Purifying method of high-temperature condensed water

A high-temperature condensate and condensate technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve pollution, high membrane requirements, and low filtration accuracy of sintered tubes question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

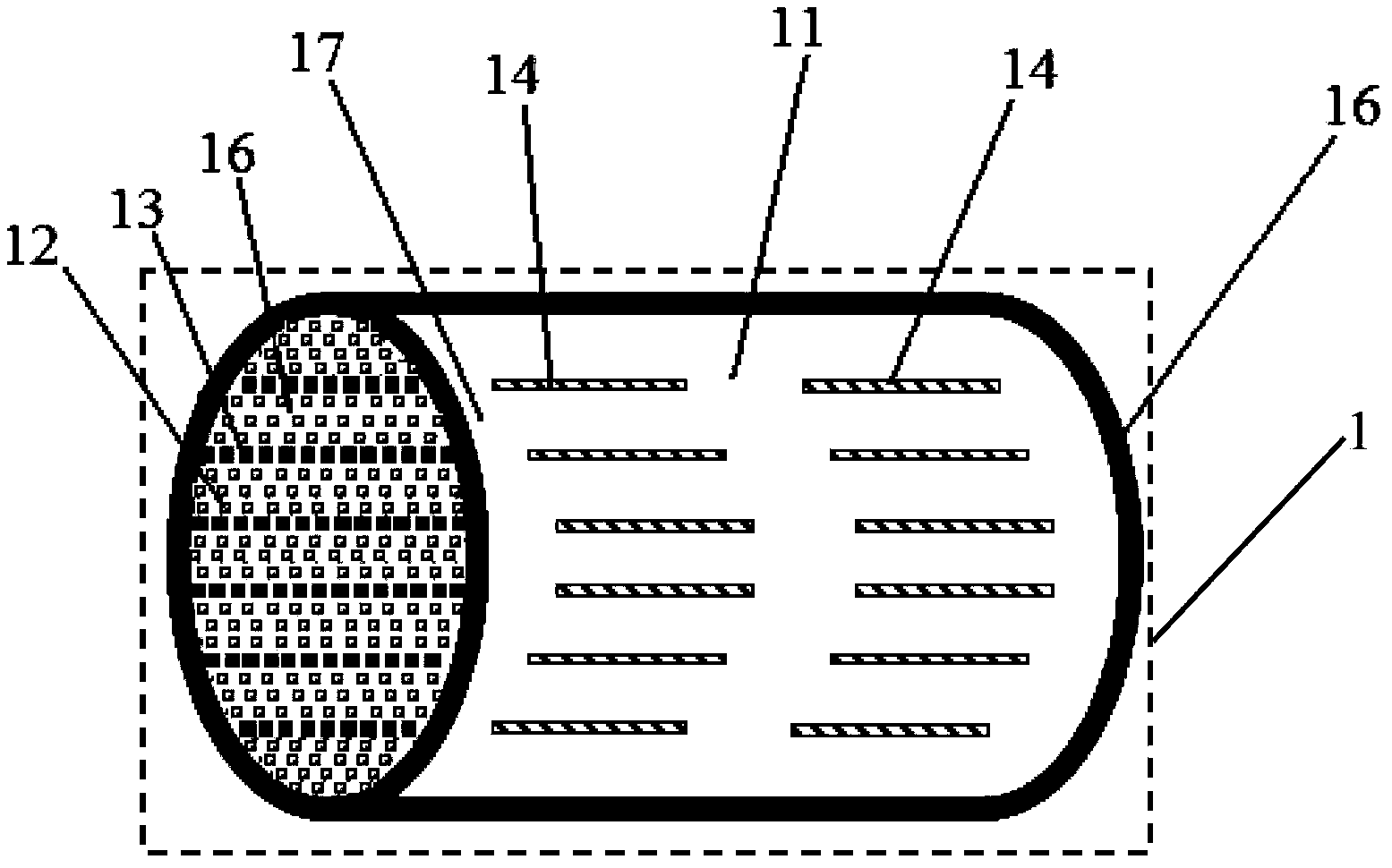

[0136] In this embodiment, the main body 11 of the membrane core 1 is provided with 1480 filter channels 12 and water production channels 13 with a square cross section. The side lengths of the filter channels 12 and water production channels 13 are both 2 mm, as image 3 , 4 , 5 shown. The main body 1 of the membrane core of the embodiment of the present invention is a cylinder with a diameter of 14 cm and a length of 90 cm. There are three rows of filtration channels 12 between two adjacent rows of water production channels 13, and the outer side of the cylindrical membrane core main body 1 corresponds to the water production. At the corresponding position of the passage 13, two guides provided along the longitudinal direction of the main body 11 by sawing, drilling, grinding, planing or other known methods outside the range of 15 cm from the two end faces 16 of the main body 1 of the membrane core. Launder 14 divides the same row of water production channels 13 into 3 sect...

Embodiment 2

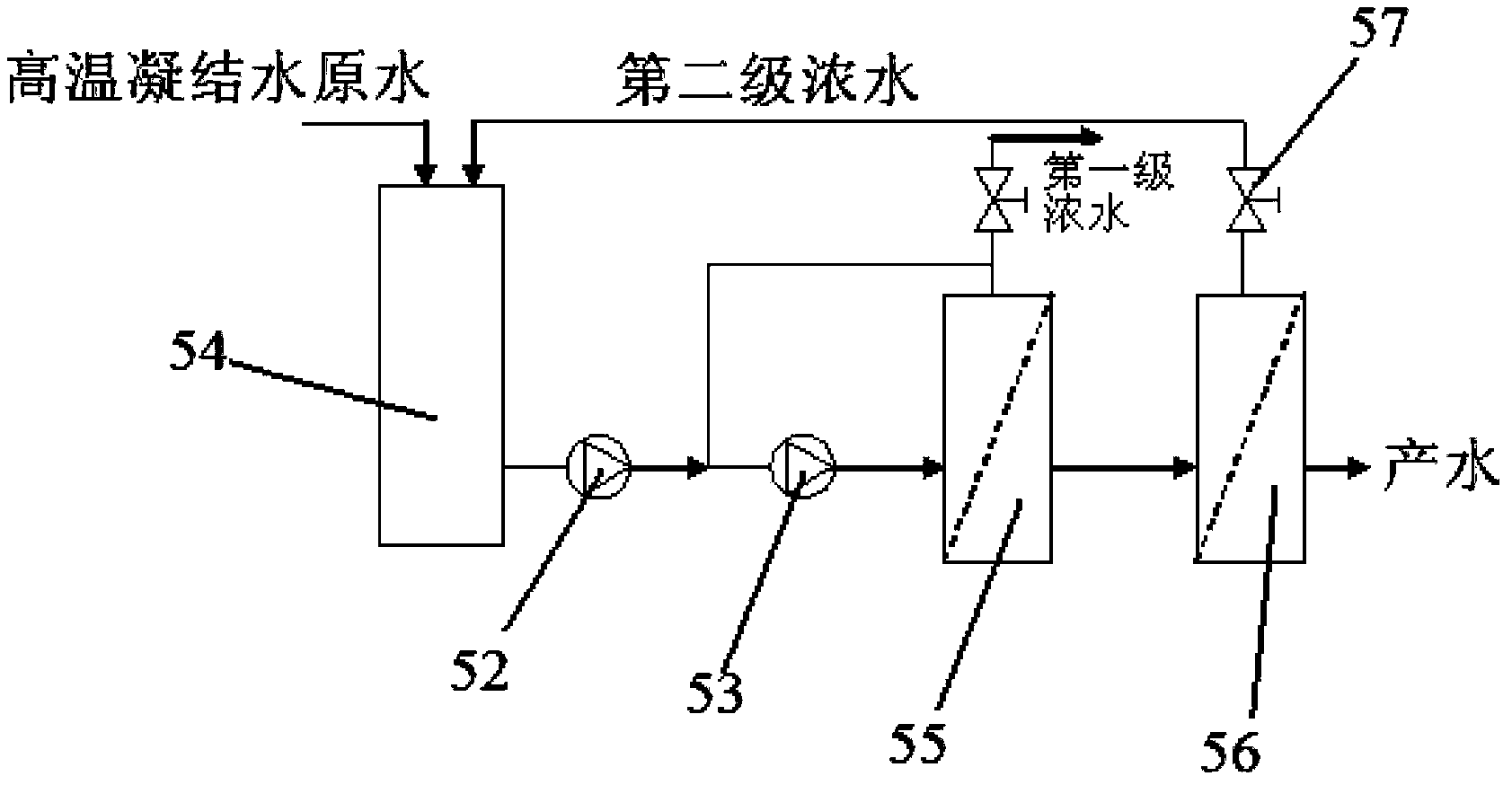

[0144] The high-temperature condensate flow flows into the first-stage membrane core through the water inlet pipe 5, and the first-stage membrane filtration treatment is performed in a cross-flow manner. Among them, in addition to controlling the inlet water pressure of the first-stage membrane filtration treatment to 0.4MPa, adjusting the outlet pressure from concentrated water The concentrated water circulation flow out of the water pipe 6 controls the membrane surface flow velocity to 0.95m / s and the concentrated water pressure to 0.3MPa during the first-stage membrane filtration process; at the same time, adjust the concentrated water discharge of the first-stage membrane filtration so that the first stage The water yield of the first-stage membrane filtration treatment is 97.5%, the pressure of the product water of the first-stage membrane filtration treatment is 0.18MPa, and the transmembrane pressure difference is 0.195MPa, and the rest are the same as in Example 1;

[0...

Embodiment 3

[0149] In addition to the high-temperature condensate flow water quality, that is, the influent water quality of the first-stage membrane filtration treatment; the influent water pressure of the first-stage filtration is 0.41MPa, the concentrated water pressure is 0.34MPa, the product water pressure is 0.17MPa, and the transmembrane pressure difference is 0.205MPa; The inlet water pressure of the secondary filtration is 0.17MPa, the concentrated water pressure is 0.15MPa, the product water pressure is 0.06MPa, and the transmembrane pressure difference is 0.1MPa, and the rest are the same as in Example 2. Table 3 shows the water quality of the pretreated water and the water quality after the secondary membrane filtration treatment.

[0150] Table 3 embodiment 3 water quality analysis results

[0151] project

[0152] Iron, μg / L

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com