Low NOX dry ash extraction coal powder burning method

A technology of slagging coal powder and combustion method, which is applied in the direction of combustion method, combustion using gaseous fuel and powder fuel, combustion using multiple fuels, etc., and can solve problems such as insufficient mixing with air, low burnout rate, and high dust concentration. problems, to achieve the effect of avoiding excessive temperature, sufficient combustion, and high burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

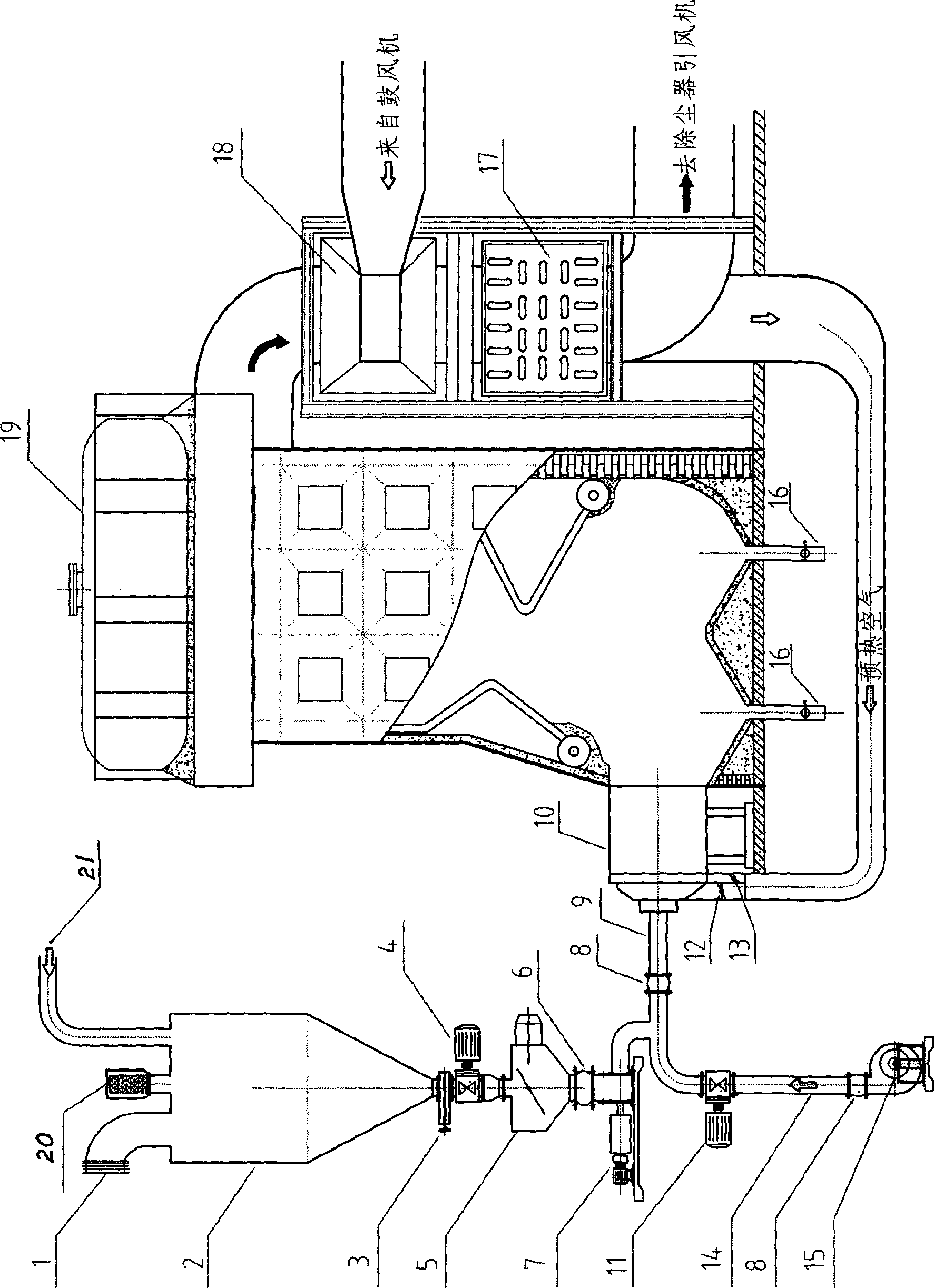

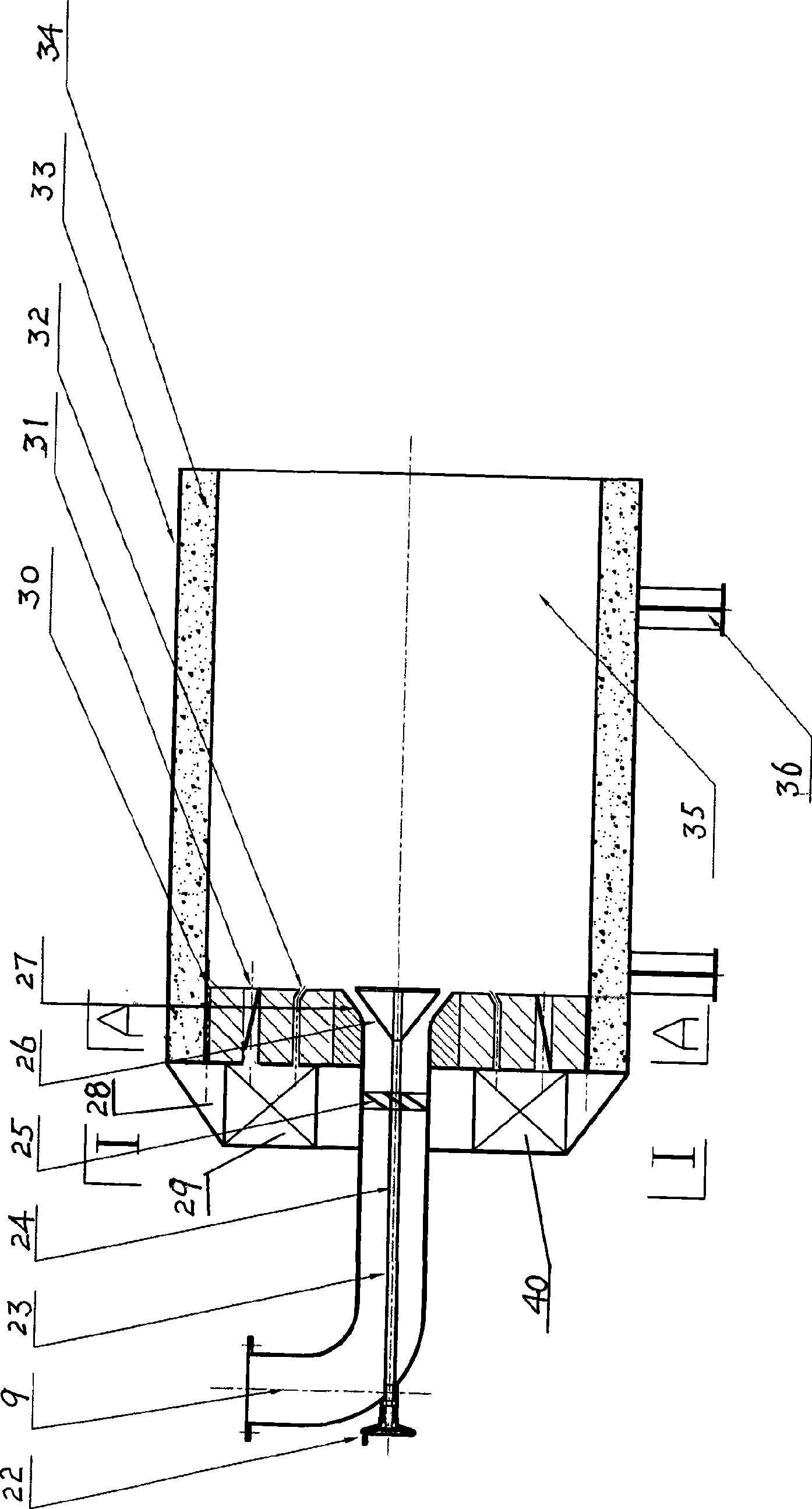

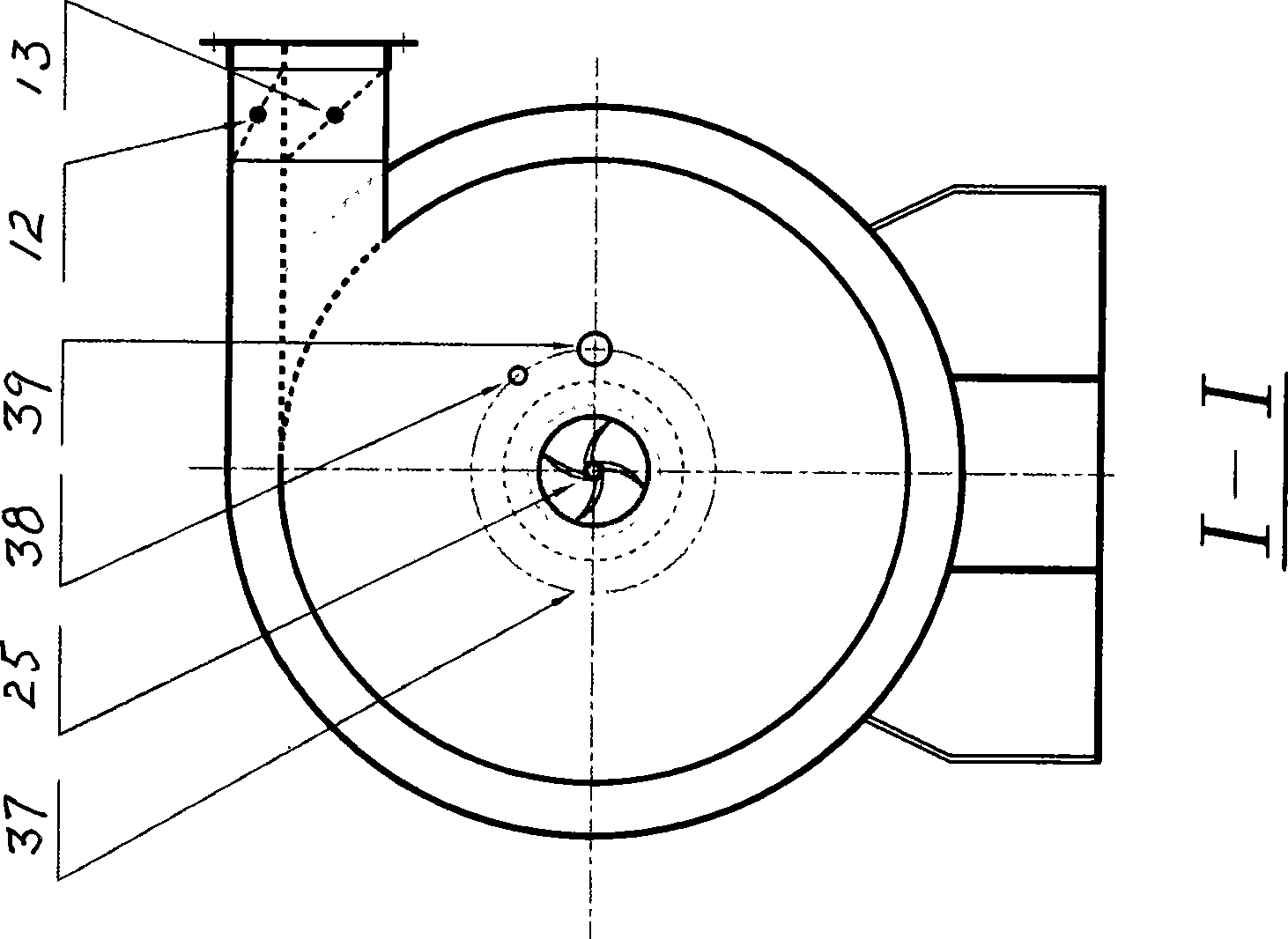

[0019] like figure 1 shown, for a low NO X Schematic diagram of the solid state slagging pulverized coal combustion system, a low NO X Solid state slagging pulverized coal combustion method is characterized in that,

[0020] The first step is to remove the grate at the bottom of the old boiler to become a pure furnace 19, or manufacture a boiler with a pure furnace 19 that matches the burner, and install an air preheater 18 and an economizer on the side of the pure furnace 19 17. The upper end of the pure furnace 19 is connected to the air preheater 18 through a pipeline, and the lower end of the air preheater 18 is connected to the economizer 17;

[0021] In the second step, at least one burner 10 is installed on one side of the bottom of the pure furnace 19, which communicates with the pure furnace 19, and the inlet end of each burner 10 is connected to one end of the primary air / coal pipe 9, and the primary air / coal The other end of the powder pipe 9 is respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com