Running machine with automatic dedusting function

An automatic dust removal and treadmill technology, applied in the field of treadmills, can solve problems such as damage to treadmills and shortened service life of treadmills, and achieve the effects of prolonging service life, simple operation and reducing frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

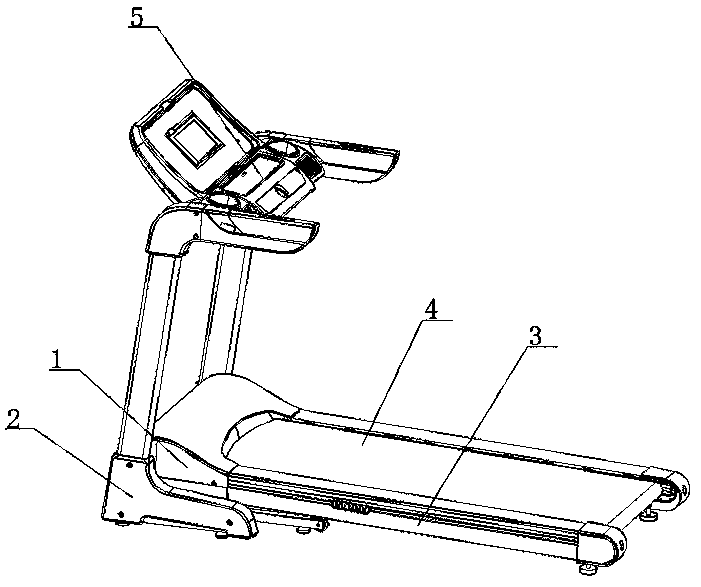

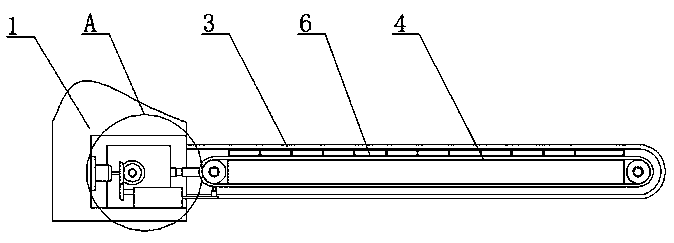

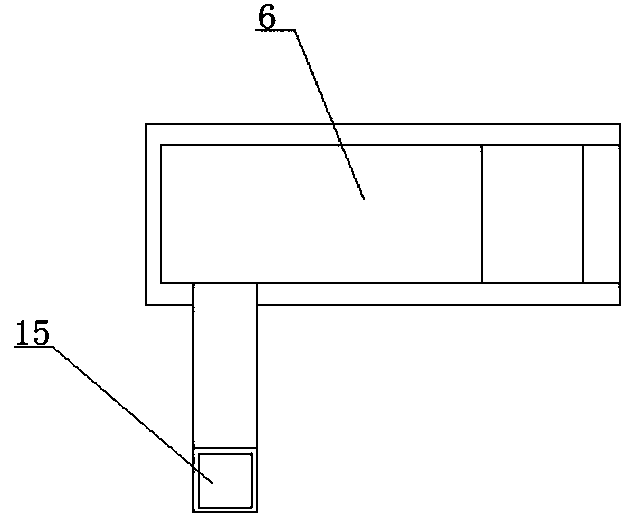

[0031]refer to Figure 1-10 , a treadmill with automatic dust removal is proposed in this embodiment, including a mounting base 1, a mounting frame 2 is fixedly installed on the mounting base 1, a control panel 5 is fixedly mounted on the top of the mounting frame 2, and one side of the mounting base 1 is symmetrical Two installation covers 3 are fixedly installed, and the same running belt 4 is arranged in the two installation covers 3, and a dust collection cover 6 is fixedly installed in the installation cover 3, and the dust collection cover 6 is positioned at the top of the running belt 4, and the dust suction The inner wall of the bottom of the cover 6 is sealed and fixed with an L-shaped pipe 15, and one side of the mounting seat 1 is provided with a connecting groove 7, and two fixing seats 8 are symmetrically fixed on the inner wall of the bottom of the connecting groove 7. A collection chamber 16 is provided, and the two collection chambers 16 are rotatably connected...

Embodiment 2

[0039] refer to Figure 1-10 The difference between the automatic dust-removing treadmill proposed in this embodiment and the first embodiment is that:

[0040] In this embodiment, a ball screw nut 36 is rotatably connected in the limit groove 35 , and the ball screw 38 penetrates the ball screw nut 36 and is threadedly connected with the ball screw nut 36 , so as to apply force to the torsion spring 37 conveniently.

[0041] In this embodiment, a limit ring is fixedly installed on the inner wall of the limit groove 35, and the limit ring is located on one side of the ball screw nut 36, and the ball screw 38 runs through the limit ring and is slidably connected with the inner wall of the limit ring. A torsion spring 37 is sleeved on the ball screw 38, and the torsion spring 37 is located between the spacer ring and the ball screw nut 36, and the two ends of the torsion spring 37 are fixedly connected with the spacer ring and the ball screw nut 36 respectively. The torsion spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com