Wall-type arranged two-stage burn-up air device

A burn-out wind and burn-out technology is applied in the combustion of multiple fuels, the combustion of lump fuel and liquid fuel, the combustion of lump fuel and gaseous fuel, etc. Fluctuation, low pulverized coal burnout, and high carbon content in fly ash can improve furnace mixing, strengthen turbulent mixing, and improve penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

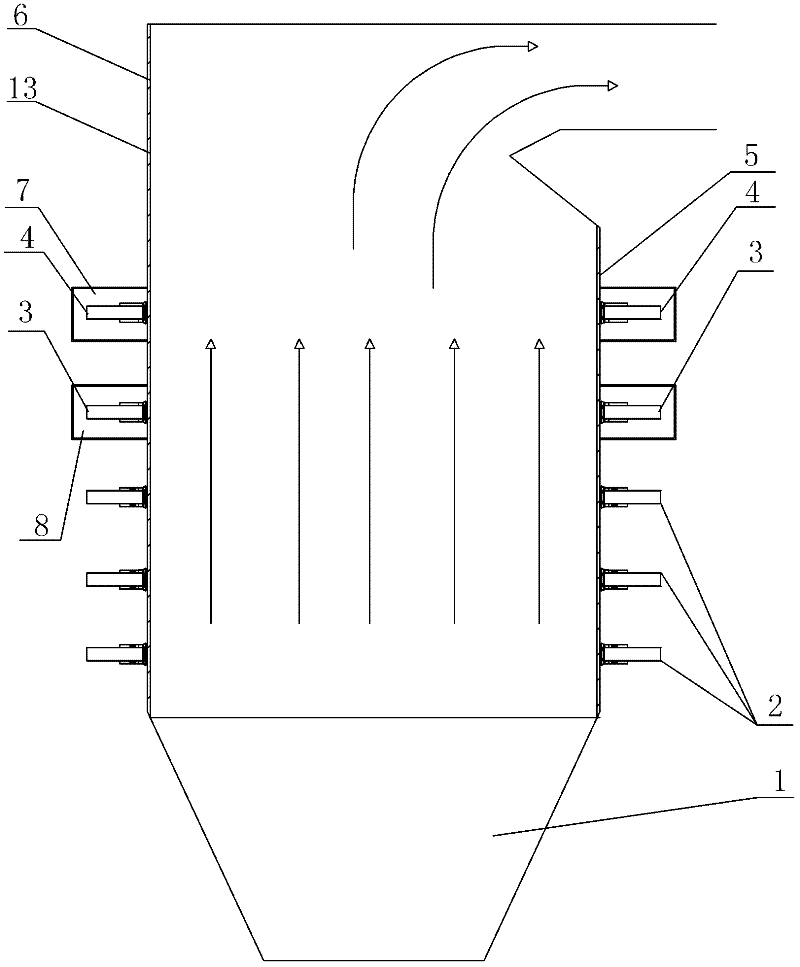

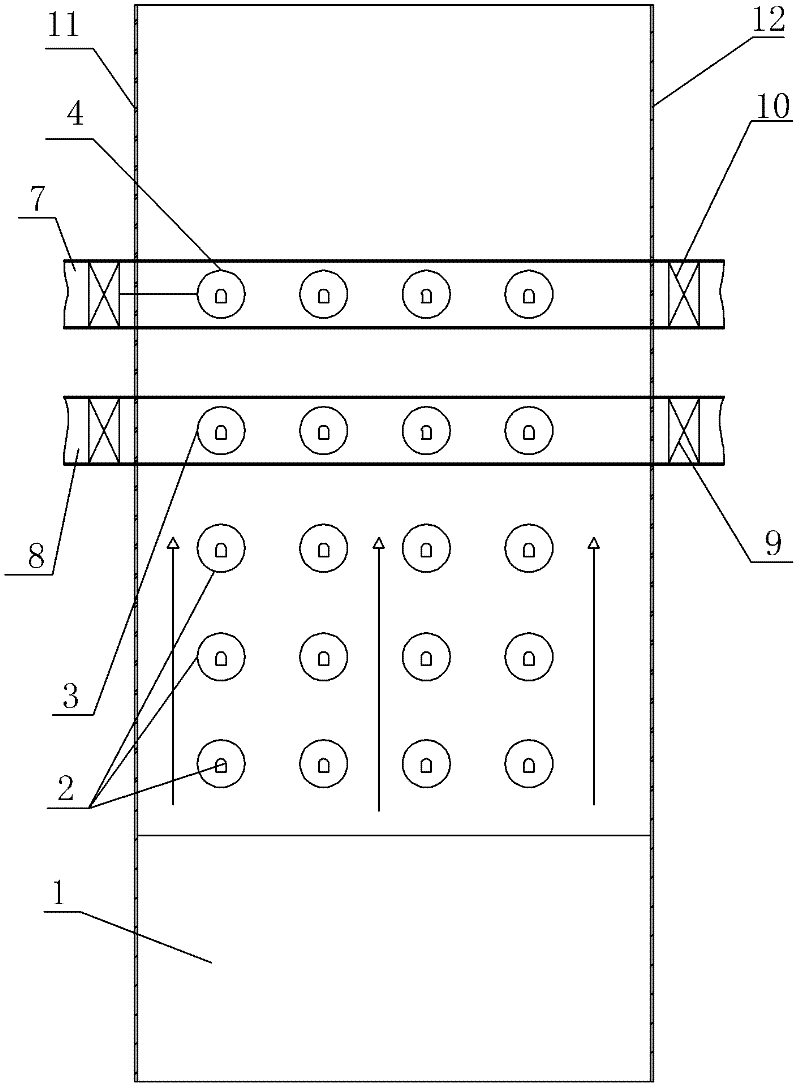

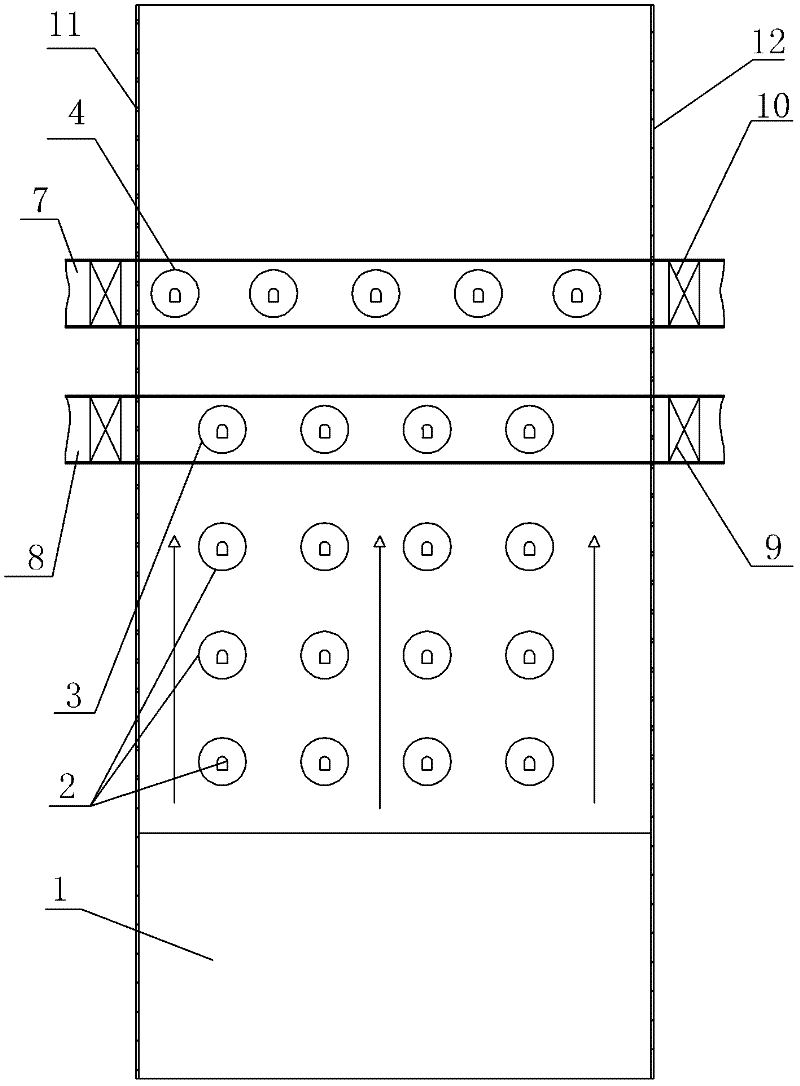

[0010] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a wall-type two-stage overfire air device of this embodiment includes a cold ash hopper 1, a furnace wall 13 and a plurality of swirl burners 2, and the furnace wall 13 includes a rear wall 5. The front wall 6, the left wall 11 and the right wall 12. The device also includes multiple first-stage burn-off air 3, multiple second-stage burn-off air 4, multiple first-stage burn-off air bellows 8, multiple A second-stage overburning air wind box 7, a plurality of first-stage overburning air dampers 9 and a plurality of second-stage overburning air dampers 10, the lower end of the furnace wall 13 is connected to the upper end of the cold ash hopper 1, the described A plurality of swirl burners 2 are arranged on the wall 13 in multiple layers, a plurality of first-stage burn-off air 3 is arranged on the wall 13 and above the uppermost swirl burner 2, and a plurality of first-stage burners...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, a plurality of swirl burners 2 described in this embodiment are arranged in multiple layers on the front wall 6 and the rear wall 5, and a plurality of first-stage overfire air 3 are symmetrically arranged on the front wall 6 and the rear wall 5 and above the uppermost swirl burner 2 , a plurality of second-stage overfire air 4 is symmetrically arranged on the front wall 6 and rear wall 5 and above the first-stage overfire air 3 . Such setting can more effectively improve the penetration of the overburning air, and can strengthen the turbulent mixing of the overburning air with the high-temperature flue gas and unburned coke in the furnace, improve the mixing of the furnace, better ensure the burnout rate, and effectively Control the carbon content of the fly ash and the amount of desuperheating water at a reasonable level to meet the design requirements. Others are the...

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the arrangement of each layer of swirl burners 2 described in this embodiment is consistent with the arrangement of the first-stage overfire air 3 and the second-stage overfire air 4 . Such setting meets the design requirements. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com