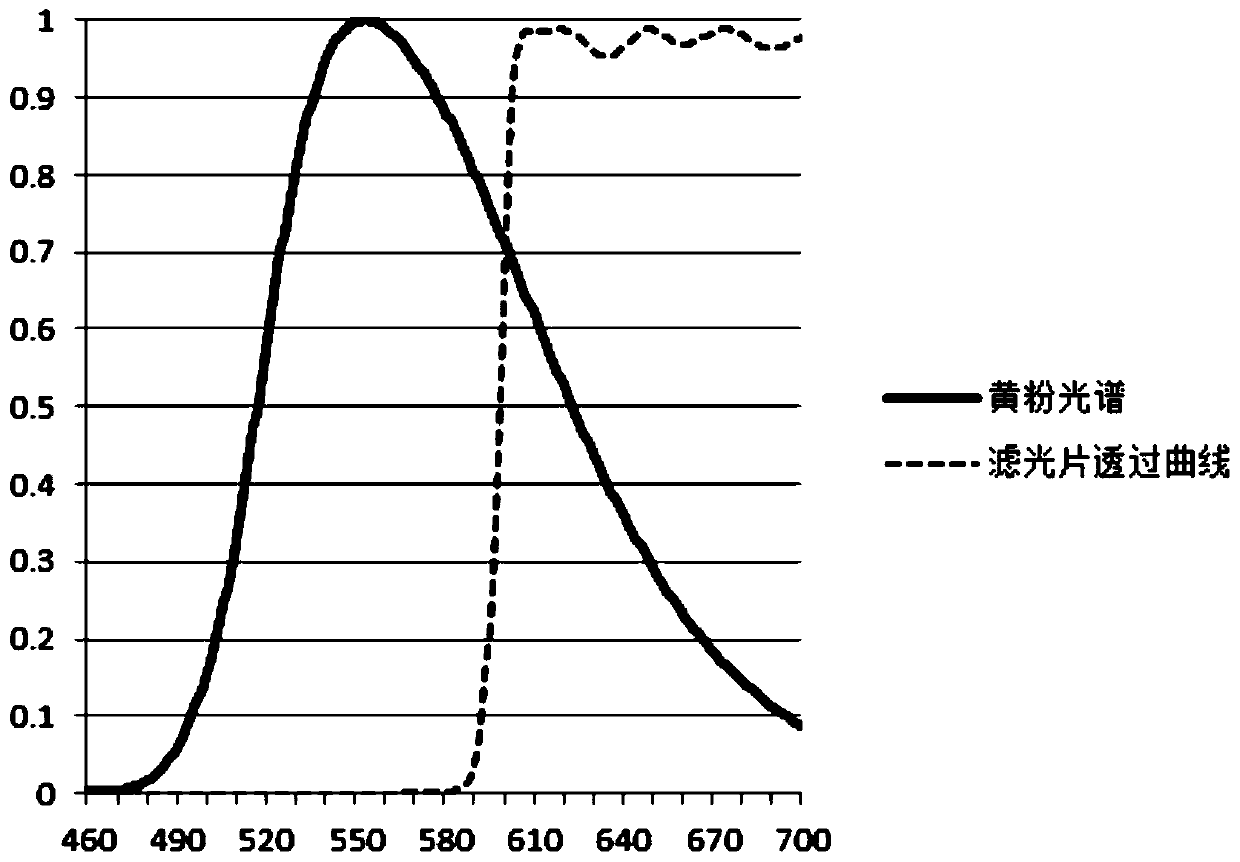

[0047] Among them, the first surface of the diffuser 803 is a diffuse scattering surface, HWHM=3°, and the second surface is a mirror surface; the first surface of the color filter 804 is a mirror surface, coated with an anti-reflection coating, and the second surface is a mirror surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com