Powder combustion experiment platform

An experimental platform, powder technology, applied in the direction of chemical analysis by combustion, analysis of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

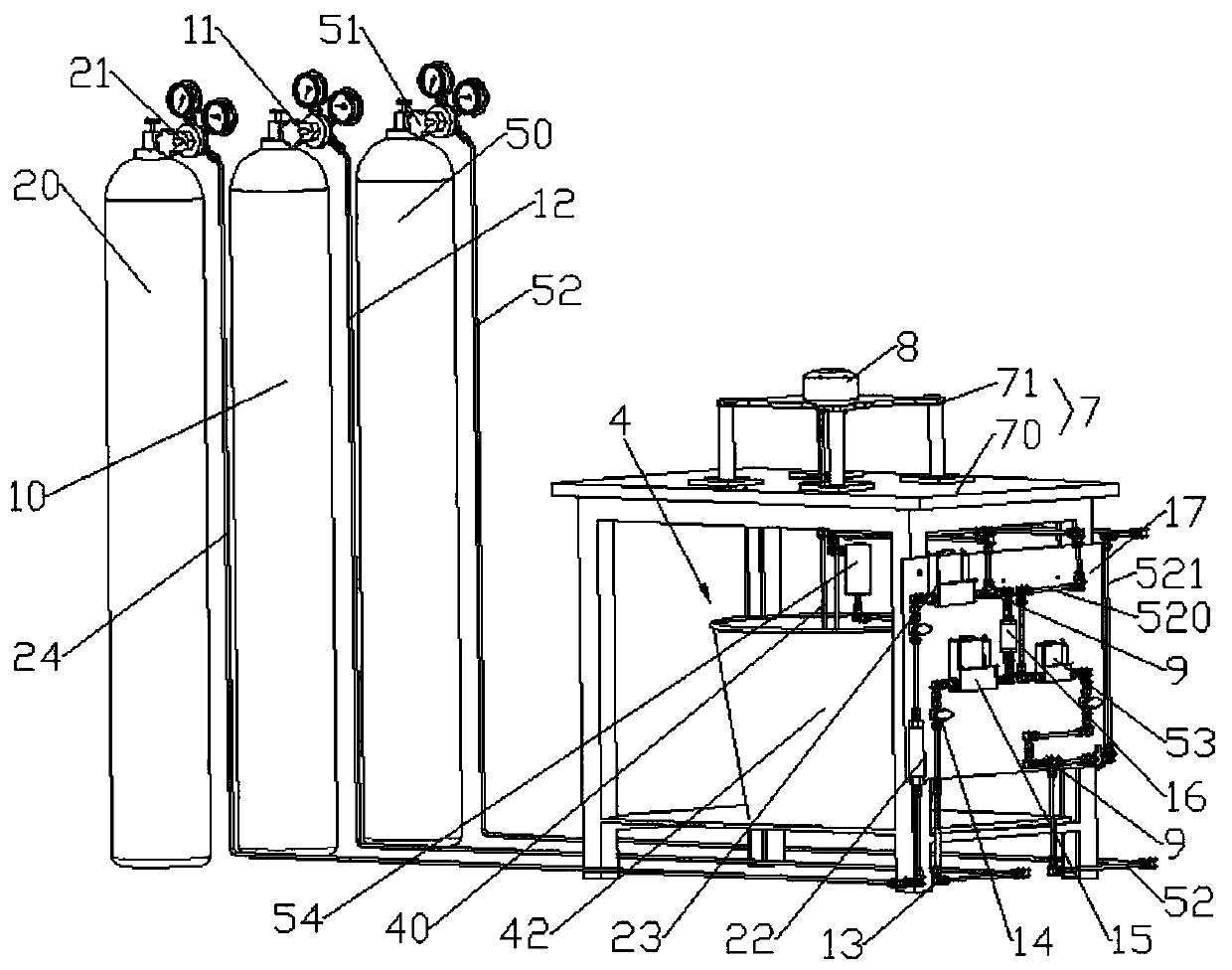

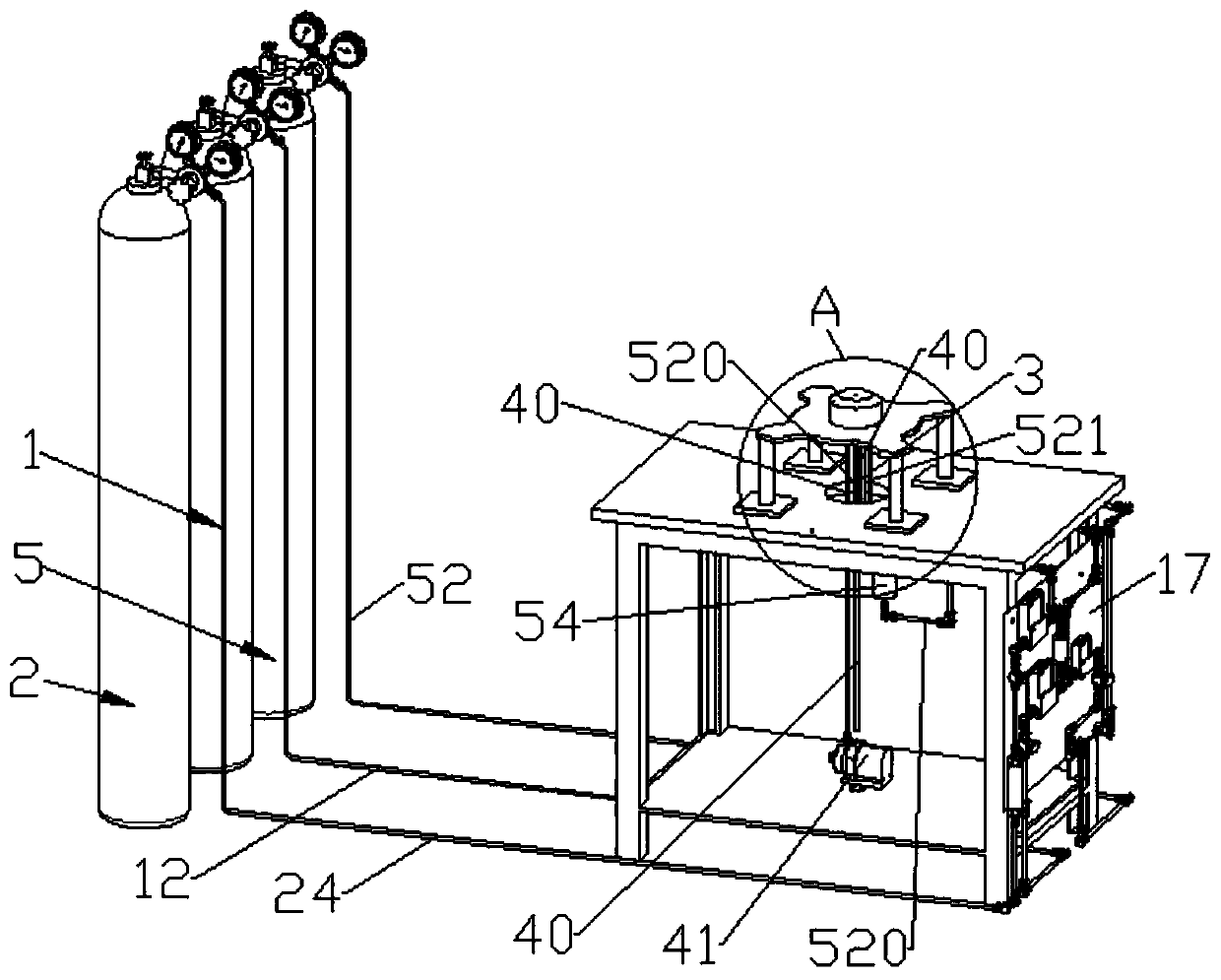

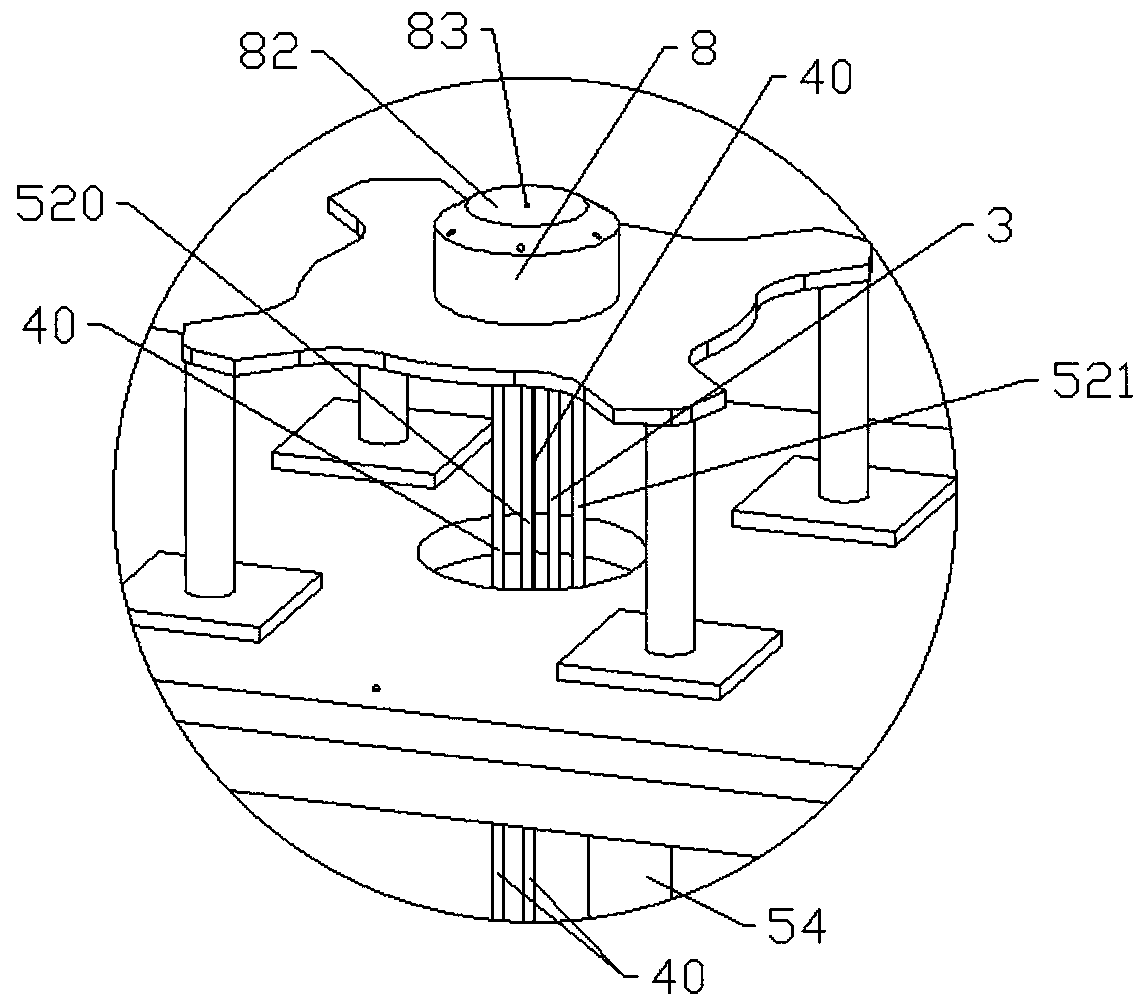

[0050] This embodiment proposes a kind of powder combustion experiment platform, its structure is as follows Figure 1-8 As shown, it includes a gas delivery system, a nitrogen system 5 , a water cooling circulation system 4 , a test bench 7 , and a flat flame burner 8 .

[0051] The gas delivery system includes an air system 1 , a methane system 2 and a mixed gas pipeline 3 . Wherein, the air system 1 includes an air cylinder 10 and an air delivery pipeline 12, and the air delivery pipeline 12 is provided with a mass flow controller 15 for air, a one-way valve 16, an air pressure reducing valve 11 and a ferrule air source ball valve 14 . The air cylinder 10 is used to contain air and is connected to the head end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com