Field biogas slurry fertilization integrated irrigating system

An irrigation system and biogas slurry technology, which can be applied to the pressurized spreading method of liquid fertilizer, agricultural gas emission reduction, etc., can solve the problems of inability to meet the requirements of large-scale ecological agricultural fertilization, high labor intensity, and burnt economic crops. , to achieve the effect of reducing labor intensity, avoiding manual transportation, and lower water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

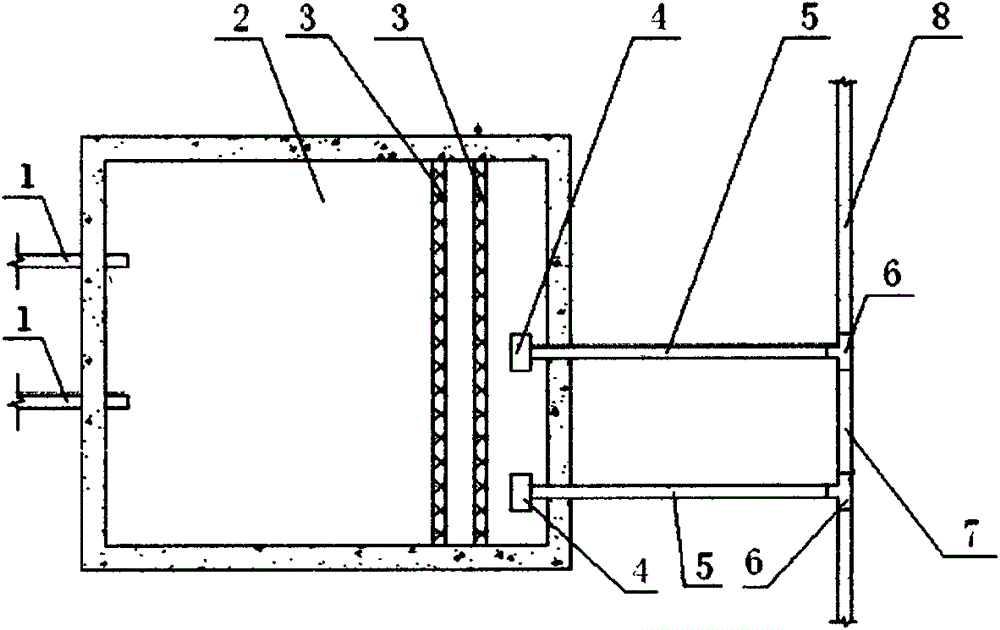

[0011] Such as figure 1 As shown, an integrated irrigation system for biogas slurry fertilization in the field includes biogas slurry input pipe 1, biogas slurry tank 2, filter screen 3, sewage pump 4, biogas slurry output pipe 5, tee pipe 6, water inlet pipe 7, outlet water pipe8. The biogas slurry input pipe 1 is connected with the biogas slurry tank 2; the biogas slurry tank 2 has a built-in filter 3 and a sewage pump 4; one end of the biogas slurry output pipe 5 is connected with the sewage pump 4, and the other end is connected with the tee pipe 6 ; The water inlet pipe 7 and the water outlet pipe 8 are connected with the three-way pipe 6 .

[0012] In actual use, the biogas slurry is first input into the biogas slurry tank 2 through the biogas slurry input pipe 1, and the biogas slurry passes through the filter screen 3 in the biogas slurry tank 2 to filter the suspended matter, and the sewage placed in the biogas slurry tank 2 The pump 4 is pumped out and delivered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com