Quick-response conical micro-nano optical fiber humidity sensor and preparation method thereof

A technology of humidity sensor and micro-nano optical fiber, which is applied in the field of environmental humidity measurement, can solve the problems of complicated manufacturing process and cannot meet ultra-fast response, etc., and achieve the effect of high-sensitivity humidity sensing, quick-response humidity sensing, and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

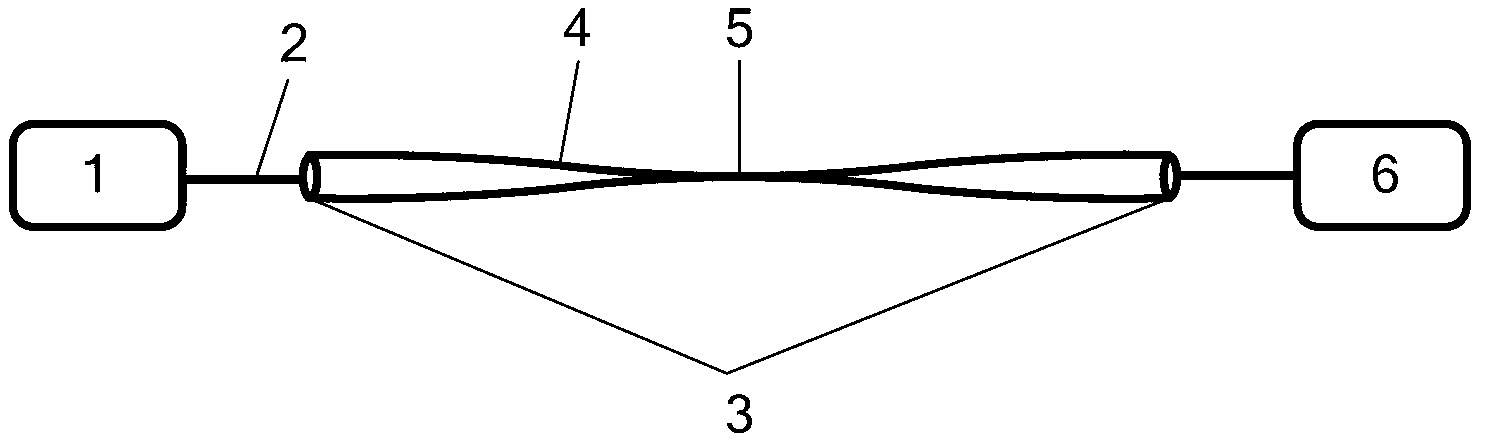

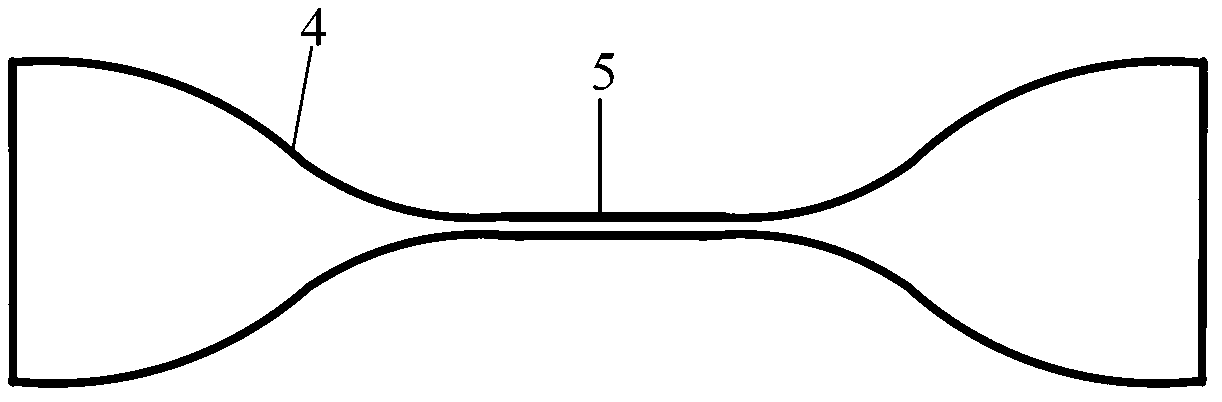

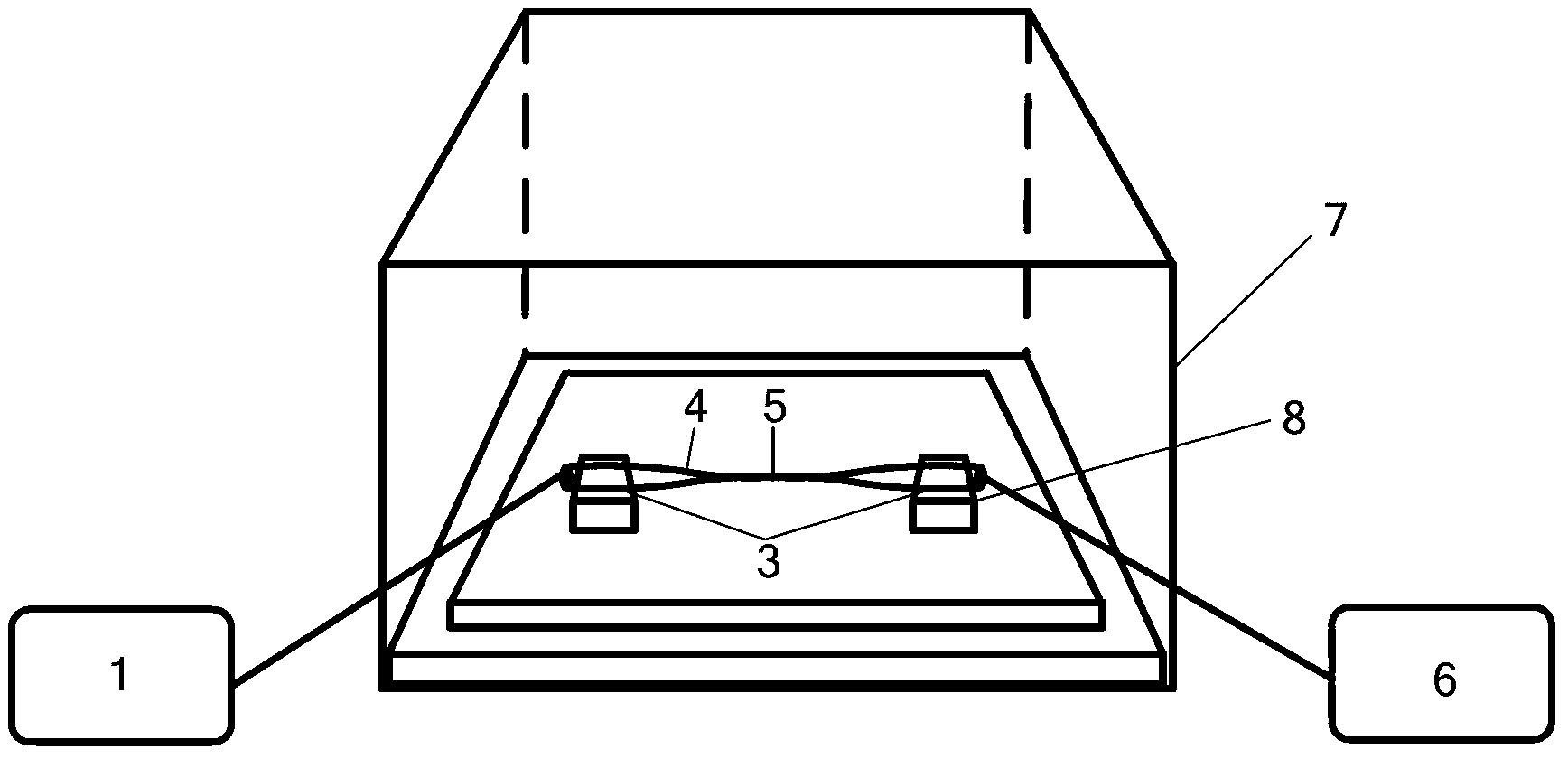

[0037] Such as figure 1 and figure 2 As shown, the tapered micro-nano optical fiber humidity sensor of this embodiment includes a broadband light source 1, a micro-nano optical fiber tapered structure 3 and a spectrum analyzer 6 connected in sequence, and the micro-nano optical fiber tapered structure 3 includes a tapered waist region 5 And two tapered transition regions 4 located at both ends of the tapered waist region, the two tapered transition regions 4 are respectively connected to the broadband light source 1 and the spectrum analyzer 6 through standard optical fibers 2 .

[0038] The micro-nano optical fiber tapered structure 3 is a structure made by using fusion tapering technology for double-clad optical fibers, and the double-clad optical fiber is sequentially composed of core, inner cladding, outer cladding and coating layer from inside to outside ; The core is made of highly germanium-doped quartz, the inner cladding is made of germanium and fluorine co-doped qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com