Numerical simulation method for interaction of coal powder particles in burning

A combustion process, numerical simulation technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems that cannot be effectively used to guide the improvement and optimal design of pulverized coal combustion technology, energy saving, consumption reduction and emission reduction. Measures to provide convenient and efficient technical support and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

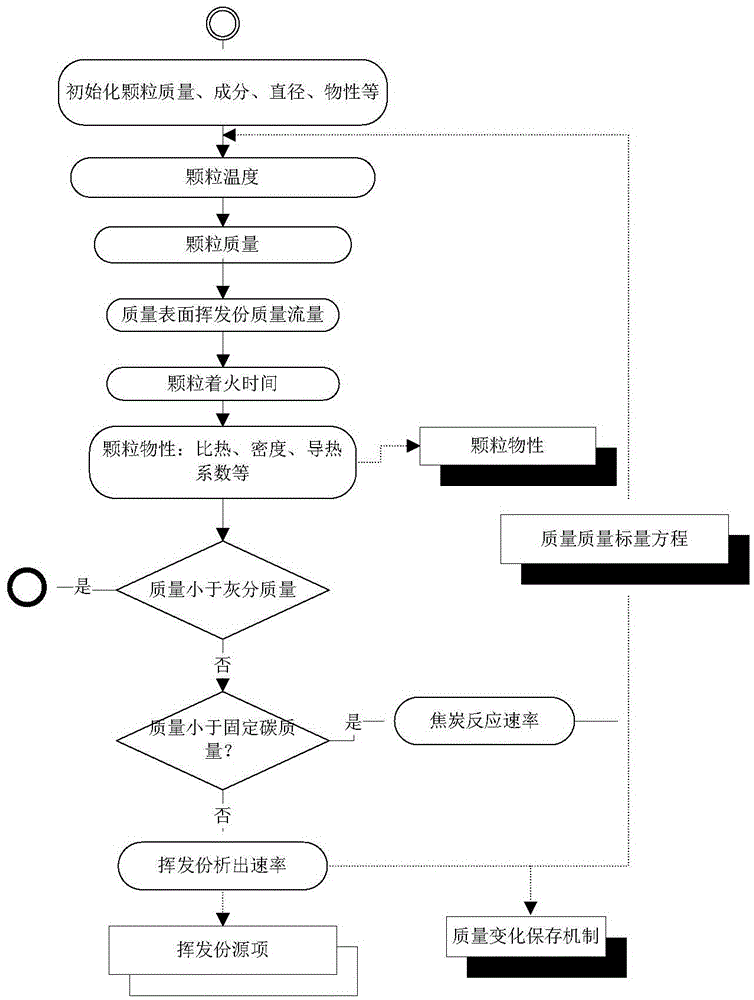

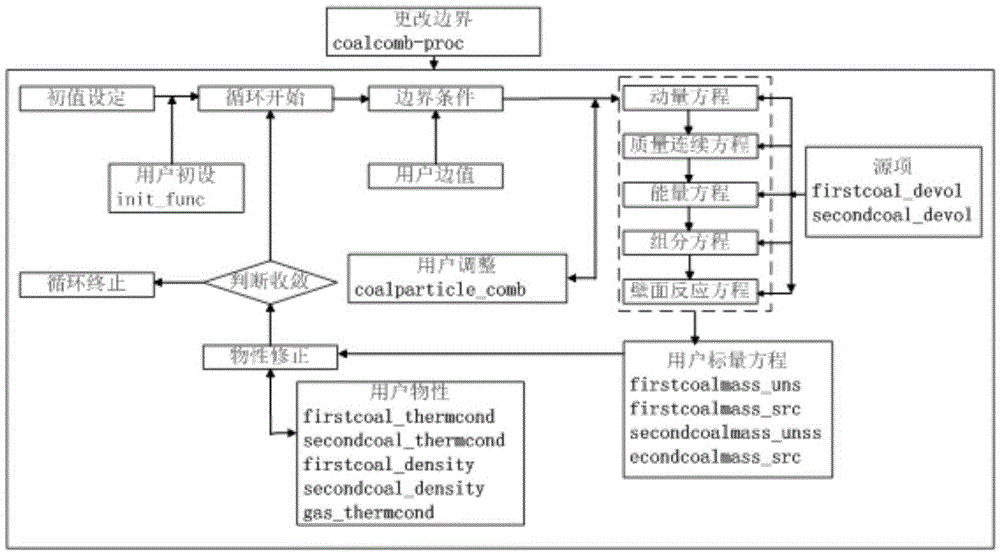

[0059] The numerical simulation method of the combustion process interaction between pulverized coal particles in this embodiment is based on the existing mathematical model of the large-scale computational fluid dynamics software FLUENT, and uses FLUENTUDF and FLUENTScheme mixed programming to couple the user-defined model, that is, pulverized coal Particle interaction model (particle structure form, particle mass change model, particle size dynamic change model, volatile matter precipitation model), mass change preservation mechanism, to realize the numerical simulation of the interaction between pulverized coal particles in the combustion process, the specific steps are as follows :

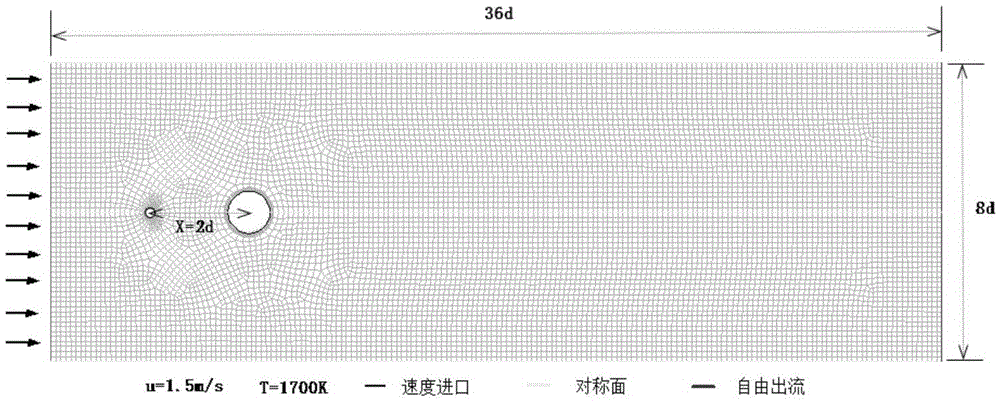

[0060] (1) Based on the real industrial composition of coal powder particles, as shown in Table 1, regardless of moisture and ash, assuming that the interior of coal powder particles is fixed carbon, and the periphery is volatile matter, the structural form of coal powder particles is construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com