Method for Rolling Rolling Stock Having a Transitional Region

a technology of transitional region and rolling stock, which is applied in the direction of tension/compression control device, roll mill control device, manufacturing tools, etc., can solve the problems of rolling stock splitting, substantial disruption of process variables,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

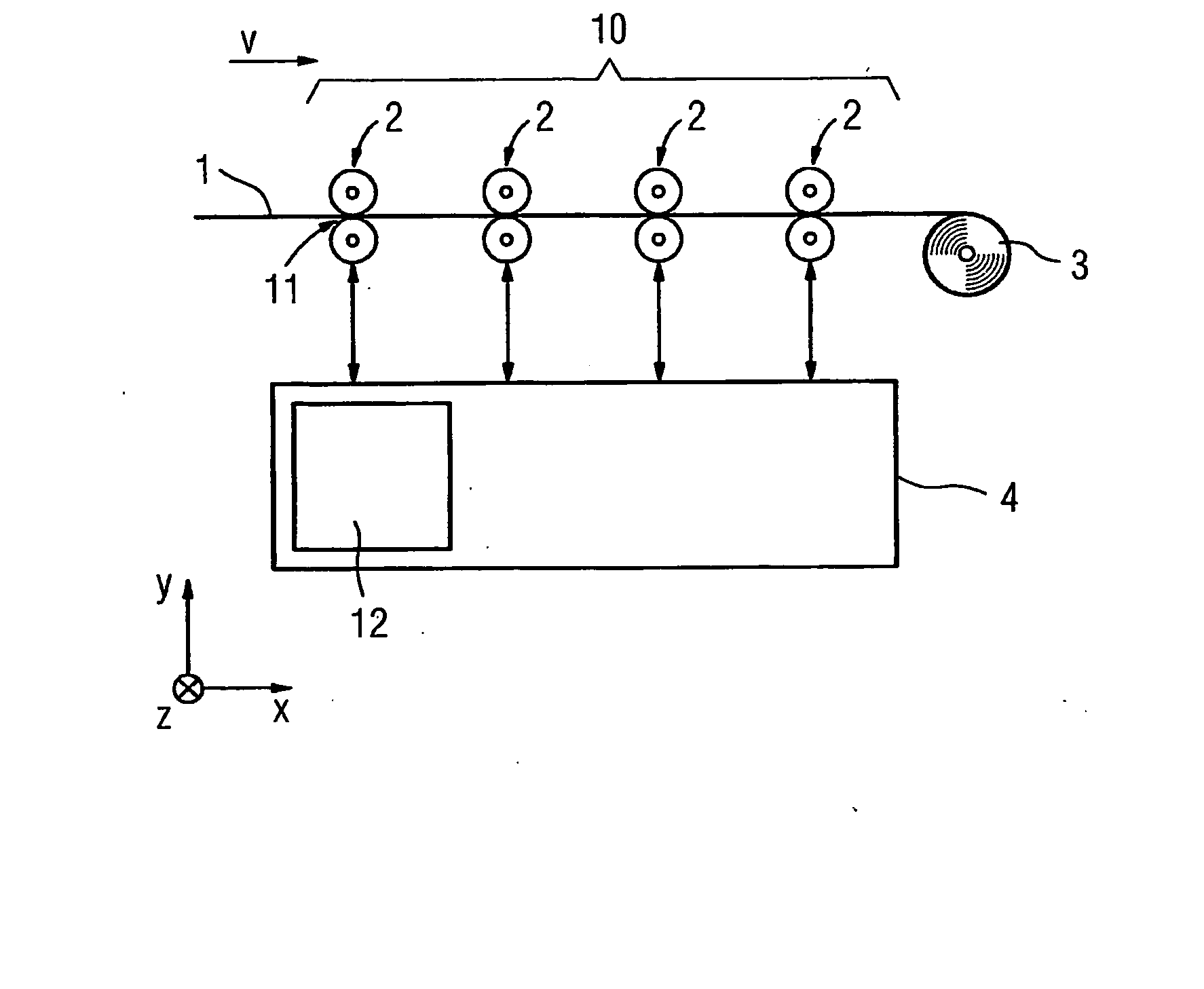

[0027]FIG. 1 shows a mill train 10 for rolling rolling stock 1 that moves through the mill train 10 at a speed v. The mill train 10 has at least two roll stands 2 which rolling stock 1 traverses. Rolling stock 1 traverses the mill train 10 in the direction of strip travel x. Rolling stock 1, preferably a metal strip, is continuously rolled in the mill train 10. The mill train 10 is preferably a cold-rolling mill train for steel having as a rule more than three roll stands 2. Located downstream of the roll stands 2 is a coiling device 3 on which the rolled rolling stock 1 is coiled.

[0028] The mill train 10, in particular the stands 2 of the mill train 10, is / are coupled to a computing device 4. Located in the mill train 10 are generators, not shown further in the drawing, which convey, for example, measuring signals to the computing device 4. The computing device 4 conveys preferably control signals to actuators in the mill train 10.

[0029] The computing device 4 preferably has a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com