Gasification combustor for biomass granules

A biomass particle and burner technology, which is used in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of insufficient gasification of biomass particles, low thermal efficiency of semi-gasification, and unpleasant smell. , to achieve the effect of compact structure, small footprint, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

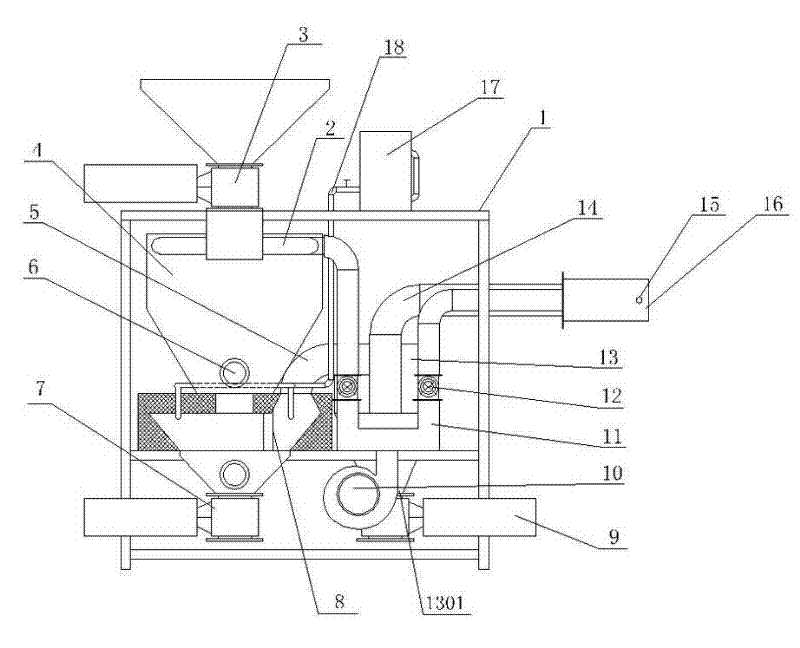

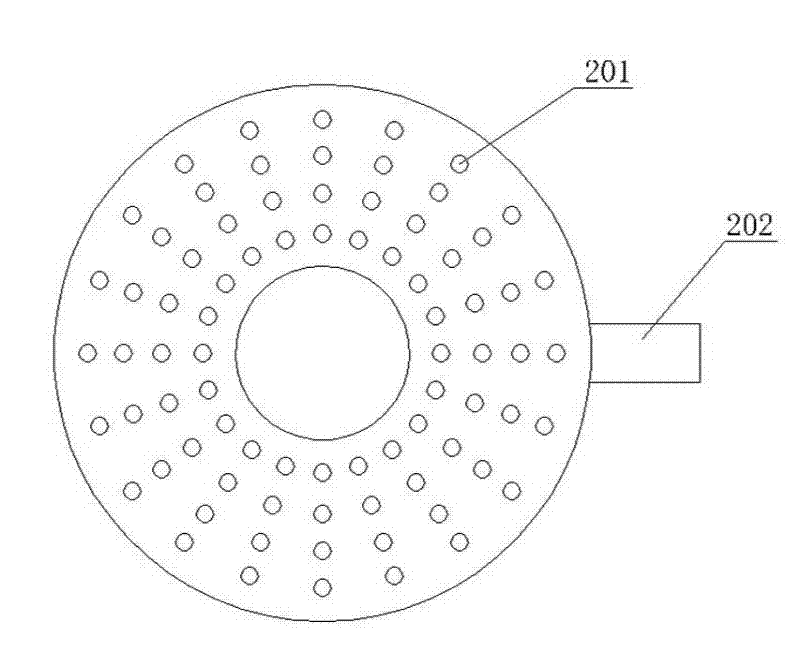

[0023] Such as Figure 1 to Figure 5 As shown, the biomass particle gasification burner has a housing 1, a packing device 3 is arranged on the housing 1, an inner tank 4 and a blower 10 are arranged in the housing 1, and an annular diffuser is arranged on the upper part of the inner tank 4. The diffuser 2 is provided with a plurality of diffuser holes 201 on the top surface of the diffuser 2 (facing the upper wall of the liner 4 ), and an air inlet 202 is provided on the side of the diffuser 2 . The lower part of the inner container 4 is provided with an ignition port 6, a fire grate 8 and an ash outlet. The area between the carbonization area and the fire grate 8 is the reduction area, and the area outside the fire grate 8 is the gasification area. Outer shell 1 is provided with water tank 17, draws water supply pipe 18 on water tank 17, is provided with valve on water supply pipe 18, and water supply pipe 18 water outlets are positioned at the reducing area of liner 4 bo...

Embodiment 2

[0026] Such as Figure 6 As shown, for the small burner, the water tank 17 and the water supply pipe 18 in the embodiment 1 are canceled, and the moisture contained in the biomass particles is mixed with the air from the blower 10 to form saturated air as the gasification agent, and the others are the same as in the embodiment 1.

Embodiment 3

[0028] Such as Figure 7 As shown, the filter 13 is a box, and a plurality of partitions 19 are vertically placed in the filter 13. The partitions 19 are arranged in a staggered up and down manner to form a serpentine passage, and ash discharge is provided at the bottom of the serpentine passage. The mouth 1301, the outlet of the connecting pipe 5 and the inlet of the gas pipe 14 are respectively located at the beginning and end of the serpentine passage. The mixed combustible gas entering the filter 13 is discharged through the serpentine channel, and the dust is discharged through the ash discharge port 1301 . Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com