Self-backheating swirling burner for fuel gas with low heat value

A combustion device and low calorific value technology, applied in gas fuel burners, burners, combustion methods, etc., can solve problems affecting energy utilization efficiency, reduced economic benefits, incomplete combustion, etc., to expand the range of fuel utilization and improve combustion performance, the effect of increasing the initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

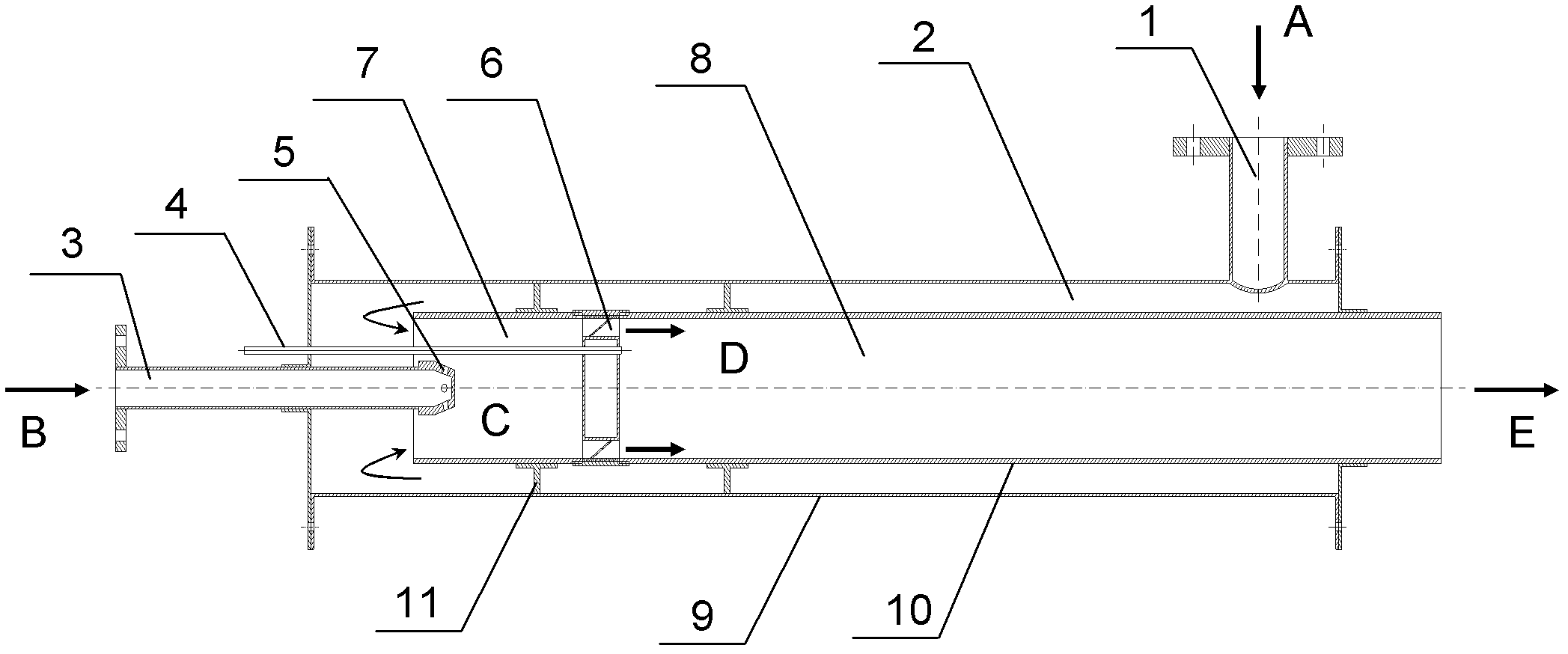

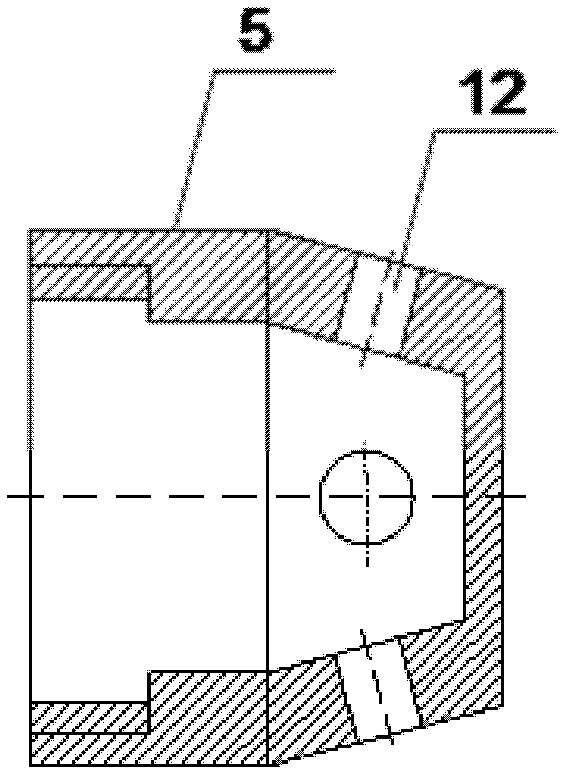

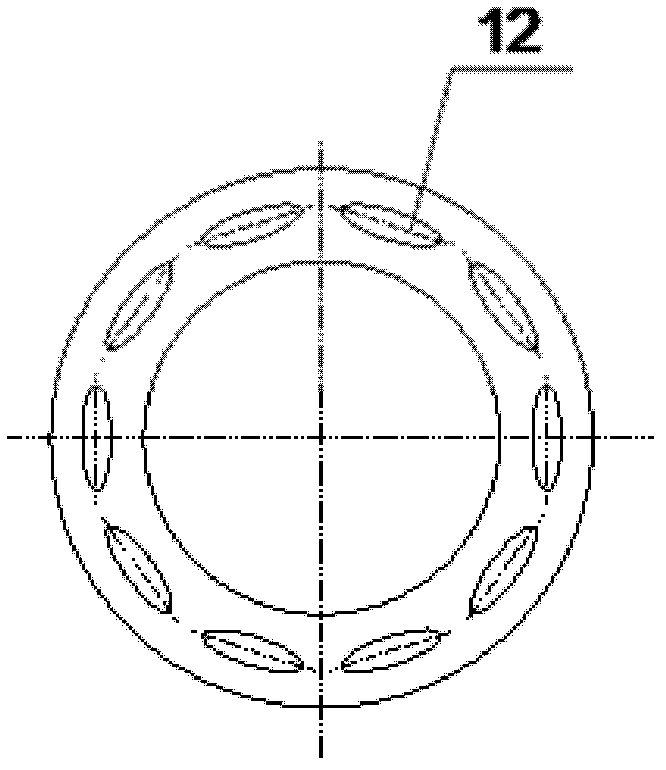

[0023] Please refer to figure 1 As shown, the self-regenerating low calorific value gas swirl combustion device of the present invention includes an outer cylinder 9, an inner tube 10 sleeved in the outer cylinder 9, an air passage 2 is formed between the outer cylinder 9 and the inner tube 10, and is arranged on The combustion-supporting air inlet 1 on the tail of the outer cylinder body 9 and the gas inlet 3 fixed on the head of the outer cylinder body 9 are arranged in the swirl flow generating device 6 in the inner pipe 10, and the swirl flow generating device 6 connects the inner pipe 10 The cavity is divided into a mixing chamber 7 and a combustion chamber 8. The inner pipe 10 is fixed in the outer cylinder 9 through an inner pipe bracket 11, and also includes a gas nozzle 5 connected to the outer cylinder 9. The outlet of the air channel 2 is connected to the outer cylinder 9. The outlets of the gas nozzles 5 converge in the mixing chamber 7 , and the swirl generator 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com