Filter cloth cleaning device

A cleaning device and filter cloth technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of increased maintenance cost and use cost, increased use cost of filter cloth replacement, and higher requirements for cleaning water quality, etc. Achieve the effect of reducing production and operation costs, prolonging service life, and not requiring high water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

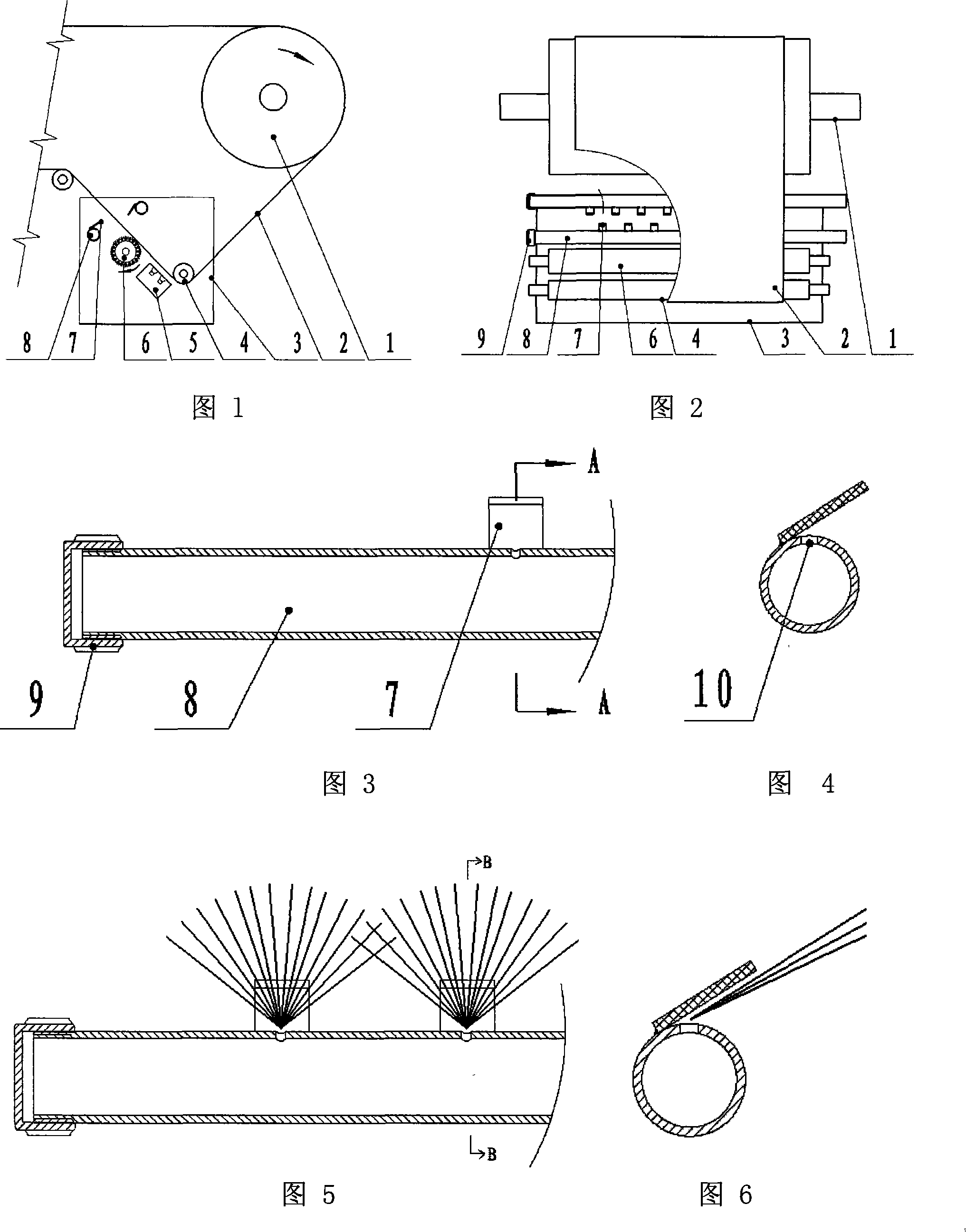

[0027] Referring to Fig. 1, Fig. 2, Fig. 3, and Fig. 4, the filter cloth cleaning device of this embodiment includes a driving roller 1, a filter cloth 2, a cleaning bucket 3, a redirection roller 4, a roller 6, and a water spray baffle 7 , Cleaning water pipe 8, movable plug 9, cleaning hole 10 components, filter cloth 2 is driven continuously by driving roller 1 to rotate continuously or indirectly, redirecting roller 4 plays the role of guiding and supporting the filter cloth, cleaning water pipe 8, water spray baffle 7 and the movable plug 9 form a filter cloth water cleaning device. The brush roller 6 rotates through a separate driving device, and relies on the bristles on the surface of the brush roller to clean off the materials attached to the surface of the filter cloth, so as to achieve efficient, clean and thorough cleaning of the filter cloth. For regeneration purposes, the cleaning bucket 3 plays the roles of storing and preventing liquid from splashing out.

[00...

Embodiment 2

[0032] Referring to Fig. 1, Fig. 2, Fig. 3, and Fig. 4, the filter cloth cleaning device of the present embodiment includes a driving roller 1, a filter cloth 2, a cleaning bucket 3, a redirecting roller 4, an ultrasonic cleaning device 5, and a water spray block Sheet 7, cleaning water pipe 8, movable plug 9, cleaning hole 10 components, filter cloth 2 is driven to rotate continuously through drive roller 1 indirectly or directly, redirecting roller 4 plays the role of guiding and supporting filter cloth, cleaning water pipe 8, spray water The baffle 7 and the movable plug 9 form a filter cloth water cleaning device, and the ultrasonic cleaning device 5 (which has been explained in many documents and will not be described in detail), relies on the cavitation of ultrasonic waves to crush the particles blocked in the filter cloth, Then the filter cloth is washed out with water, so as to achieve efficient, clean and thorough regeneration of the filter cloth. The cleaning bucket 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com