Functional component for a motor vehicle, method for producing the functional component, and motor vehicle comprising the functional component

一种功能构件、机动车的技术,应用在由塑性材料制造的弹簧、家用元件、旋转运动的轴承等方向,能够解决复杂制造方法、联接元件复杂结构、高自重等问题,达到好锚固的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

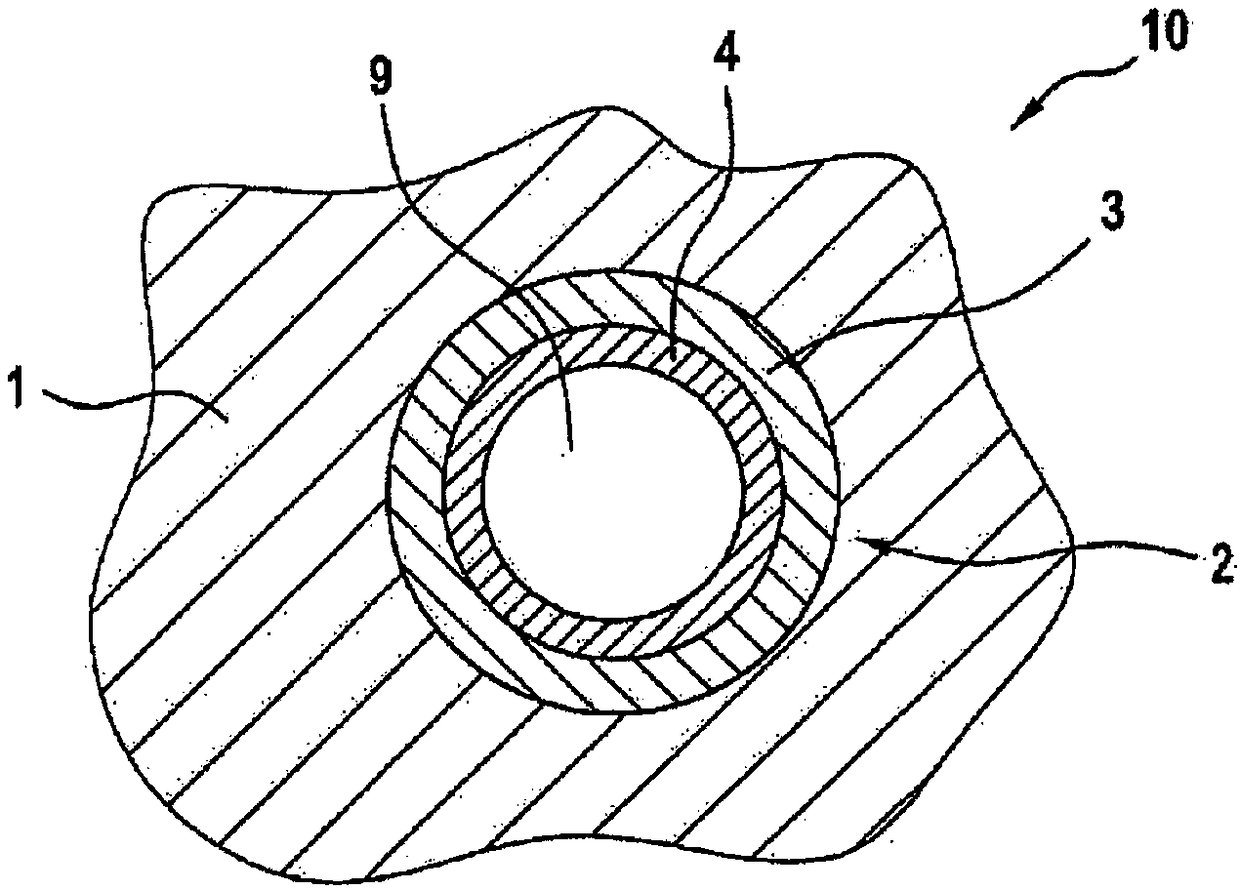

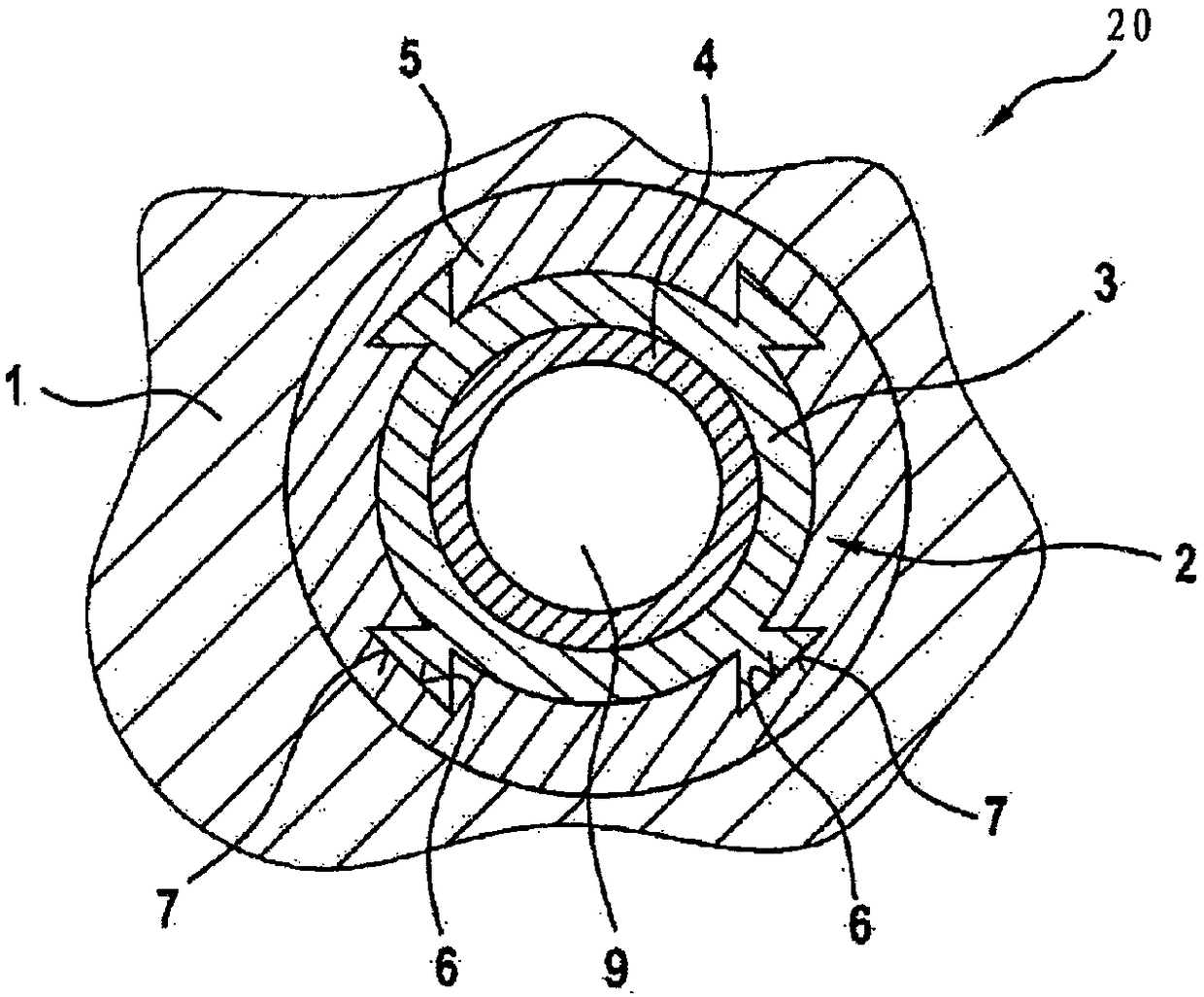

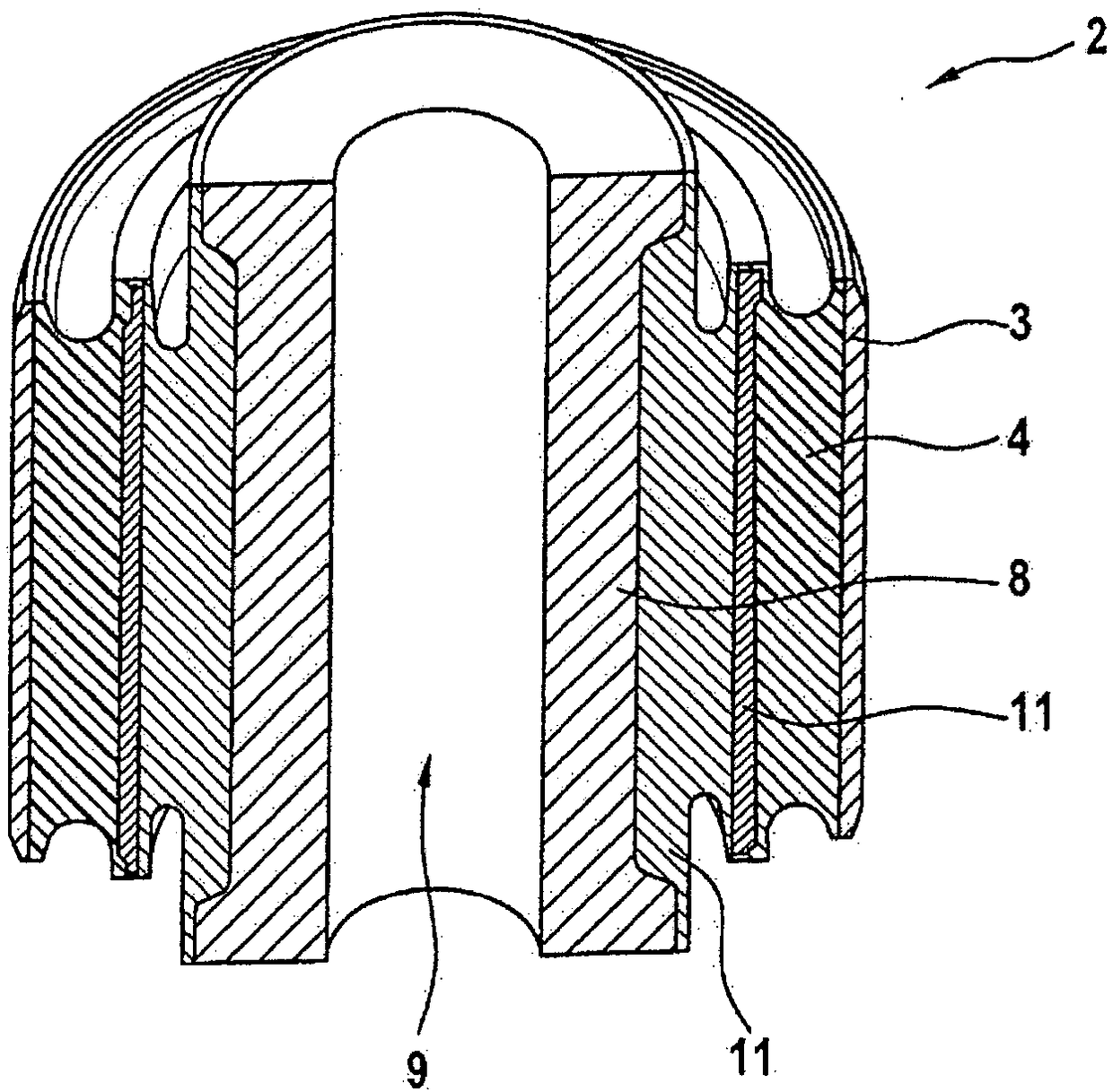

[0050] In the figures, only the rubber bearings and the relevant parts of the functional components are shown, all other elements have been omitted for the sake of clarity. In addition, the same reference numerals denote the same components.

[0051] in particular, figure 1 A longitudinal section through a rubber bearing 2 is shown, which is suitable for producing the functional component according to the invention. The rubber bearing comprises an outer ring 3 which can be closed or, for example, also grooved, an inner layer 4 of rubber or rubber-like material and a bearing core 8, for example of metal material, the inner layer The layer covers the inner surface of the outer ring 3 at least in partial sections and preferably substantially completely. The bearing core 8 is arranged at least in sections on the inner side of the layer 4 of rubber or rubber-like material. Between the bearing core 8 and the layer 4 of rubber or rubber-like material there may be further layers wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com