Patents

Literature

132 results about "Transitional Region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Areas of the axial skeleton where structure changes significantly leading to functional change. Transitional areas commonly include the following: occipitocervical region (OA), typically the OA-AA-C2 region is described. cervicothoracic region (CT), typically C7-T1. thoracolumbar region (TL), typically T10-L1. lumbosacral region (LS), typically L5-S1.

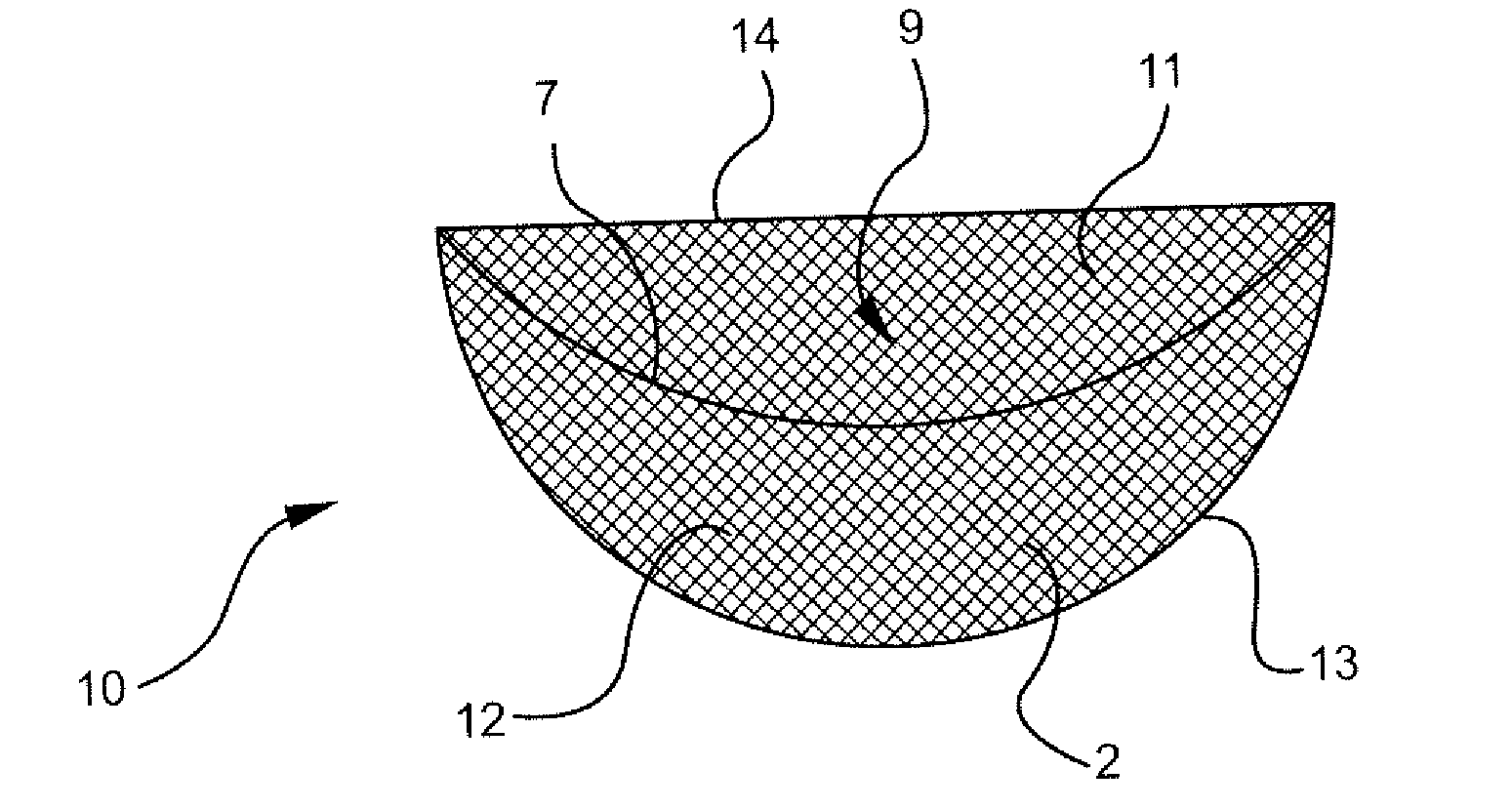

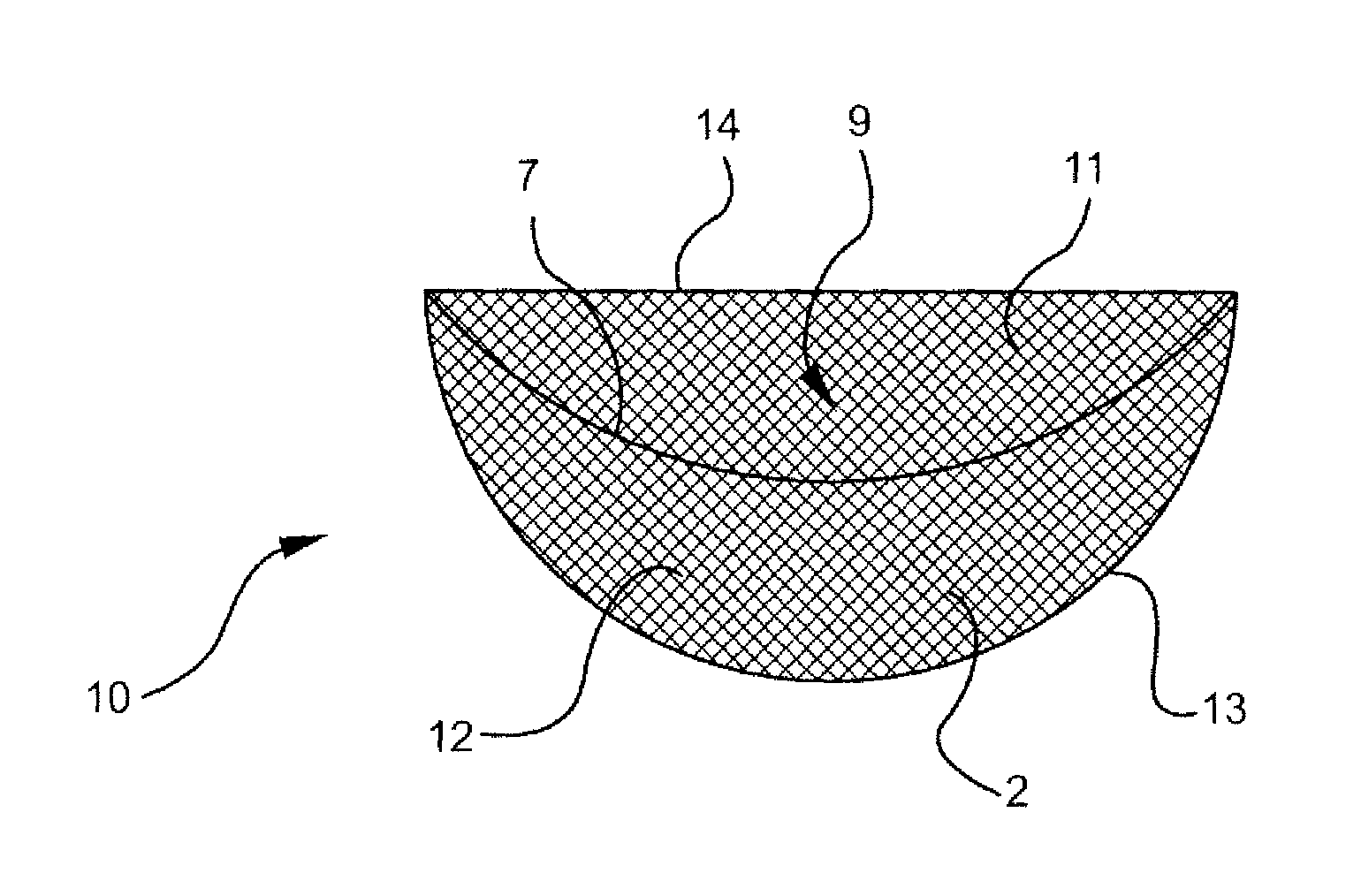

Naturally contoured, preformed, three dimensional mesh device for breast implant support

ActiveUS20090082864A1Easy to deployInherent disadvantageMammary implantsWound clampsWrinkle skinBreast implant

A preformed, seamless, three-dimensional, anatomically contoured prosthetic device for reinforcing breast tissue and supporting a breast implant includes a flat back wall, a concave front wall and a curved transitional region between the flat back wall and the front wall defining a smoothly curved bottom periphery. A concave receiving space is defined by the back wall and the front wall for at least partially receiving and supporting the breast implant therein. The three-dimensional prosthetic device is free of wrinkles, creases, folds or seams, which may have otherwise caused potential tissue irritation, bacteria hosting, infection and palpability problems.

Owner:ETHICON INC

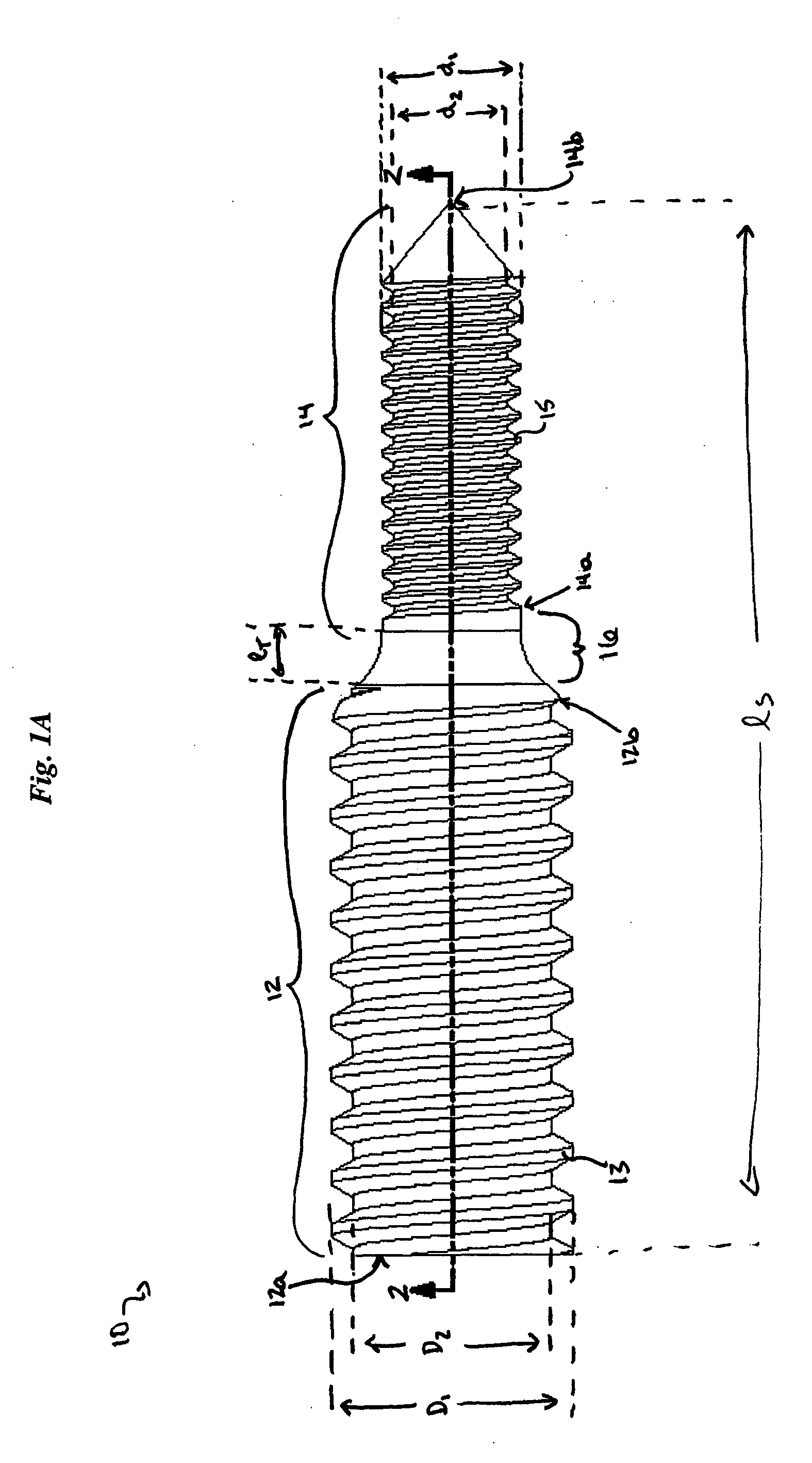

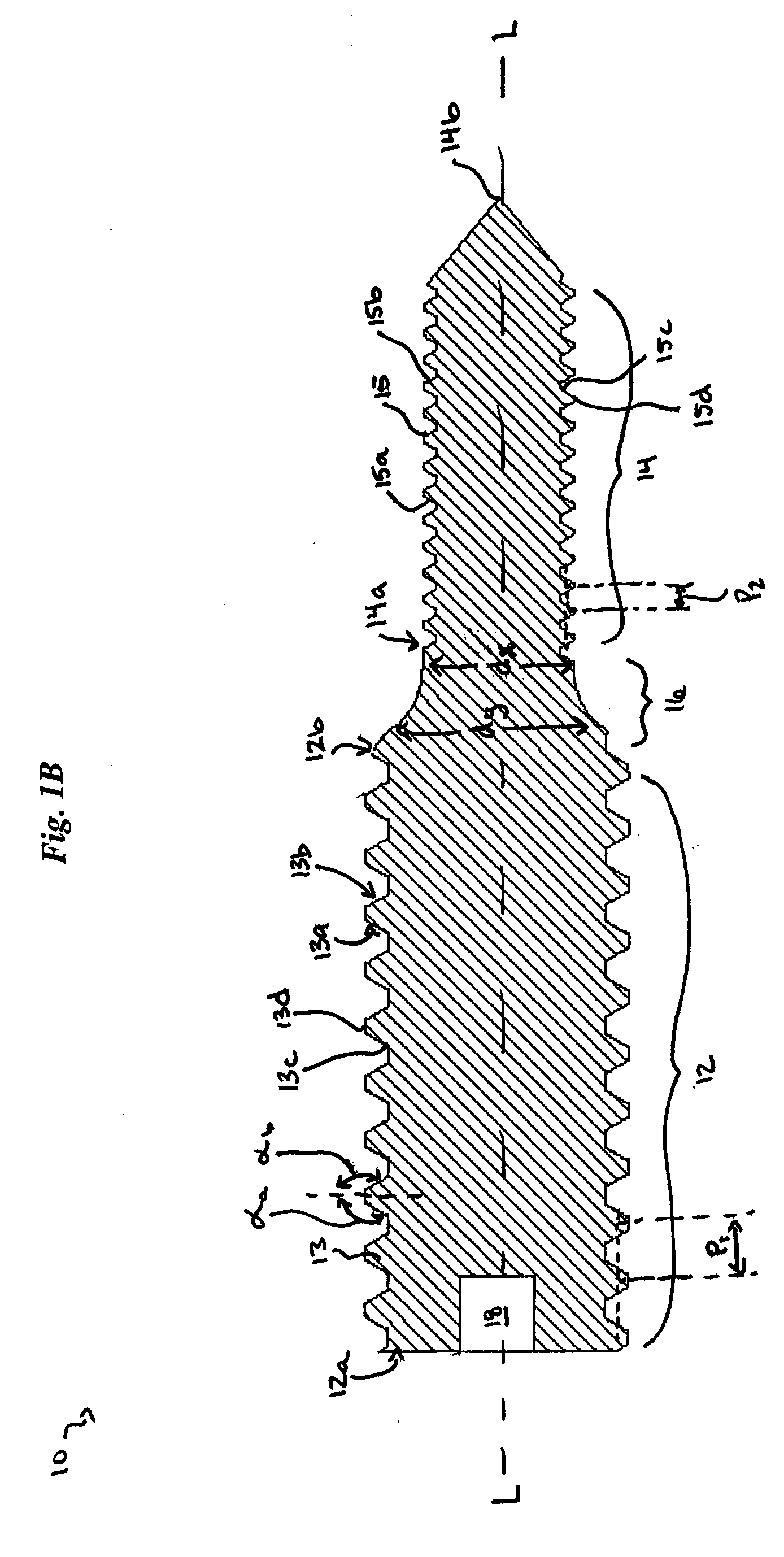

Distraction screw

InactiveUS20050038438A1Simple and safe processRelieve stressSuture equipmentsInternal osteosythesisDistractionDistal portion

A simple, safe implantable bone screw, and a method for distracting two bone segments, is provided. In general, the bone screw includes a shank having a threaded proximal portion and a distal portion with a major diameter that is less than a minor diameter of the threaded proximal portion. A transitional region of decreasing diameter can be disposed between the threaded proximal portion and the distal portion, and a driver receiving element is preferably disposed on a proximal end of the bone screw. In use, the proximal and distal portions of the bone screw are adapted to engage two segments of bone, and to create a distraction force between the two segments of bone.

Owner:DEPUY ACROMED INC

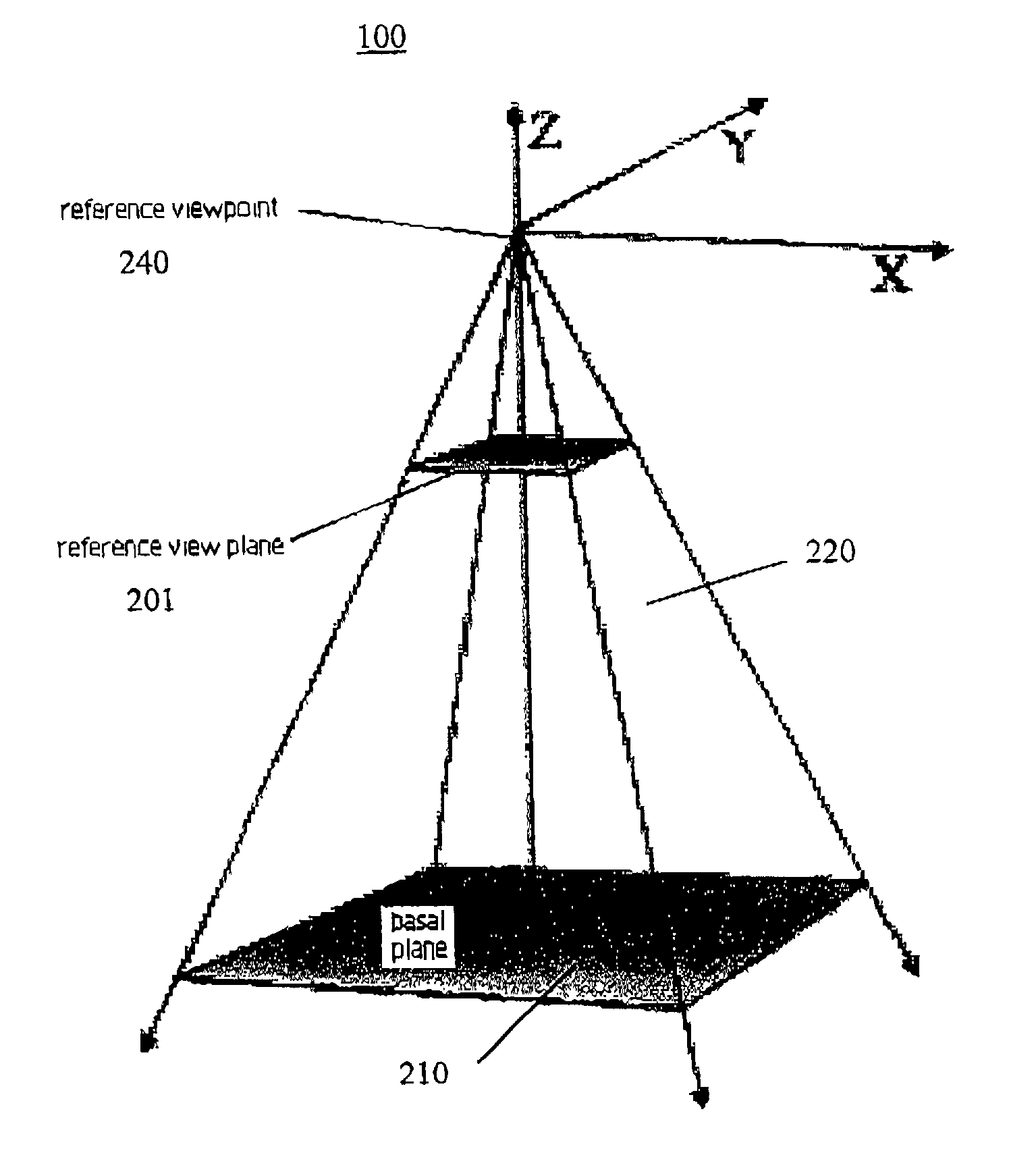

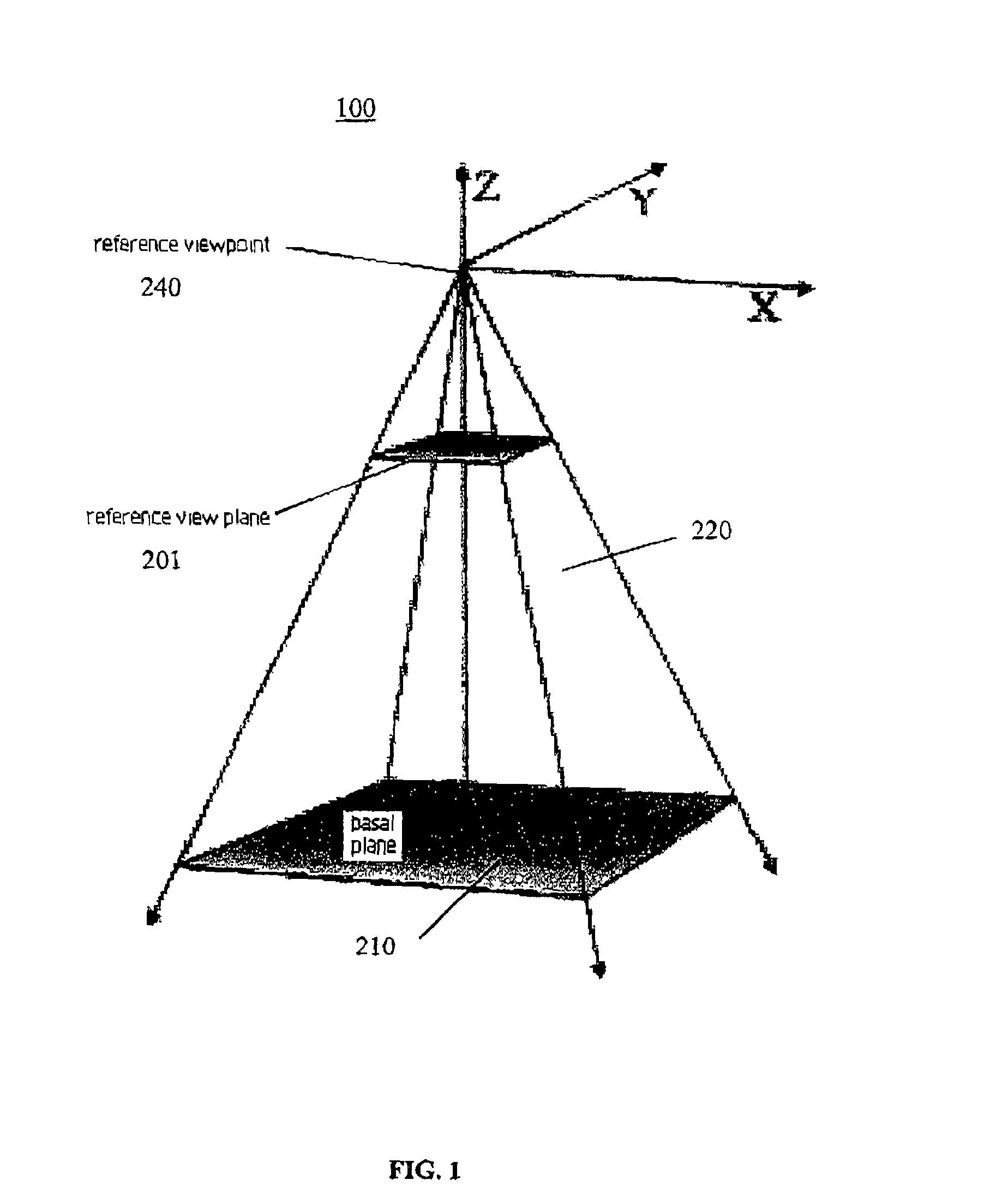

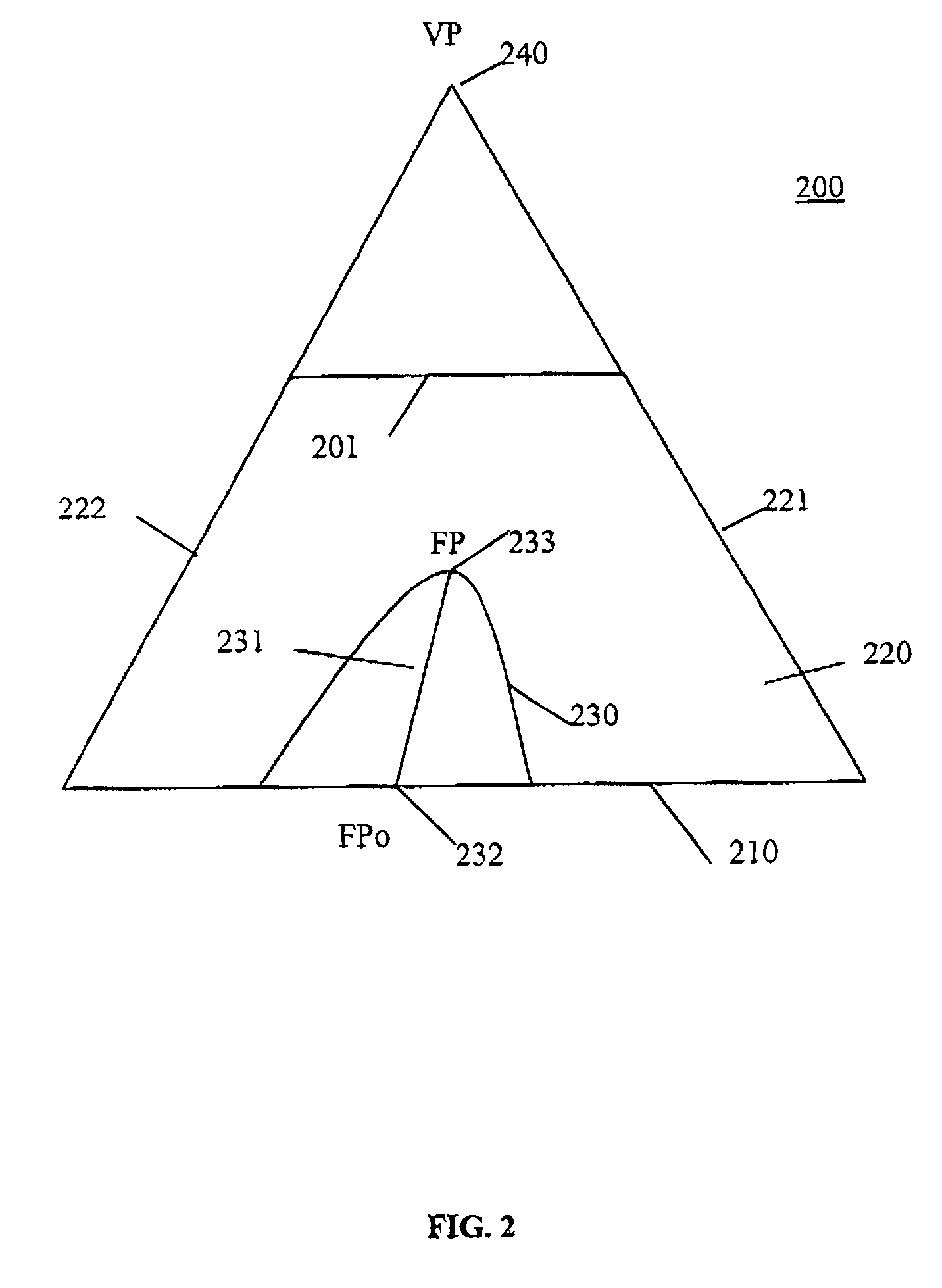

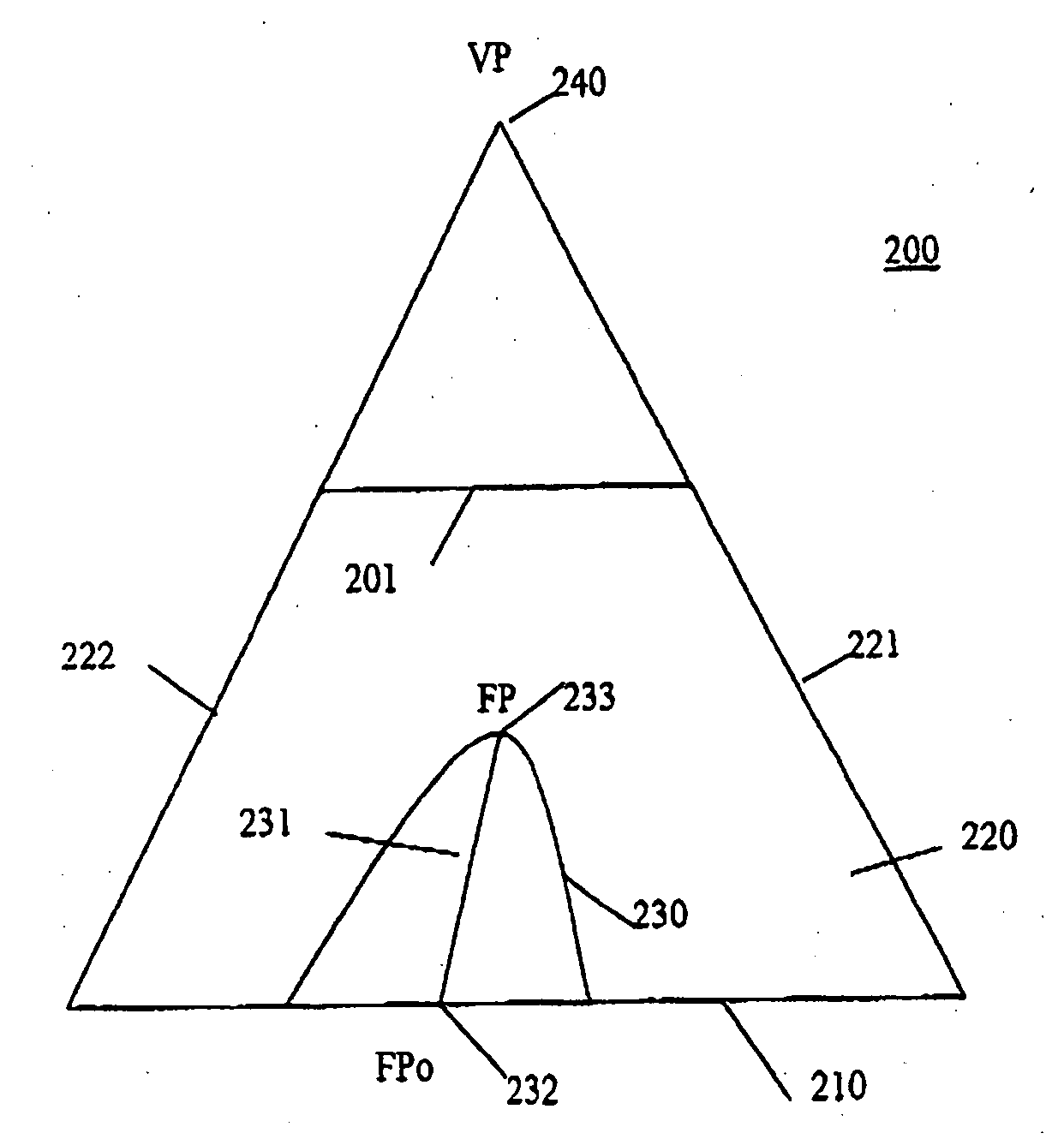

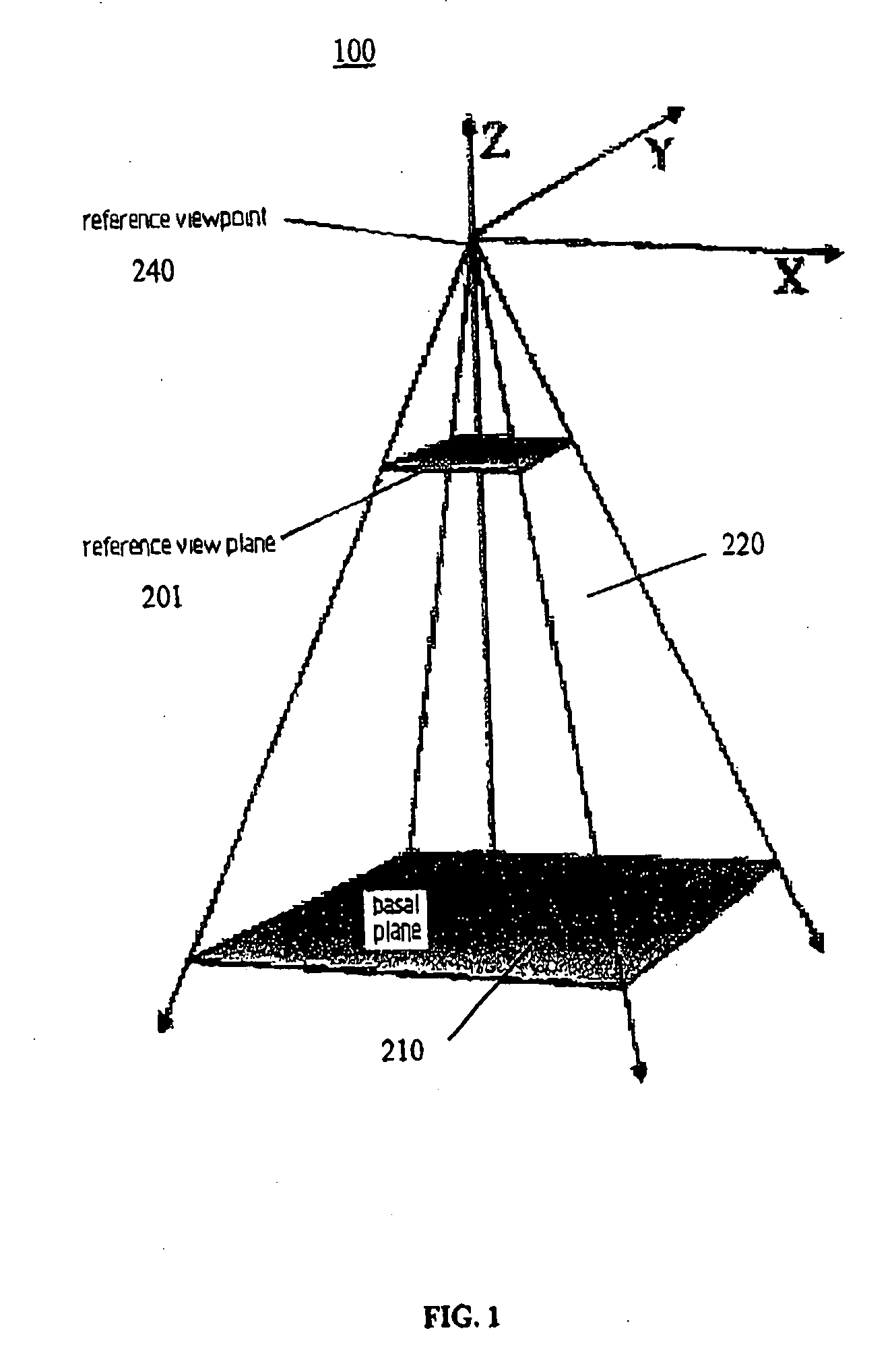

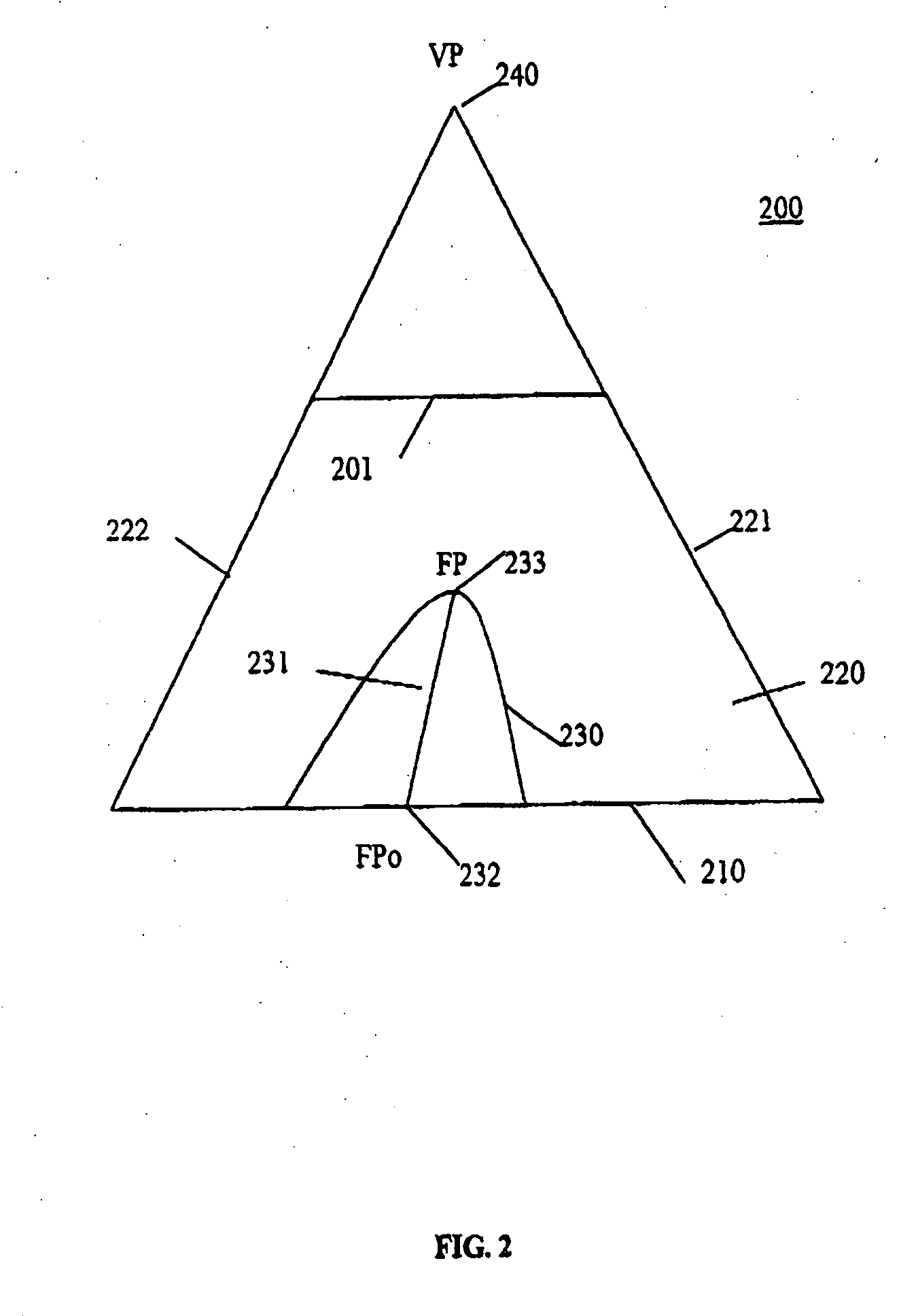

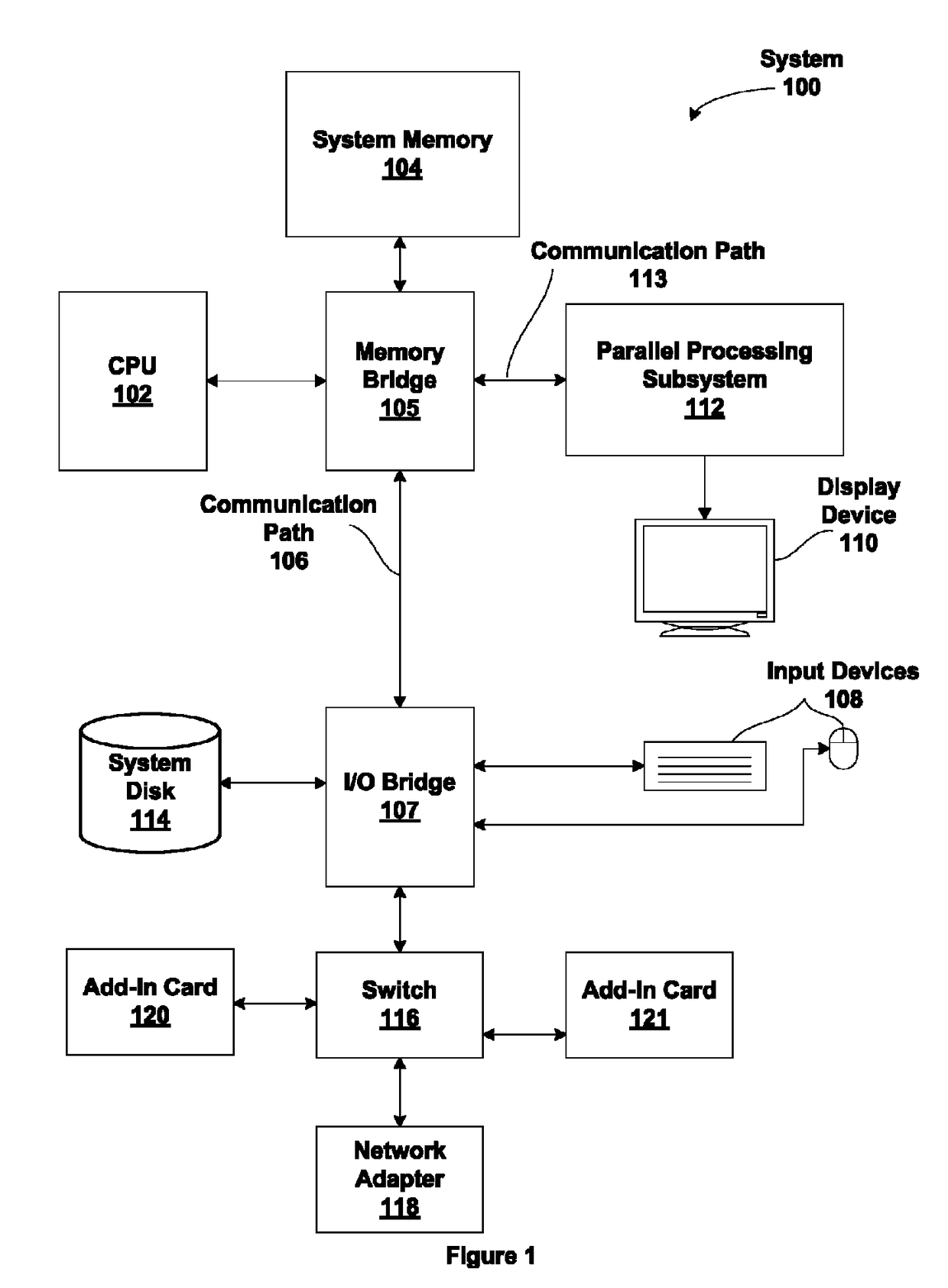

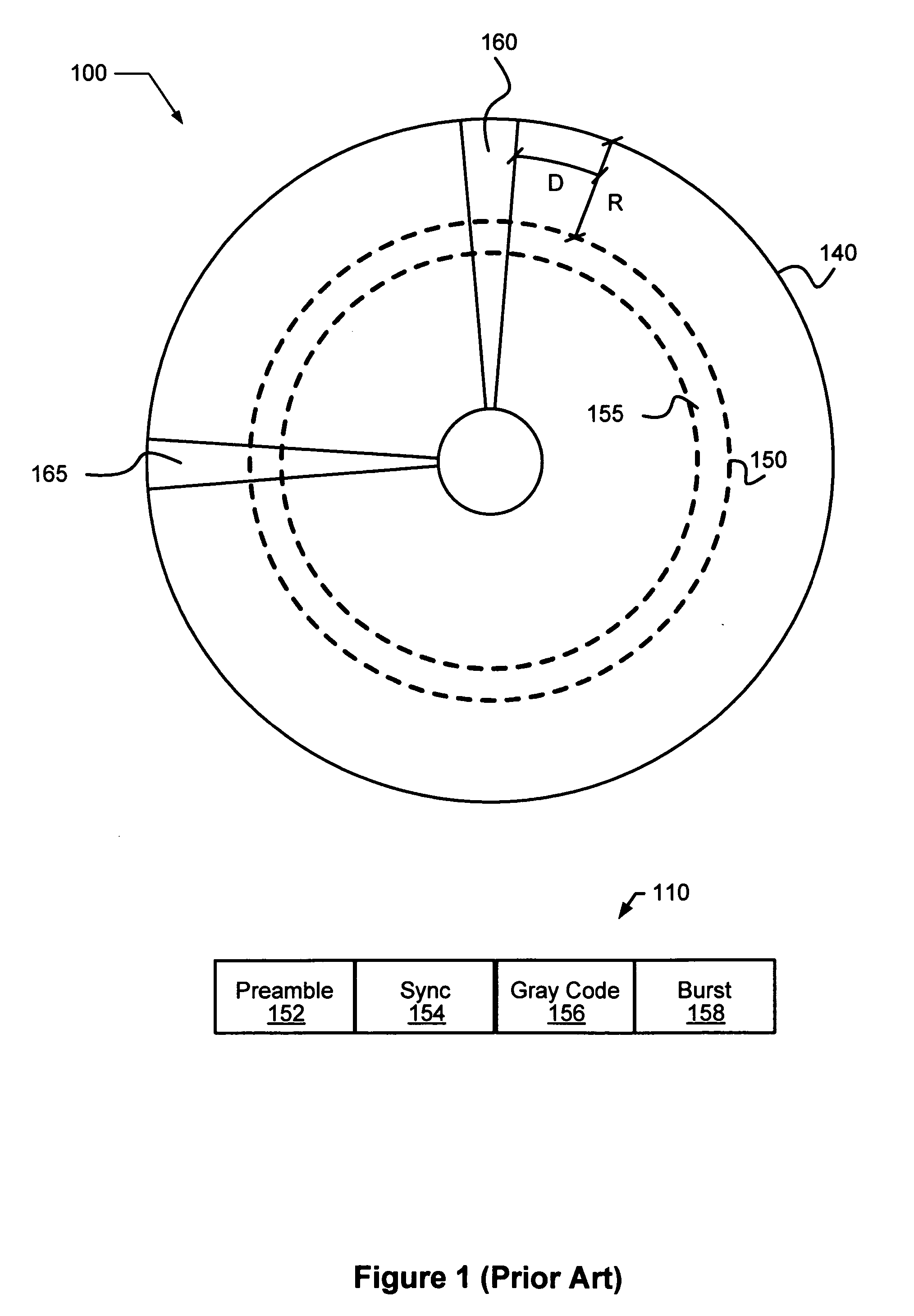

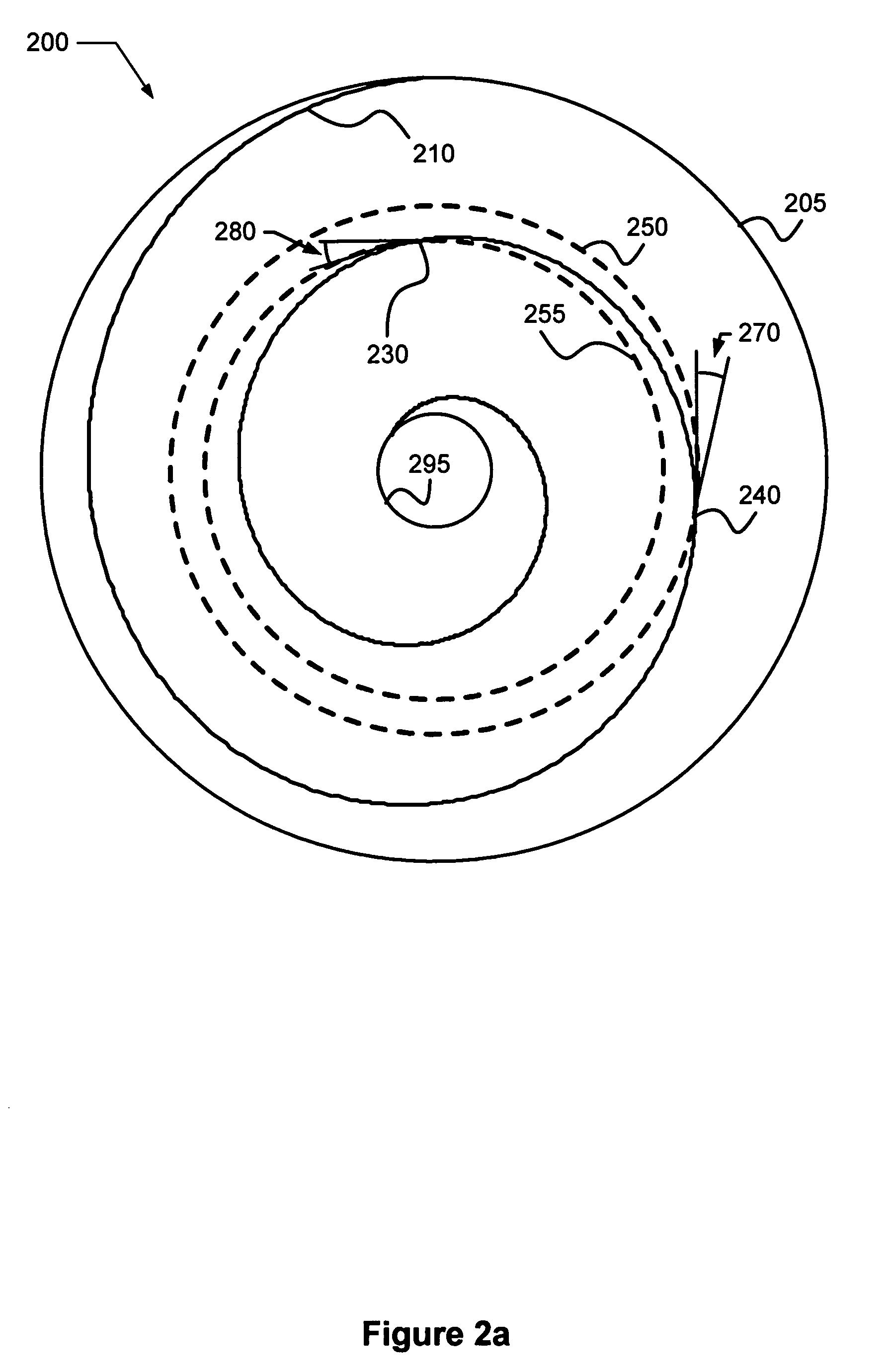

Method and system for enhanced detail-in-context viewing

InactiveUS7106349B2Improving visual detailImprove presentation qualityCathode-ray tube indicatorsInput/output processes for data processingComputer graphics (images)Transitional Region

An improved method for display of a transitional region of interest while transitioning between a first region of interest and a second region of interest within visual information on a display screen of a computer. The method comprising the steps of applying a transitional transformation to the visual information and displaying the transitional transformed visual information on the display screen. The transitional transformation requiring a reduced calculation for transforming the visual information in the transitional region.

Owner:ACCESSIFY LLC

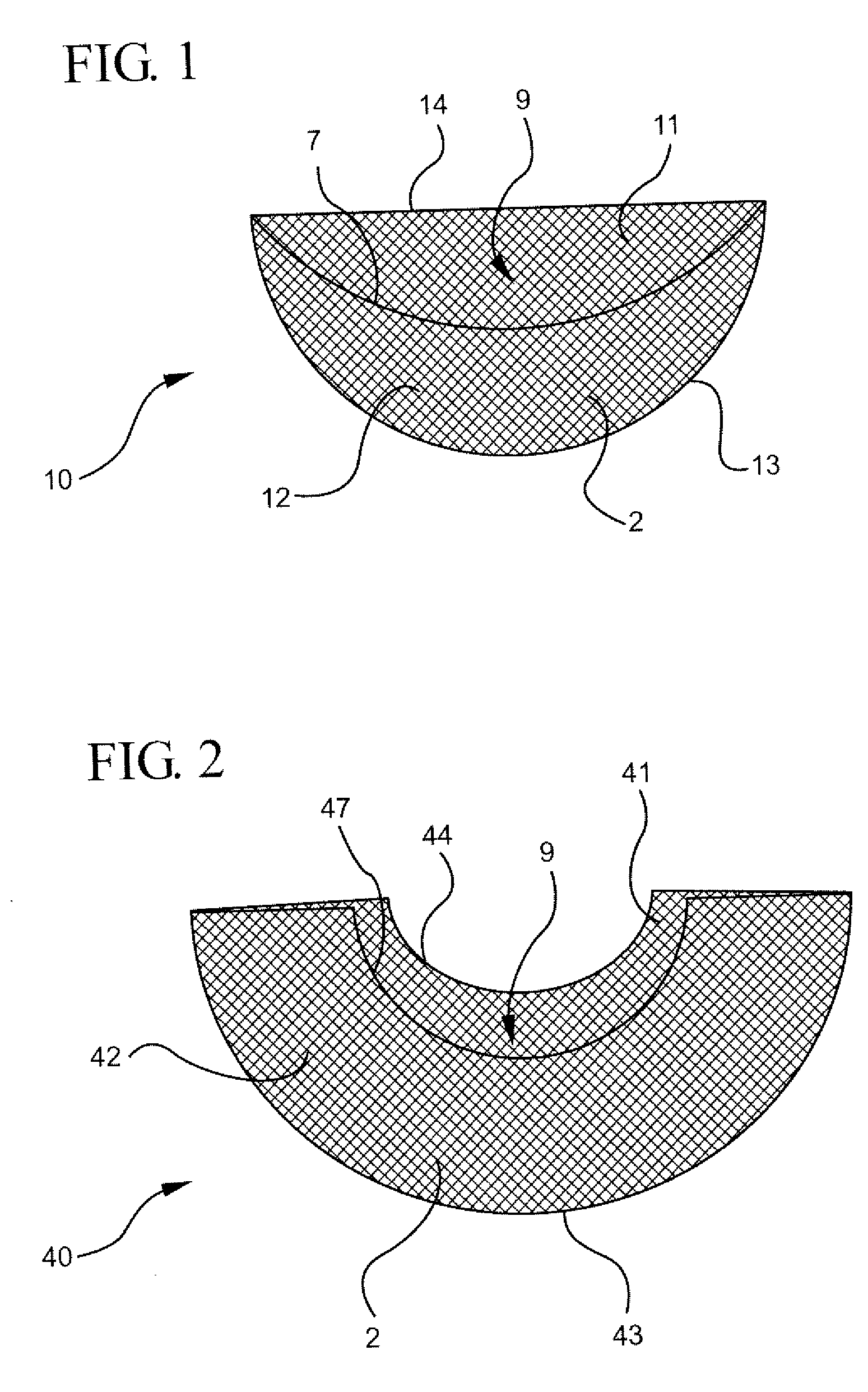

Naturally contoured, preformed, three dimensional mesh device for breast implant support

ActiveUS7875074B2Shorten the construction periodOvercomes inherent disadvantageMammary implantsWound clampsWrinkle skinBreast implant

A preformed, seamless, three-dimensional, anatomically contoured prosthetic device for reinforcing breast tissue and supporting a breast implant includes a flat back wall, a concave front wall and a curved transitional region between the flat back wall and the front wall defining a smoothly curved bottom periphery. A concave receiving space is defined by the back wall and the front wall for at least partially receiving and supporting the breast implant therein. The three-dimensional prosthetic device is free of wrinkles, creases, folds or seams, which may have otherwise caused potential tissue irritation, bacteria hosting, infection and palpability problems.

Owner:ETHICON INC

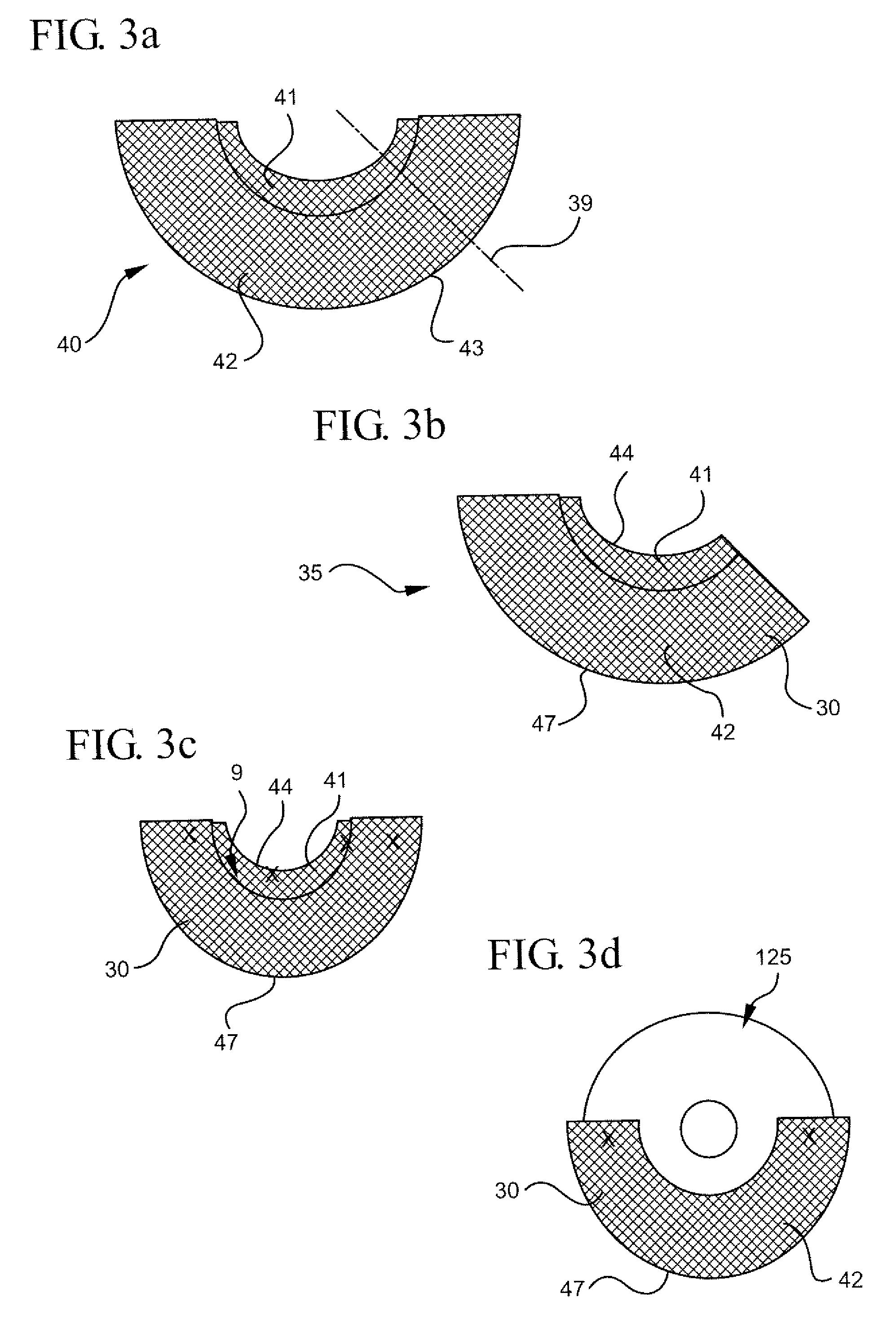

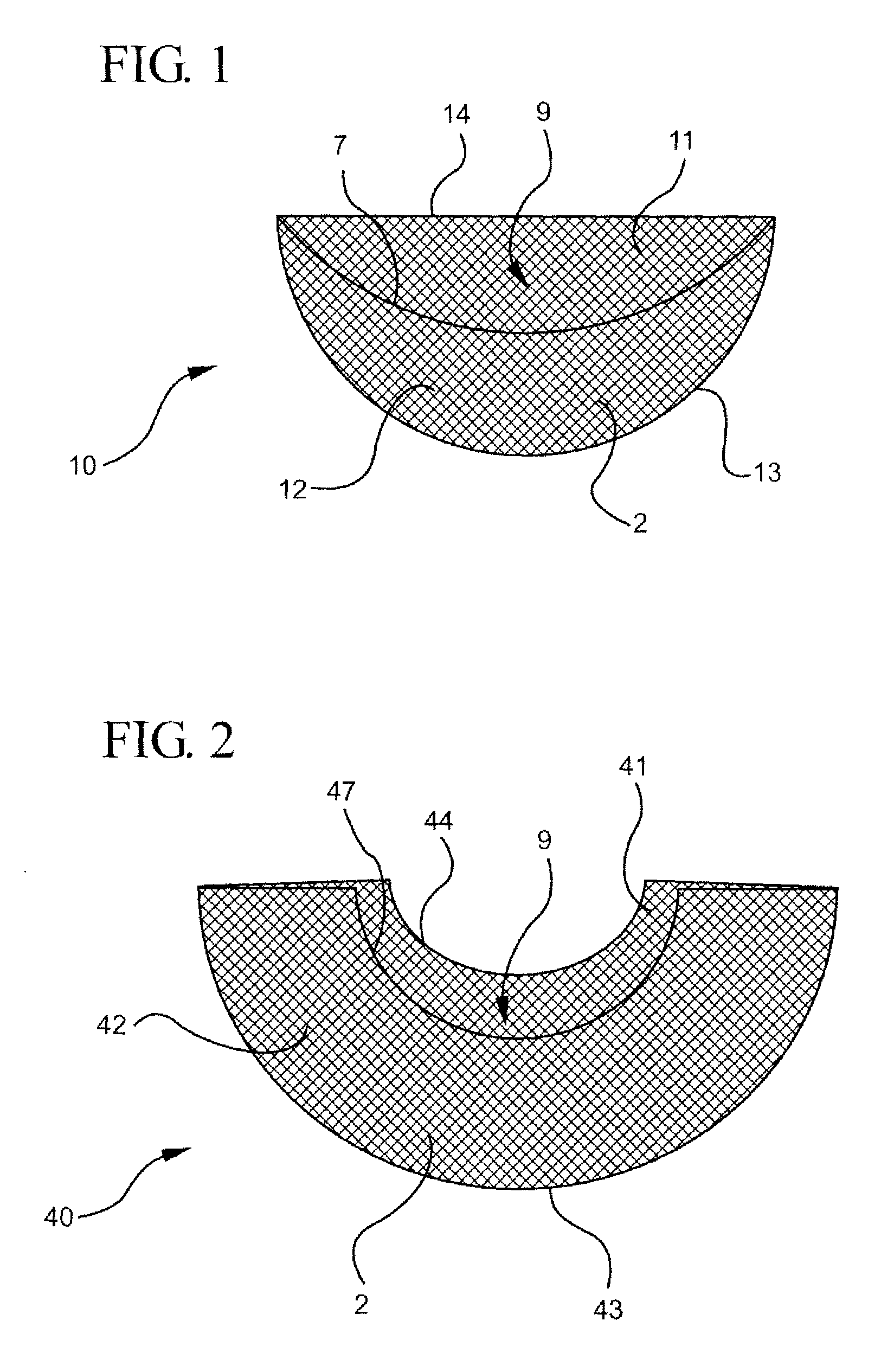

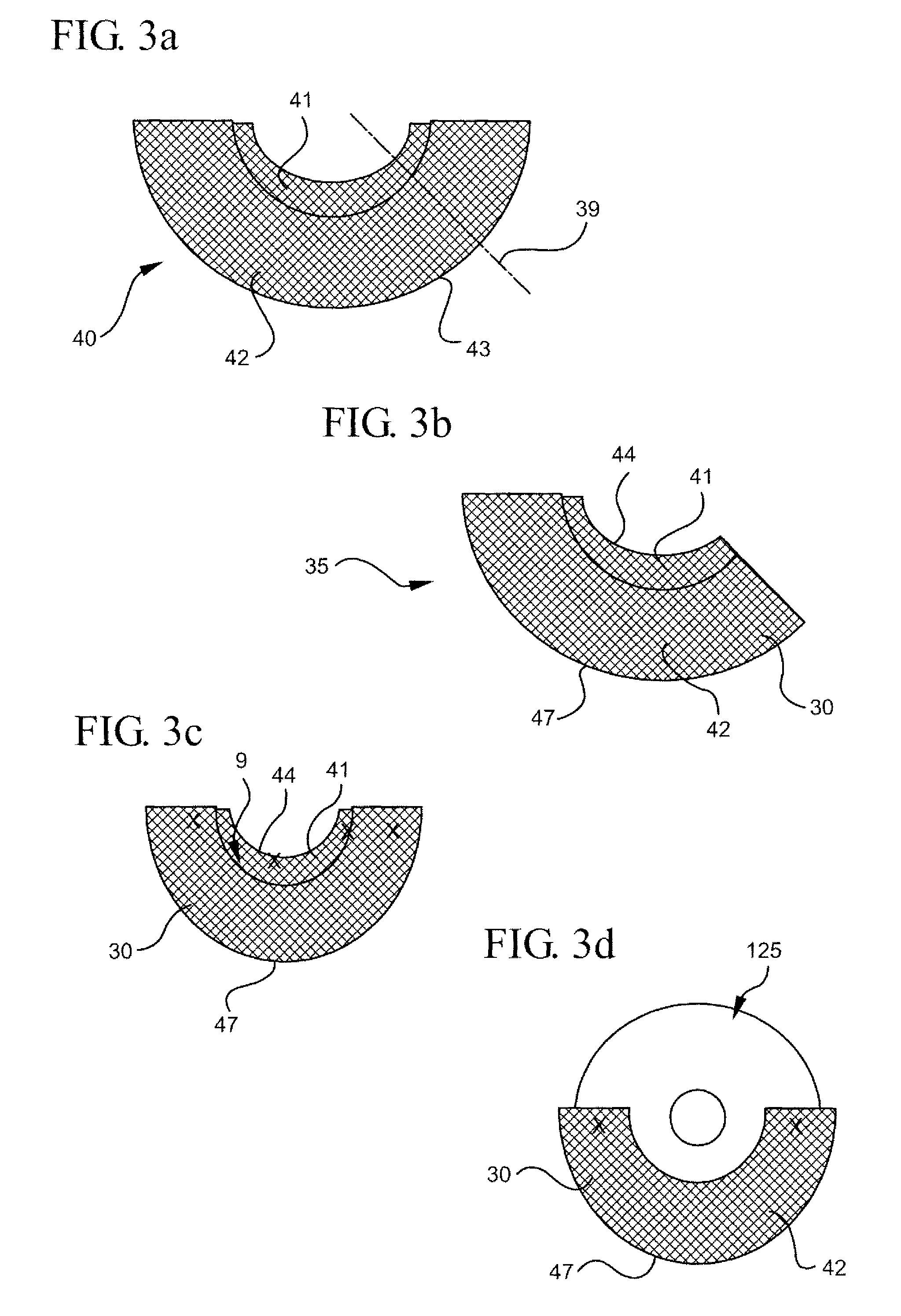

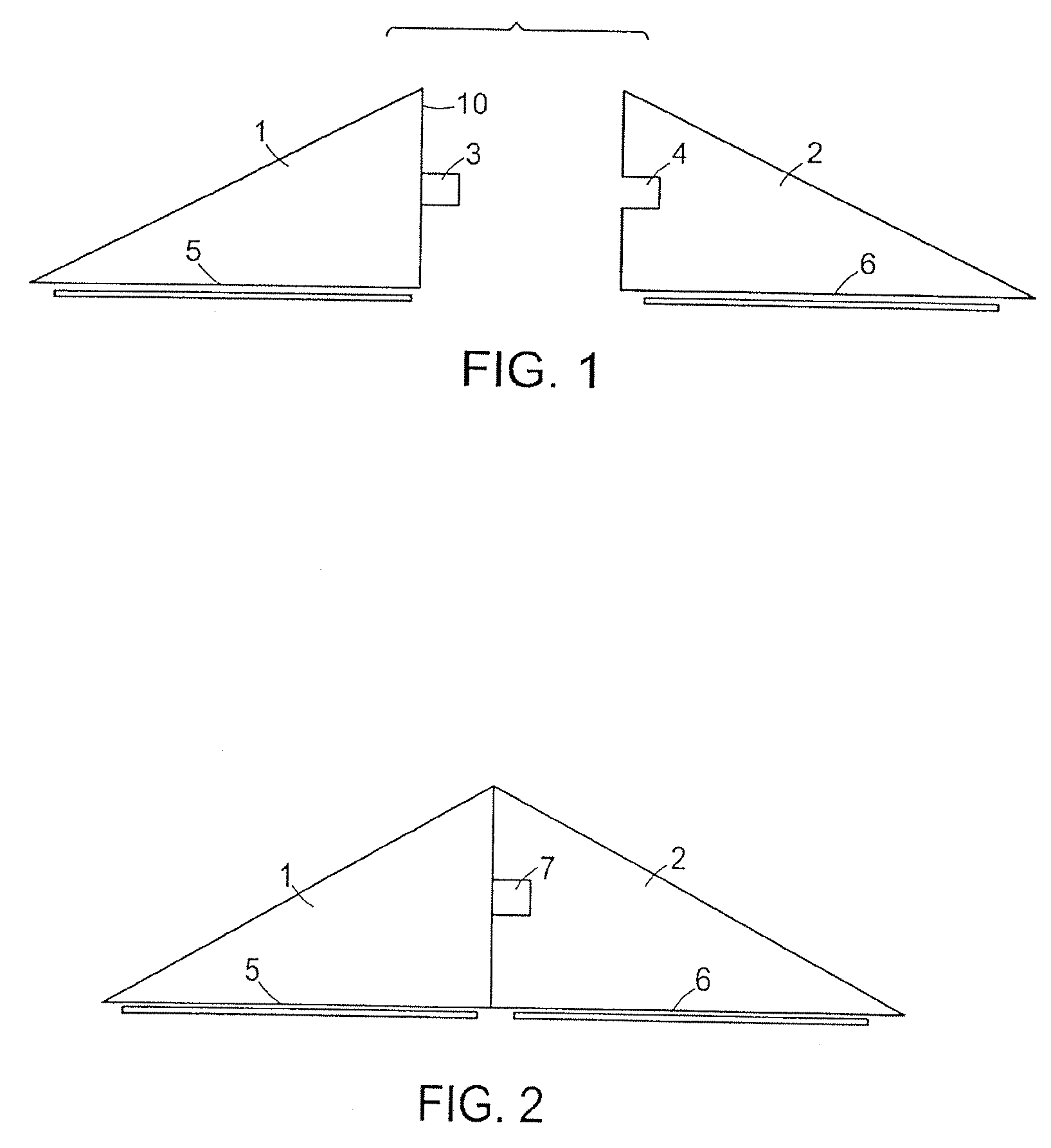

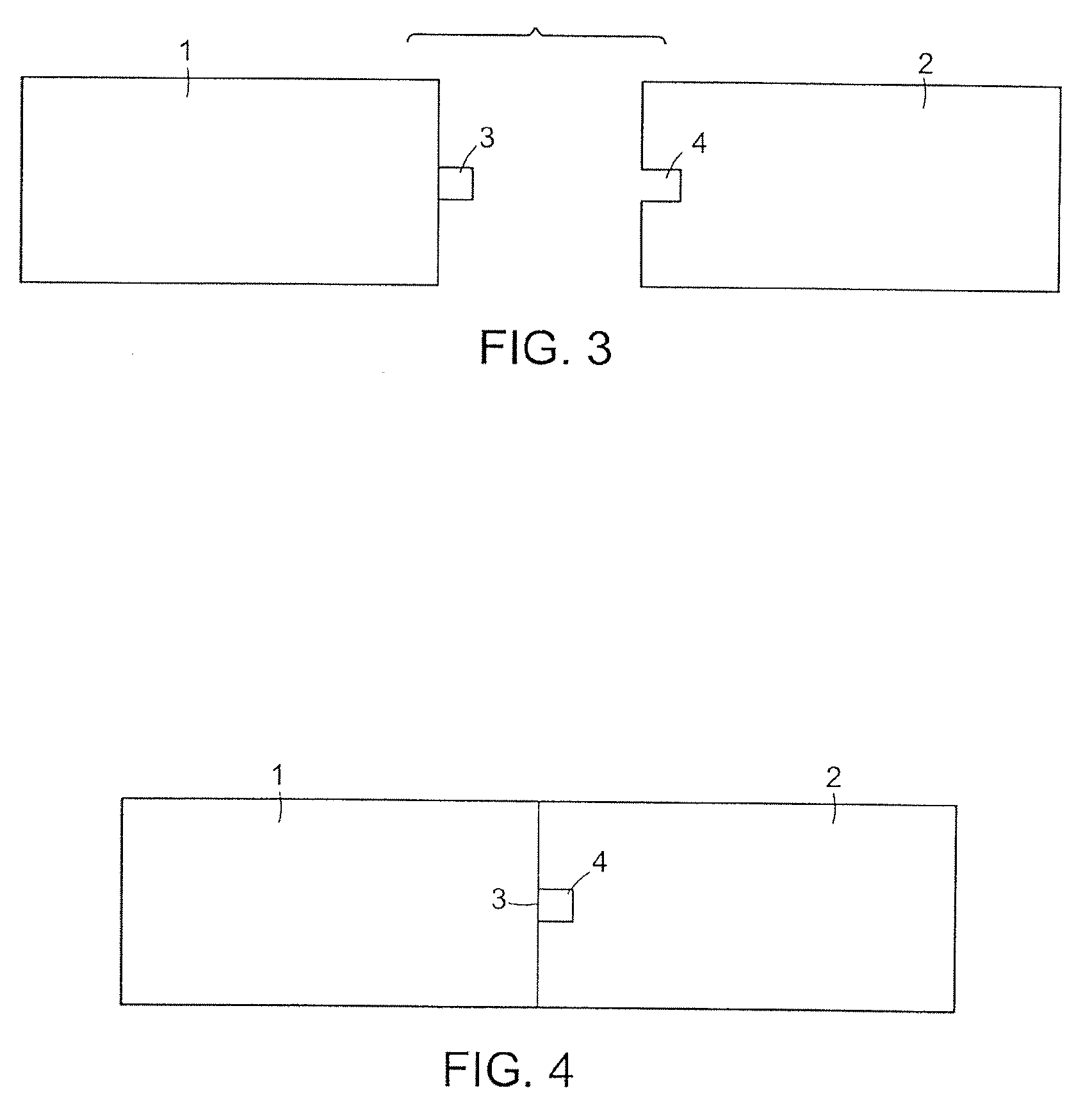

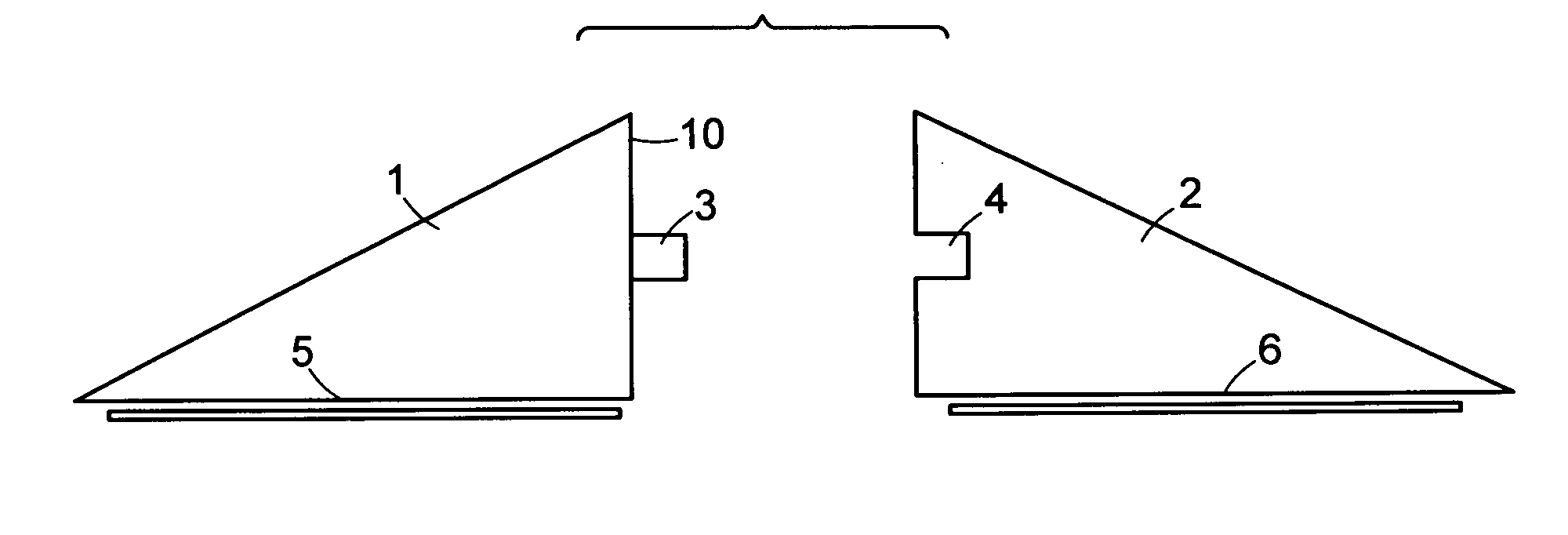

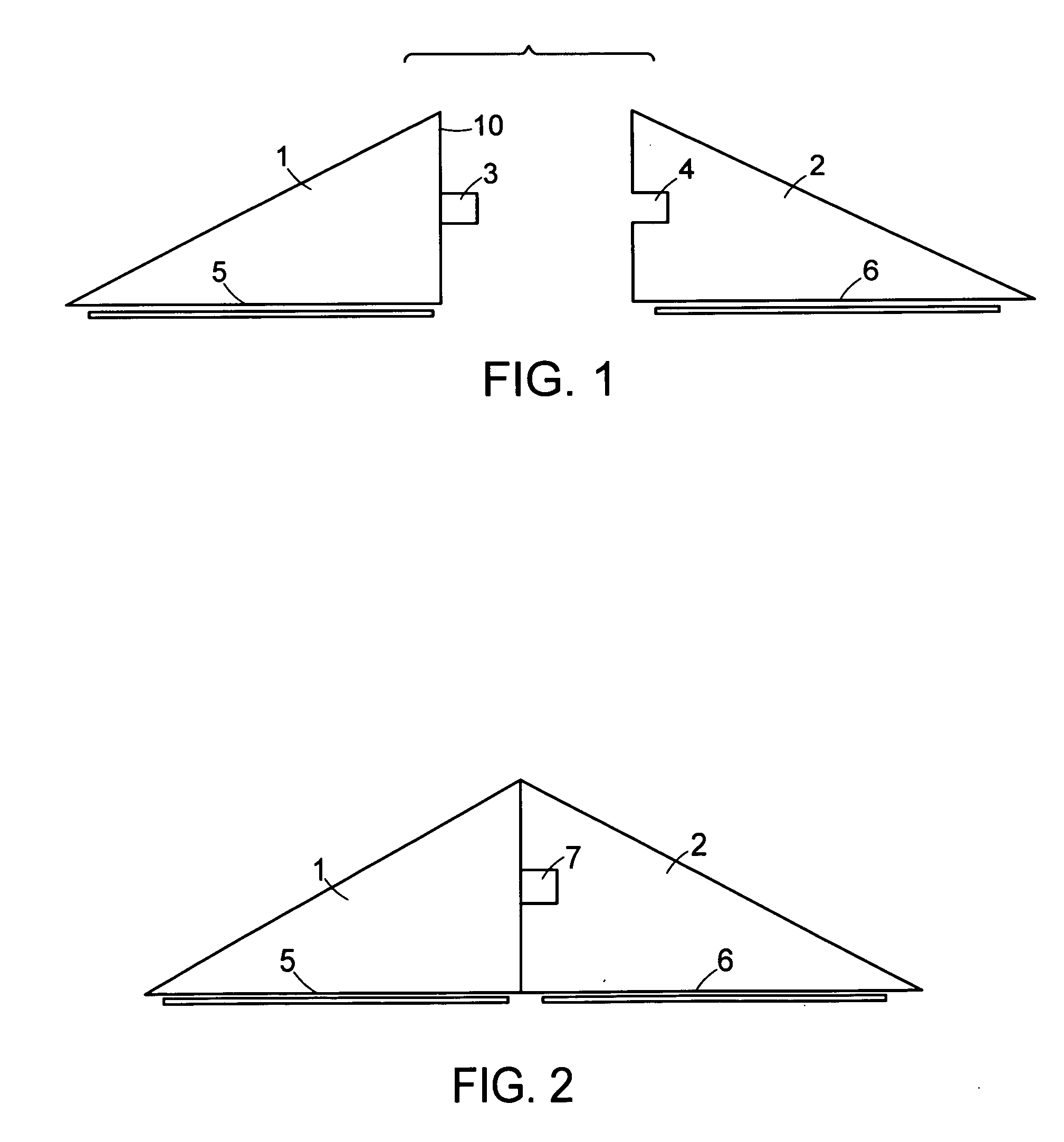

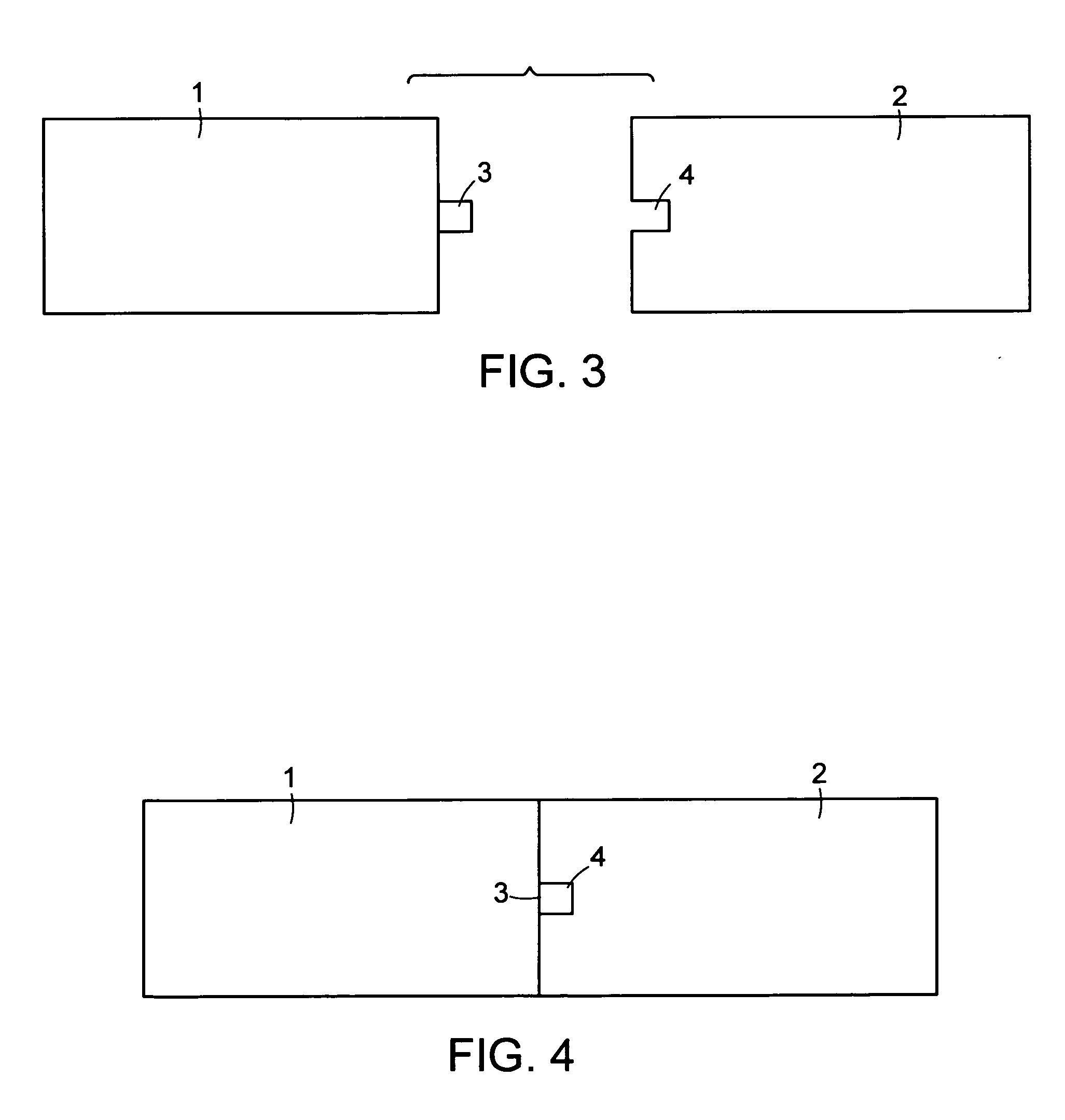

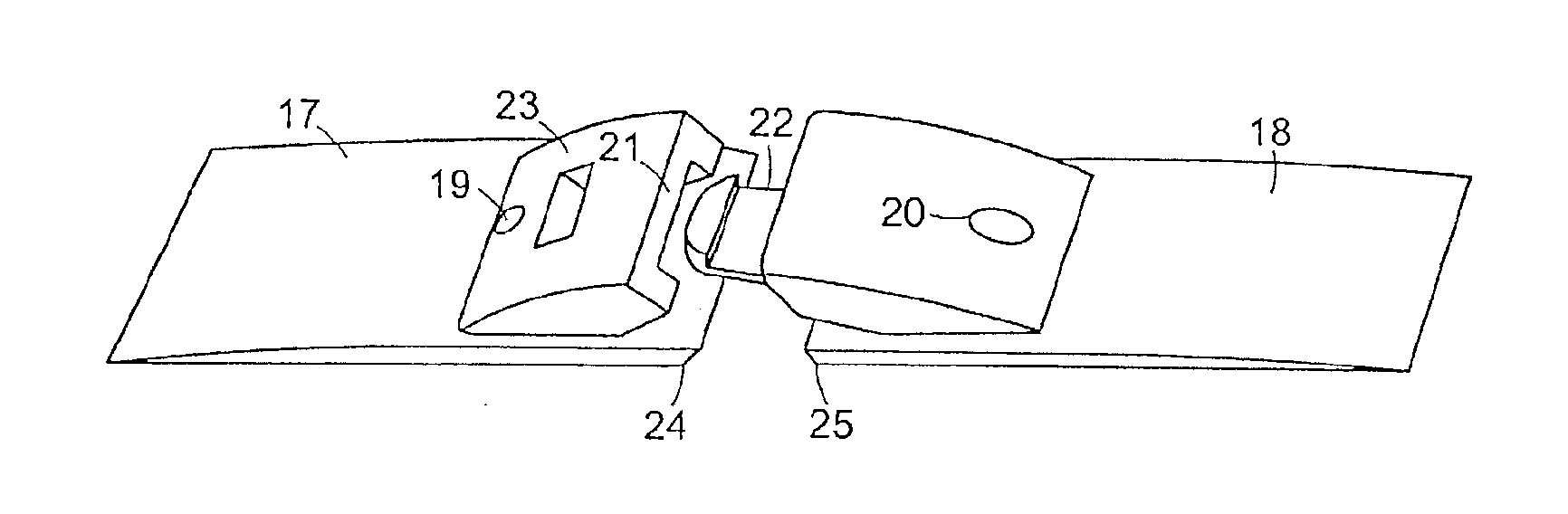

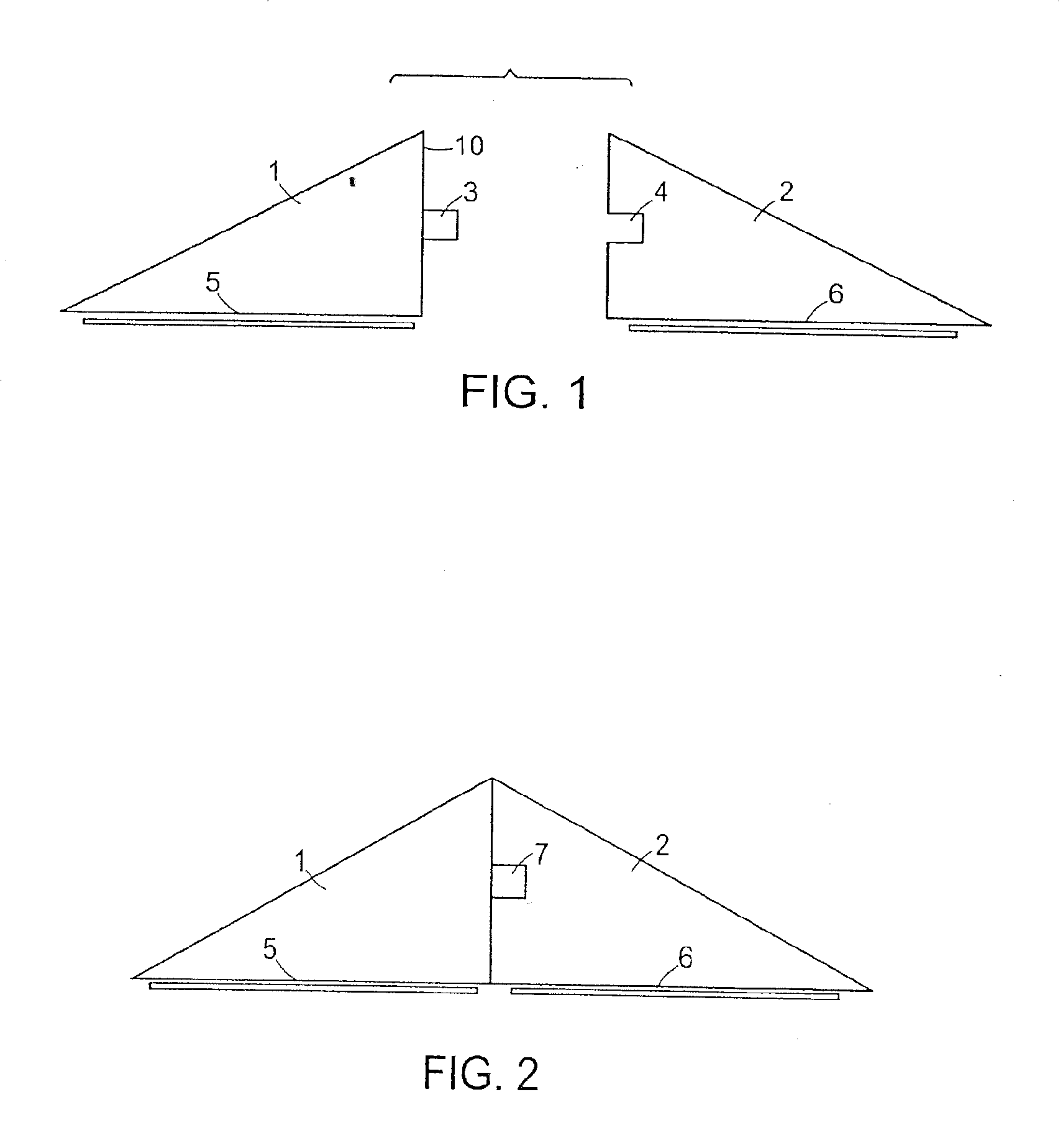

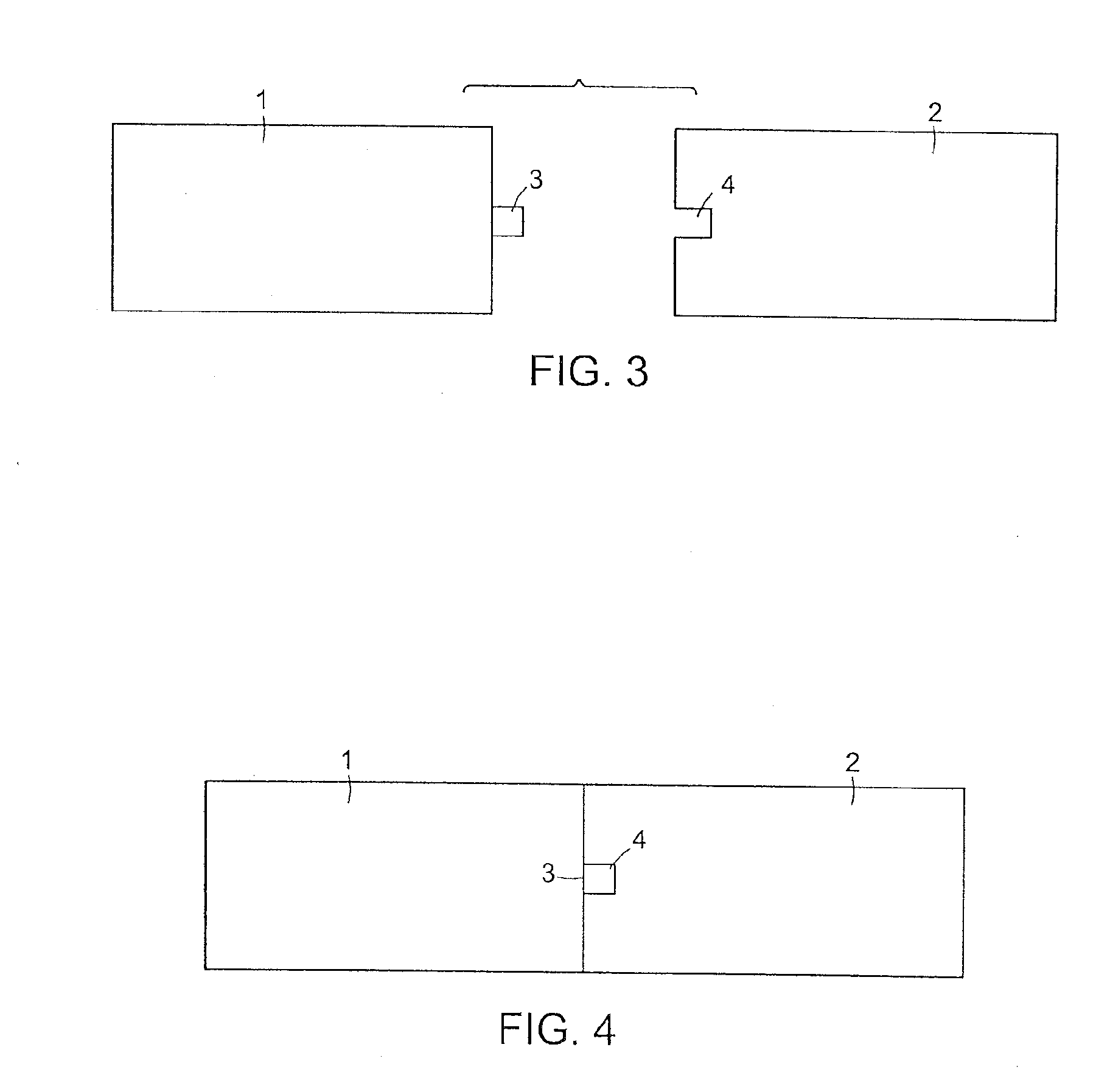

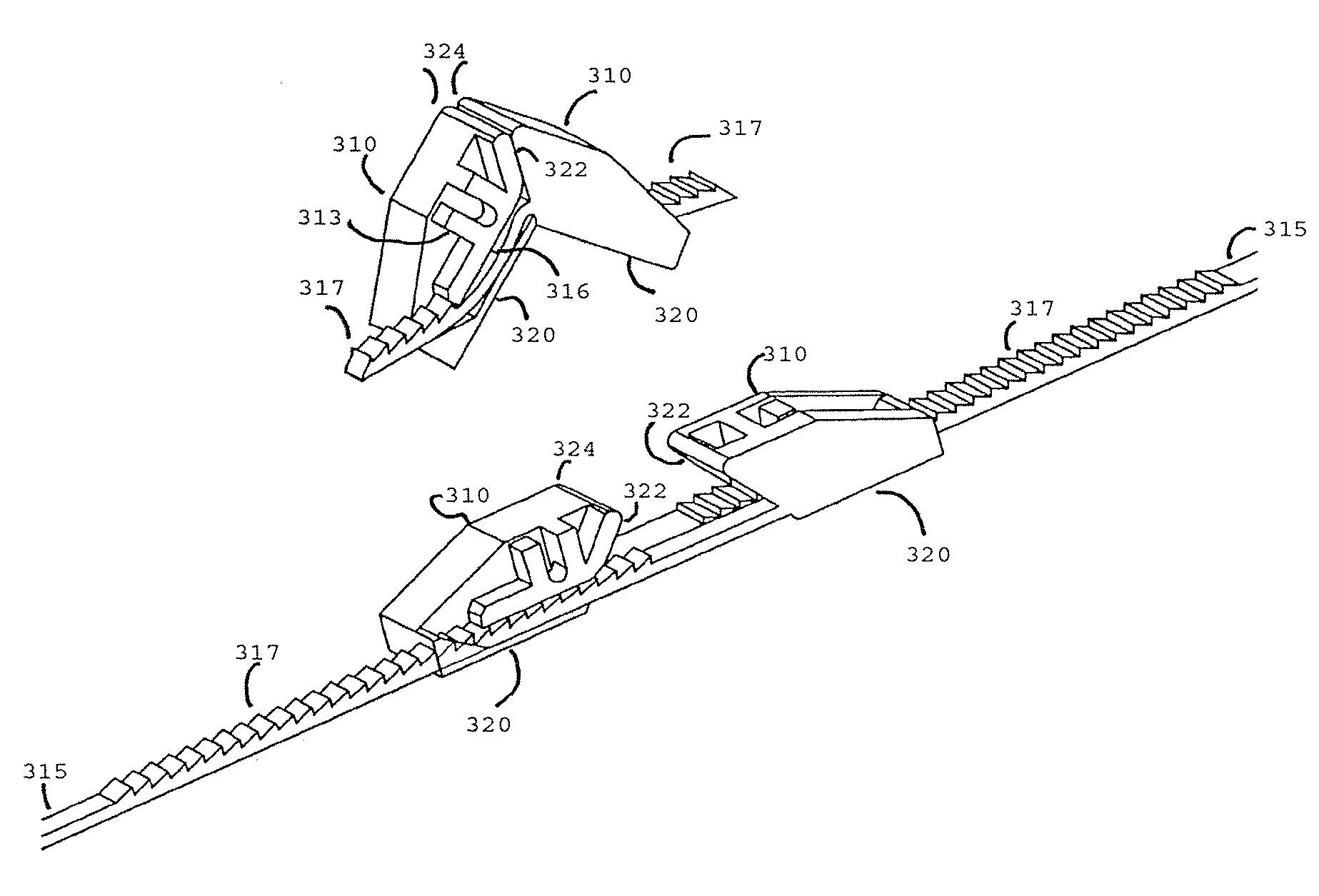

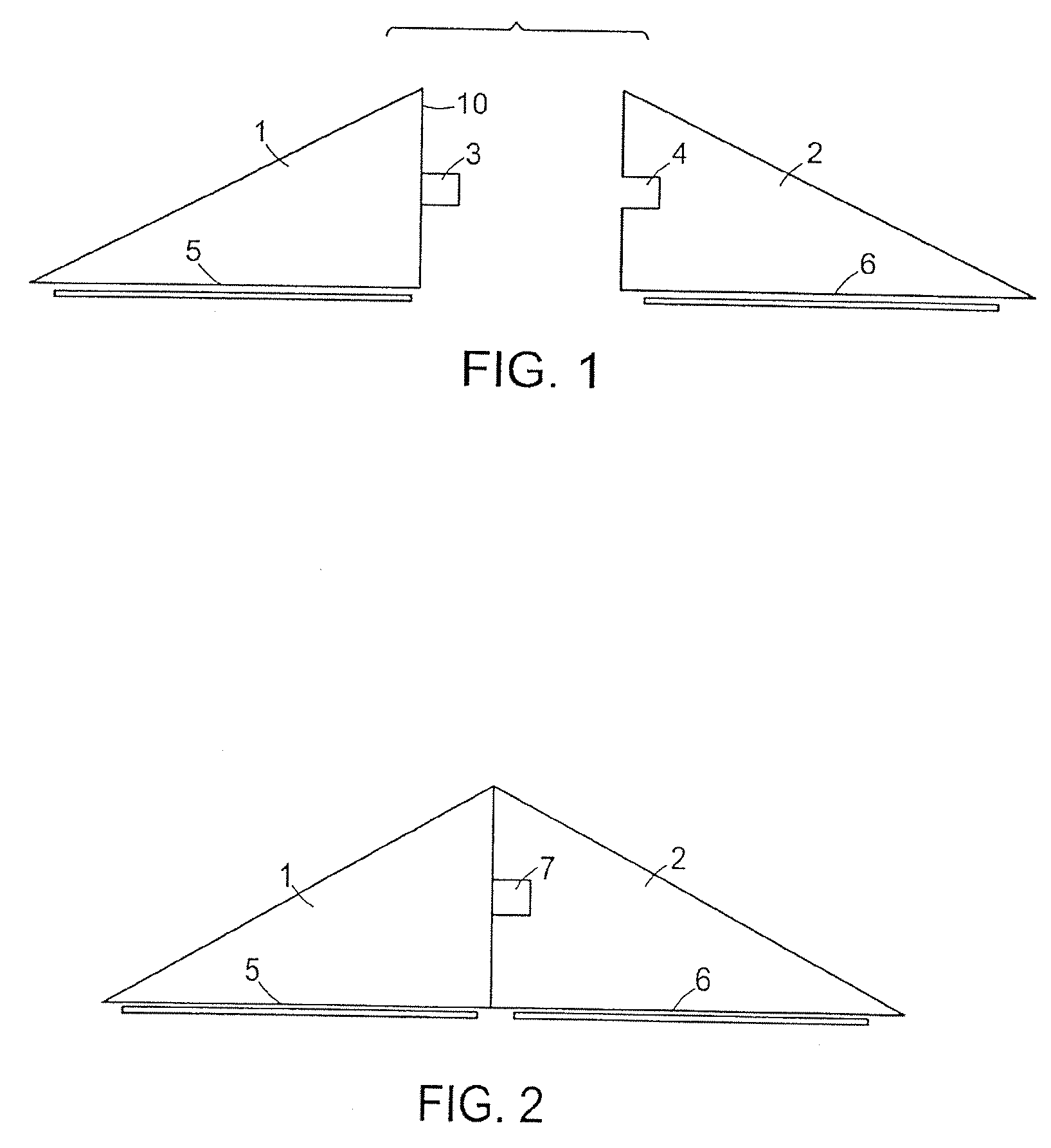

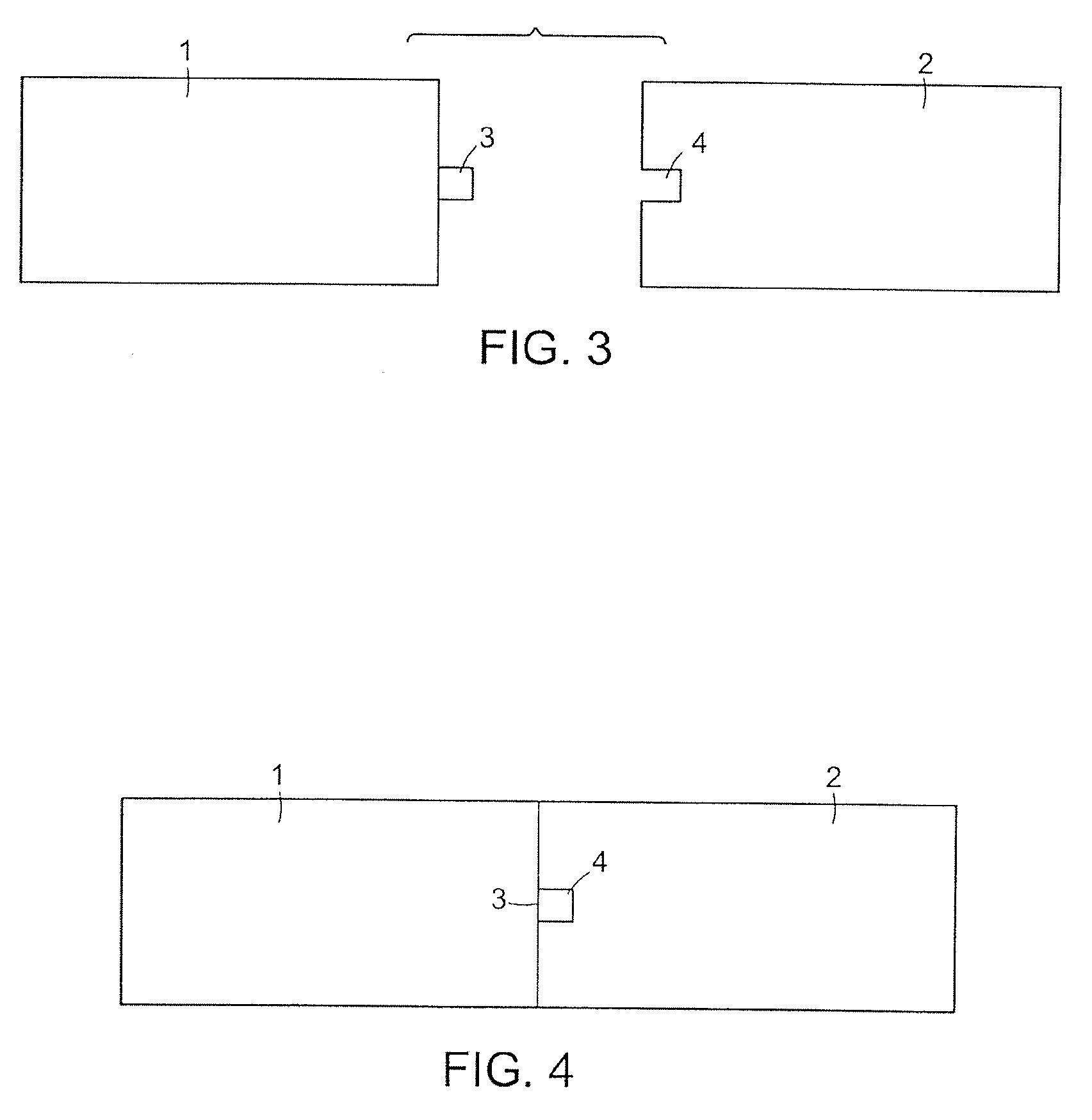

Systems and methods for closing a tissue opening

ActiveUS20090036922A1Quickly and easily affixedImprove the environmentSurgical veterinaryWound clampsTissue repairProximate

The present invention is directed to tissue closure devices for closing a tissue opening, including one or more closure components, each closure component having a first member and a second member, each of the first and second members having a first surface that adheres to a tissue surface proximate to the tissue opening, each of the first and second members having a second surface substantially orthogonal to the first surface, and each of the first and second members having a transitional region between the first surface and the second surface which is contoured to evert an edge of the tissue opening upon the drawing together of the first and second members. The present invention is also directed to systems and kits, dressing systems, and methods for tissue repair and closure.

Owner:DERMACLIP US

Systems and methods for closing a tissue opening

InactiveUS20060200198A1Enlarging woundPromote healingSurgical veterinaryWound clampsTissue repairProximate

The present invention is directed to tissue closure devices for closing a tissue opening, including one or more closure components, each closure component having a first member and a second member, each of the first and second members having a first surface that adheres to a tissue surface proximate to the tissue opening, each of the first and second members having a second surface substantially orthogonal to the first surface, and each of the first and second members having a transitional region between the first surface and the second surface which is contoured to evert an edge of the tissue opening upon the drawing together of the first and second members. The present invention is also directed to systems and kits, dressing systems, and methods for tissue repair and closure.

Owner:DERMACLIP US

Systems and Methods for Closing a Tissue Opening

The present invention is directed to tissue closure devices for closing a tissue opening, including one or more closure components, each closure component having a first member and a second member, each of the first and second members having a first surface that adheres to a tissue surface proximate to the tissue opening, each of the first and second members having a second surface substantially orthogonal to the first surface, and each of the first and second members having a transitional region between the first surface and the second surface which is contoured to evert an edge of the tissue opening upon the drawing together of the first and second members. The present invention is also directed to systems and kits, dressing systems, and methods for tissue repair and closure.

Owner:DERMACLIP US LLC

Method and system for enhanced detail-in-context viewing

InactiveUS20060214951A1Improving visual detail and presentation qualityEnhanced informationCathode-ray tube indicatorsInput/output processes for data processingTransitional RegionImproved method

An improved method for display of a transitional region of interest while transitioning between a first region of interest and a second region of interest within visual information on a display screen of a computer. The method comprising the steps of applying a transitional transformation to the visual information and displaying the transitional transformed visual information on the display screen. The transitional transformation requiring a reduced calculation for transforming the visual information in the transitional region.

Owner:ACCESSIFY LLC

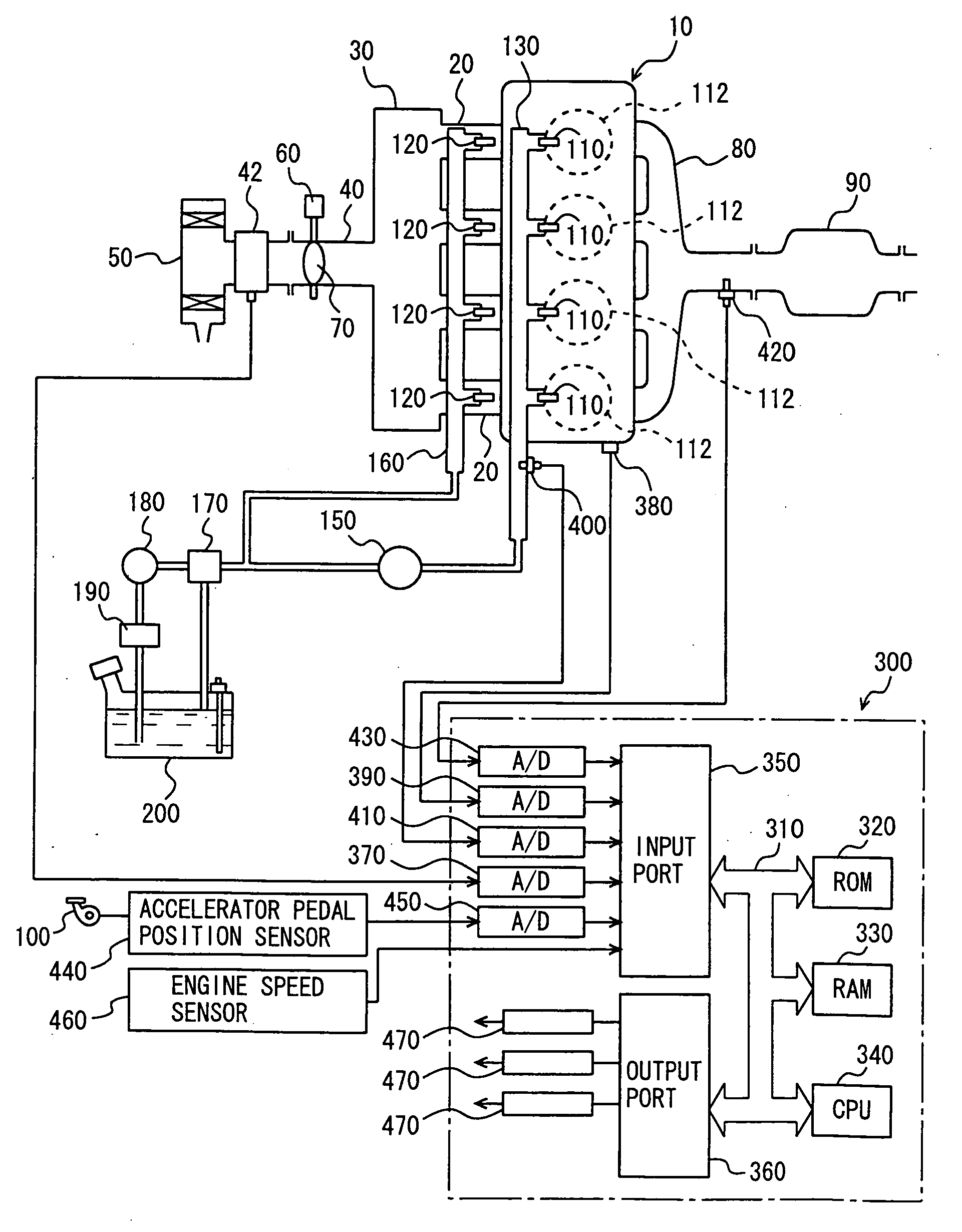

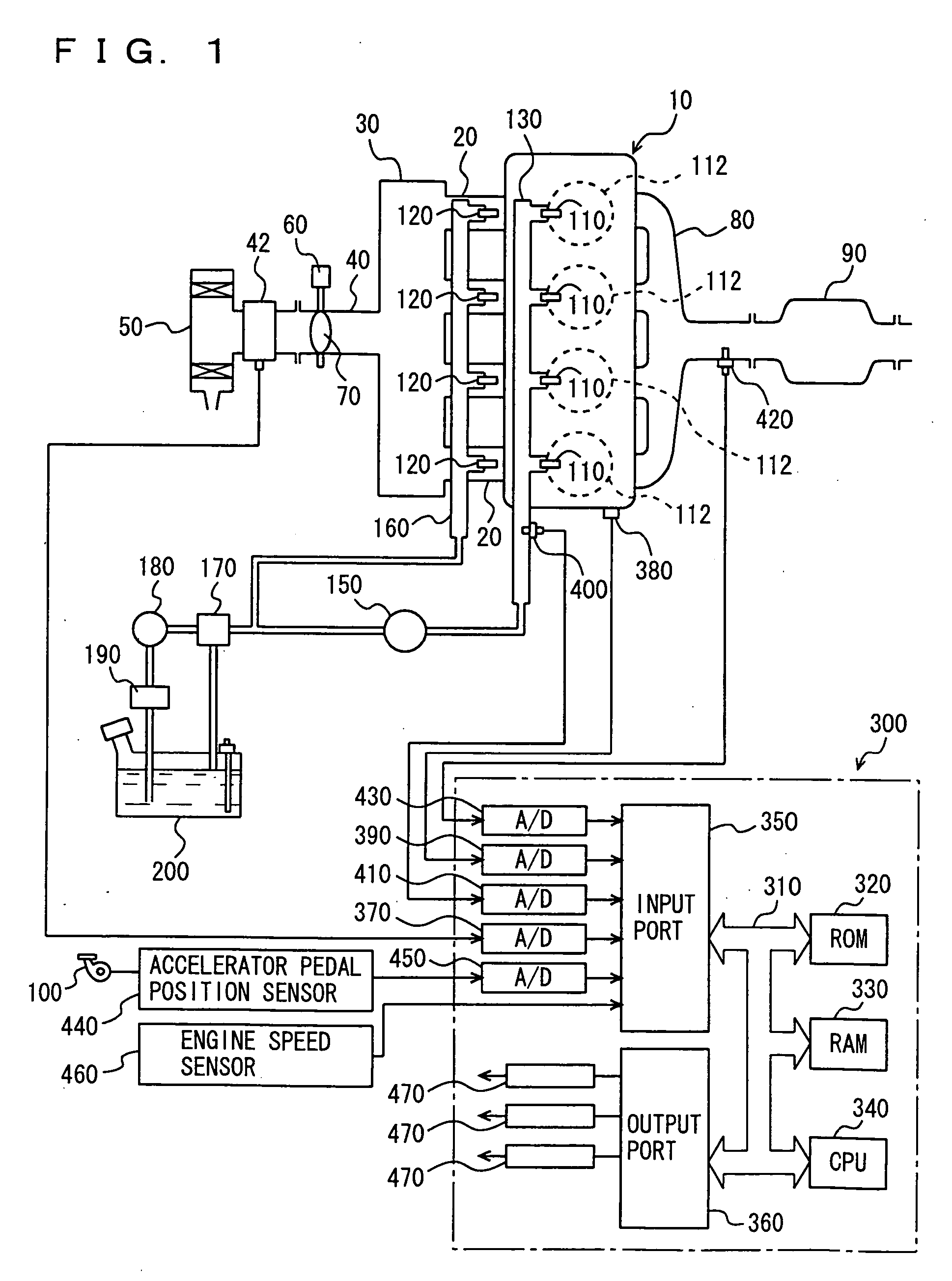

Control apparatus for internal combustion engine

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

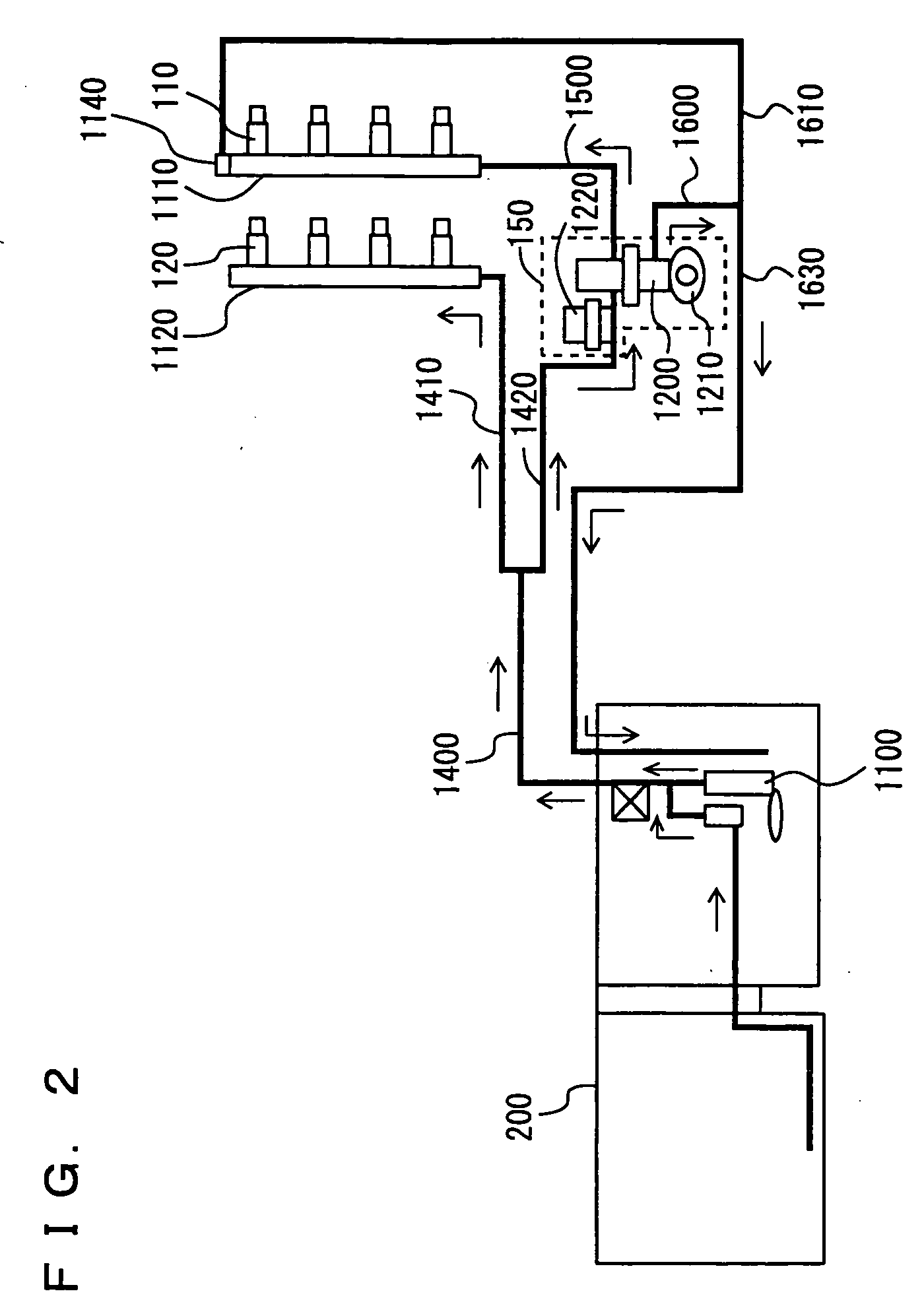

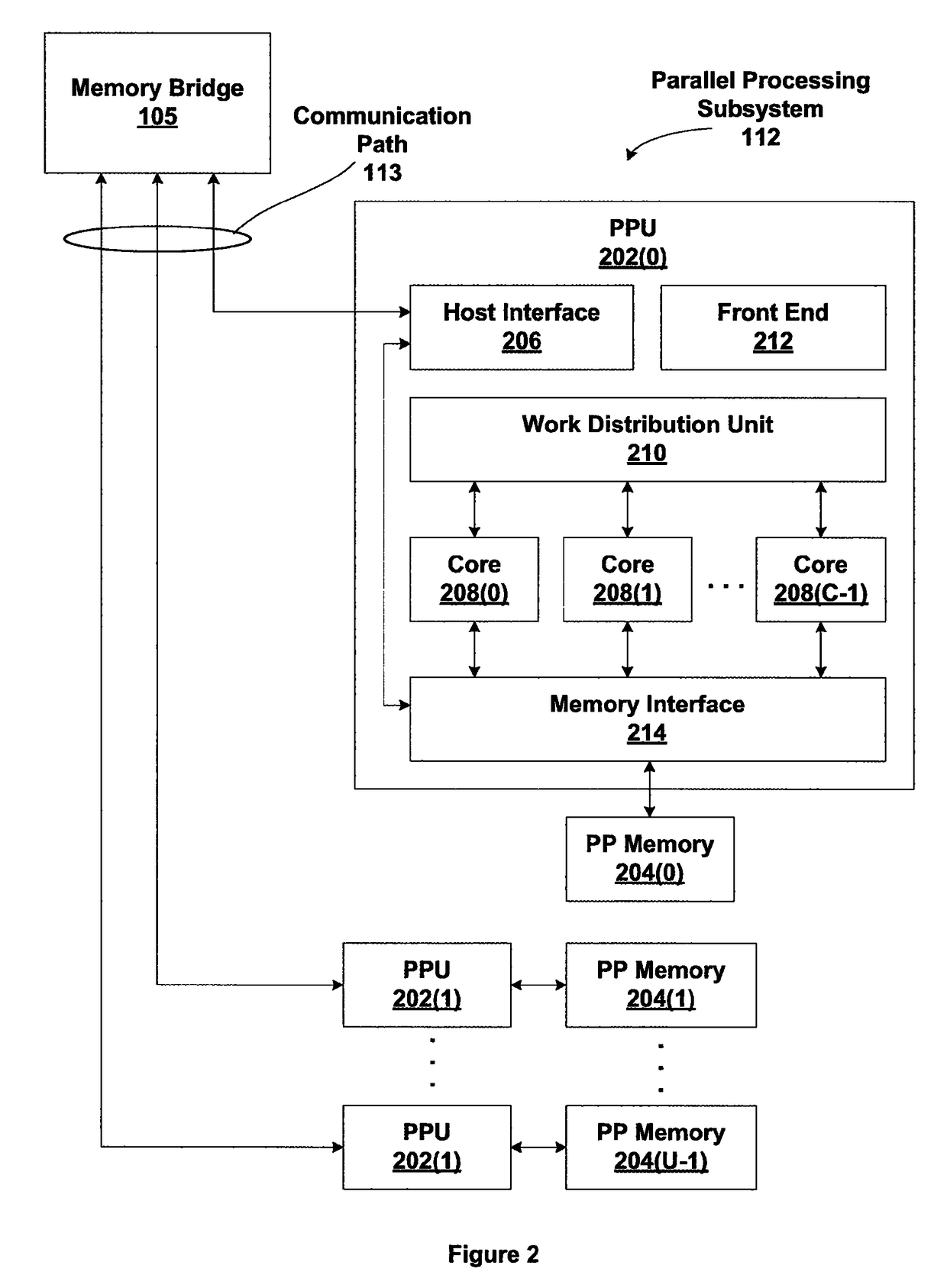

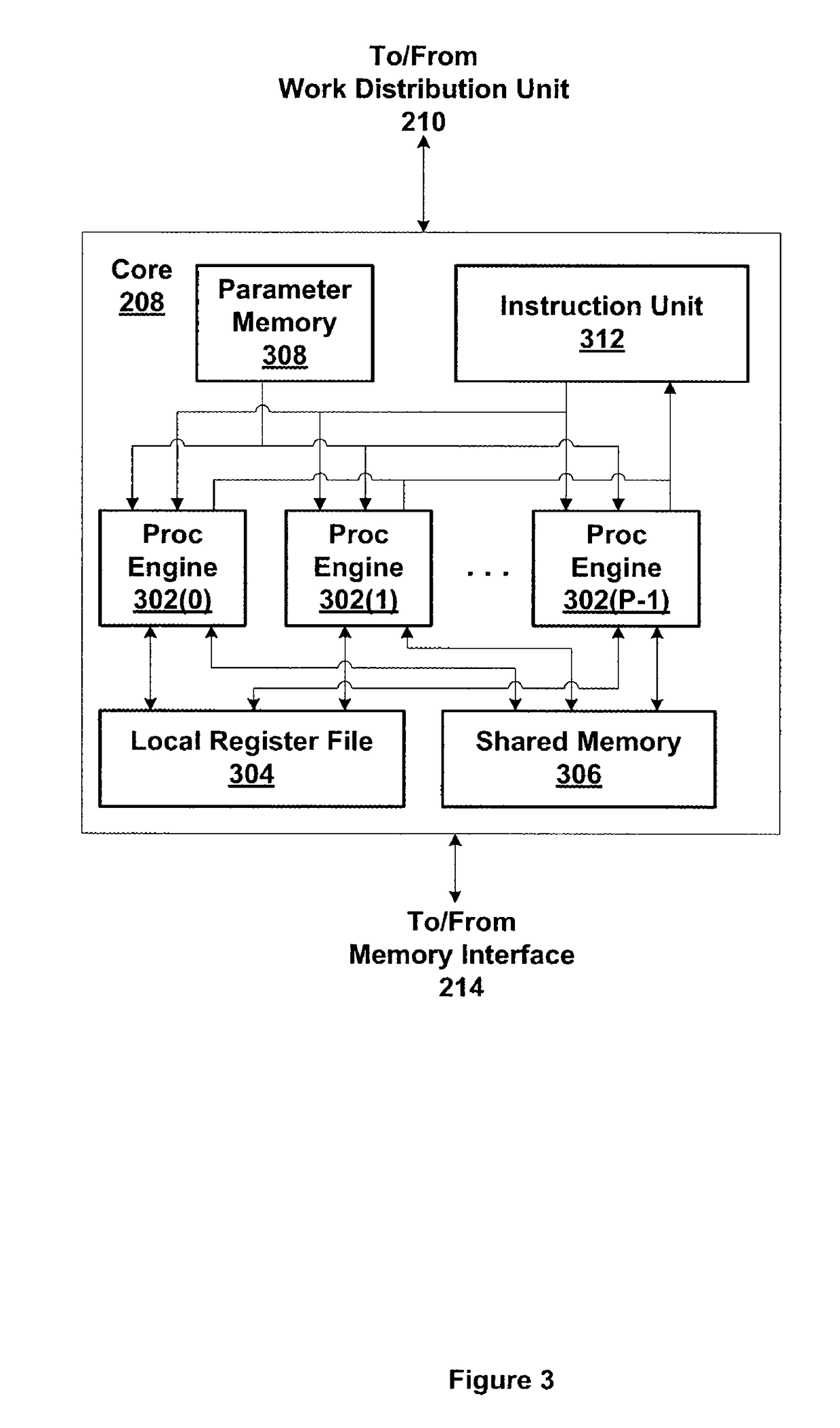

Boundary transition region stitching for tessellation

ActiveUS8120607B1Quality improvementStable change3D-image rendering3D modellingGraphicsLevel of detail

A system and method for stitching a boundary transition region of a patch produces a graphics primitive topology for the boundary transition region of the patch. A first number of vertices is computed for an inside edge of the boundary transition region using a first tessellation level of detail (LOD) of the inside edge. A second number of vertices is computed for an outside edge of the boundary transition region using a second tessellation LOD of the outside edge. A portion of the first number of vertices and the second number of vertices are merged based on a stitching pattern to produce a set of vertices for the boundary transition region. The set of vertices is stitched to produce an ordered list representing the graphics primitive topology.

Owner:NVIDIA CORP

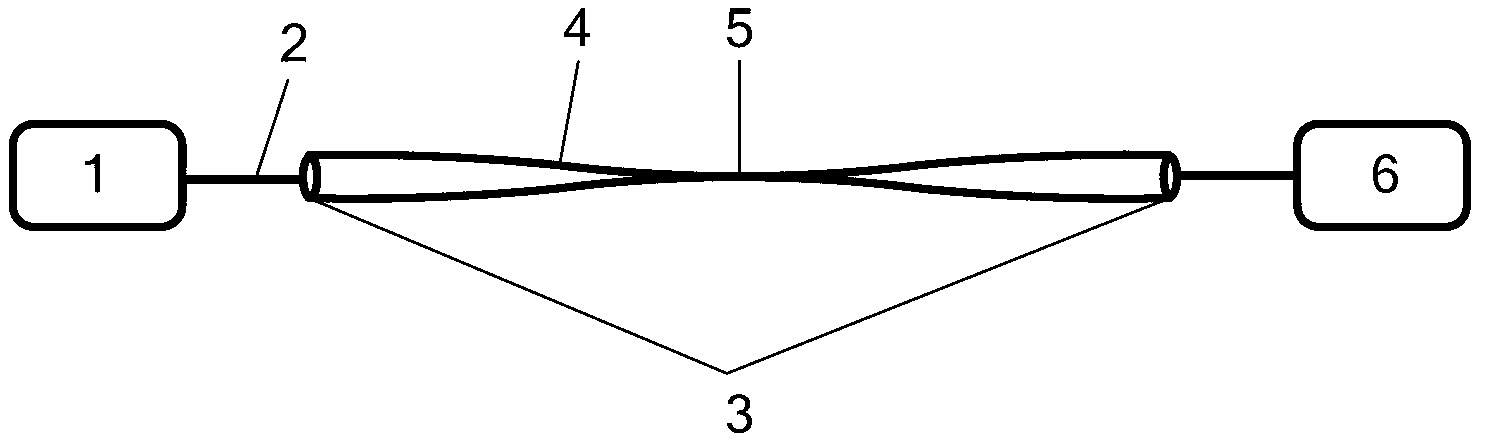

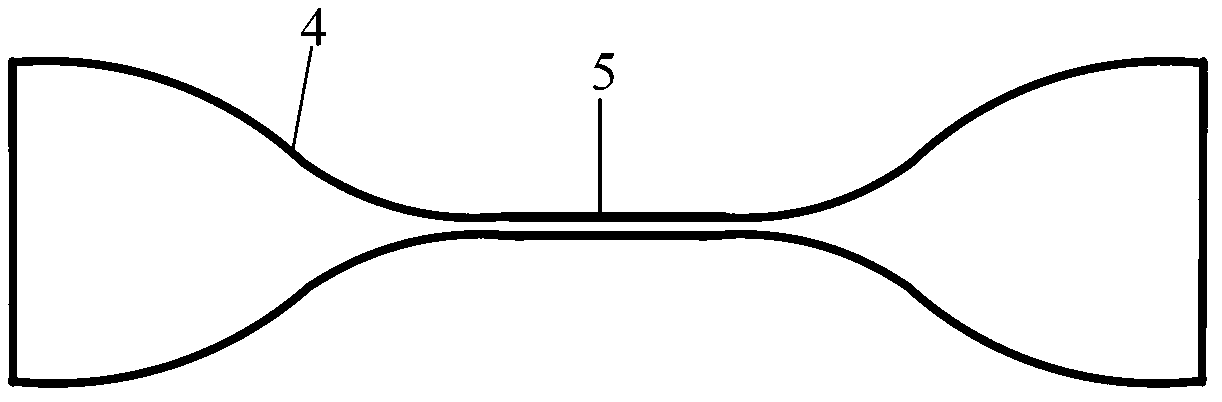

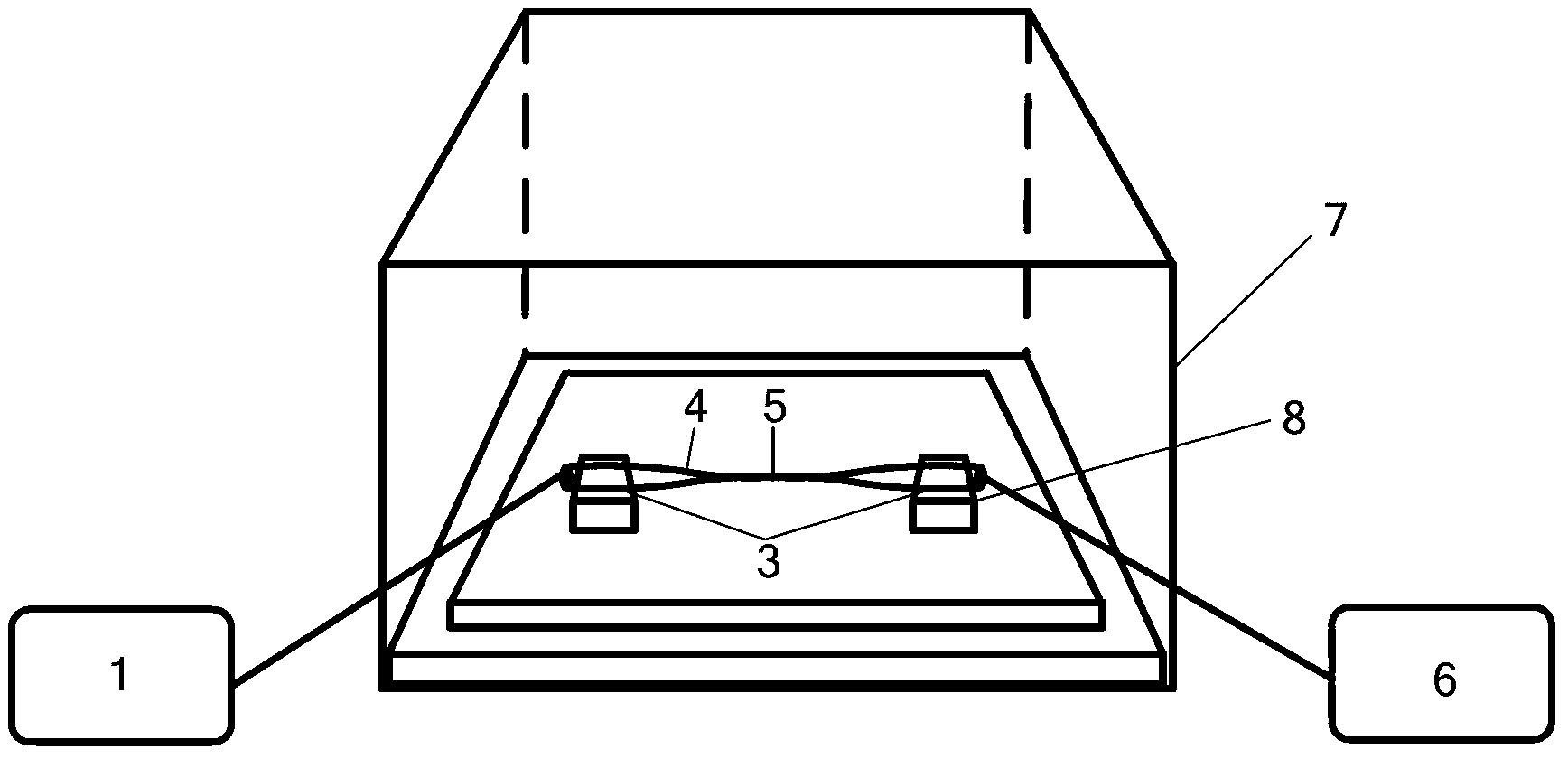

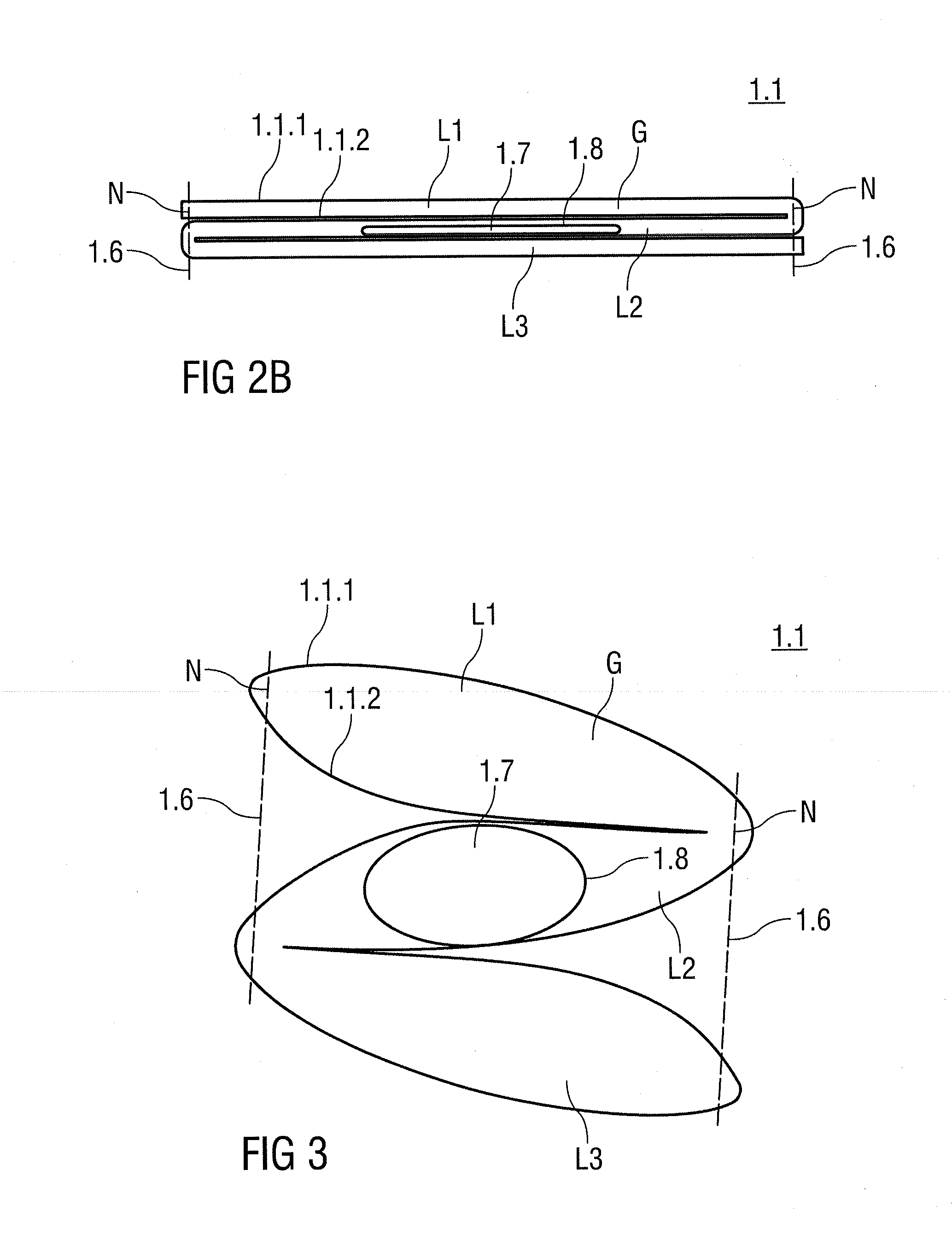

Quick-response conical micro-nano optical fiber humidity sensor and preparation method thereof

InactiveCN103293131AAchieve the purpose of cleaningHigh sensitivityPhase-affecting property measurementsMicro nanoDouble-clad fiber

The invention discloses a quick-response conical micro-nano optical fiber humidity sensor and a preparation method thereof. The humidity sensor comprises a broadband light source, a conical micro-nano optical fiber structure and an optical spectrum analyzer which are sequentially connected, wherein the conical micro-nano optical fiber structure comprises a conical waist region and two conical transitional regions which are positioned at two ends of the conical waist region; the two conical transitional regions are connected with the broadband light source and the optical spectrum analyzer through a standard optical fiber respectively. The method comprises the following steps of: (1) removing a coating layer of a double-clad optical fiber to remain a bare optical fiber containing a fiber core, an inner cladding layer and an outer cladding layer; (2) fusing two ends of the bare optical fiber with the standard optical fiber through an optical fiber welding machine respectively; (3) performing fused biconical taper on the bare optical fiber to obtain the conical micro-nano optical fiber structure; (4) connecting the standard optical fiber of which the two ends are fused with the broadband light source and the optical spectrum analyzer to form the conical micro-nano optical fiber humidity sensor. The quick-response conical micro-nano optical fiber humidity sensor has a simple optical fiber structure, and is high in response speed, wide in measurement range and high in detection sensitivity.

Owner:JINAN UNIVERSITY

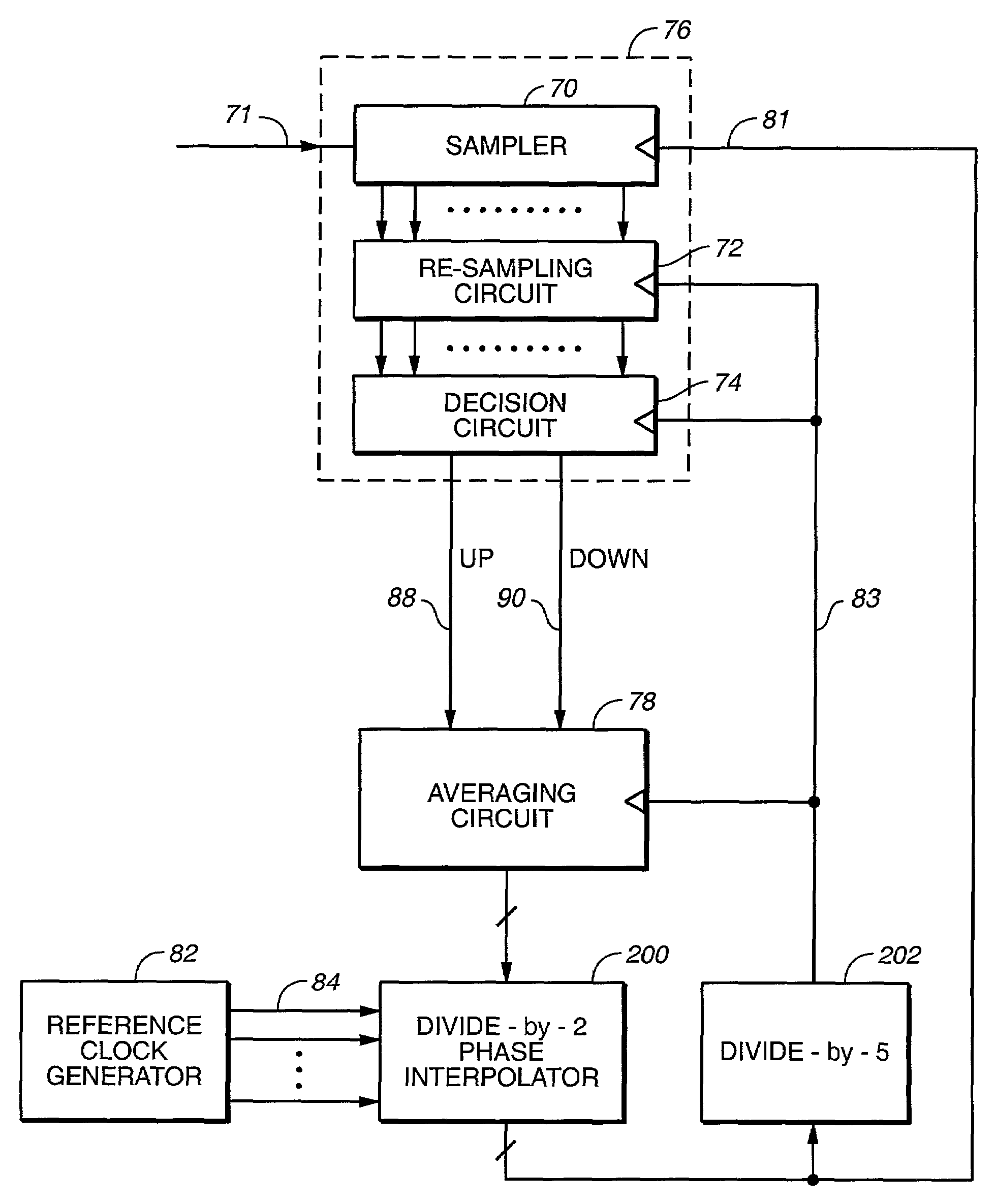

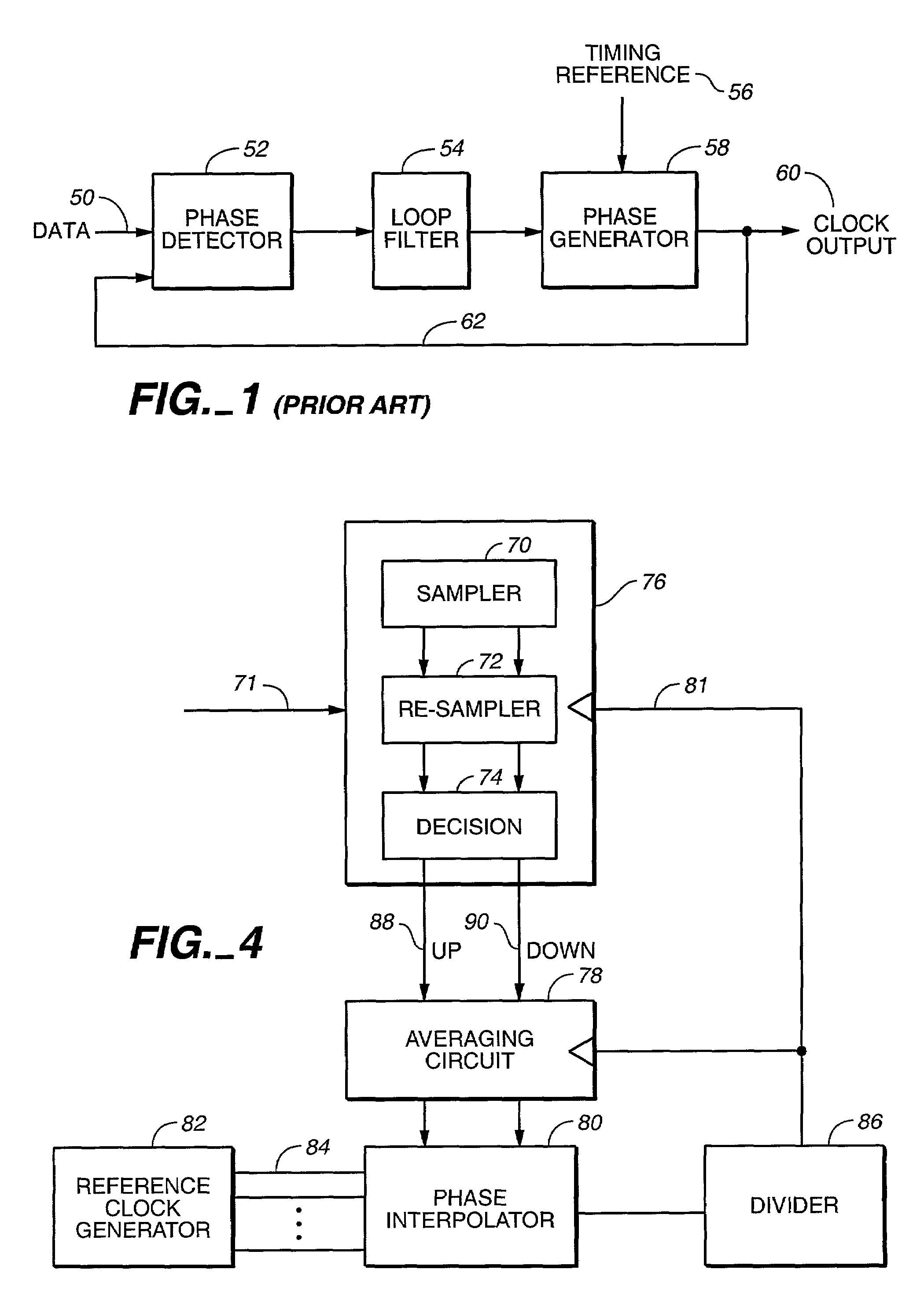

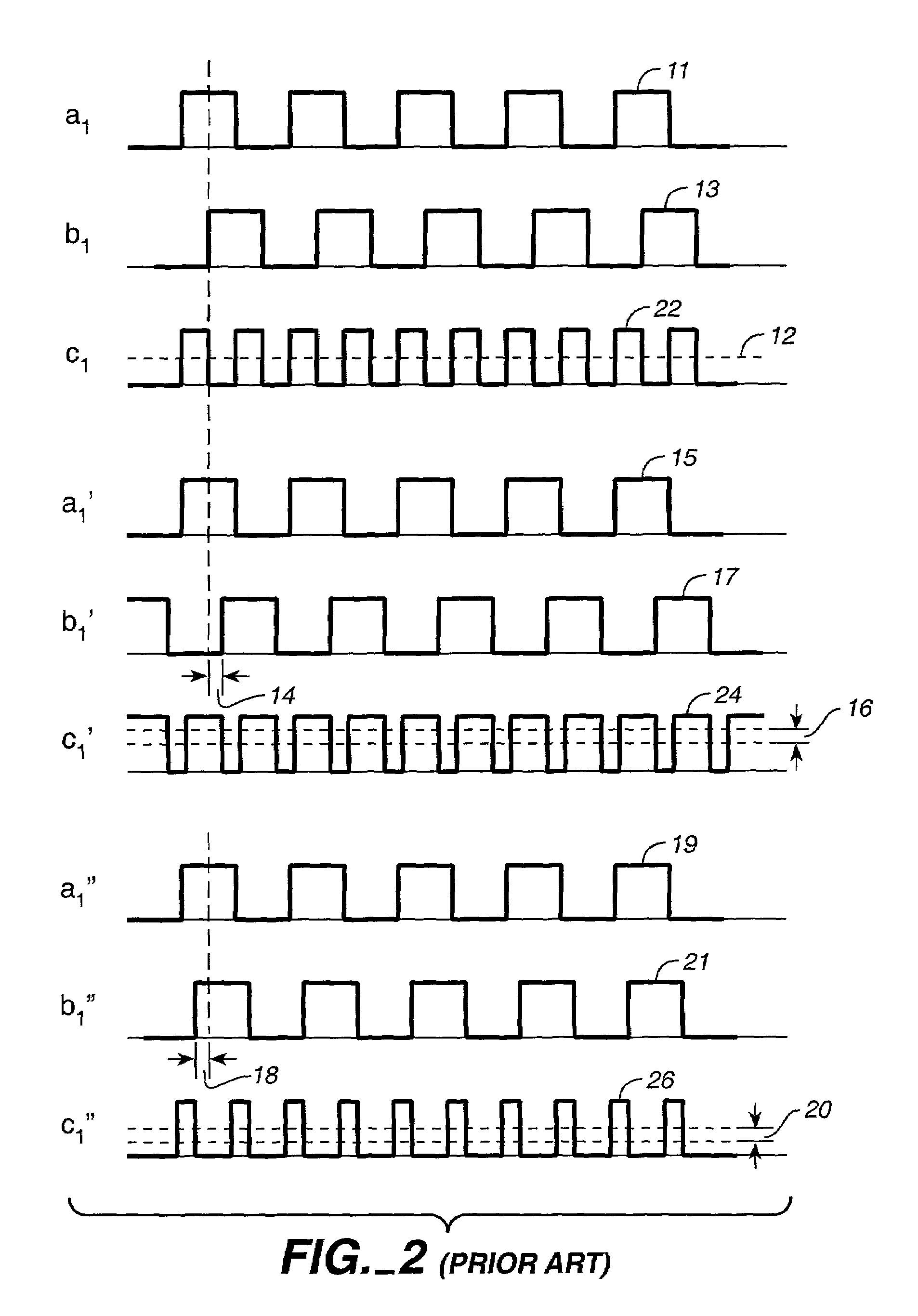

Method and apparatus for high-speed clock data recovery using low-speed circuits

InactiveUS7020227B1Reduces processing frequency requirementPulse automatic controlAngle demodulation by phase difference detectionLow speedData stream

A clock data recovery (CDR) circuit that can be used for recovering data from a high-speed serial transmission using components that operate at a fraction of the data speed. The CDR consists of a phase detector, an averaging circuit and a phase interpolator. The phase detector samples each data bit at its midpoint and at its transitional region and then compares the two samples to determine whether the sampling clock, which is generated by a phase interpolator, is leading or lagging the data stream. The averaging circuit filters out the high frequency jitters in the phase detector output and then passes the filtered signals on to the phase interpolator for phase selection. The phase interpolator uses the filtered signals from the averaging circuit as a guide in the selection of an output clock phase that minimizes the phase difference between the output clock and the incoming data.

Owner:ACARD TECH CORP

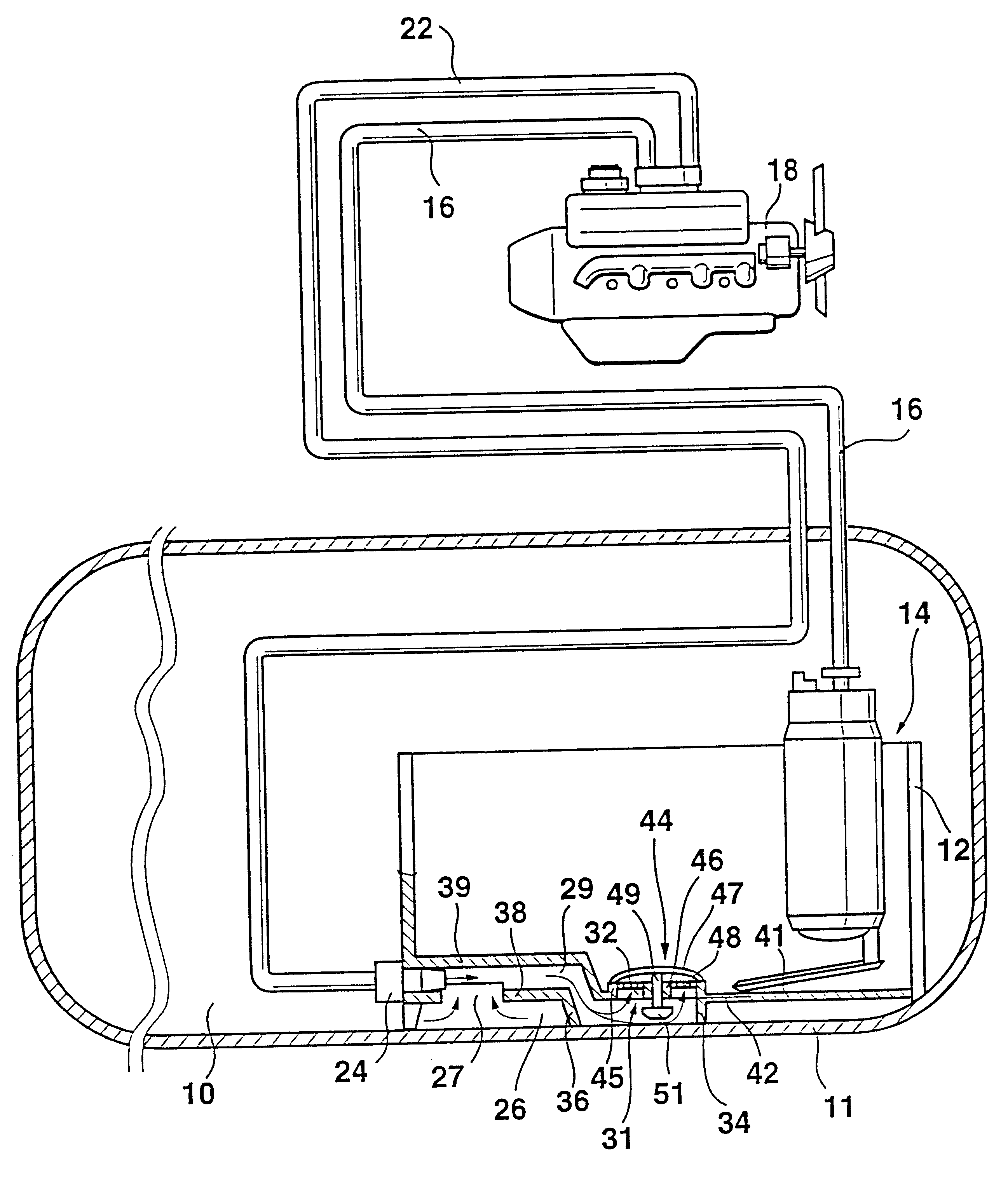

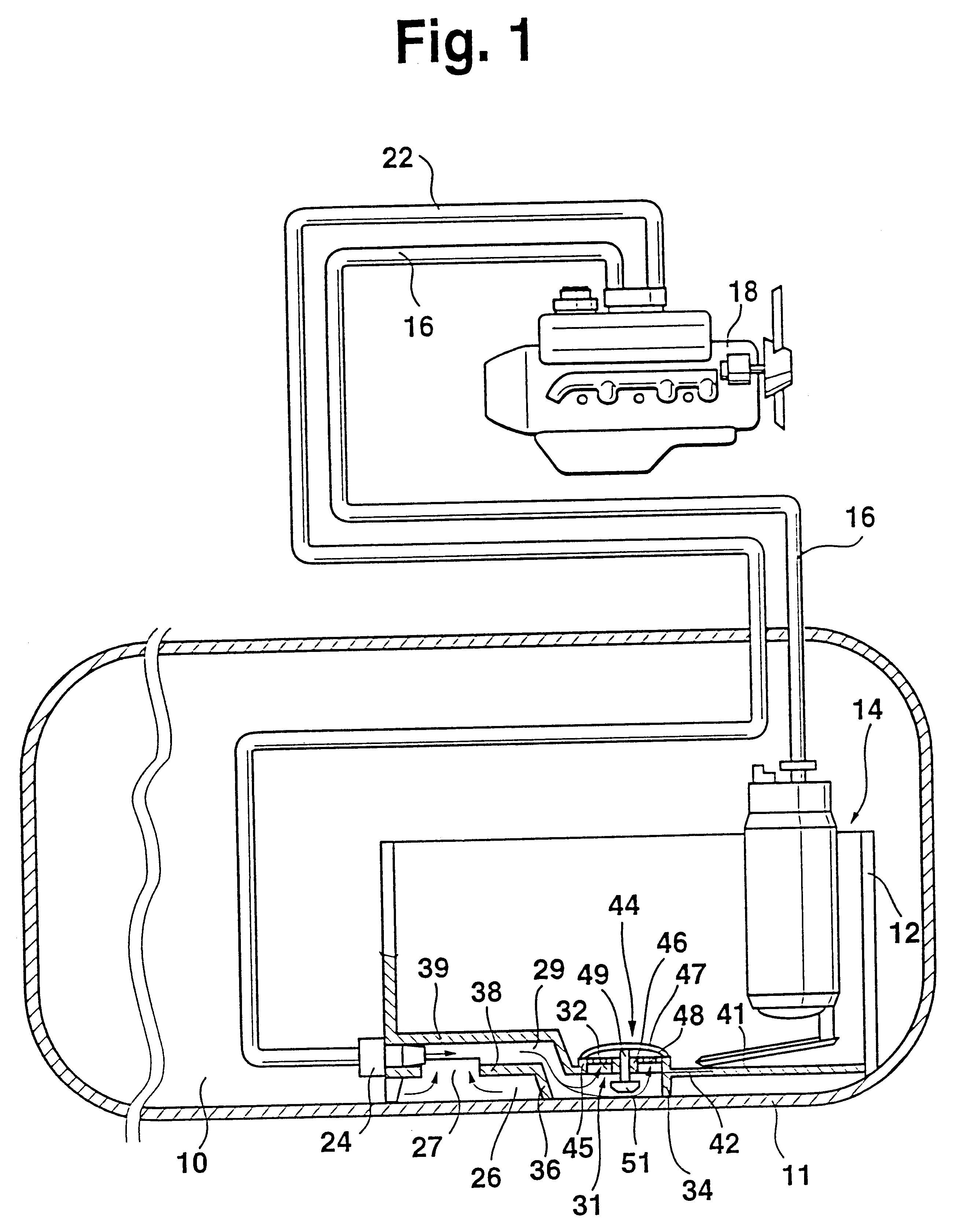

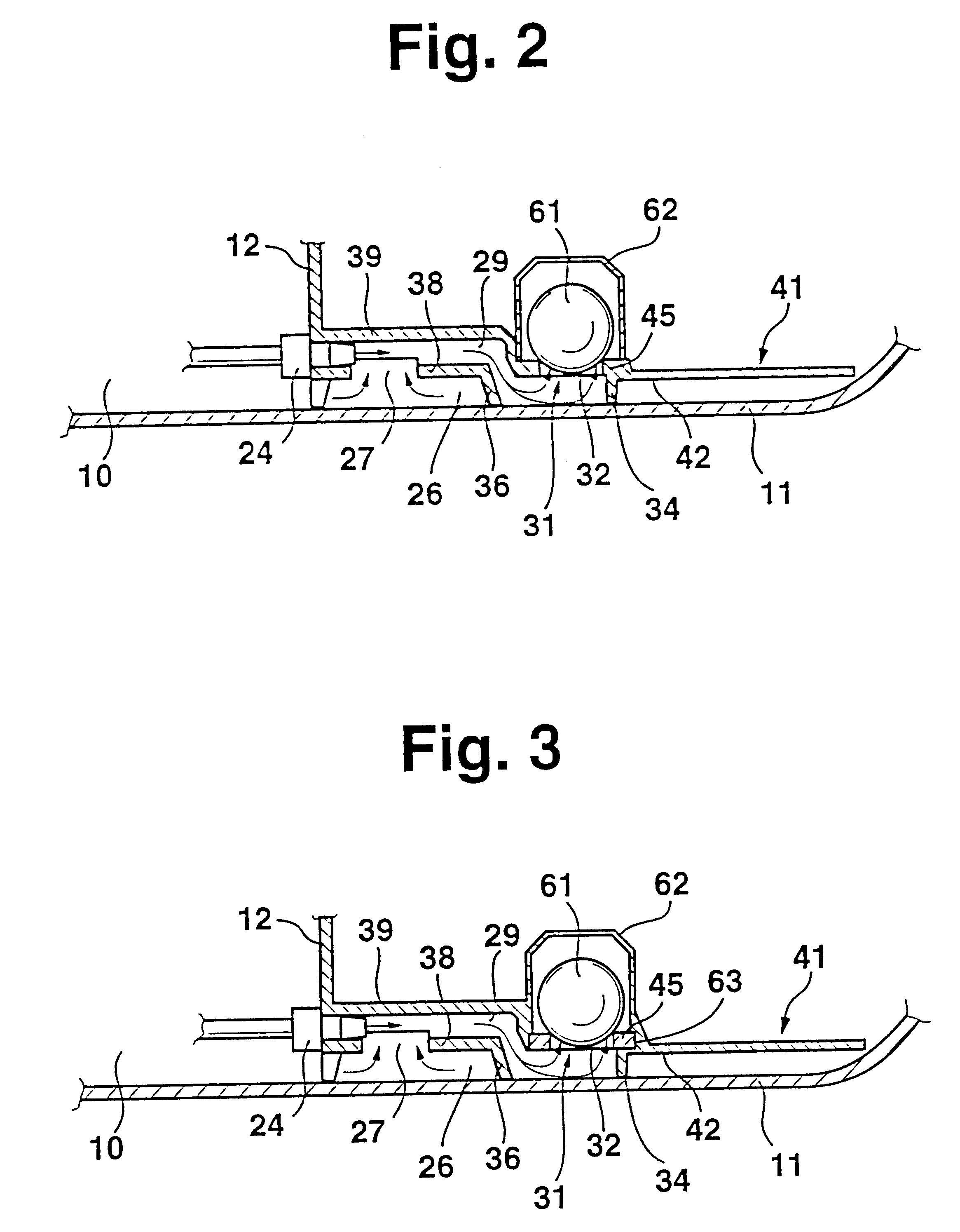

Device for conveying fuel from a reserve pot to the internal combustion engine of a motor vehicle

InactiveUS6273131B1Simple and economical arrangementOptimize volumePump componentsUsing liquid separation agentSiphonFuel tank

The device for conveying fuel from a fuel tank (10) to an engine (18) of a motor vehicle has a conveying unit (14), communicating on the intake side with the fuel tank (10) and, on the pressurized side, with the engine (18), and a return line (22), which leads to a jet pump (24), located near a tank bottom (11), that pumps excess fuel via a mixing region into a reserve pot (12), from which the conveying unit (14) draws fuel. According to the invention a siphon-like mixing region (29) is provided between the reserve pot (12) and the tank bottom (11). An opening (32) or a filter element (48) is provided in a transitional region (31) of the mixing region (29) to the reserve pot (12). The opening (32) or filter element (48) which extends parallel to the tank bottom is closable by an axially movable closing element (44,51) so that a fuel flow can occur into the reserve pot (12) but not back from the reserve pot (12) into the mixing region (29).

Owner:ROBERT BOSCH GMBH

Systems and methods for closing a tissue opening

Owner:DERMACLIP US

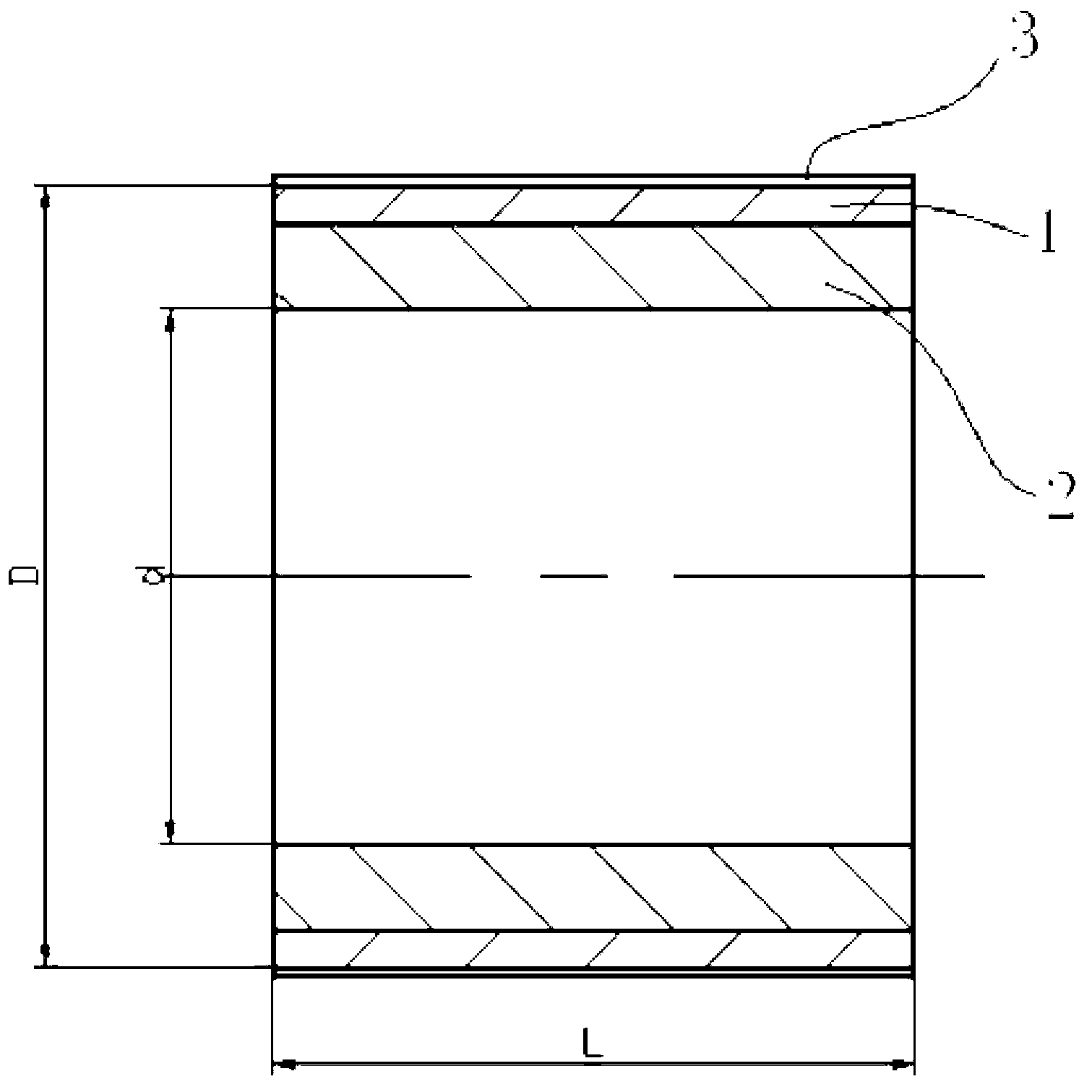

Surfacing-free centrifugal combined ultra-high anti-abrasion roll squeezer roller sleeve and manufacturing method thereof

ActiveCN103008050AImprove toughnessWith super high wear-resistant outer layerGrain treatmentsTransitional RegionPulp and paper industry

The invention discloses a surfacing-free centrifugal combined ultra-high anti-abrasion roll squeezer roller sleeve and a manufacturing method thereof. The roller sleeve comprises a roller sleeve body, wherein the roller sleeve body has a double-layer structure with an inner high-flexibility layer and an outer high abrasion resistance layer; and cast textures are arranged on the surface of the high abrasion resistance layer of the roller sleeve body. The roller sleeve has the characteristics that under the action of centrifugal force, the compactness of the roller sleeve is high, and metallurgical bonding of the inner layer and the outer layer is fully realized; a transitional region is smooth; by control over a cast organization subjected to 'less oxidization' thermal treatment, when the ultra-high abrasion resistance of the outer layer and the high flexibility of the core part are guaranteed, the impact resistance of the outer layer is improved; the centrifugally cast textures are basically the same as that of the outer layer; under the action of the centrifugal force, heavy points in steel liquid are subjected to offshoring segregation, so that the abrasion resistance of the textures is slightly higher than that of the outer layer; due to full metallurgical bonding under the action of the centrifugal force, casting defects such as cracks, impurities and air holes areavoided; ineffective forms such as falling and stripping which are caused by welding micro cracks are completely eliminated; the roller sleeve is maintenance free all the time; the production period is short; and large-scale production is realized.

Owner:河北奥木森陶瓷辊套有限公司

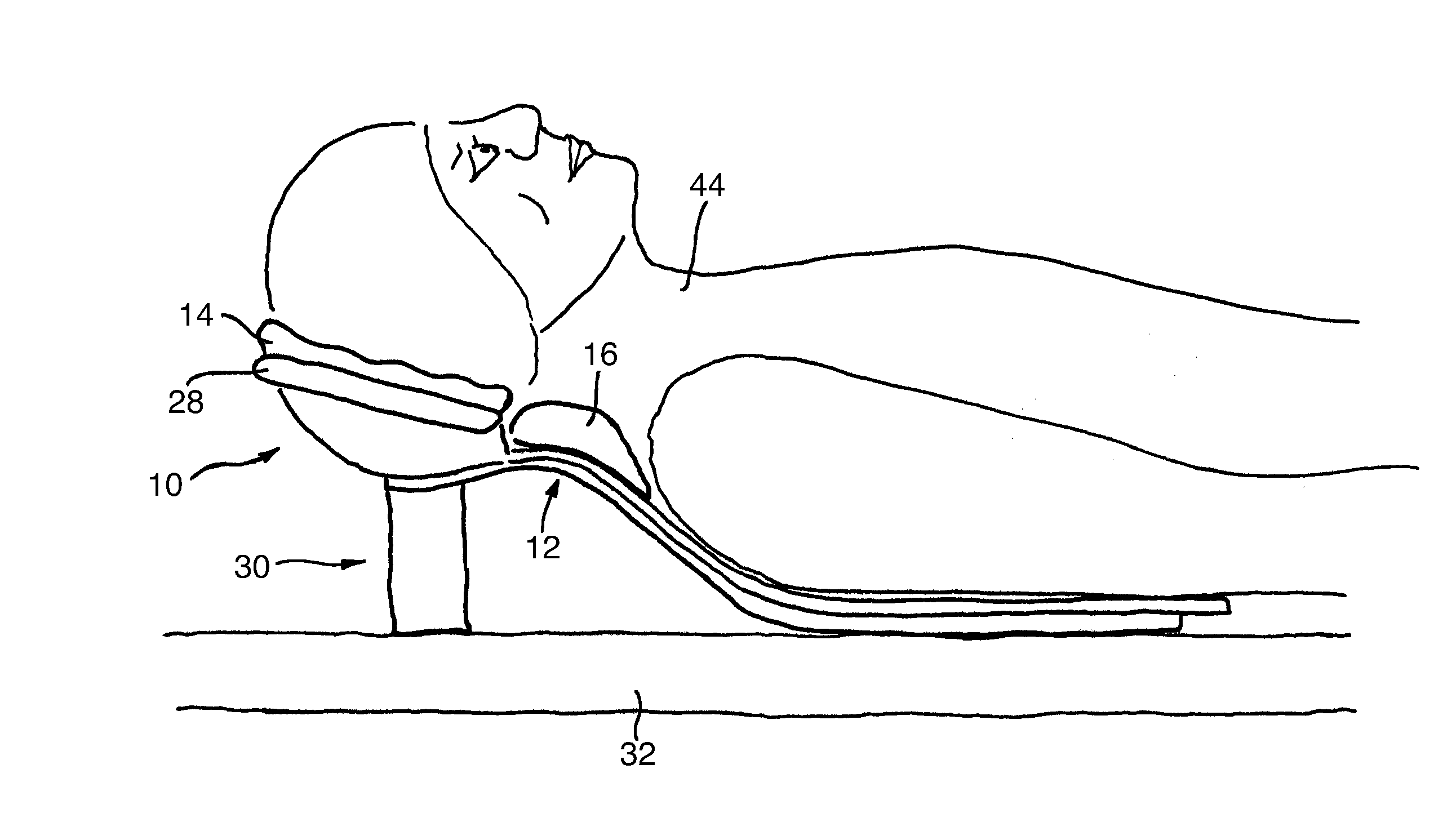

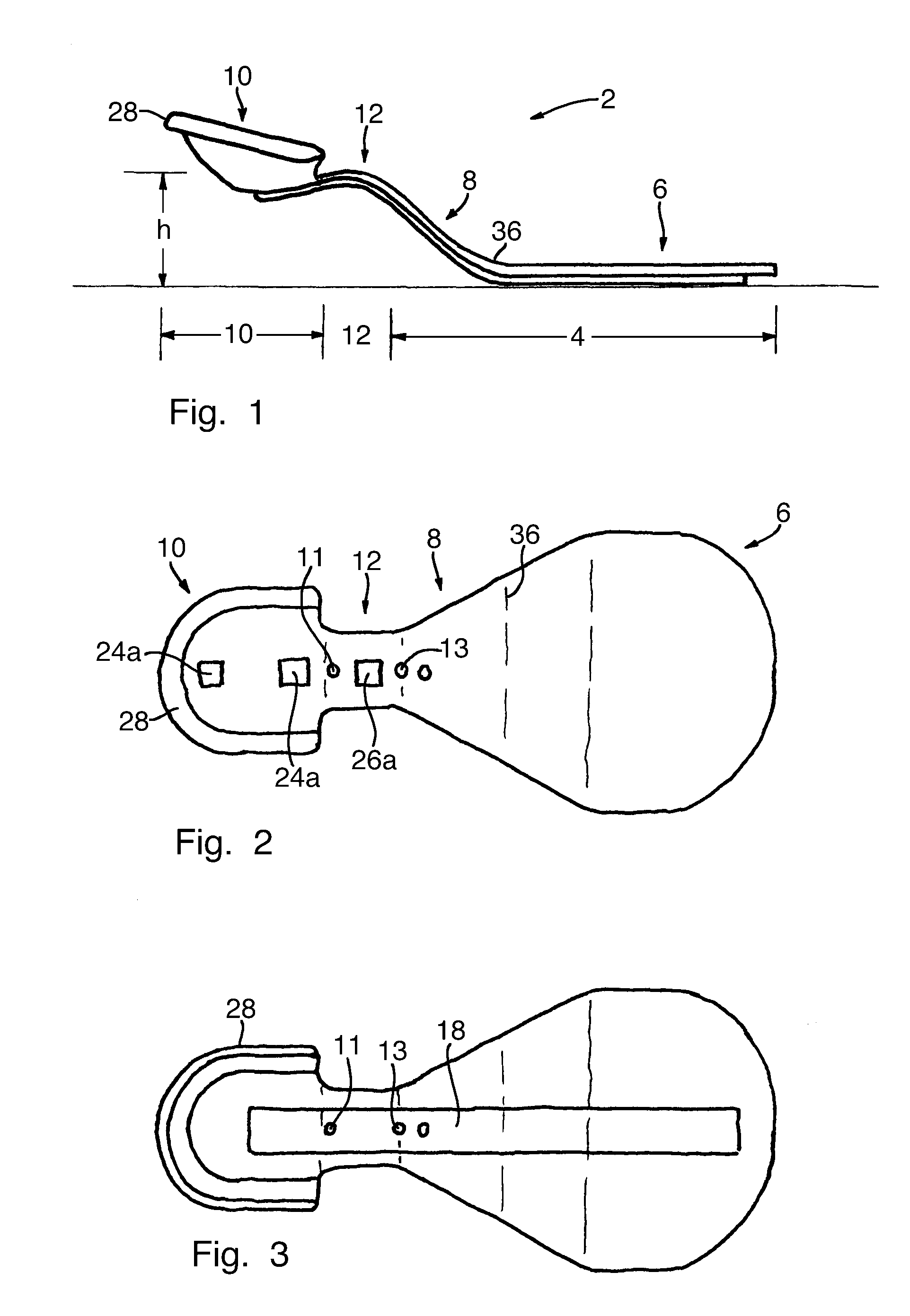

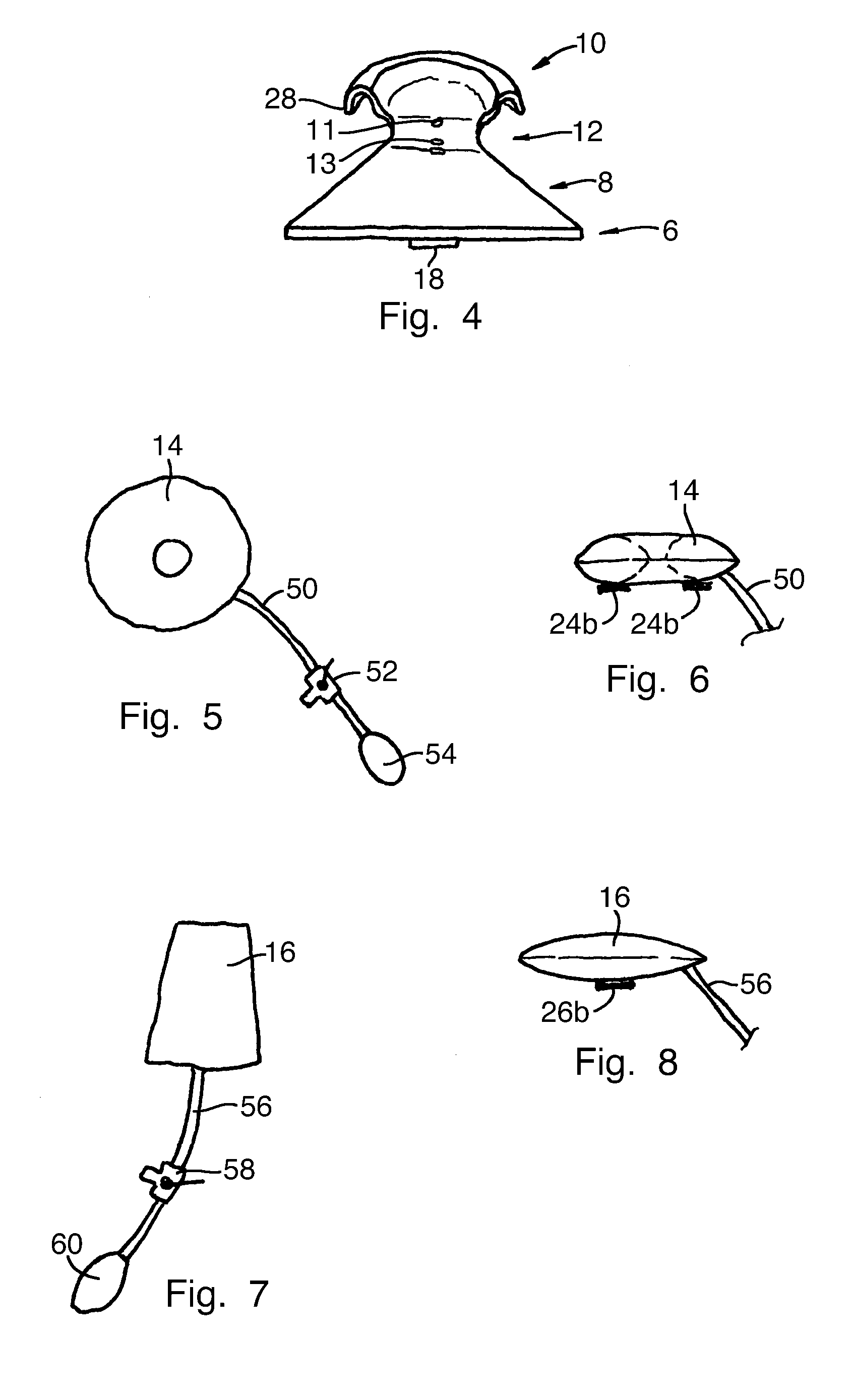

Support for supporting a patient

InactiveUS20100147313A1Improve stabilitySimple handlingOperating chairsOperating tablesNeck partsShoulder region

In order to improve a support (2) for supporting a patient, particularly for surgical procedures in the shoulder region, said support comprising a substantially flat body part (4) and a bowl-shaped head part, said body part (4) comprising a back part (6) and a thorax part (8) tapered in relation thereto, the head part (10) being disposed on said thorax part by means of a transitional region, with the thorax part (8) and the transitional region sloping upwards such that the head part (10) is higher than the back part (6), and with said head part being adapted to the human profile and comprising a removable, inflatable support for adapting the position of the patient to the current positional or treatment requirements, the invention proposes that the transitional region be designed as neck part (12) and also be adapted to the human profile, comprising a removable, inflatable support for adapting the position of the patient to the current positional or treatment requirements.

Owner:SAMARIT MEDIZINTECHN

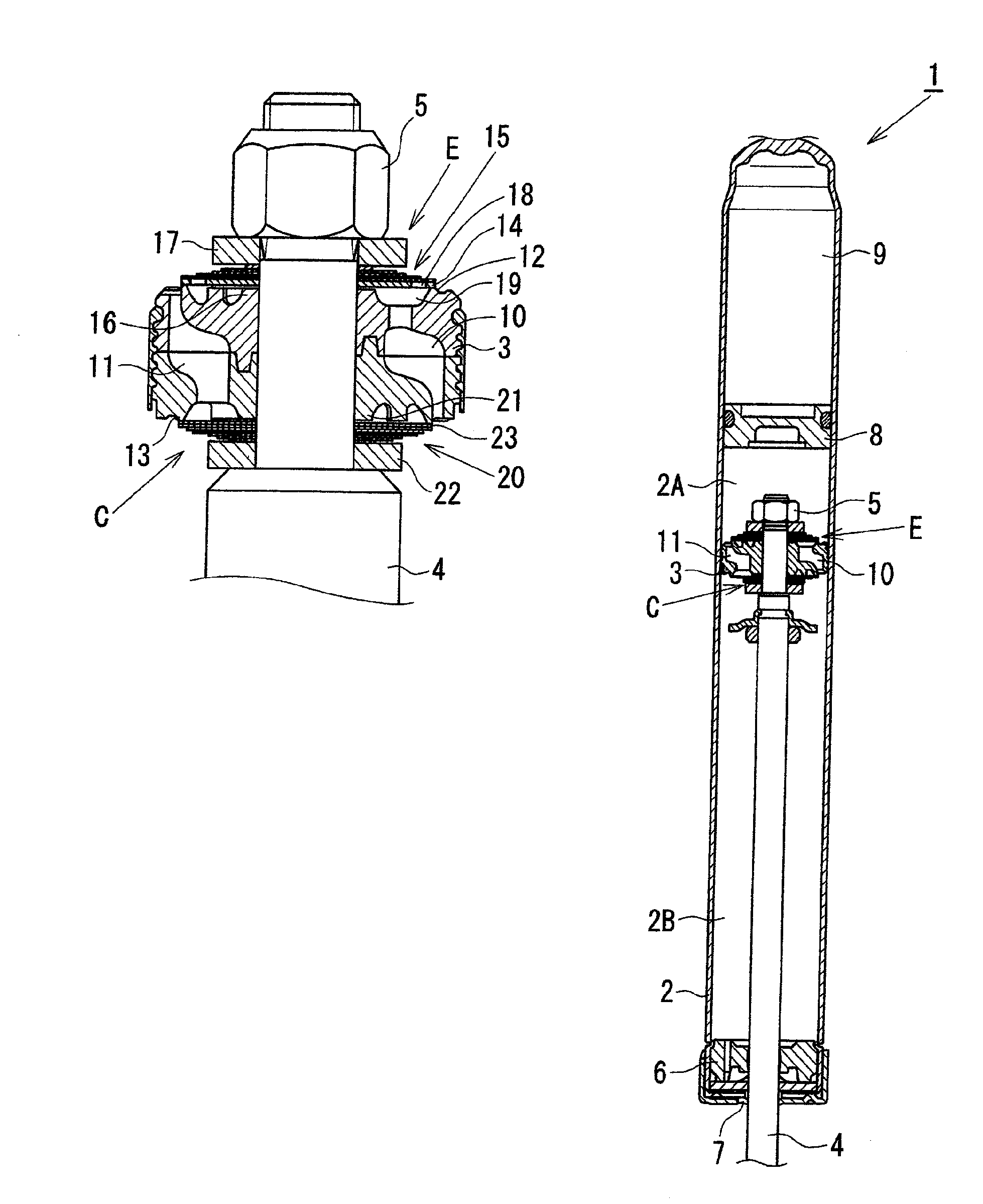

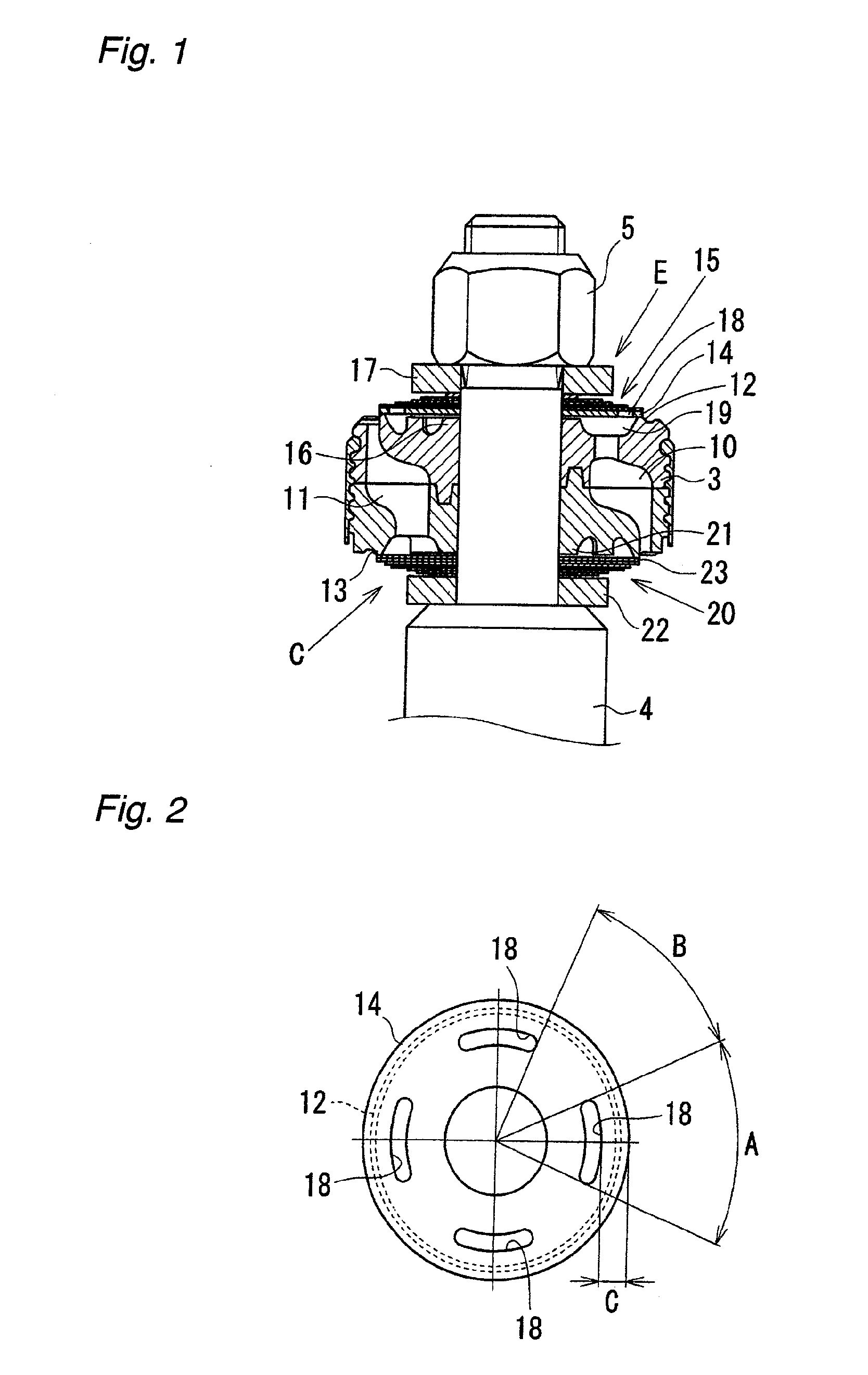

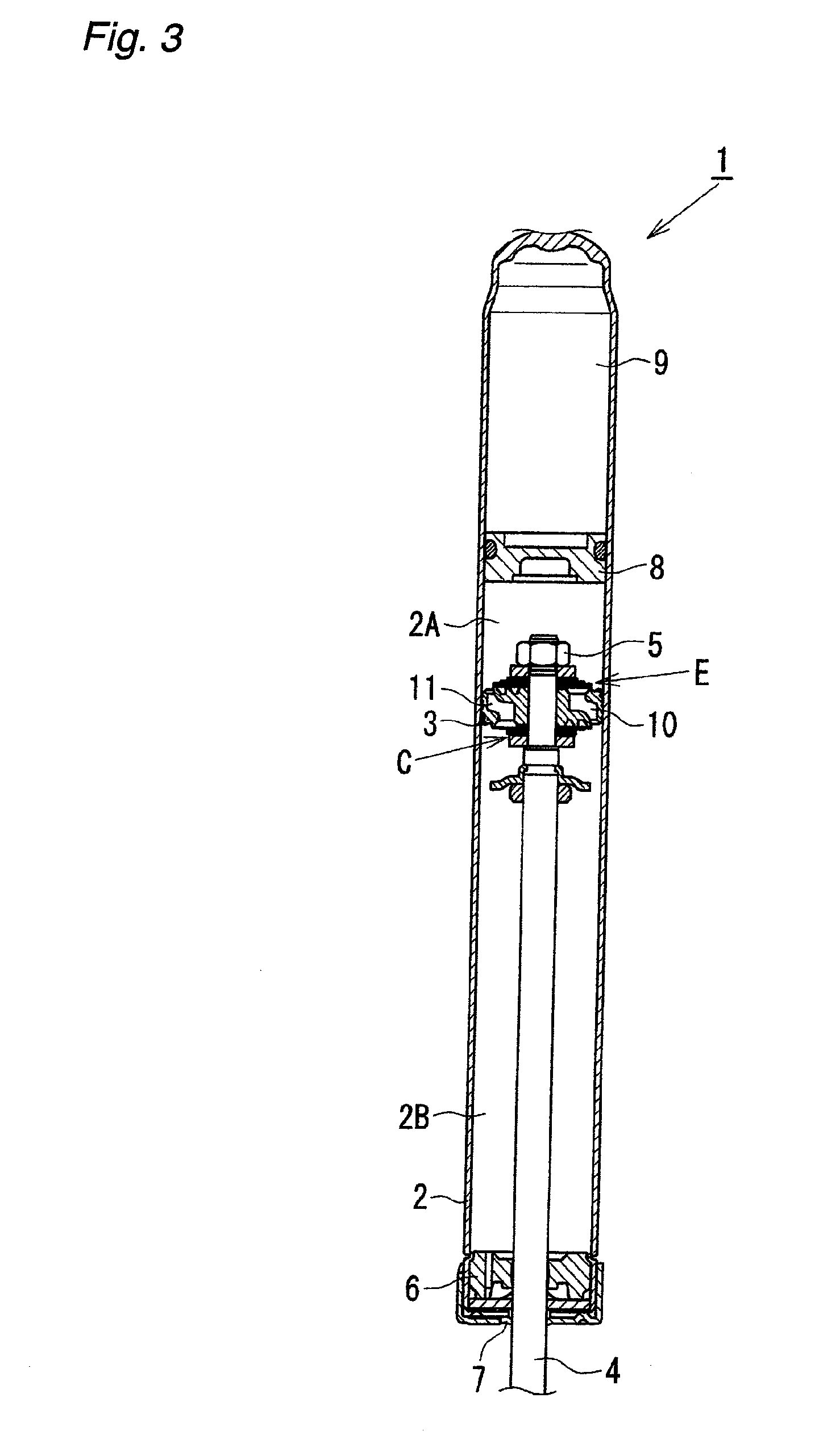

Shock absorber

InactiveUS20090260938A1Avoid drastic changesSmooth damping force characteristicSpringsShock absorbersTransitional RegionEngineering

A shock absorber has a seat disk seated on a valve seat of a piston. A disk valve opens and closes a slot provided in the seat disk to extend in the circumferential direction thereof. In a low piston speed region, an orifice passage generates a damping force of orifice characteristics. In an intermediate piston speed region, the disk valve opens to generate a damping force of valve characteristics. In a high piston speed region, the seat disk opens to prevent an excessive increase in damping force. The disk valve partially opens the slot relative to the circumferential direction to gradually increase the flow path area, thereby preventing a sharp change in damping force in a transitional region from the low to intermediate piston speed region.

Owner:HITACHI LTD

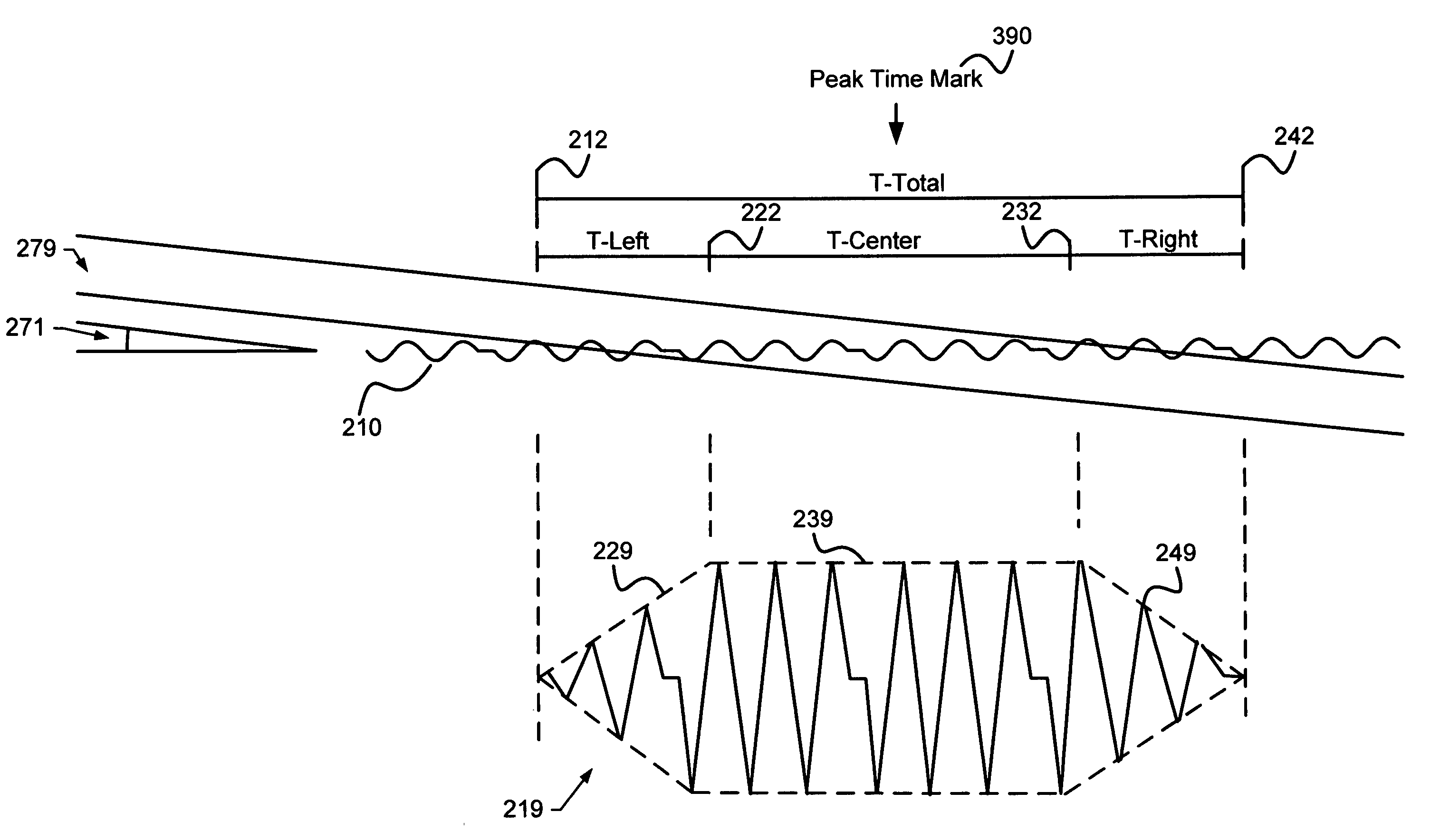

Systems and methods for estimating time corresponding to peak signal amplitude

InactiveUS7738200B2Modification of read/write signalsDriving/moving recording headsTransitional RegionEngineering

Owner:BROADCOM INT PTE LTD

Angle-dependent Interference Pigments

ActiveUS20110306678A1Low refractive indexHigh refractive indexBiocideCosmetic preparationsRefractive indexSilicon oxide

An angle-dependent interference pigment based on transparent or translucent inorganic flake serving as a substrate is provided. The substrate is coated by coatings (A)+(B)+(C) and optionally coating (D), so as to form a “high-low-high” refractive index layered structure. The coatings (A) and (C) consist of metal oxides, silicate, aluminates and / or a mixture thereof. The coating (B) consist of silicon oxide, hydrous silicon oxide, aluminum oxide, hydrous aluminum oxide, magnesium oxide, hydrous magnesium oxide and / or a mixture thereof. The angle-dependent interference pigments have high color saturation in the transitional region and a significantly gradual color change in the color changing region. The present pigments can be used as colored coatings, including printing ink, or can be used in the preparation of plastics, glass, ceramics and the like. The pigment of the present invention is particularly used in the cosmetic industry which has a very high requirement on gradual color change.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

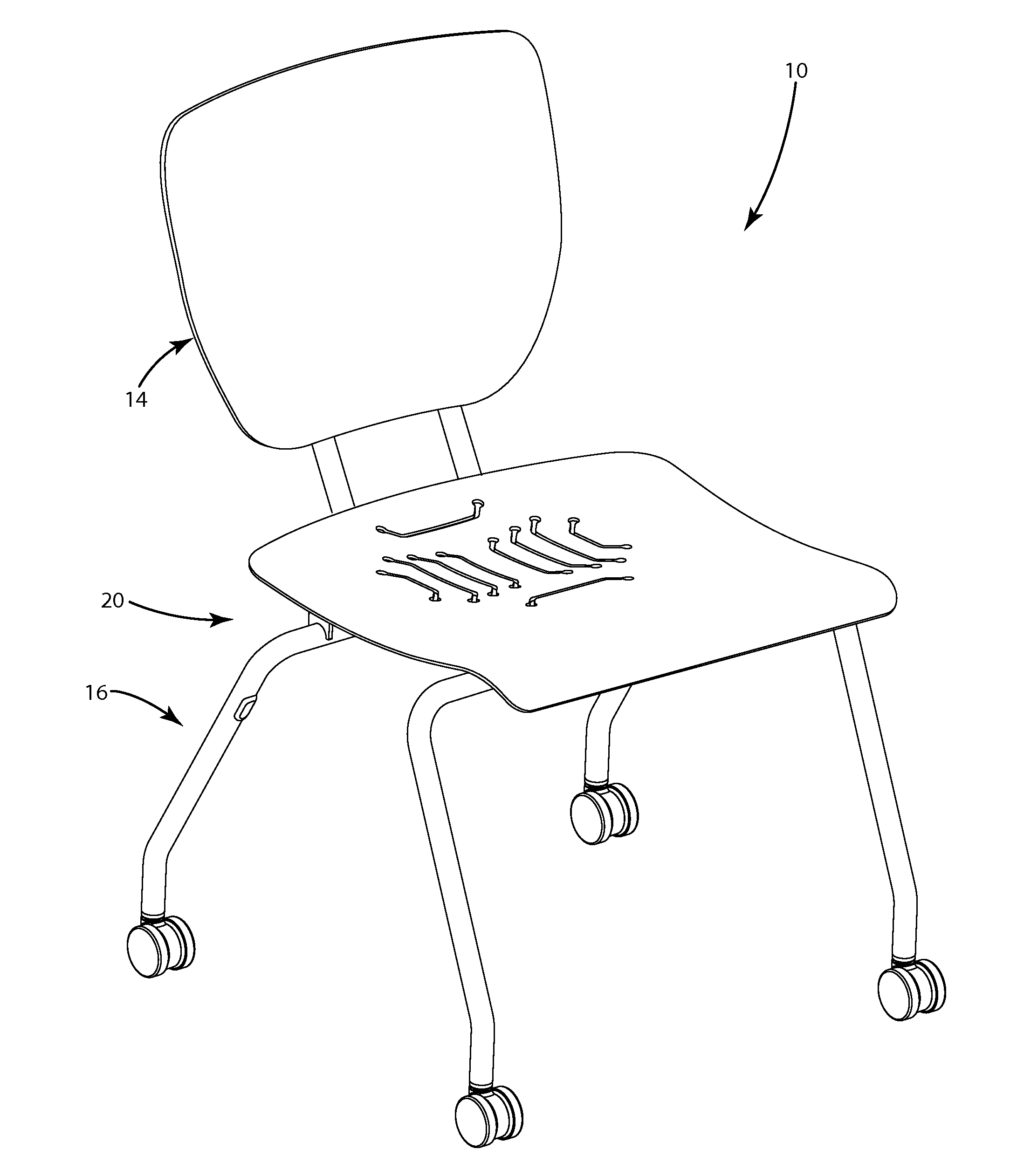

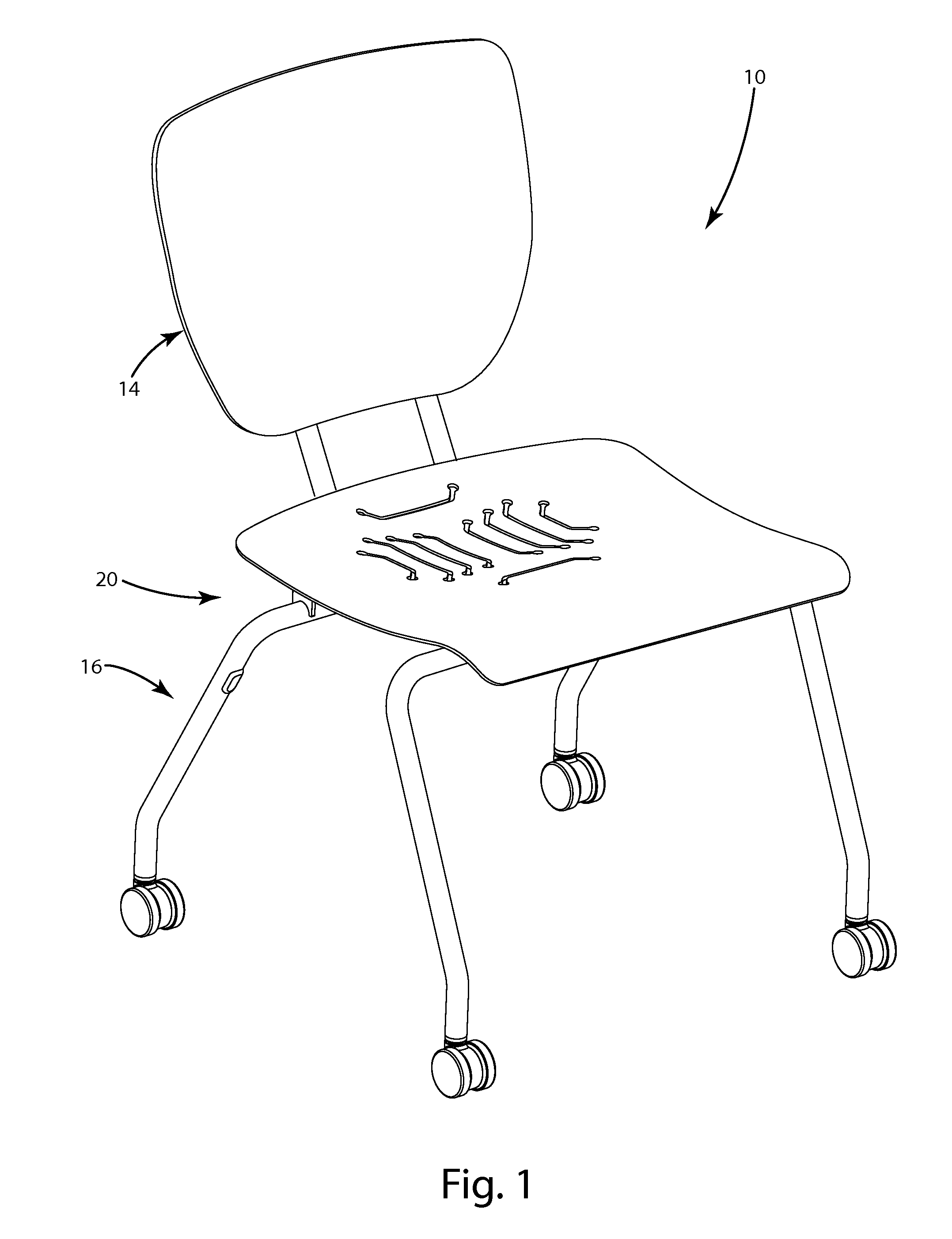

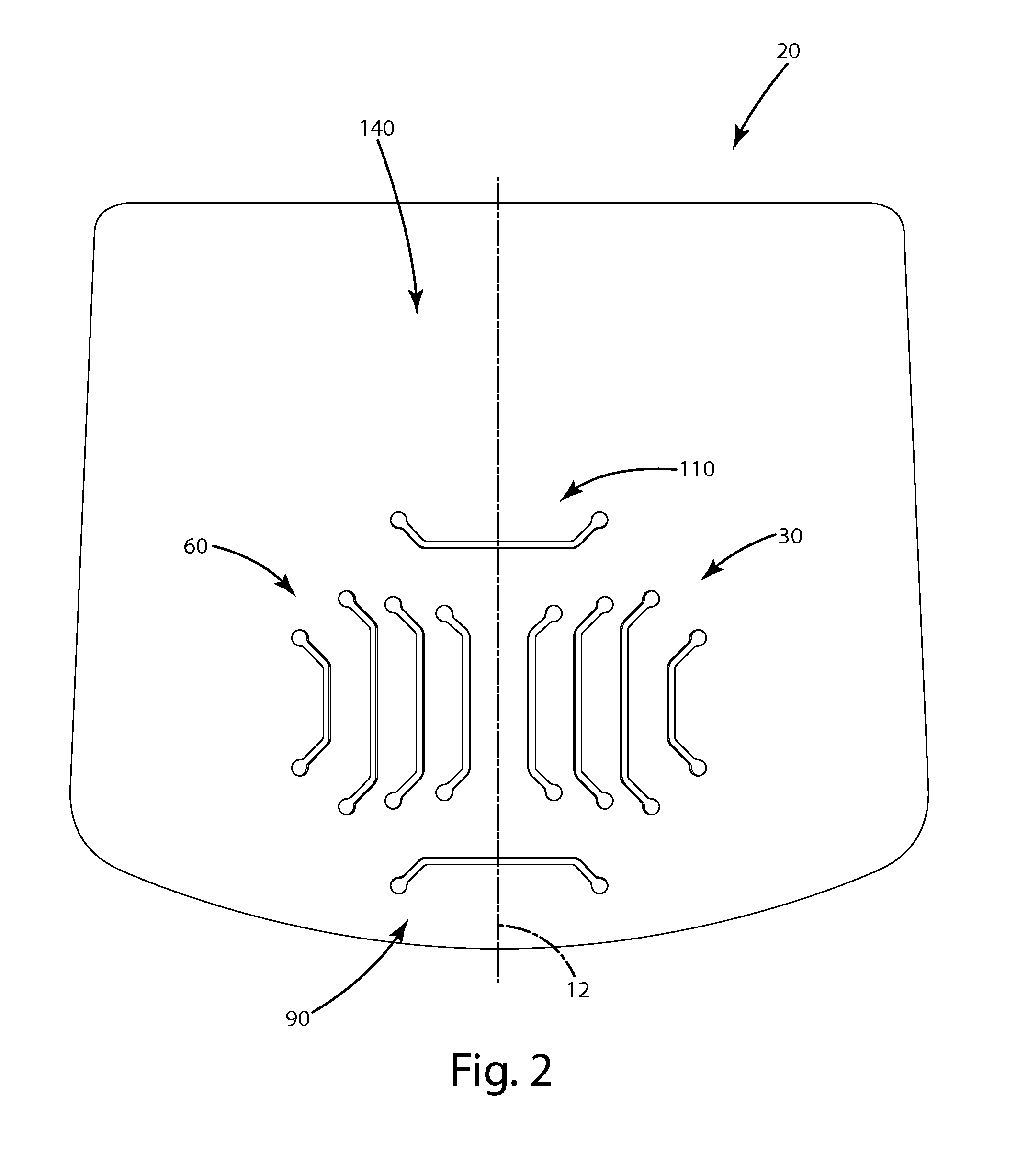

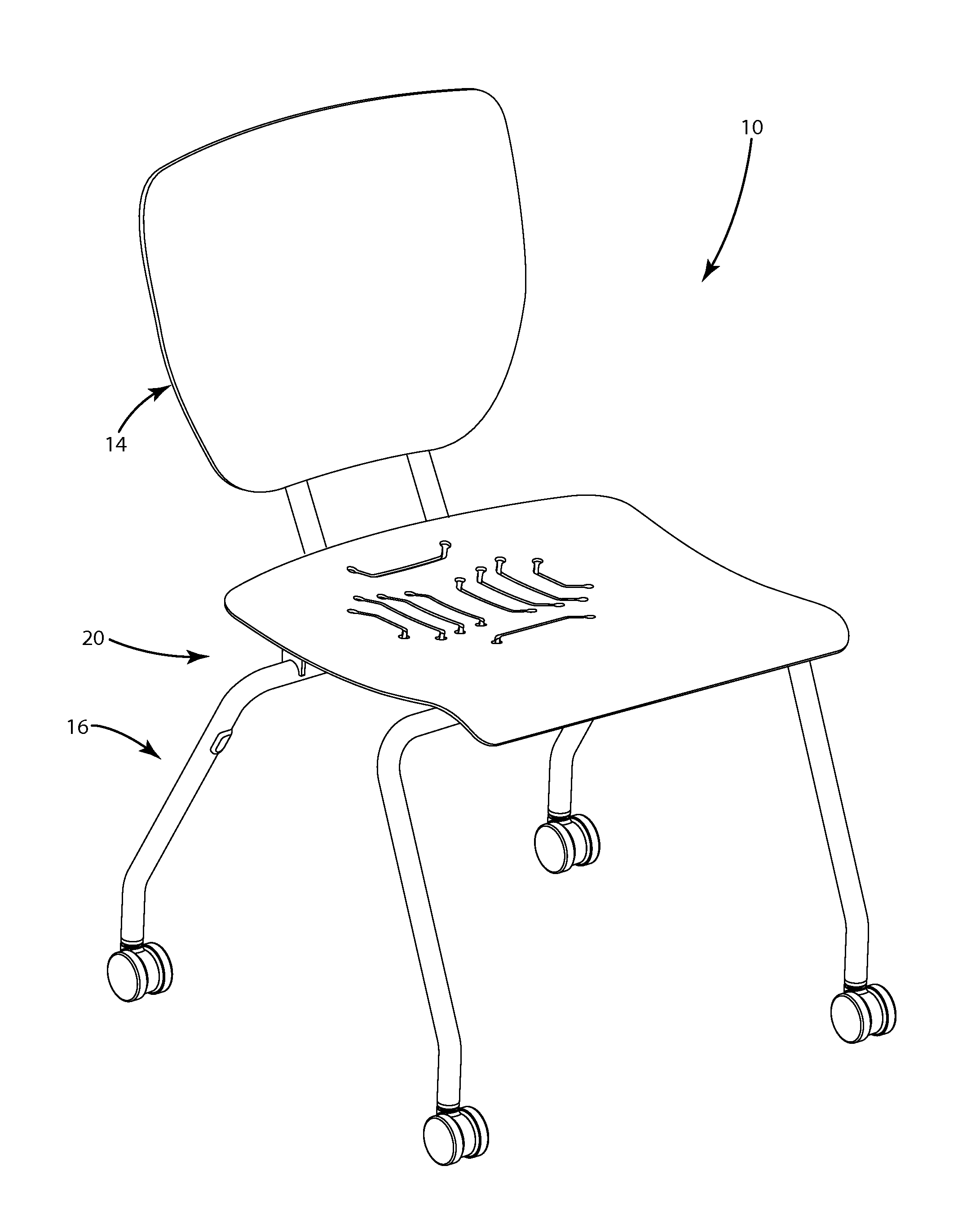

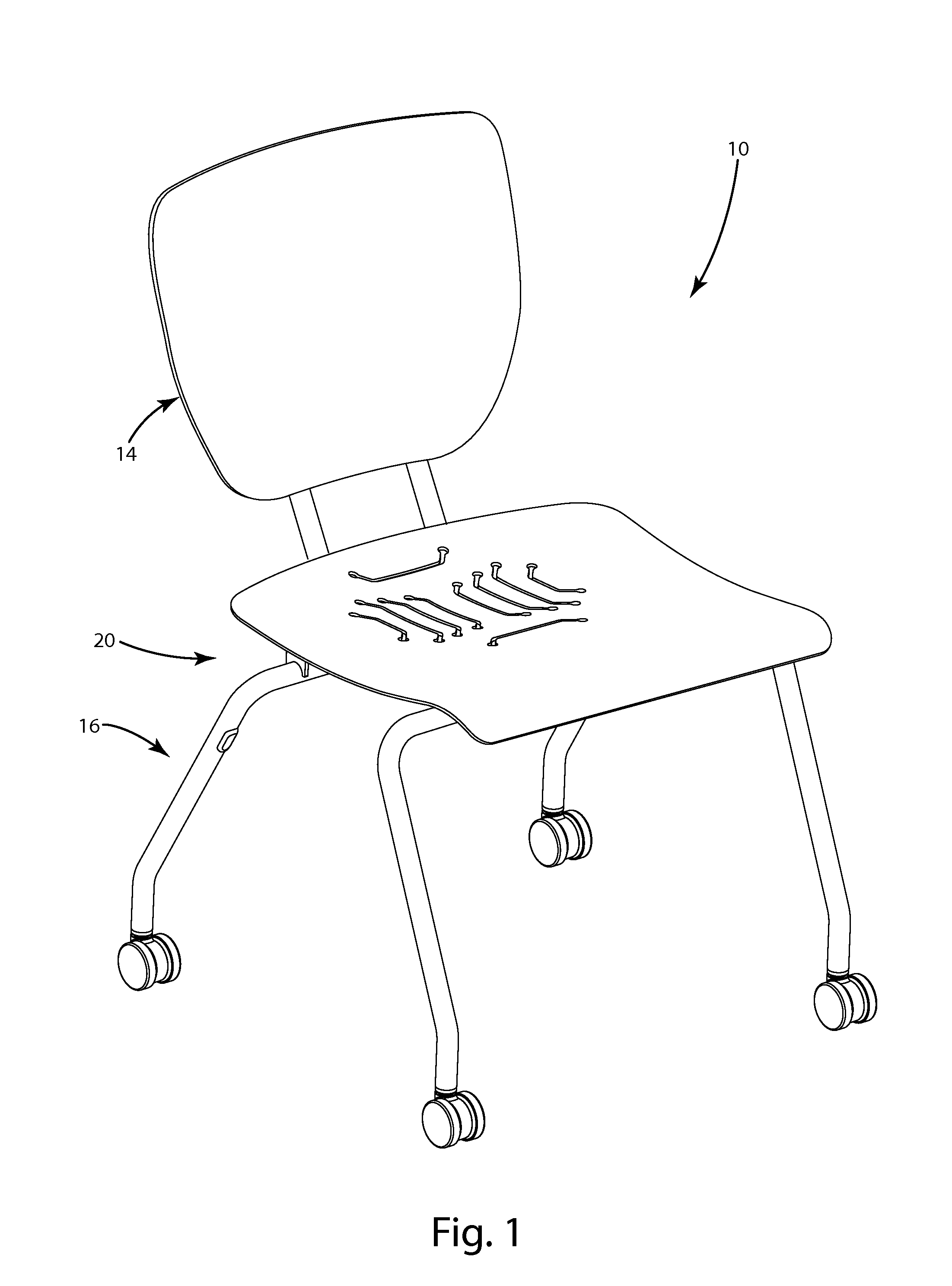

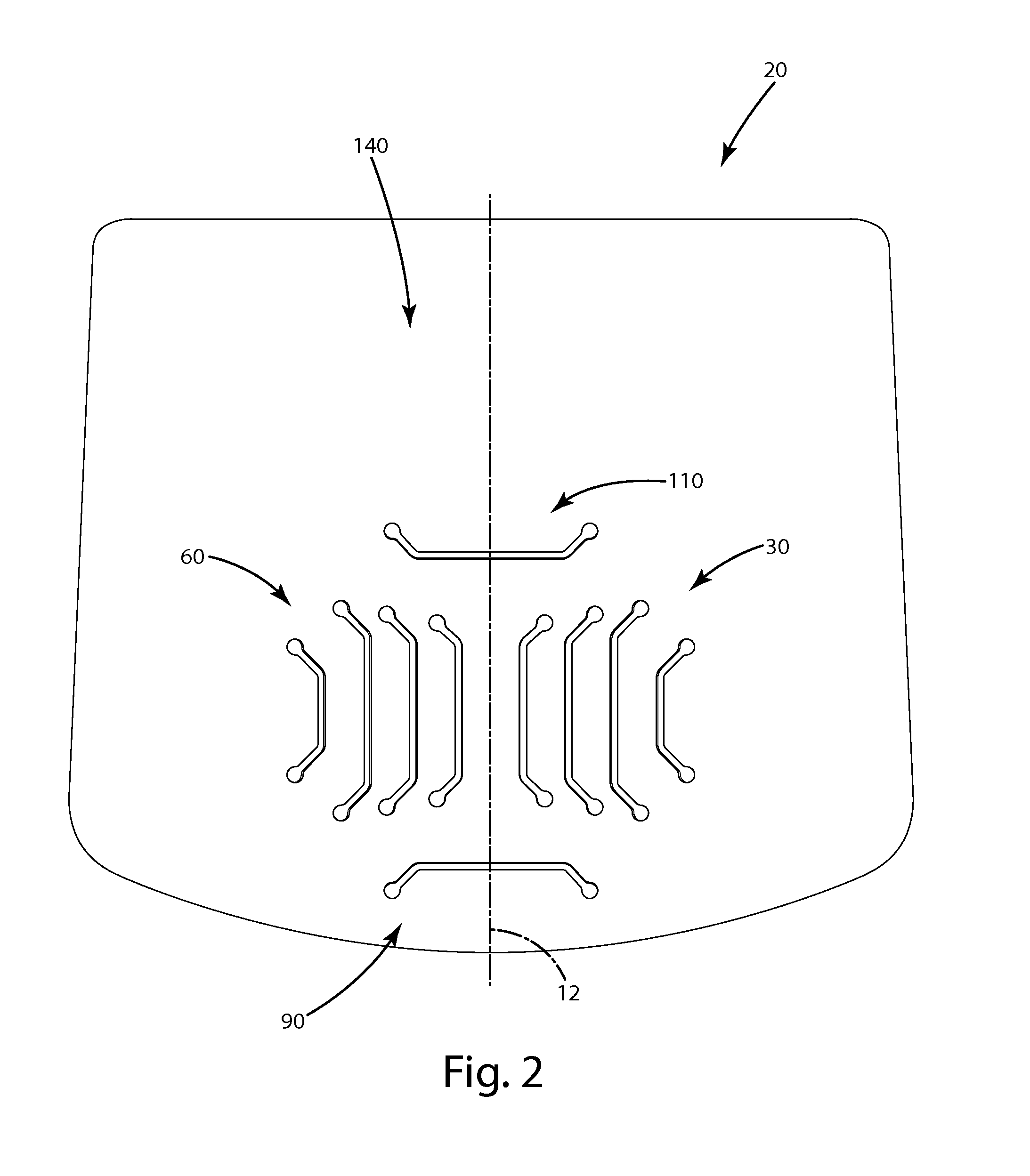

Flexible seating surface

ActiveUS8919880B2Relieve pressureStable supportStoolsAdjustable chairsDistal portionTransitional Region

Owner:HAWORTH SPA

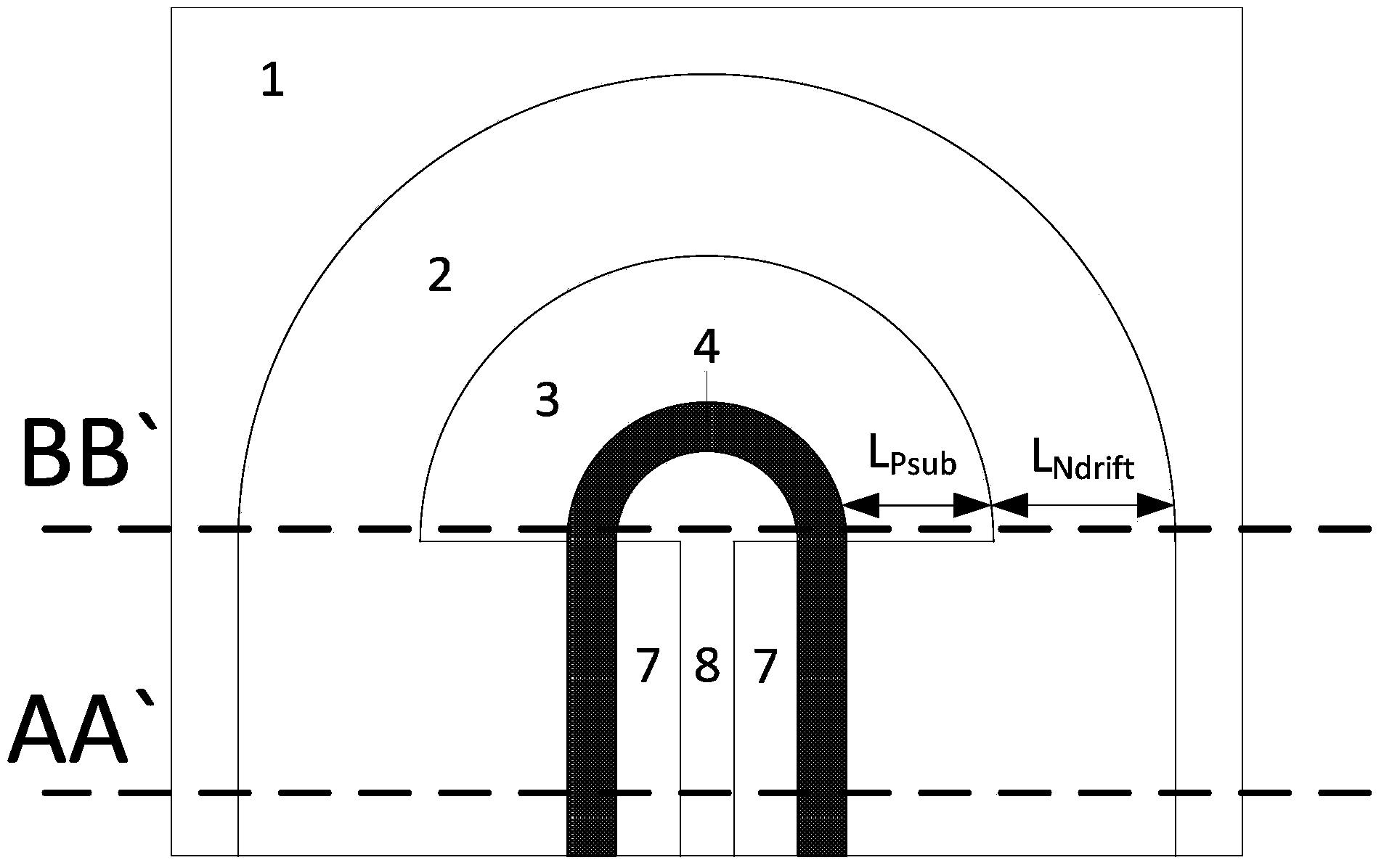

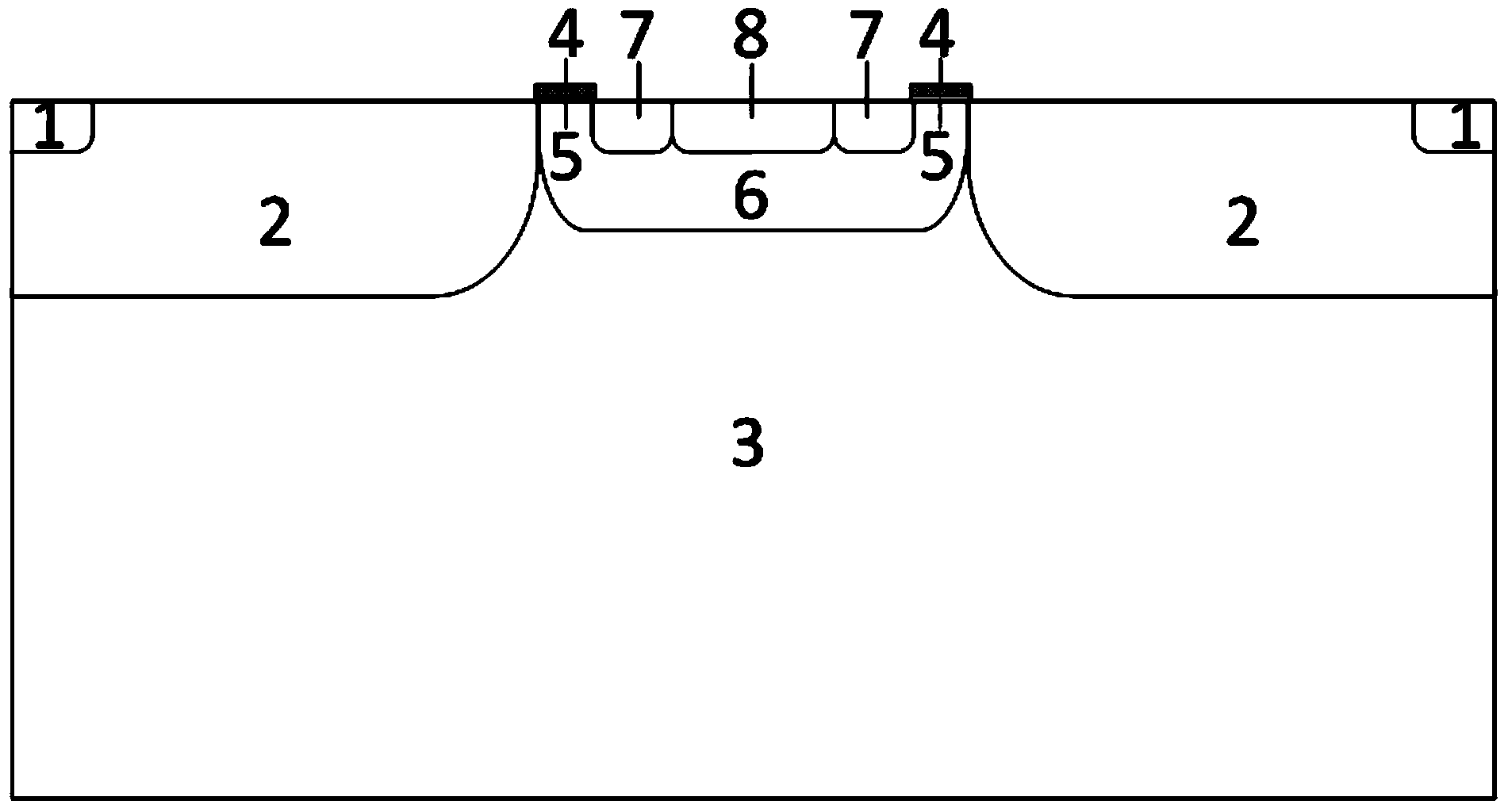

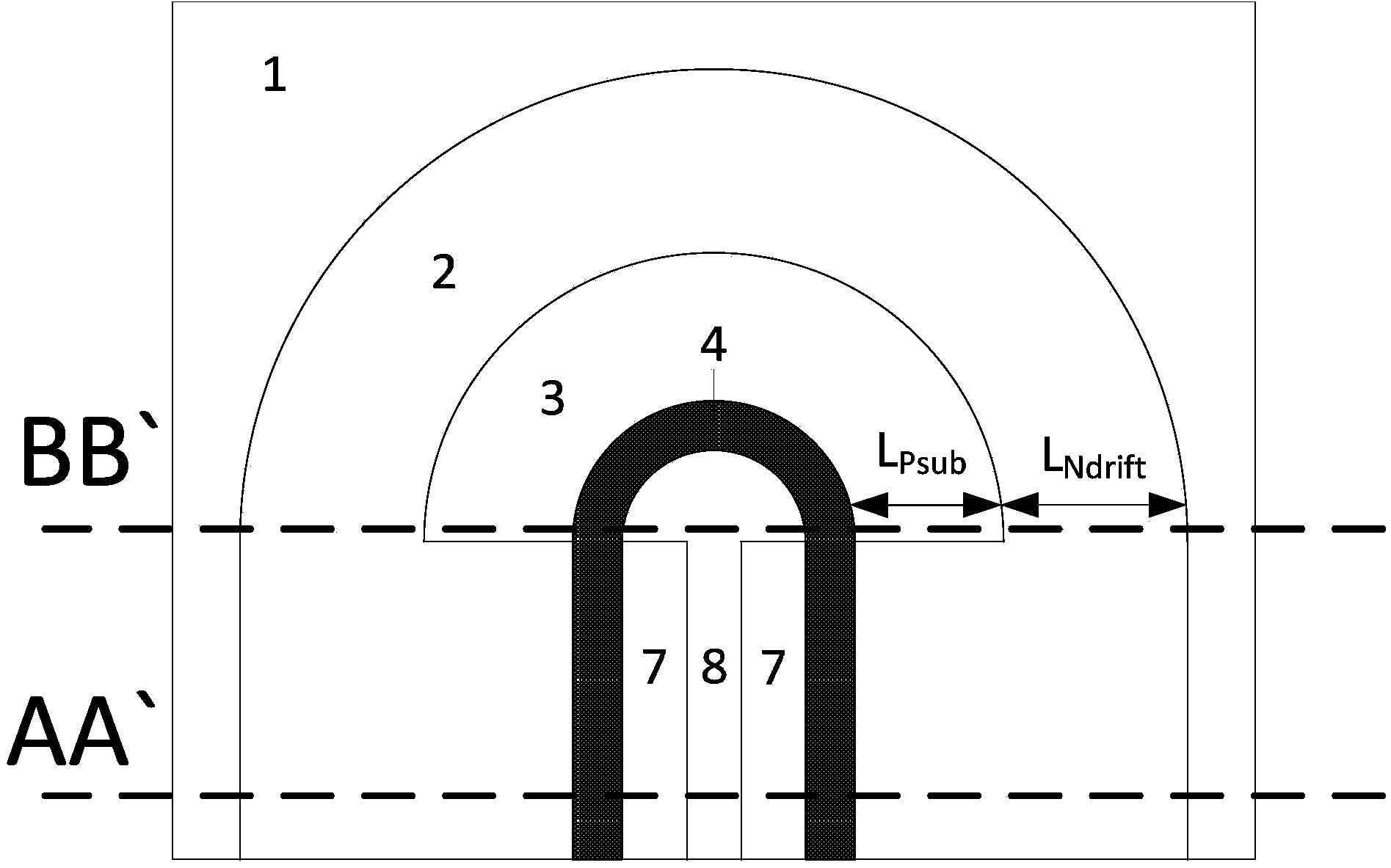

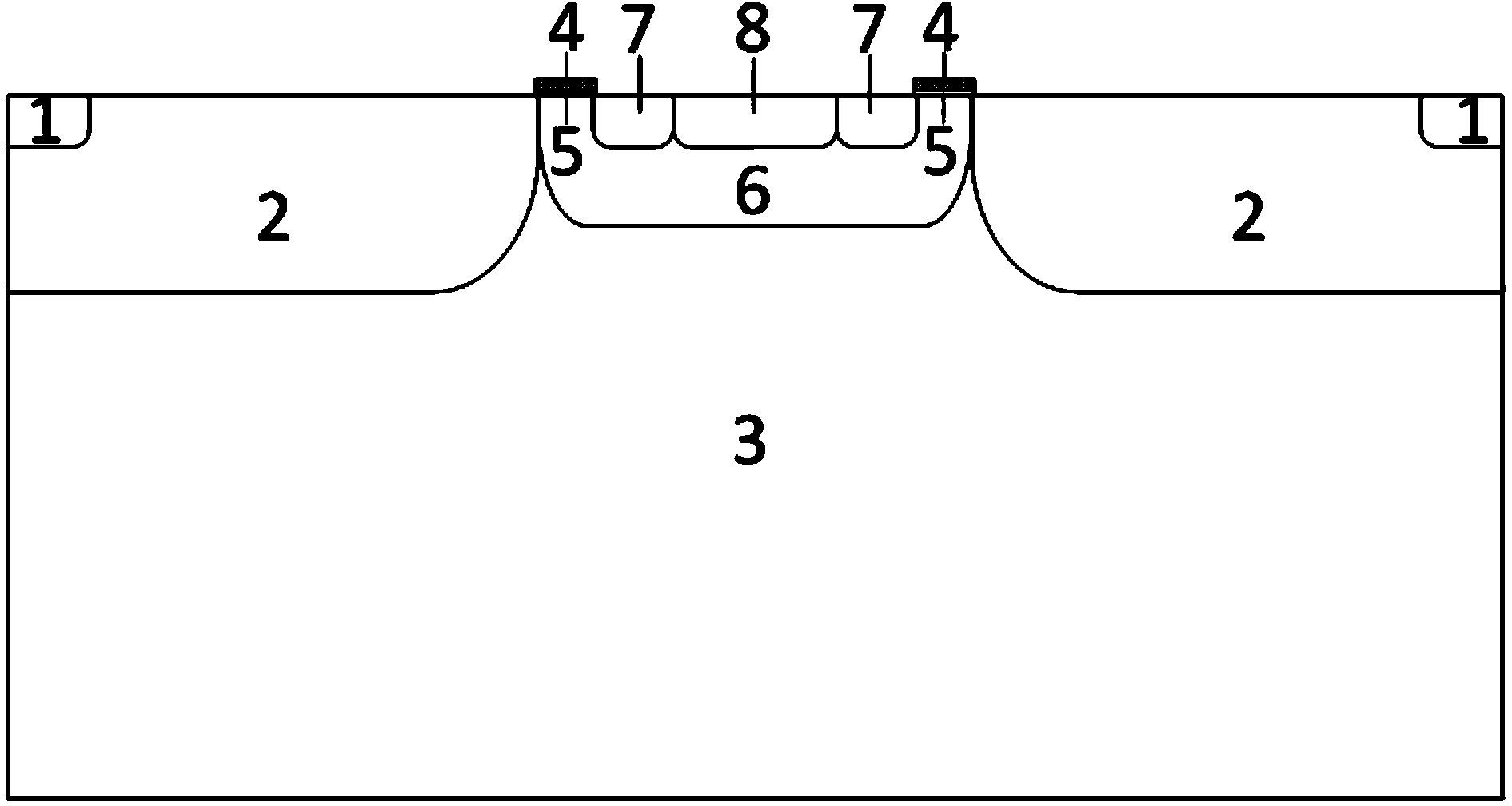

Junction terminal structure of transverse high-voltage power semiconductor device

ActiveCN103928527AReduce the impact of withstand voltageGuaranteed withstand voltageSemiconductor devicesPower semiconductor deviceTransitional Region

The invention relates to the technical field of semiconductor power devices, in particular to a junction terminal structure of a transverse high-voltage power semiconductor device. According to the junction terminal structure, by increasing the total area of a P-type substrate and an N-type shift region, at the position of a curvature junction terminal, of the device, the device is prevented from being used up in advance in the region of the P-type substrate, and the withstand voltage of the device at the position of the curvature junction terminal is guaranteed. The junction terminal structure of the transverse high-voltage power semiconductor device has the advantages that the influences on the withstand voltage of the whole device from the curvature junction terminal can be obviously reduced, the electric field, in a transitional region, of the device cannot be too high, the withstand voltage of the device is optimized by changing the area of the shift region or the area of the P-type substrate, and the withstand voltage of the device is guaranteed accordingly. The junction terminal structure of the transverse high-voltage power semiconductor device is particularly suitable for junction structures of transverse high-voltage semiconductor devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

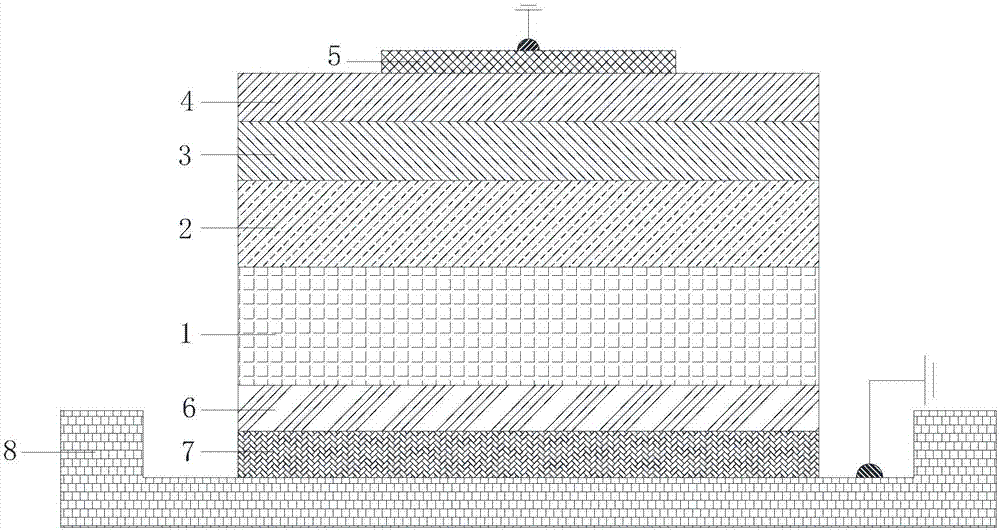

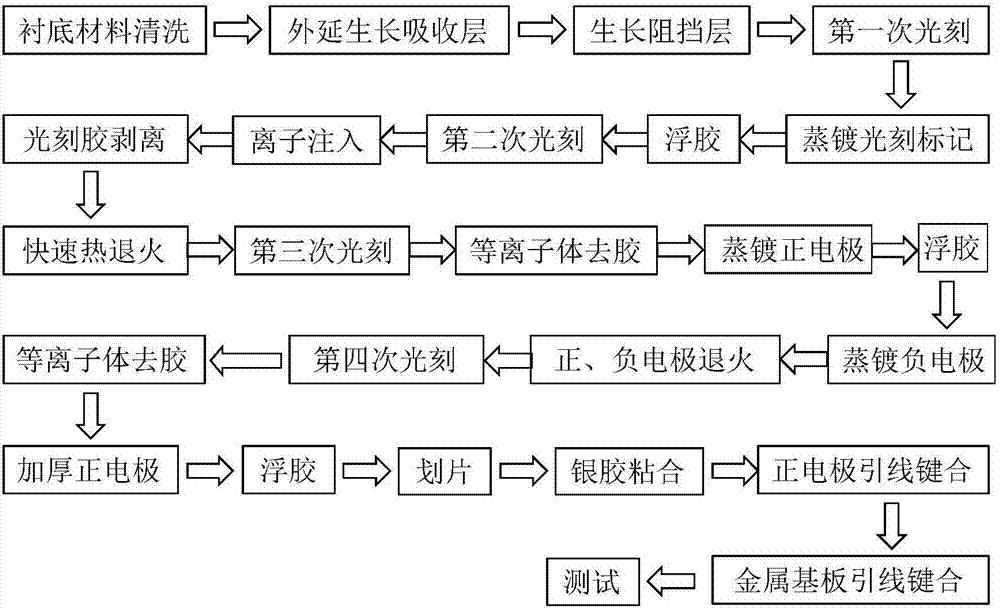

Back electrode structured impurity barrier band detector and manufacturing method therefor

ActiveCN107017315AFix damageReduce dark currentFinal product manufactureSemiconductor devicesSilver pasteLead bonding

The invention provides a back electrode structured impurity barrier band detector. The back electrode structured impurity barrier band detector comprises a high-conductivity silicon substrate, a silicon-doped phosphorus absorption layer, a high-purity silicon barrier layer, an electrode transitional region, a positive electrode region, a negative electrode region and a metal substrate, wherein the silicon-doped phosphorus absorption layer is arranged on the high-conductivity silicon substrate; the high-purity silicon barrier layer is arranged on the silicon-doped phosphorus absorption layer; the electrode transitional region is arranged on the high-purity silicon barrier layer; the positive electrode region is arranged on the electrode transitional region; a positive electrode lead is arranged on the positive electrode region; the negative electrode region is arranged at the bottom of the high-conductivity silicon substrate; the negative electrode region is connected with the metal substrate through conductive silver paste; and a negative electrode lead is arranged on the negative electrode region. The back electrode structured impurity barrier band detector has the beneficial effects as follows: the negative electrode and the metal substrate are glued together through the silver paste; gold lines are led from the positive electrode and the metal substrate separately through a lead bonding process to be connected to adjacent pins of the metal substrate respectively; and therefore, deep hole etching to the negative electrode in the conventional preparation method is avoided, and the problem of damage to the device caused by the conventional etching process is solved.

Owner:NO 50 RES INST OF CHINA ELECTRONICS TECH GRP

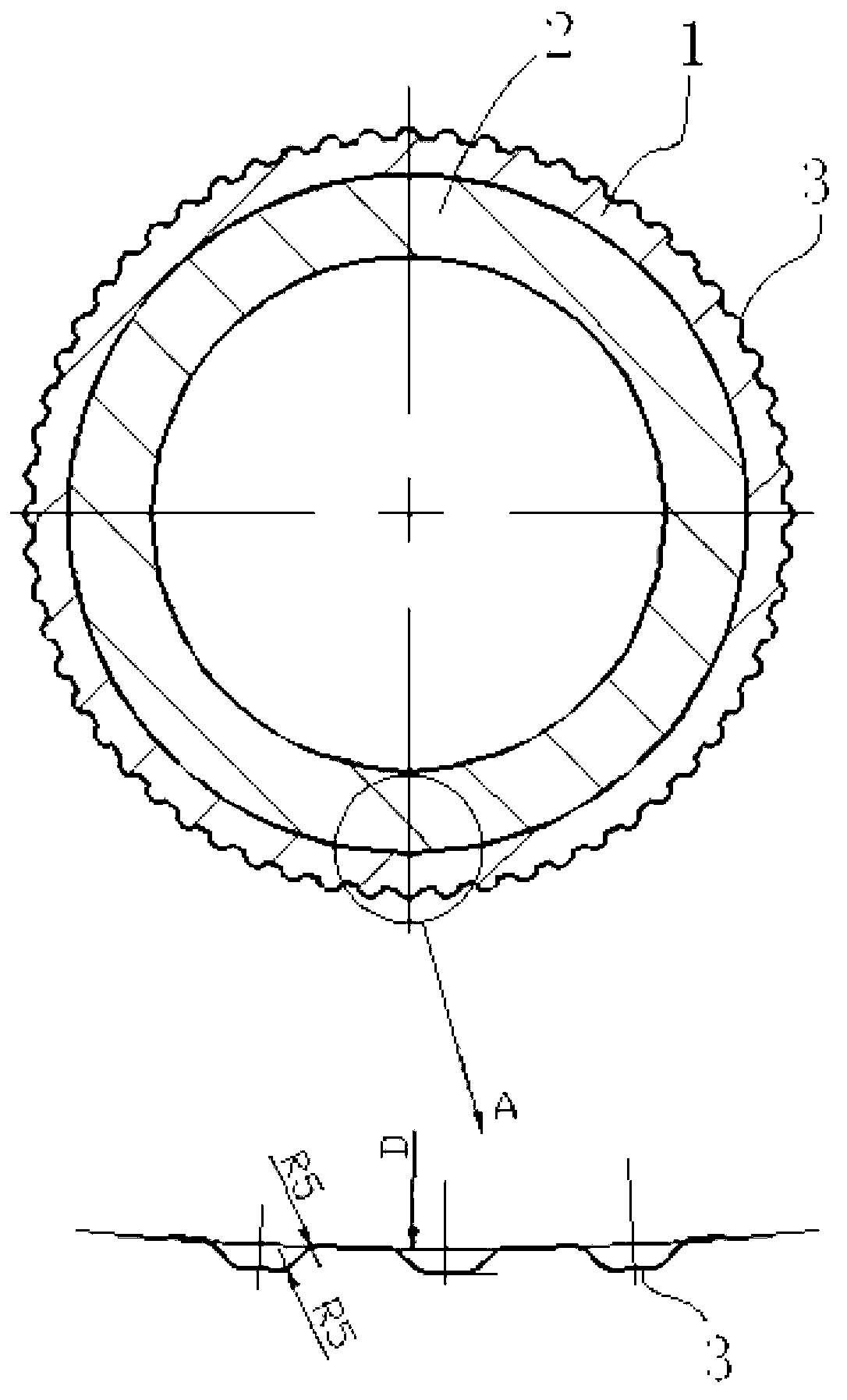

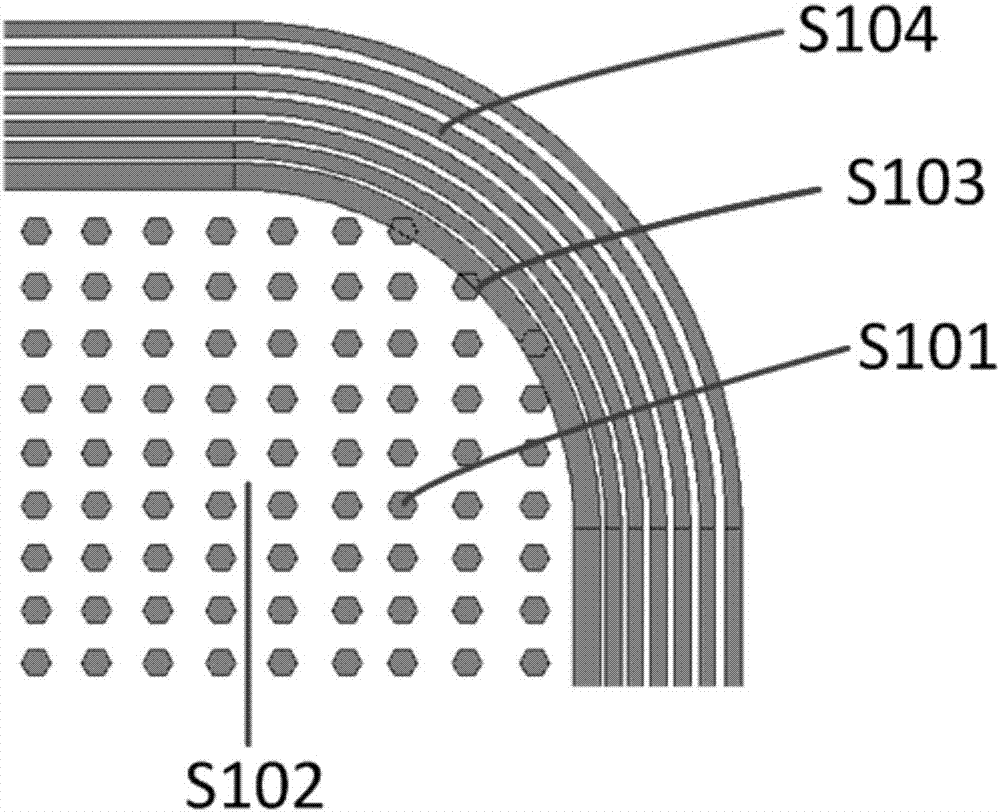

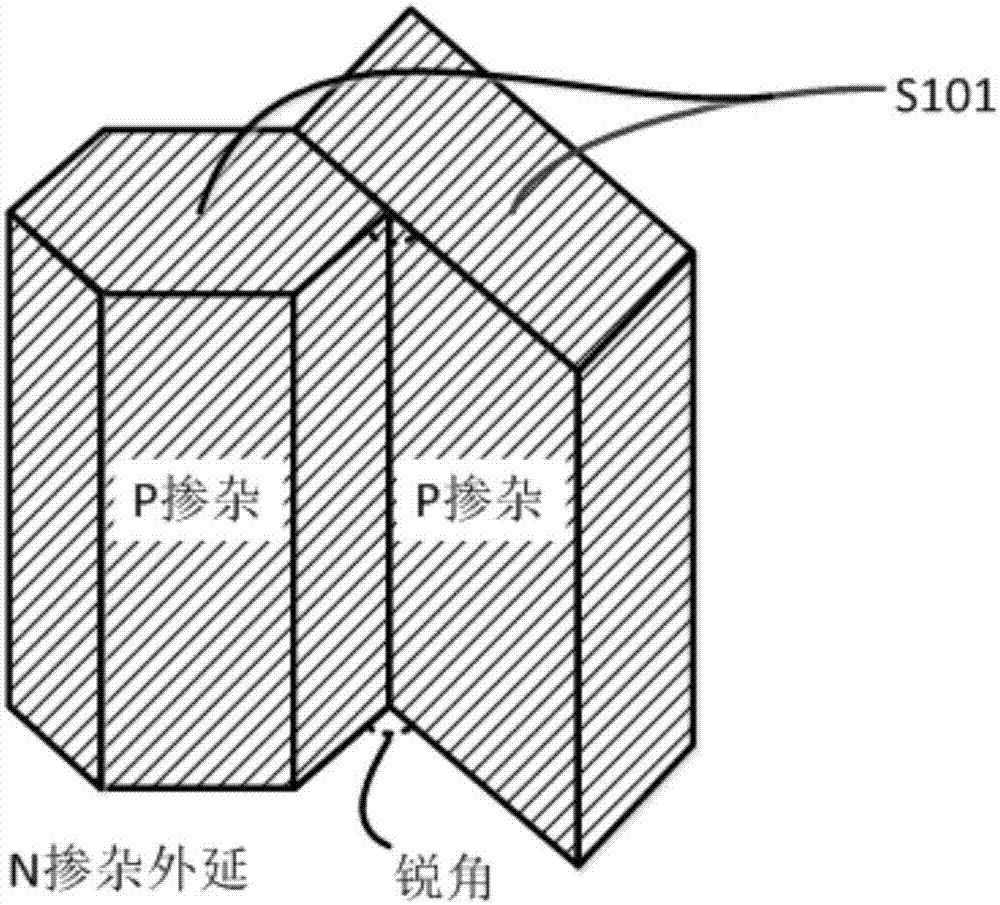

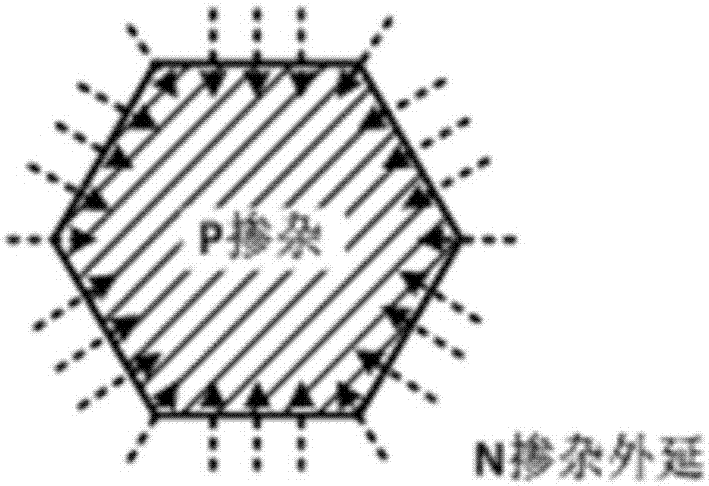

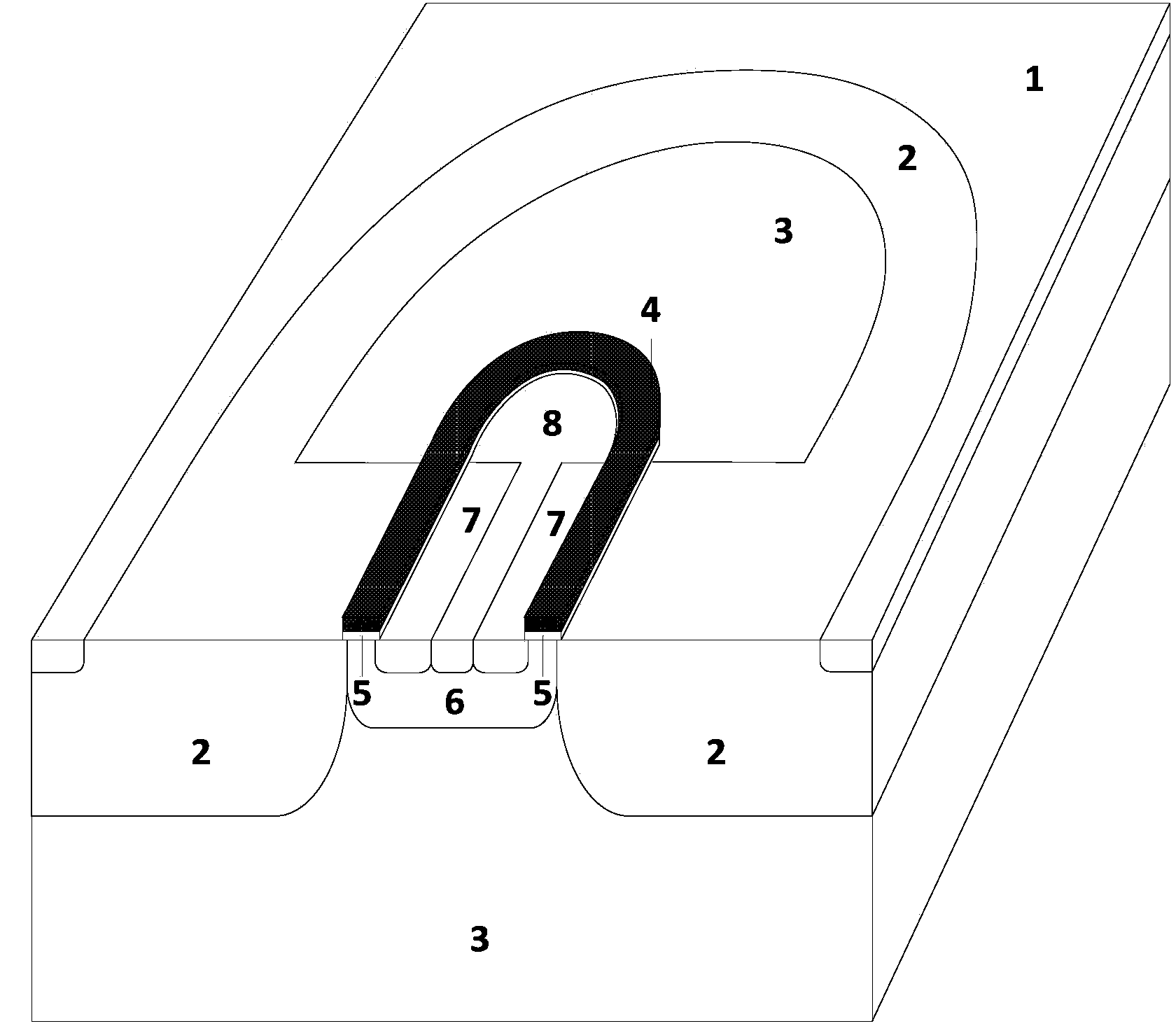

Cellular layout, cellular structure and manufacturing method of silicon carbide junction barrier schottky diode

InactiveCN107170836ANot easy to damageIncrease current densitySemiconductor/solid-state device manufacturingSemiconductor devicesPower flowTransitional Region

The invention relates to a cellular layout, a cellular structure and a manufacturing method of a silicon carbide junction barrier schottky diode. The silicon carbide junction barrier schottky diode comprises a silicon carbide substrate, an epitaxial layer on the substrate and a P-doped region formed on the epitaxial layer in an injection manner; and the P-doped region is formed by circular / polygonal cells and strip-shaped cells in a mixed manner. By virtue of the circular / polygonal cells, the schottky contact area occupation ratio is improved, and the forward current density of a device is improved; by virtue of the strip-shaped cells, sharps formed by the cells in the corner positions and annular transitional regions can be eliminated, the reverse voltage withstand performance of the device is improved, and the device is not burn down easily; and in addition, the safety performance of the device is improved, the forward current density of the device is improved, and cost is lowered.

Owner:YANGZHOU YANGJIE ELECTRONIC TECH CO LTD

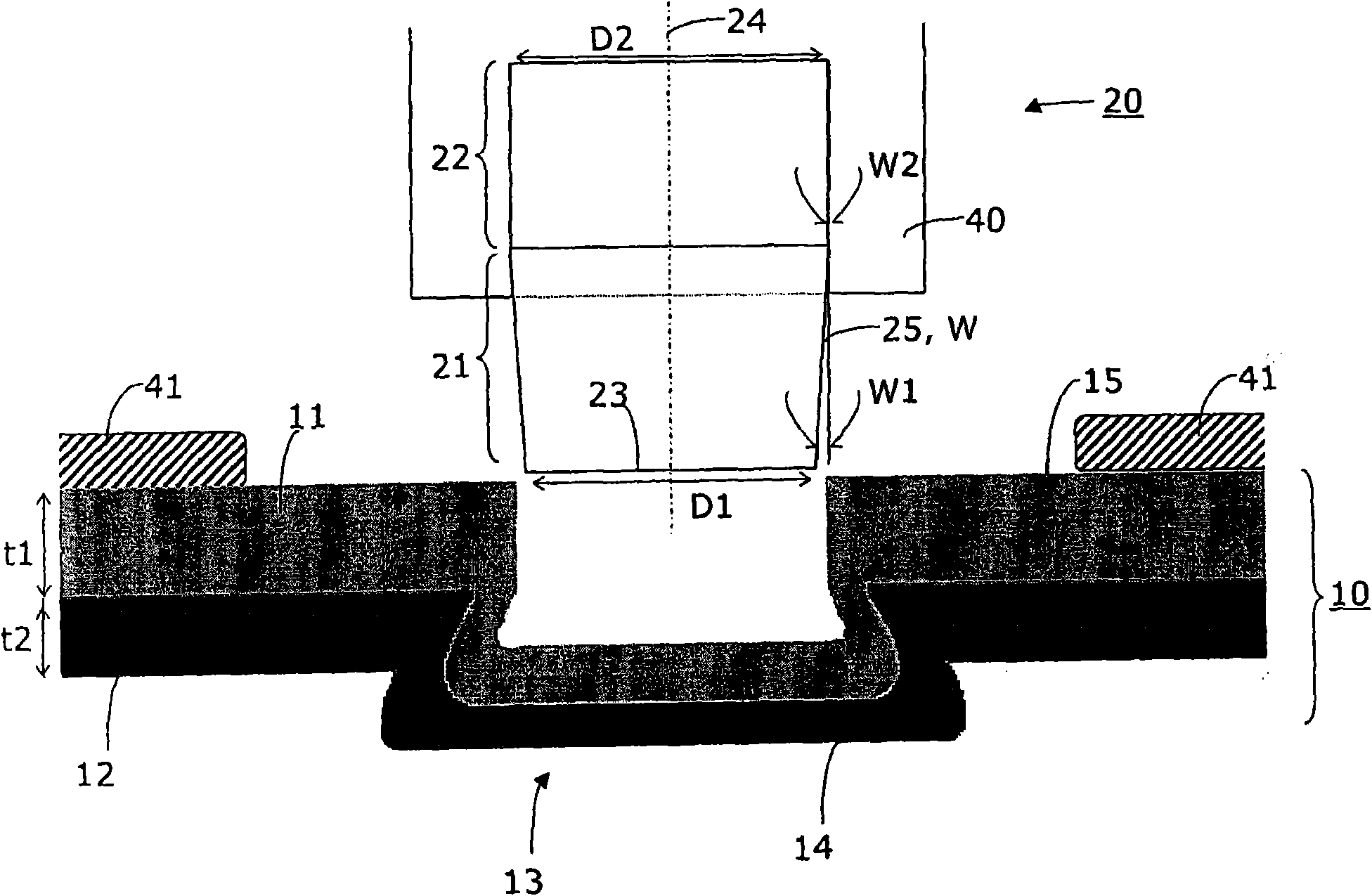

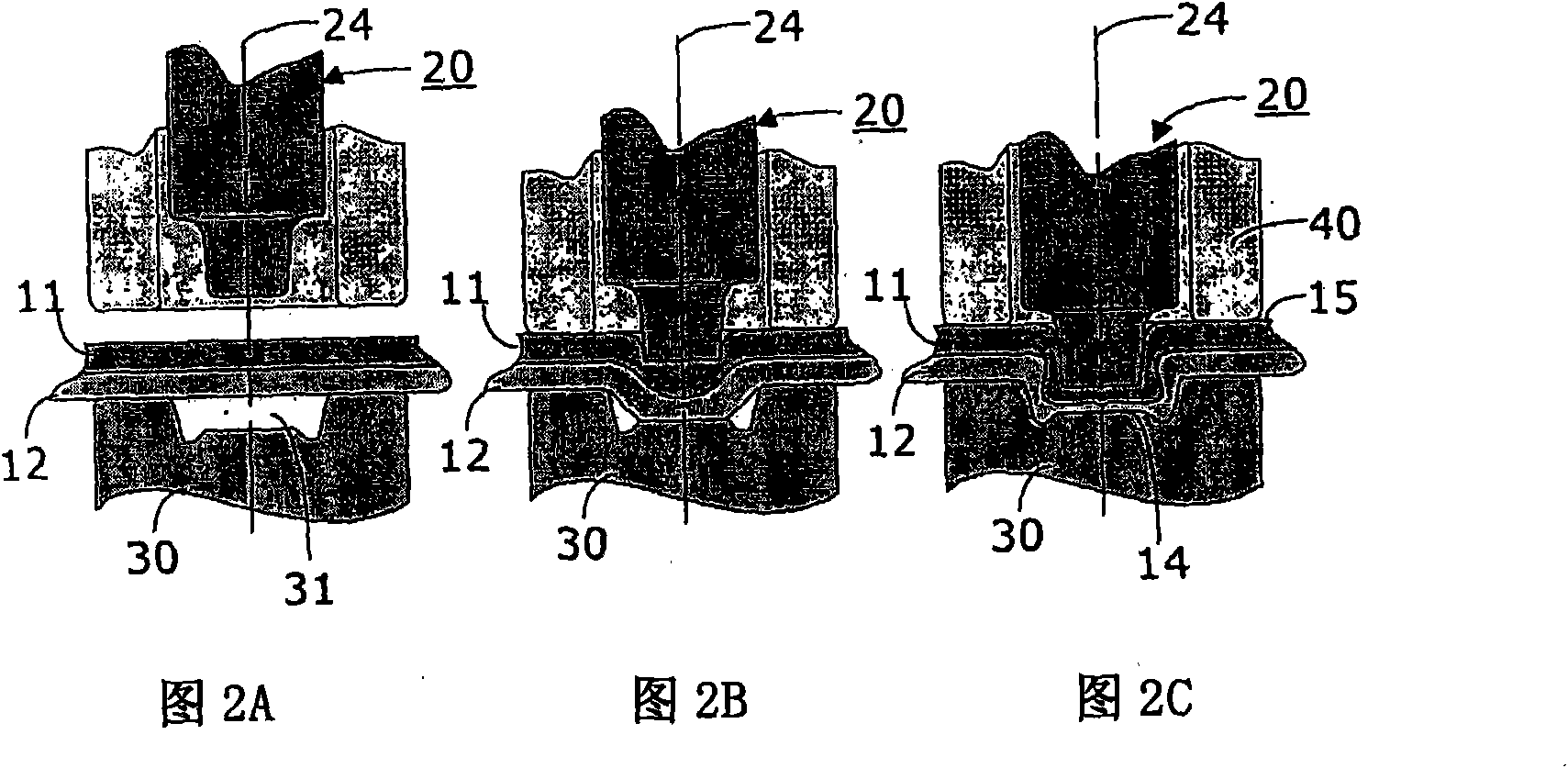

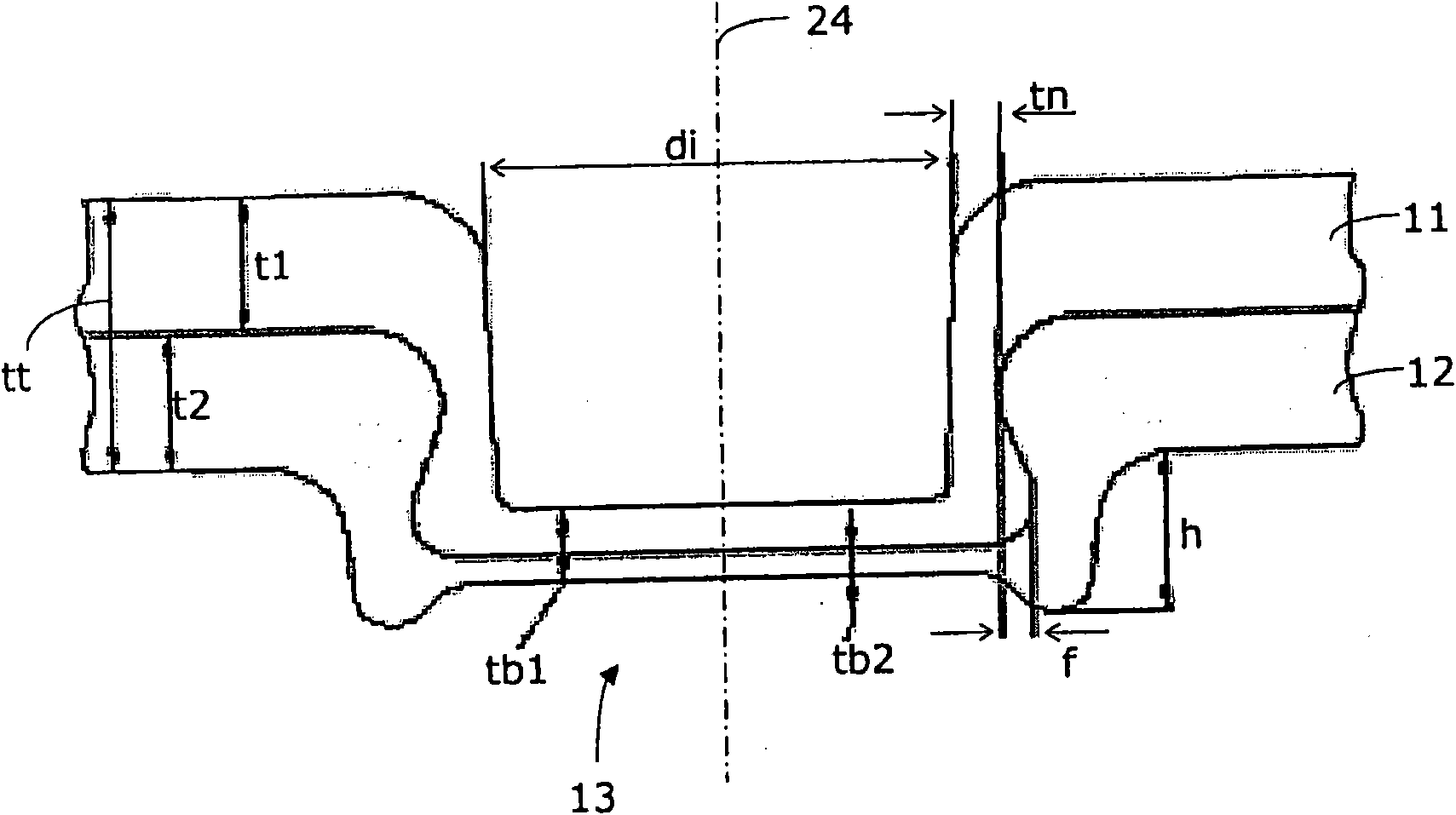

Method for clinching thick metal workpieces, use of a clinching tool, and steel structural element produced accordingly

InactiveCN101610860AGood support characteristicsImprove self-sustainabilitySheet joiningEscalatorsRotational axisTransitional Region

The invention relates to a method for the production of a load-bearing structural steel connection, wherein a clinching connection (13) is formed by means of a male die (20) and a female die (30) using local deformation, the connection connecting a first metal workpiece (6.1, 6.2) to a second metal workpiece (6.3, 6.4). For this purpose, the first metal workpiece (6.1, 6.2) and the second metal workpiece (6.3, 6.4) are first placed on top of each other on a processing surface of the female die and aligned. Subsequently the die of the male die is applied and lowered into the two metal workpieces (6.1, 6.2; 6.3, 6.4) placed on top of each other until the clinching connection (13) has been formed by plastic deformation. The first metal workpiece (6.1, 6.2) has a first workpiece thickness (tl), and the second metal workpiece (6.3, 6.4) has a second workpiece thickness (t2) that together result in a total workpiece thickness (tt), which is greater than 8 mm. The die is configured in a rotationally symmetrical manner with regard to the rotational axis (24) thereof and has a conically shaped transitional region (21, 22) tapering at an angle (W, W1, W2) in the lowering direction of the die.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Junction terminal structure of transverse high-voltage power semiconductor device

ActiveCN103928528AReduce the impact of withstand voltageGuaranteed withstand voltageSemiconductor devicesPower semiconductor deviceTransitional Region

The invention relates to the technical field of semiconductor power devices, in particular to a junction terminal structure of a transverse high-voltage power semiconductor device. According to the junction terminal structure, by reducing the total area of a P-type substrate and an N-type shift region, at the position of a curvature junction terminal, of the device, the device is prevented from being used up in advance in the region of the P-type substrate, and the withstand voltage of the device at the position of the curvature junction terminal is guaranteed. The junction terminal structure of the transverse high-voltage power semiconductor device has the advantages that the influences on the withstand voltage of the whole device from the curvature junction terminal can be obviously reduced, the electric field, in a transitional region, of the device cannot be too high, the withstand voltage of the device is optimized by changing the area of the shift region or the area of the P-type substrate, and the withstand voltage of the device is guaranteed accordingly. The junction terminal structure of the transverse high-voltage power semiconductor device is particularly suitable for junction structures of transverse high-voltage semiconductor devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

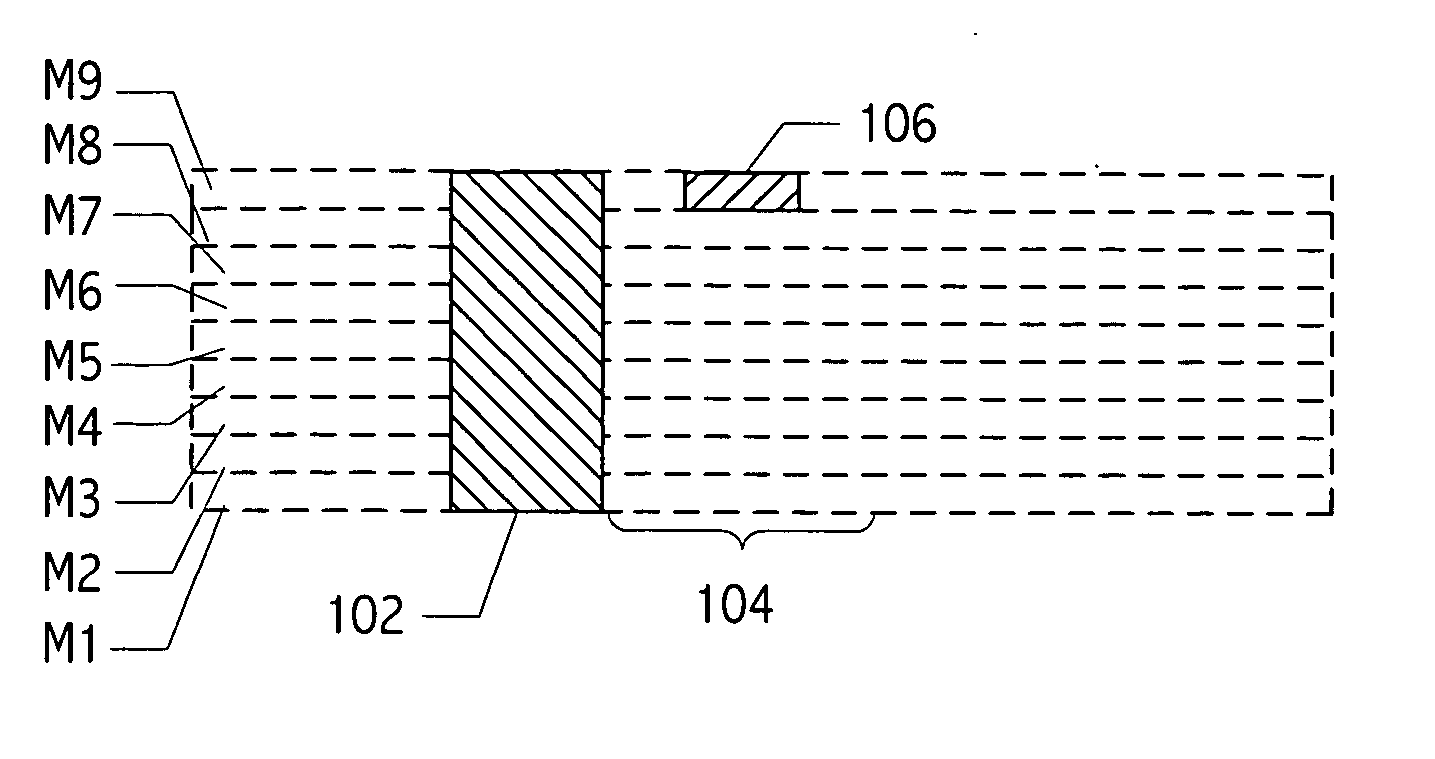

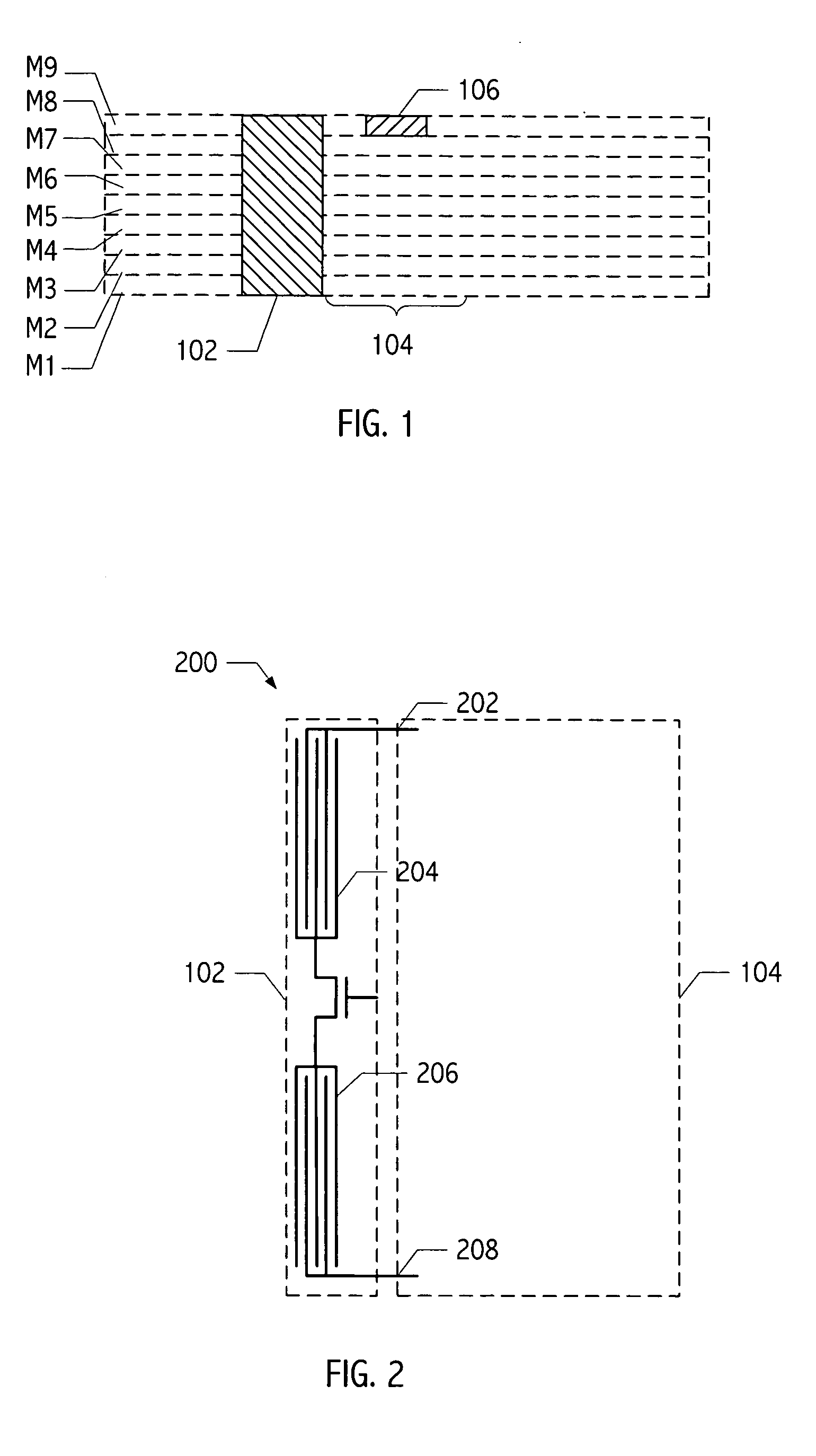

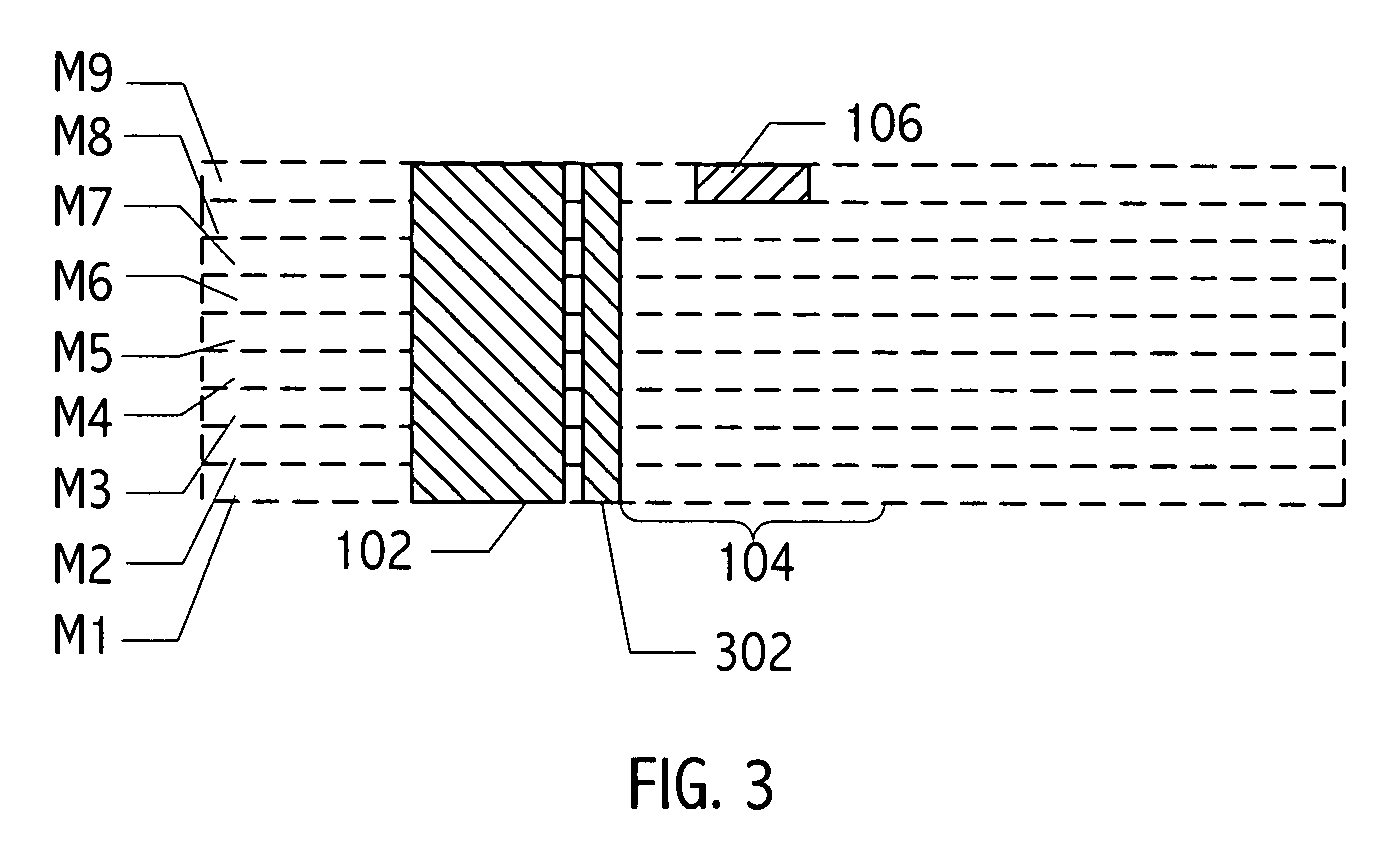

Method and structure for forming relatively dense conductive layers

ActiveUS20050269668A1Reduce manufacturing defectsNegligible amountSemiconductor/solid-state device detailsSolid-state devicesTransitional RegionInductor

A region of high metal density may be placed in metal layers proximate to an area of low metal density below an inductor on an integrated circuit without violating manufacturing design rules for reducing manufacturing defects and without substantially impacting performance of the inductor. These results are achieved by including a transitional region that includes conductive structures electrically isolated from each other between the region of high metal density and the region of low metal density. The transitional region has a structure that allows a negligible amount of current flow to be induced in the structure.

Owner:SILICON LAB INC

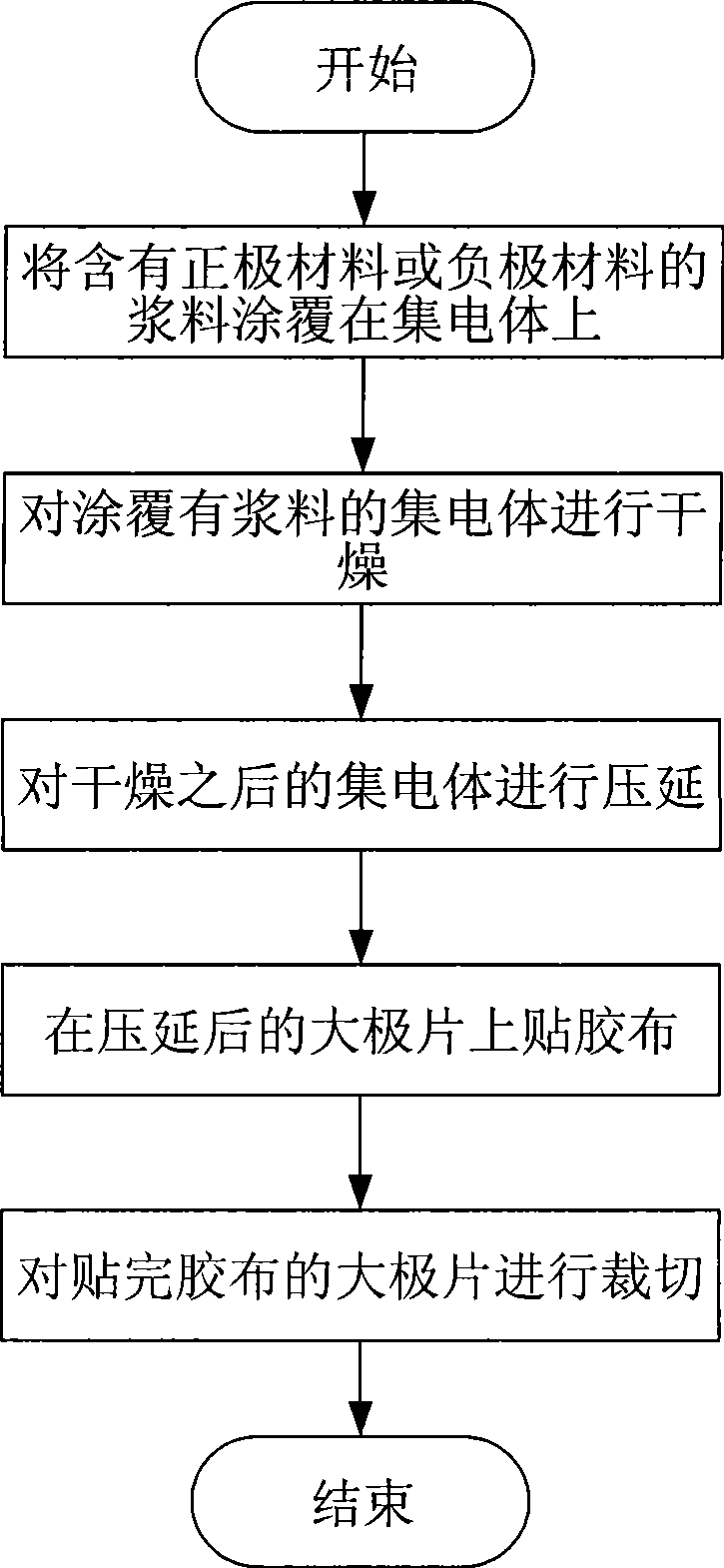

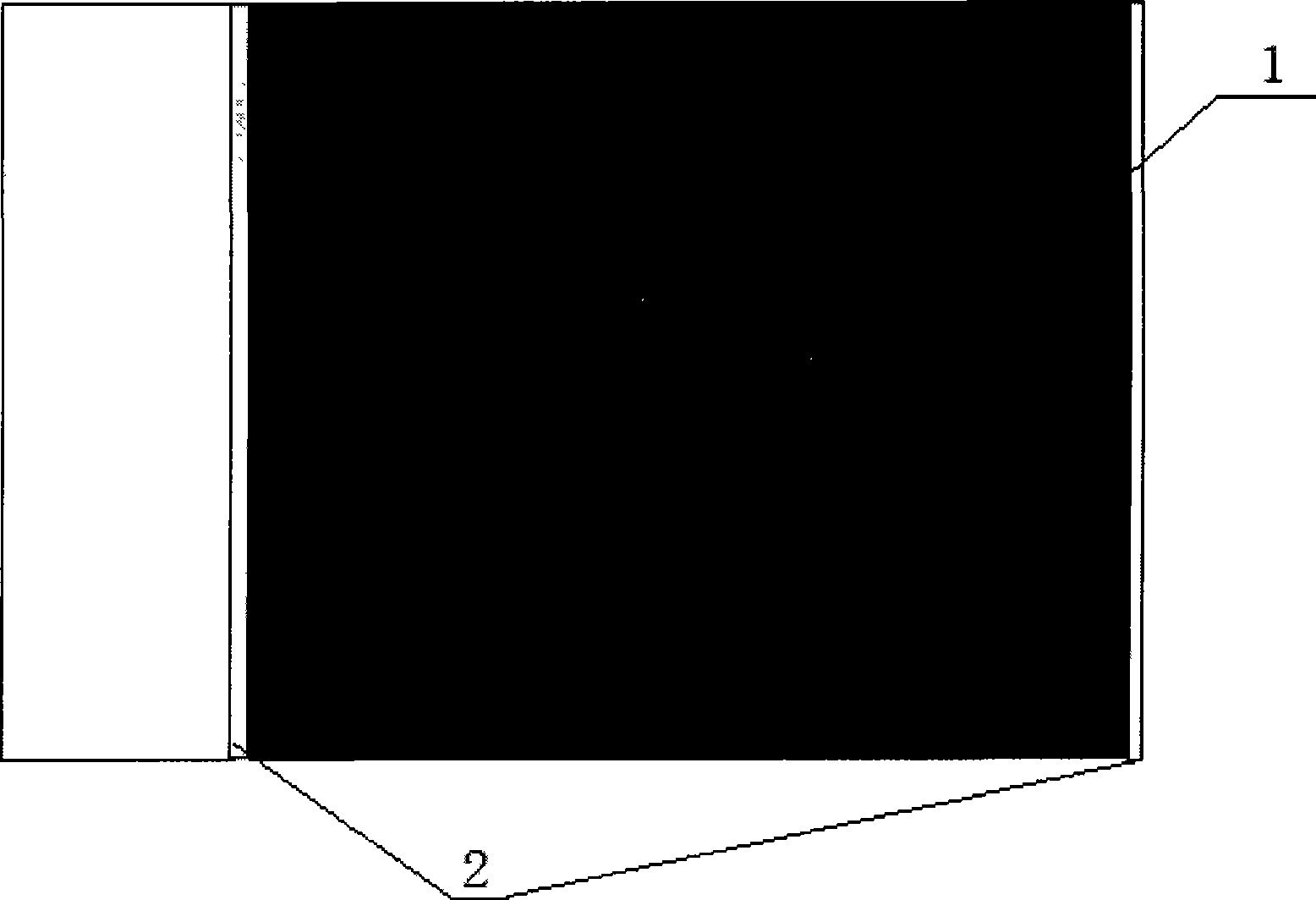

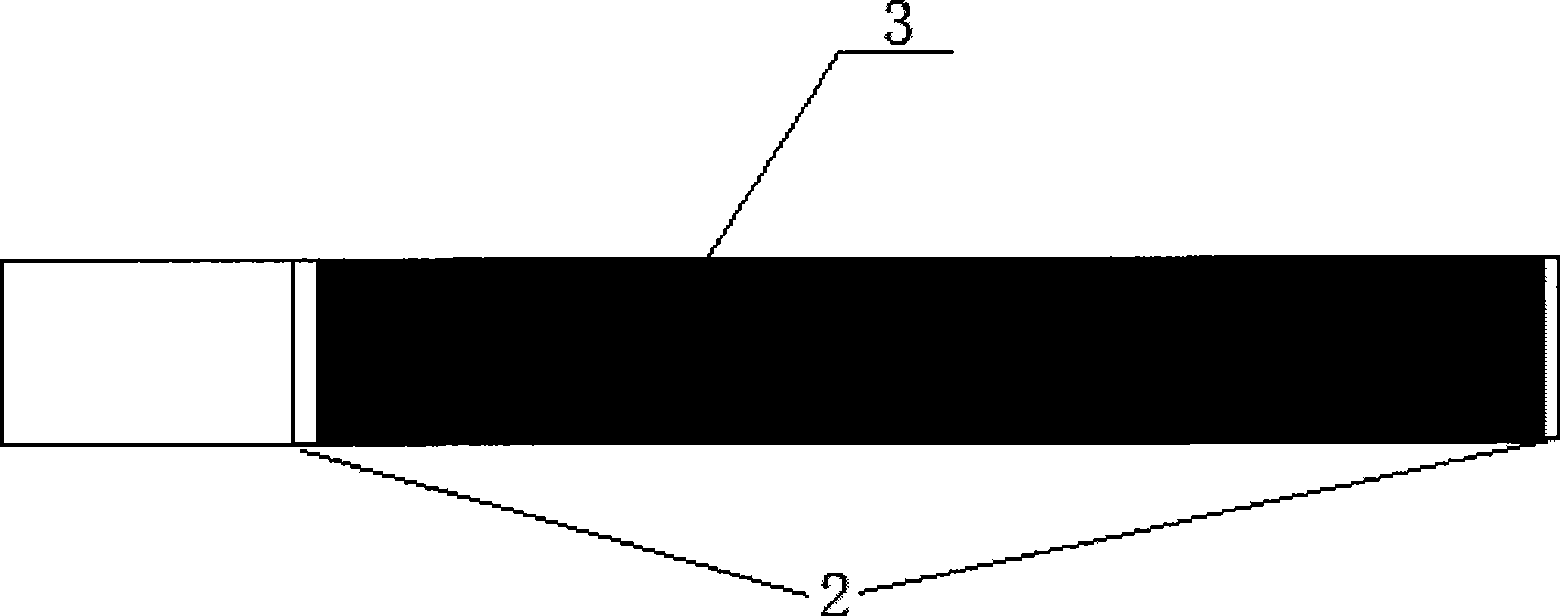

Preparation method for lithium ion battery pole piece

InactiveCN101442114AReduce workloadIncrease productivityElectrode manufacturing processesElectricityTransitional Region

The invention provides a method for preparing lithium-ion battery pole pieces. The method comprise the steps of coating an electricity gathering body with sizing agent containing anode material or cathode material, drying and calendering the electricity gathering body coated with the sizing agent, so as to prepare a big pole piece (1), wherein the method also comprises the steps of sticking adhesive tape (2) on a transitional region connected with a dressing area a non-dressing area on at least one end of the calendered big pole piece (1) and cutting the big pole piece (1) along the direction perpendicular to the length direction of the adhesive tape (2), so as to prepare a pole piece (3). When the method is used to manufacture the lithium-ion battery pole pieces, the aim of sticking the adhesive tape on every cut pole piece can be achieved by sticking the adhesive tape only once, thereby reducing the workload of sticking the adhesive tape and improving production efficiency. In addition, the method has the advantage of improving the uniformity and consistency of the adhesive tape on the prepared pole pieces.

Owner:海宁市盐官工业投资有限公司

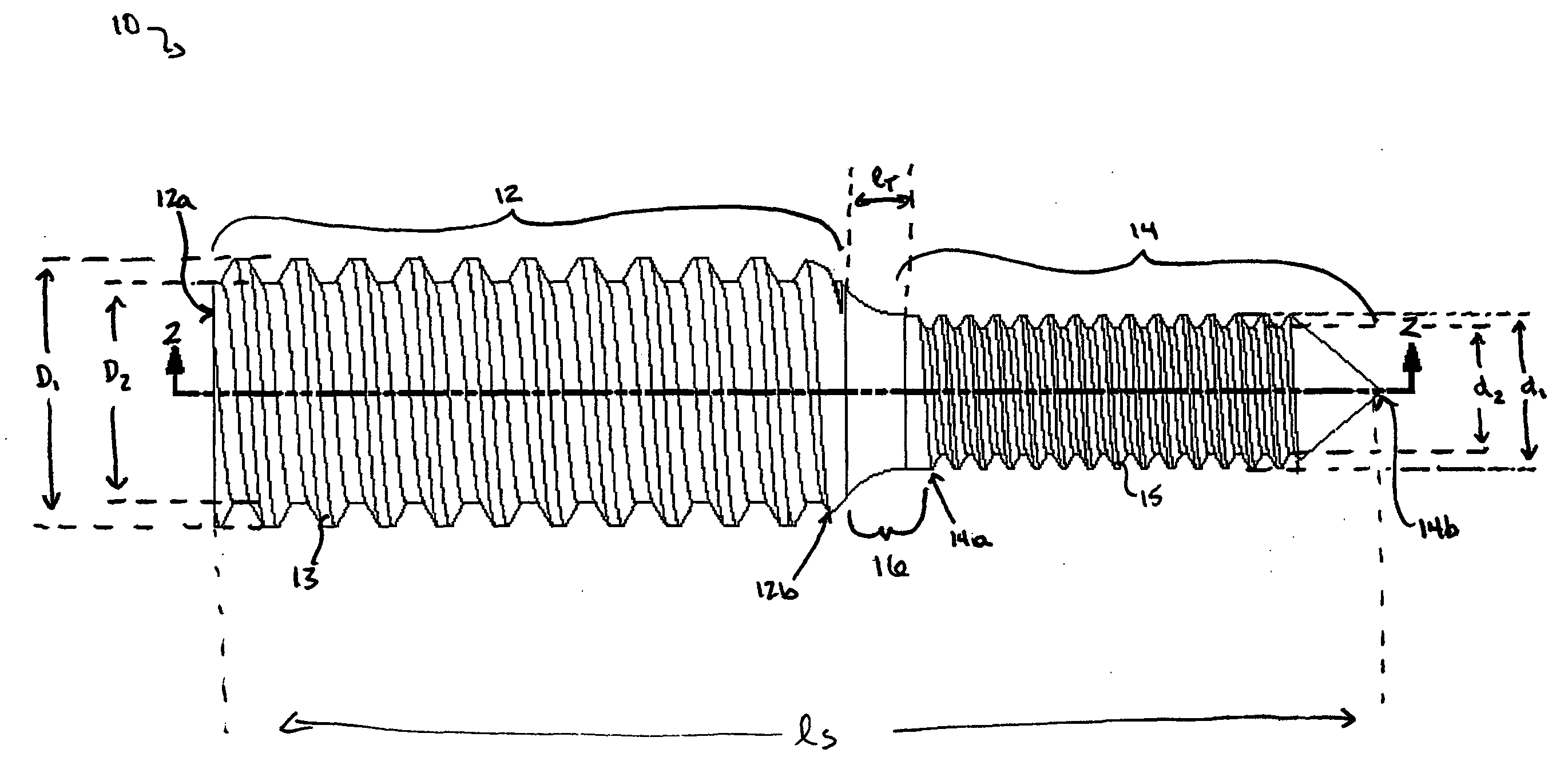

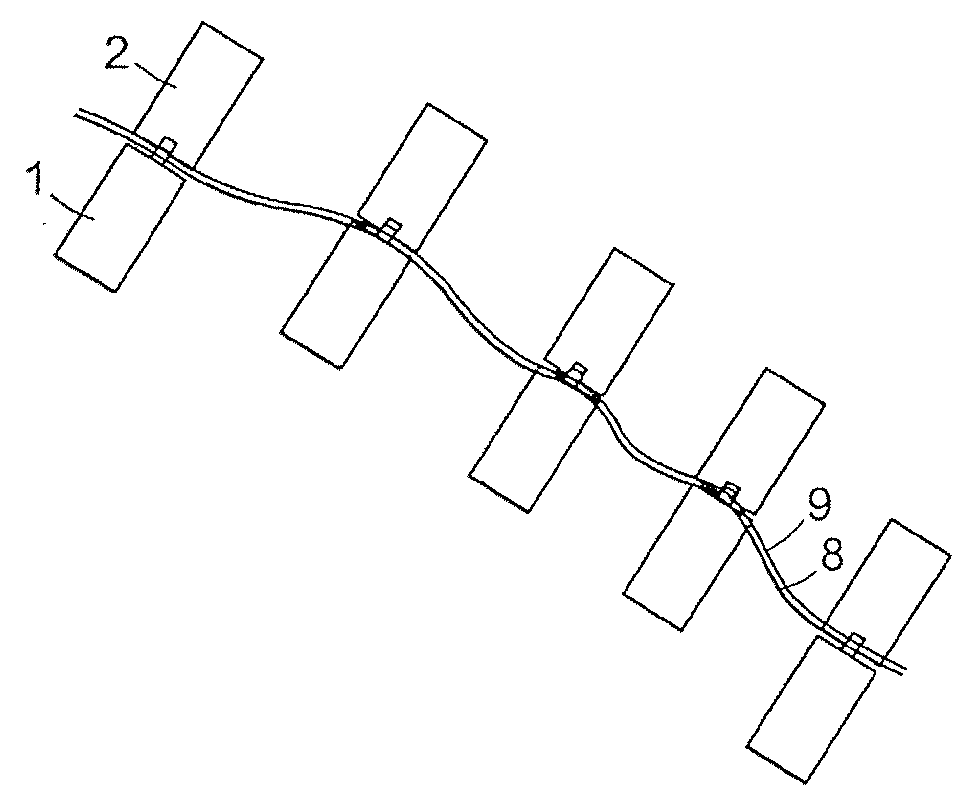

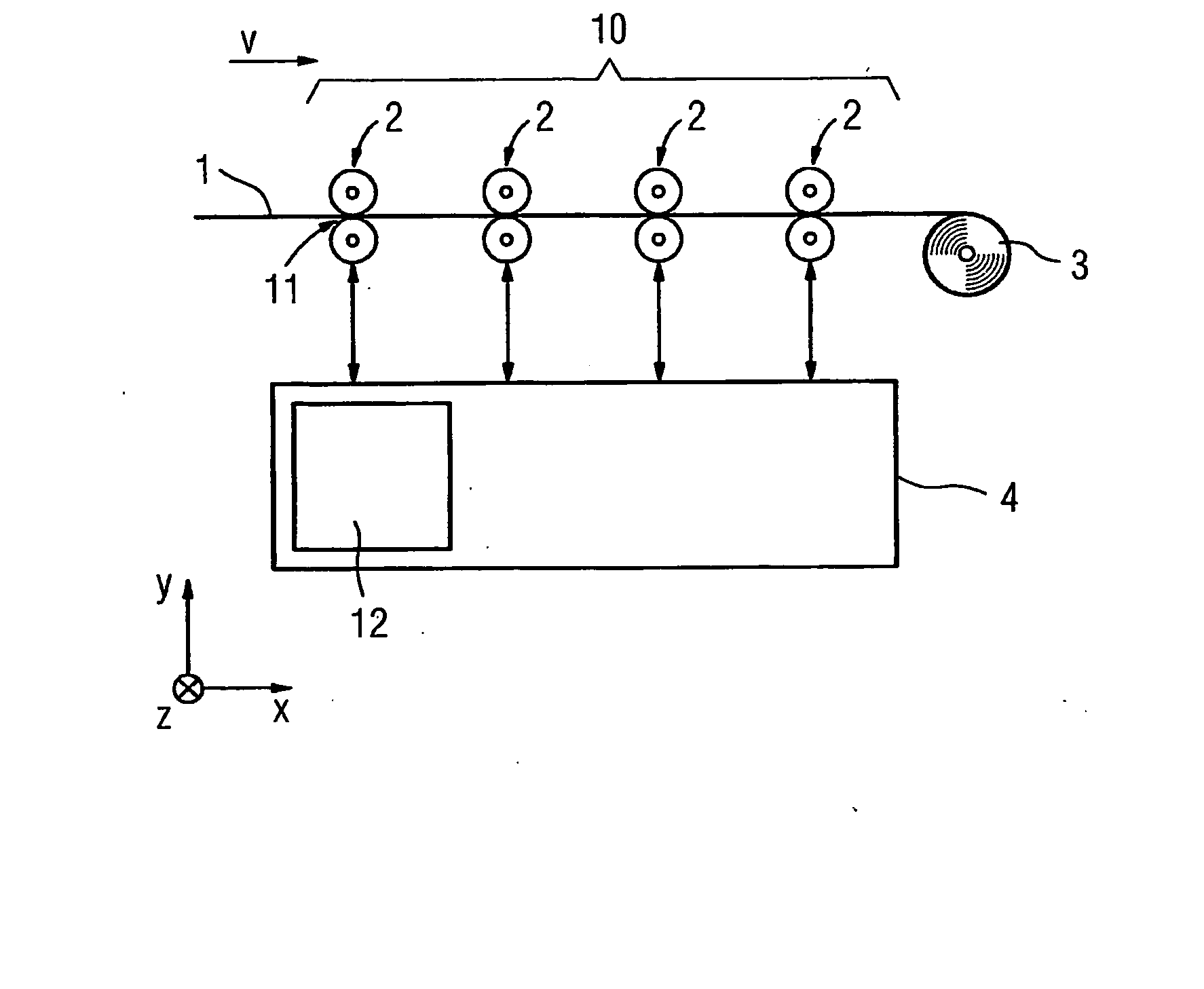

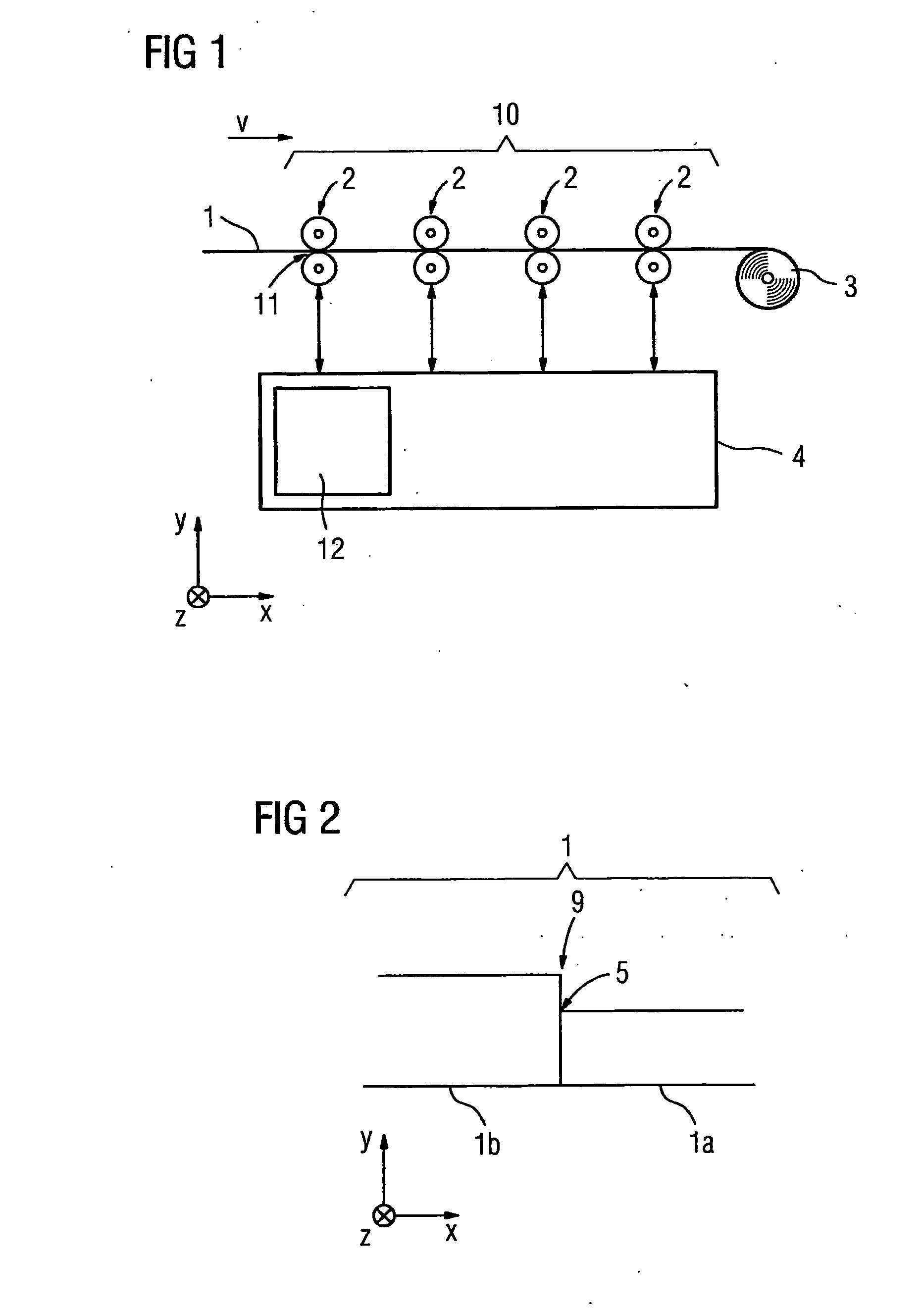

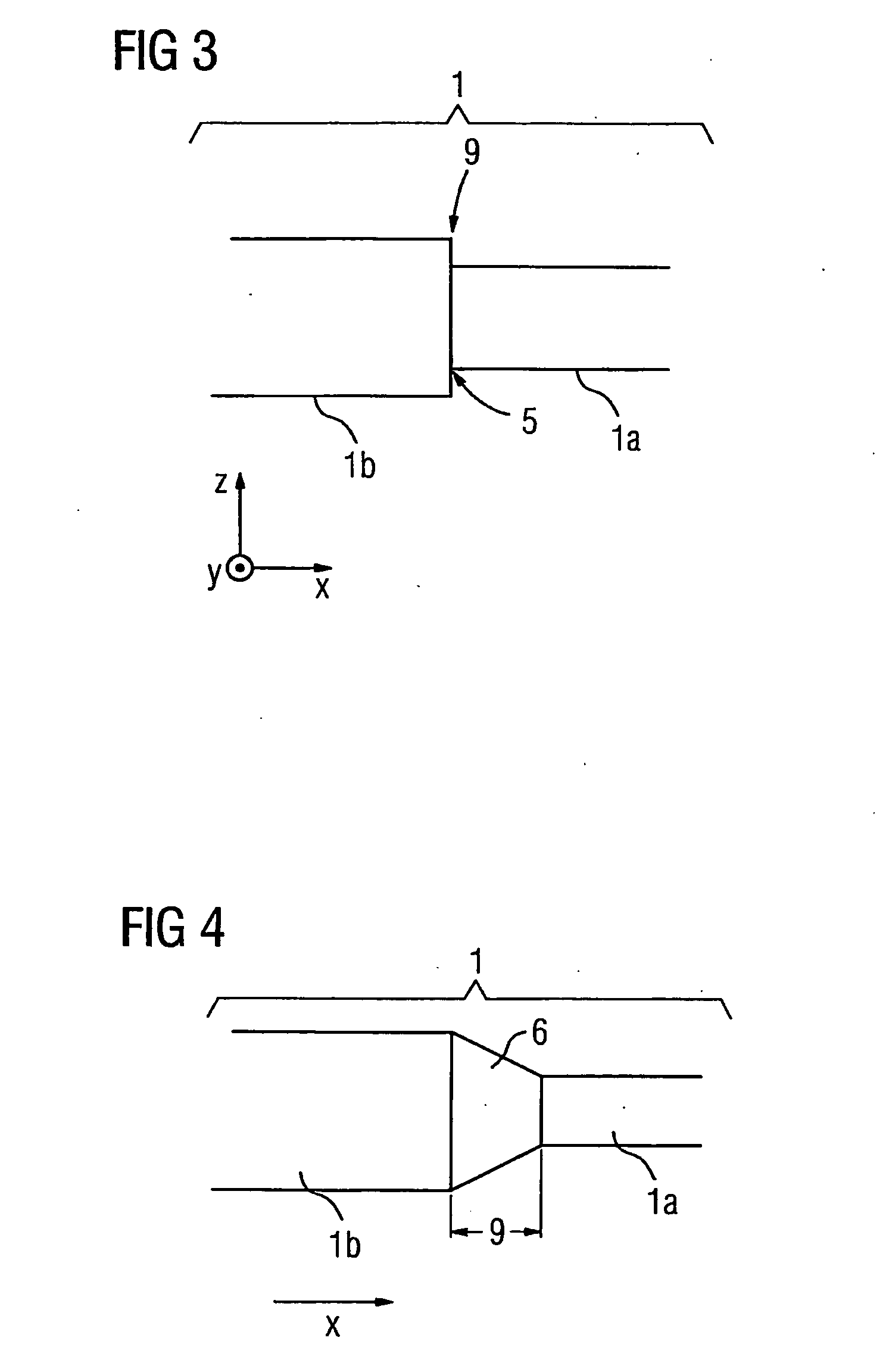

Method for Rolling Rolling Stock Having a Transitional Region

InactiveUS20080060403A1Avoid disadvantagesRoll force/gap control deviceWork manipulationCritical transitionTransitional Region

The invention relates to a method for rolling a product in a rolling train comprising at least two roll stands having a roll gap, the product to be rolled comprising a transition region. If a critical transition region crosses the rolling train, the roll gaps of the roll stands are successively opened and closed according to the position of the transition region moving at speed through the rolling train, in the direction of the direction of travel of the conveyor. The opening of the roll gaps occurs parallel to the position of the critical transition region when the product is displaced. A transition region is critical when the structure requires the roll gaps to be opened. The inventive opening of the roll gaps, when the device is moving, enables the controlled transition of a product to be rolled with extreme variations in dimensions and / or hardness, for a shorter length.

Owner:SIEMENS AG

Flexible seating surface

ActiveUS20130257125A1Relieve pressureBeneficial support characteristicStoolsAdjustable chairsThighDistal portion

A seat has a first ischial region, a second ischial region, a tailbone region and a thigh transitional region, each having at least one slot. Each slot generally opens outward, away from a center of the seat. Each slot may have an elongated central portion and two distal portions extending from the central portion. The central portion and distal portions may be substantially linear and may have a specific configuration relative to each other to provide desired support characteristics. The slots may allow flexing and cantilevering of portions of the seat to dynamically contour the seat based on the weight of the user. Multiple grooves may be included at the front of the seat to facilitate curling of the front of the seat.

Owner:HAWORTH SPA

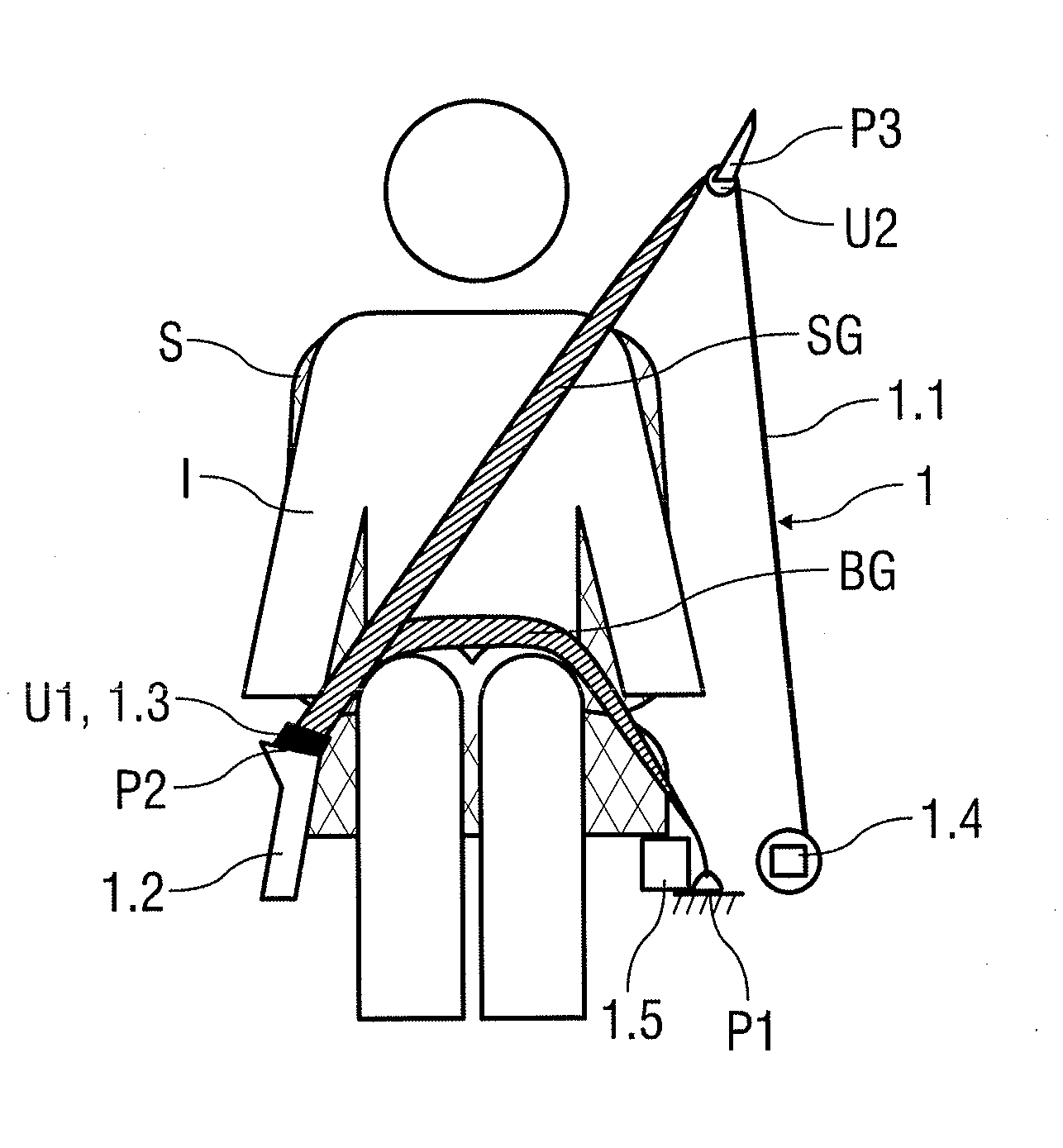

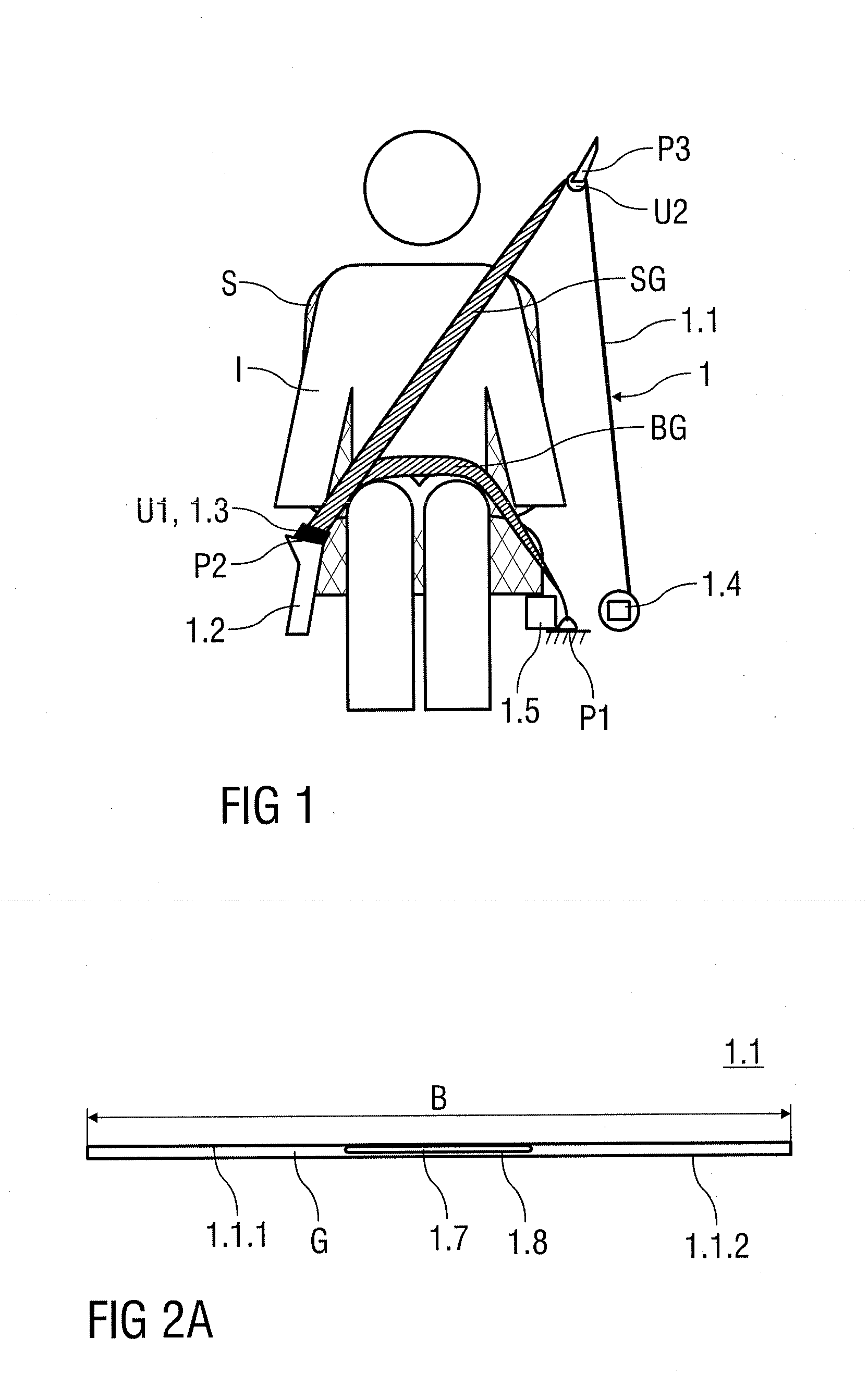

Safety Belt for a Vehicle

ActiveUS20130134695A1Upper pointMinimizes gas quantityPedestrian/occupant safety arrangementVehicle safety beltsSeat beltBand shape

A seat belt for a vehicle includes a belt webbing with several belt webbing layers and, in a shoulder belt region and a lap belt region, a belt interior located between at least two belt webbing layers to which a gas can be applied. The belt webbing is routed through an opening of a latch plate which is insertable into a buckle, by means of which latch plate the belt webbing is, if the seat belt is fastened, deflected at a lower deflection point in a transitional region from the lap belt region to the shoulder belt region. A gas passage connecting at least two sections of the belt interior is provided at the lower deflection point between the at least two belt webbing layers. The gas passage is a tube that is flexible at least in the radial direction. The flexible tube is plastically or elastically deformable.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com