Thread and screwed assembly used as high temperatures

A threaded connection and threaded technology, which is applied in the direction of connections, connecting components, threaded fasteners, etc., can solve the problems that the tightening force cannot be transmitted to the threaded connection, cannot reliably withstand the pre-tightening force, etc., and achieve the effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The same reference numerals have the same meaning in all figures.

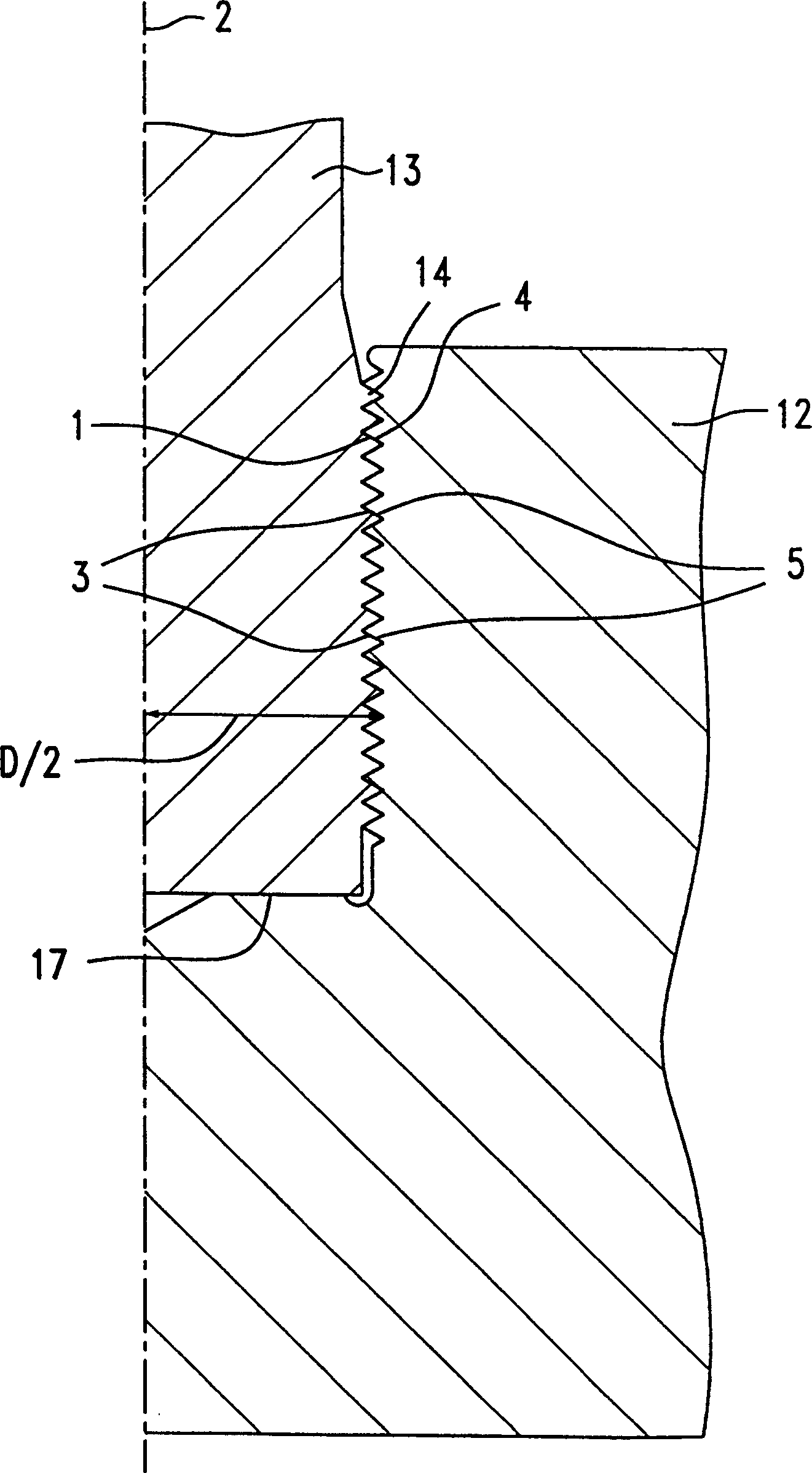

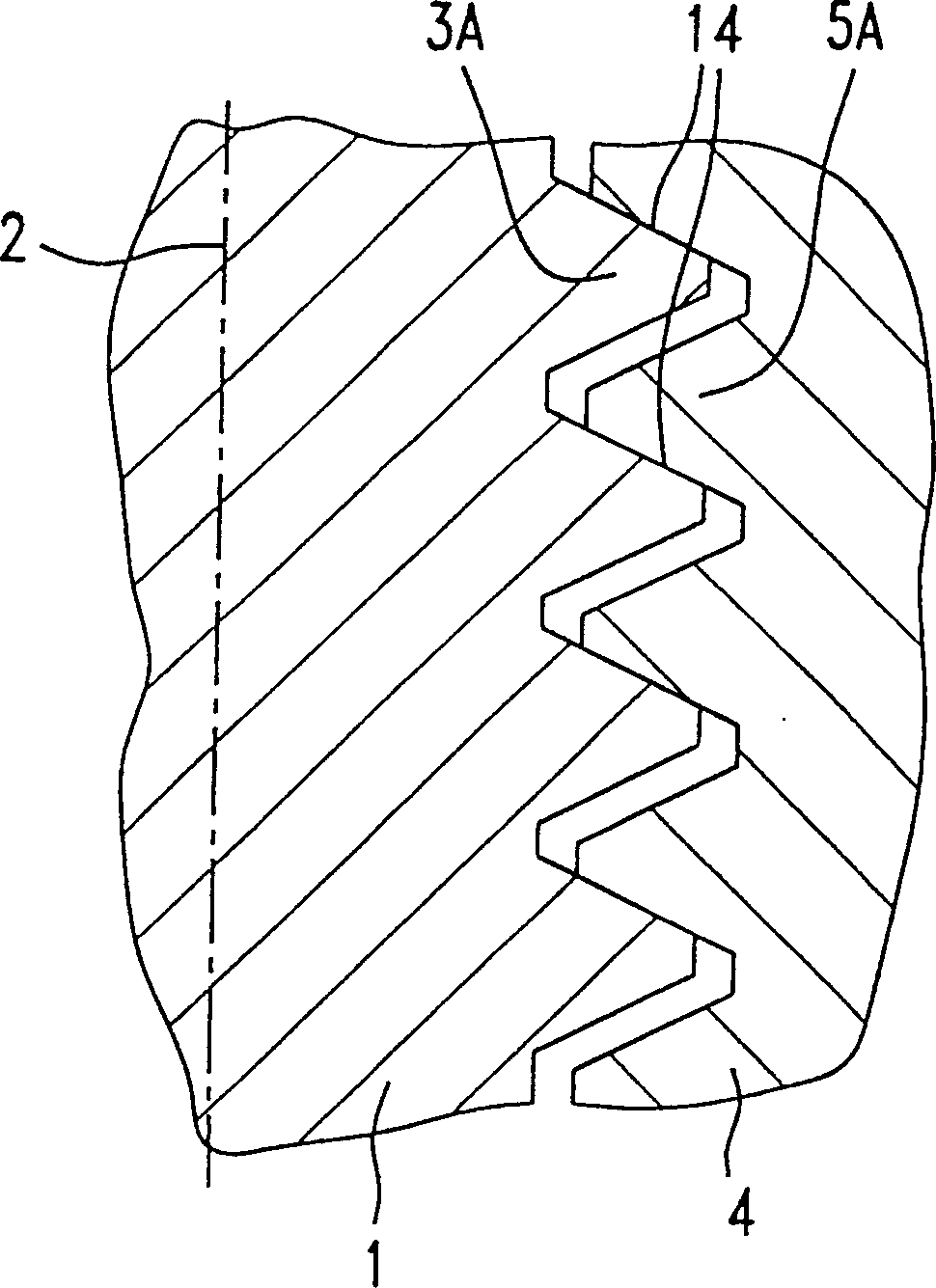

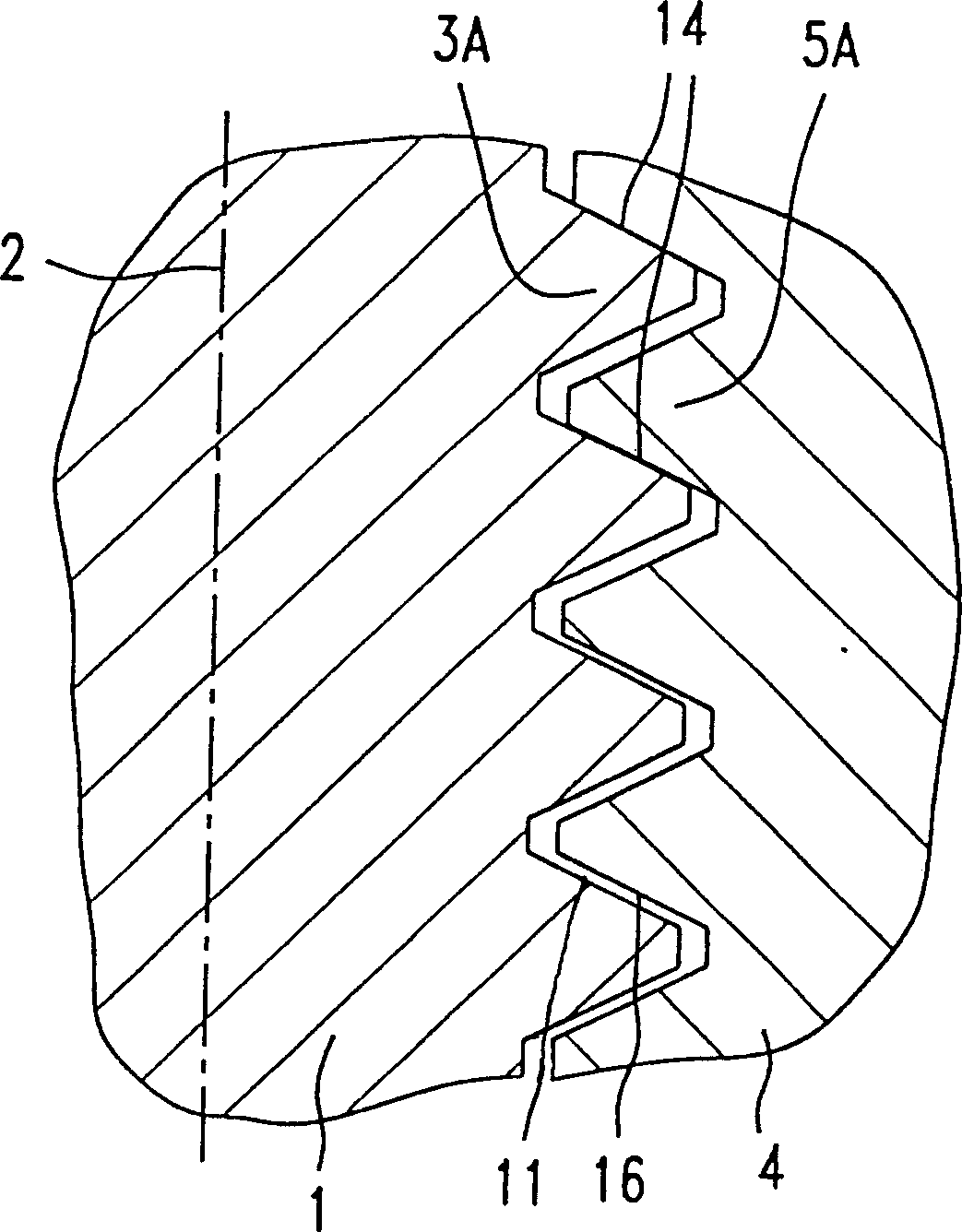

[0034] figure 1 A longitudinal section through the screw connection in the steam turbine flange 12, not shown, is shown. The flange 12 has a mating thread 4 designed as a female thread. A screw 13 extending along the thread axis 2 is screwed into the counter thread 4 (nut thread 4 ). The screw 13 has a thread 1 designed as a screw thread, which engages in a nut thread 4 . The bolt thread 1 has a thread structure 3, and the nut thread 4 has a matching thread structure 5. Due to the rotational symmetry of the screw 13 with respect to the thread axis 2 , only half of the longitudinal section of the screw 13 is shown. The screw 13 has an end face 17 perpendicular to the thread axis 2, and the screw 13 is screwed into the flange 12 as far as it will go. From here on, the area of the bolt 13 protruding from the female thread 4 of the flange 12 is designated as the engagement initiation area 14 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com