Metal powder combustion device

A combustion device and metal powder technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve the problems of difficult transportation in different places, unstable power output, etc., and achieve low processing costs, simple and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

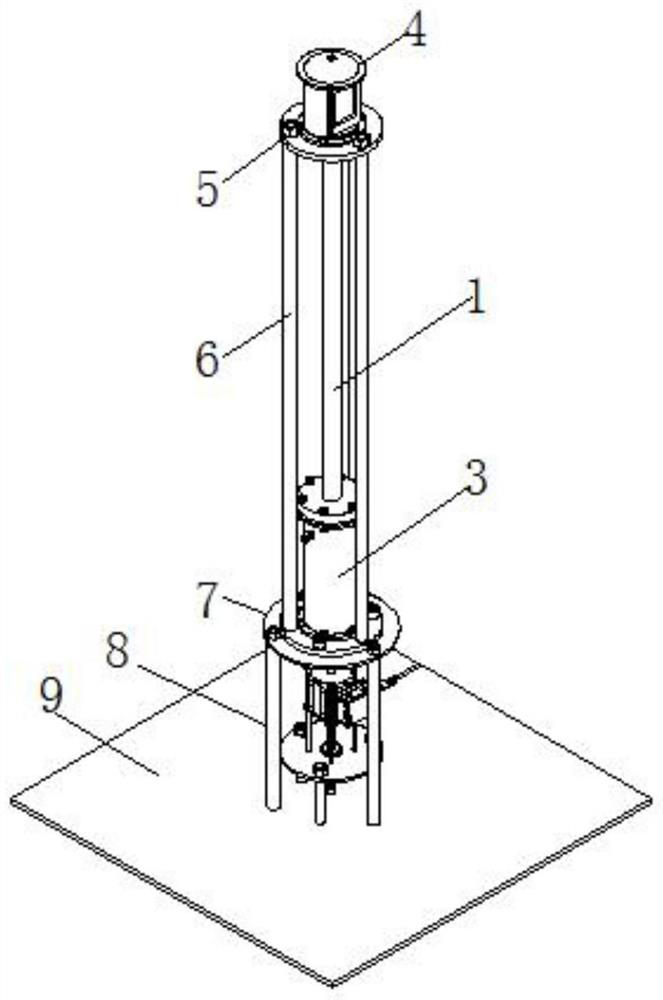

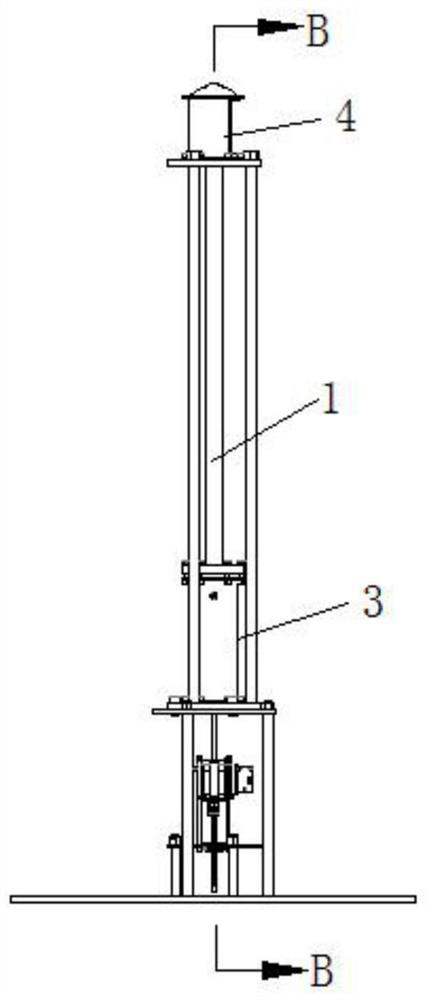

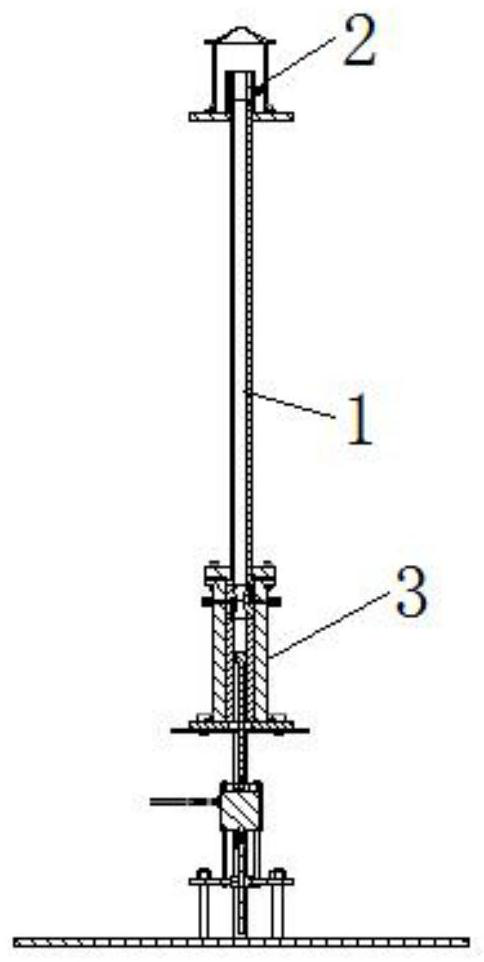

Image

Examples

Embodiment 2

[0065] like Figure 12 As shown, in this embodiment, the combustion device 2 is a turbulent flow burner 203, and the turbulent flow burner 203 includes a turbulent flow burner outer wall tube 203-1, and the inner wall of the turbulent flow burner outer wall tube 203-1 is provided with a device that can make the air flow turbulent. In order to form turbofan blades 203-2 of turbulent flame, the middle part of each turbofan blade 203-2 is fixed to the central axis.

[0066] The ignition process of the metal powder in the turbulent burner 203 is the same as that of the laminar burner 201, the difference is that the metal powder burns in the turbulent burner 203 to produce a turbulent flame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com