Method for clinching thick metal workpieces, use of a clinching tool, and steel structural element produced accordingly

A technology for metal workpieces and steel structural parts, which is used for riveting thick metal workpieces, can solve the problems of inability to rivete metal plates and other metal workpieces, and achieve the effects of less joint cost, avoidance of distortion, and good support characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] As stated at the beginning of the description, the scope of the present application relates to riveting without cutouts. The form of riveting is a pure deformation joining process. The joining of the workpieces takes place exclusively by means of osmotic bonding sinking and subsequent compression. The basic idea behind the development of this method without cutting parts is firstly to seek an increase in the hardness of the connection caused by greater material cohesion.

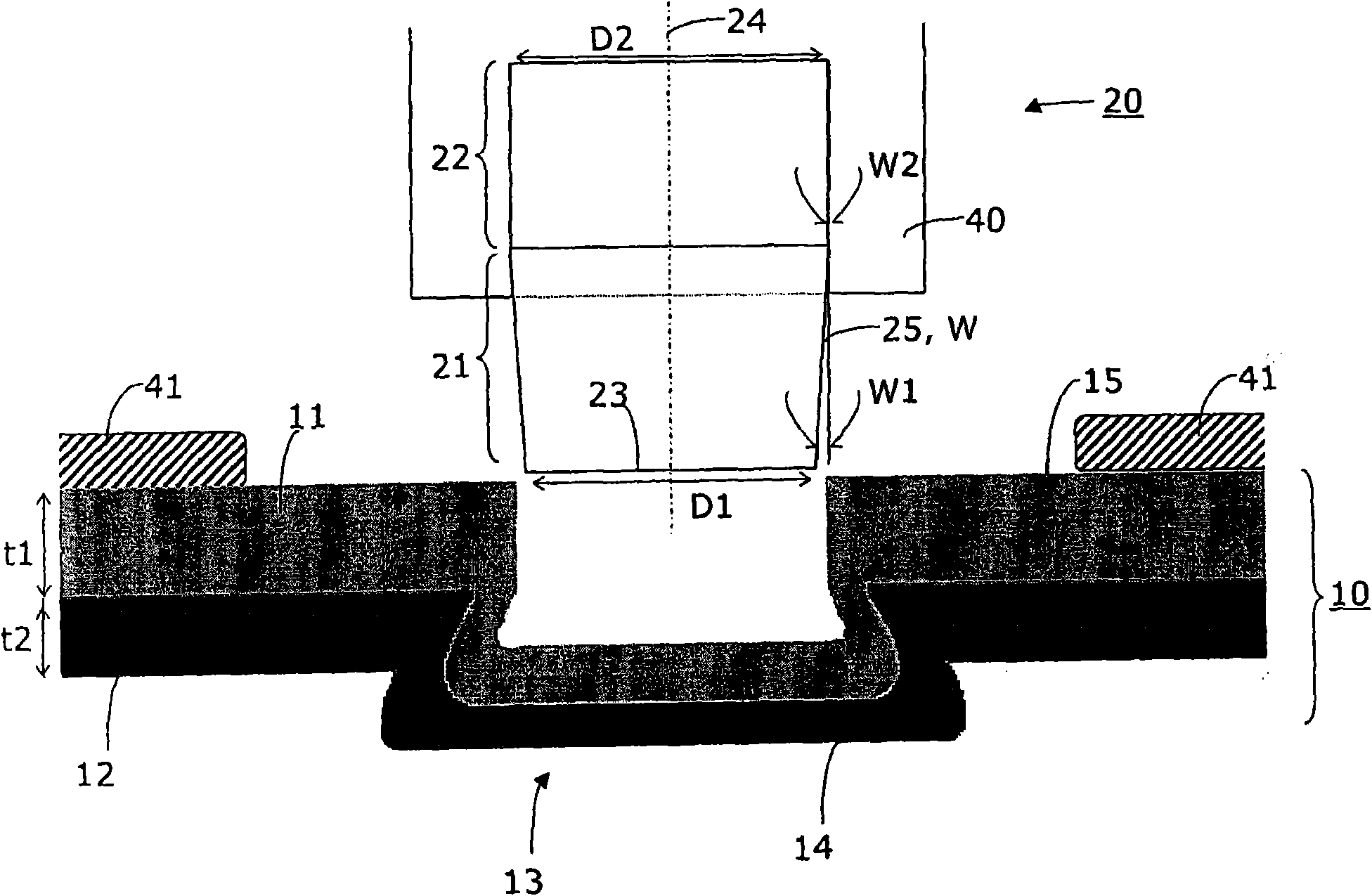

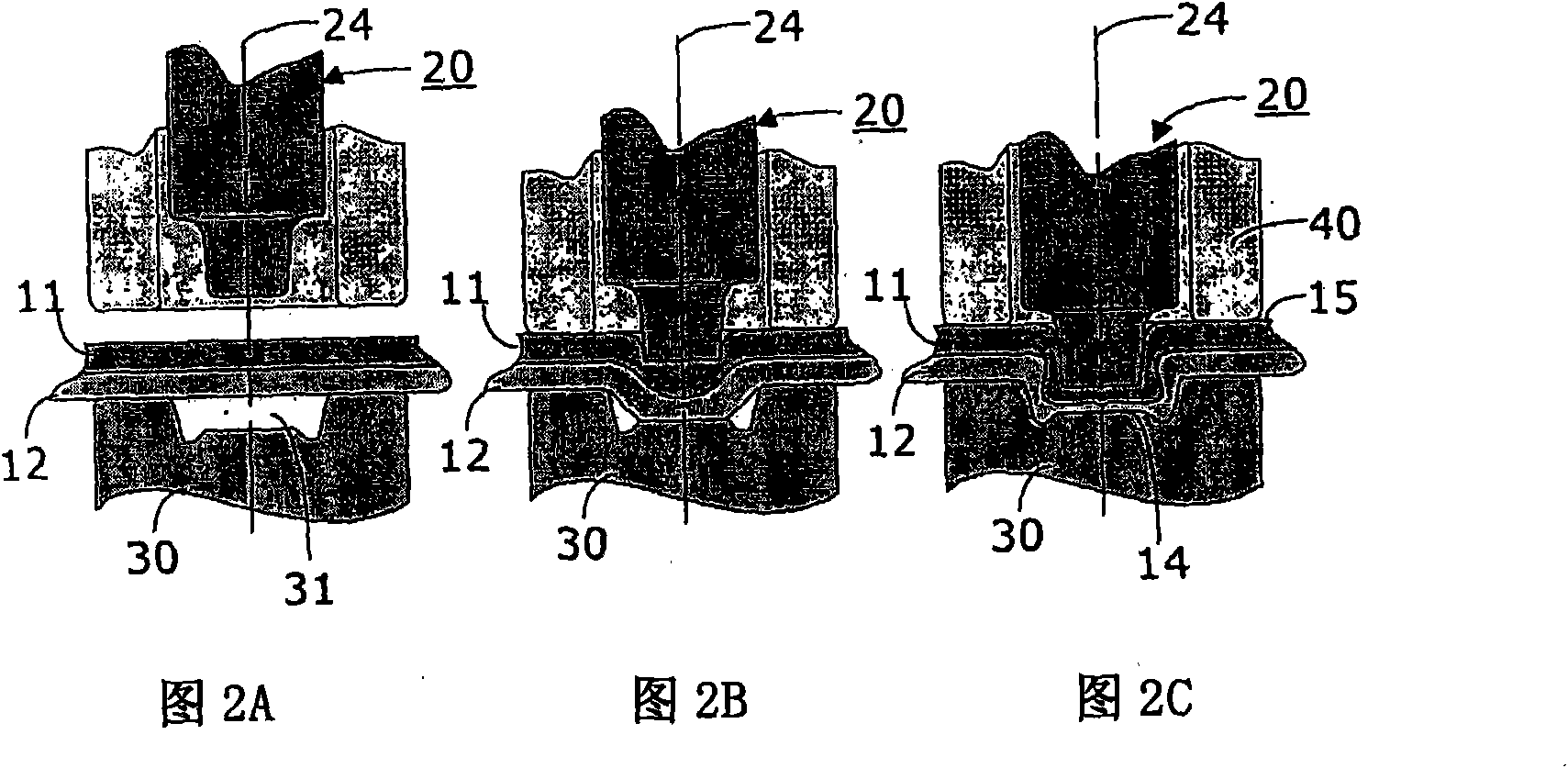

[0046] exist figure 1 The principle of the invention is only schematically shown in the diagram. The two metal workpieces 11 and 12 shown are connected to one another by means of riveting 13 . A part of the punch 20 , referred to here as the punch, is shown above the rivet 10 or the rivet point 10 .

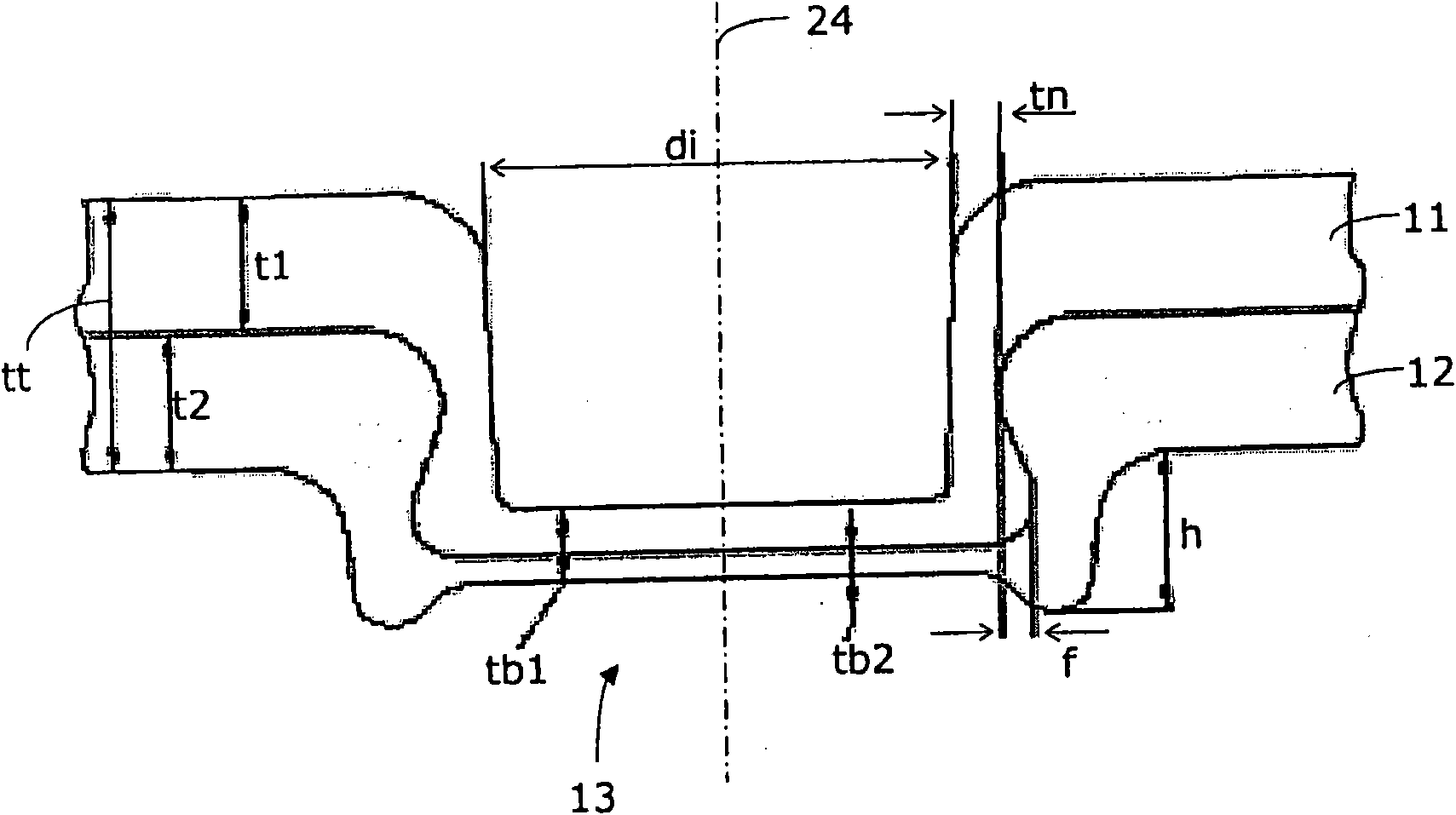

[0047] The riveting tool 20 comprises a punch and a collapsing tool 30 which can be designed as a die or an anvil. The punch is designed rotationally symmetrically with respect to its axis of rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com