Automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling automobile engine

A car engine, carbon deposit cleaning agent technology, applied in the direction of detergent composition, soap detergent composition, surface active non-soap compound and washing composition, etc., can solve the problems of reduced engine life and high temperature, and reduce fuel consumption , prolong life, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

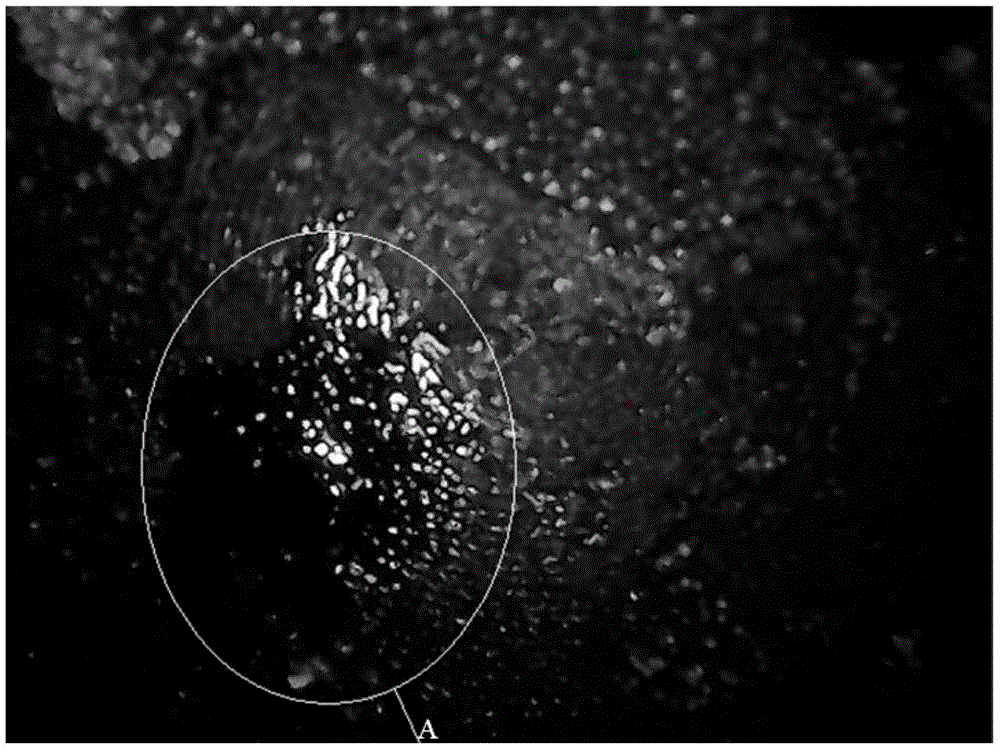

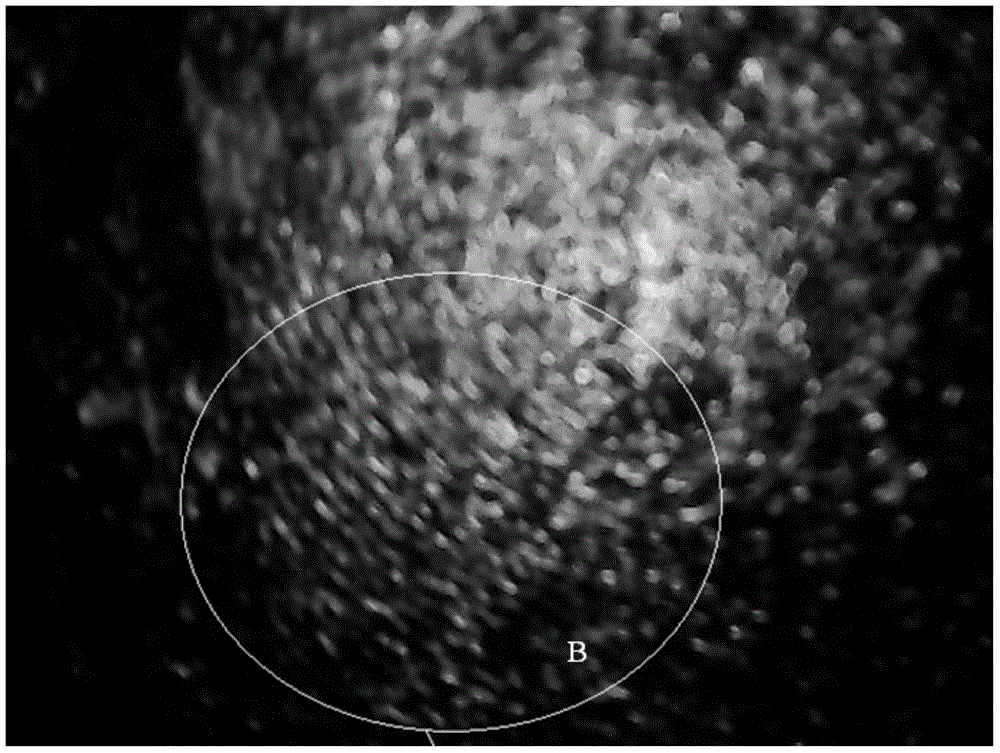

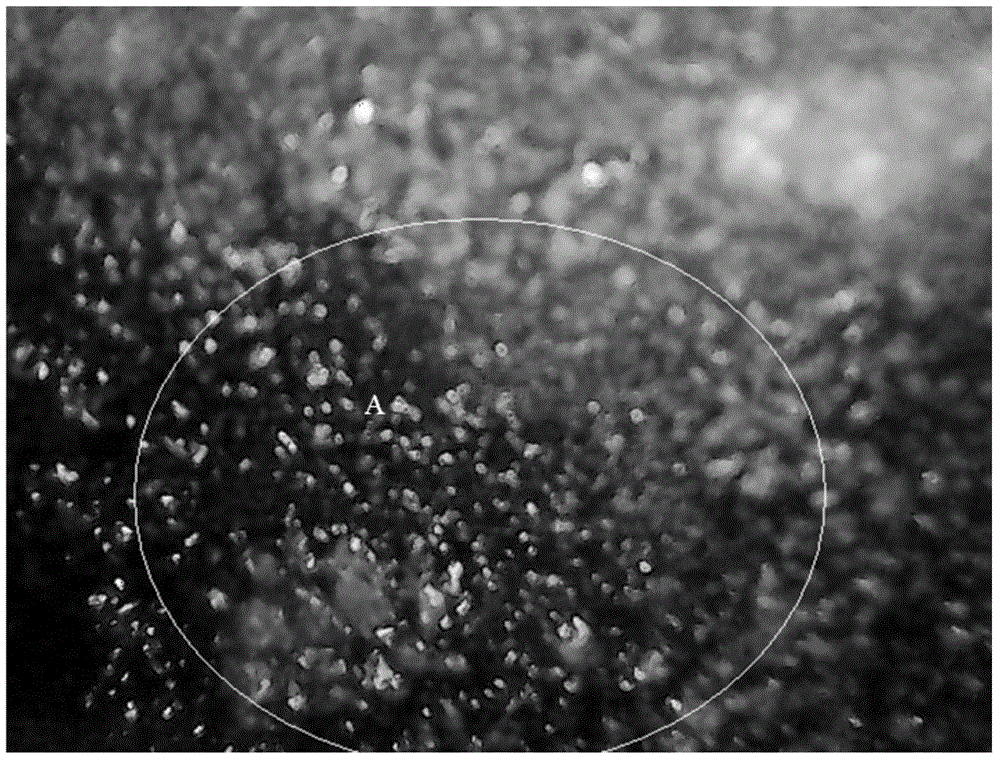

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: This embodiment is a car engine disassembly-free car carbon deposit cleaning agent consisting of dodecylphenol sulfonic acid isopropylamine salt, nonylphenol polyethylene glycol ether, ethylene glycol mono-n-propyl ether, petroleum Essence, petroleum hydrogenated light distillate, hexamethylenetetramine and deionized water are mixed; the mass fraction of dodecylphenol sulfonic acid isopropylamine salt is 1 % to 3%; the mass fraction of nonylphenol polyglycol ether in the automobile engine disassembly-free car carbon deposit cleaning agent is 1% to 3%; The mass fraction of diol mono-n-propyl ether is 5% to 10%; the mass fraction of petroleum hydrogenated light distillate in the car engine carbon deposit cleaning agent without disassembly is 2% to 5%; the car engine is free from disassembly The mass fraction of naphtha in the car carbon deposit cleaning agent is 2% to 5%; the mass fraction of hexamethylenetetramine in the automobile carbon deposit...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of dodecylphenolsulfonic acid isopropylamine salt in the described automotive engine disassembly-free car carbon deposit cleaning agent is 1%; The massfraction of nonylphenol polyglycol ether in the car engine free from disassembly car carbon deposit cleaning agent is 3%; 5%; the mass fraction of petroleum hydrogenated light distillate in the automobile engine free-disassembly car carbon deposit cleaning agent is 2%; the mass fraction of naphtha in the described automobile engine free-disassembly automobile carbon deposit cleaning agent is 5%; The mass fraction of hexamethylenetetramine in the automobile engine disassembly-free automobile carbon deposit cleaning agent is 0.5%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the mass fraction of dodecylphenol sulfonic acid isopropylamine salt in the described automobile engine disassembly-free car carbon deposit cleaning agent is 3%; The massfraction of nonylphenol polyglycol ether in the car engine free from disassembly car carbon deposit cleaning agent is 1%; 7%; the mass fraction of petroleum hydrogenated light distillate in the automobile engine free-disassembly car carbon deposit cleaning agent is 5%; the mass fraction of naphtha in the described automobile engine free-disassembly car carbon deposit cleaning agent is 3%; The mass fraction of hexamethylenetetramine in the automobile engine disassembly-free automobile carbon deposit cleaning agent is 0.5%. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com