Zinc sulphide micron hollow sphere and preparation thereof

A technology of zinc sulfide and hollow balls, applied in the direction of zinc sulfide, etc., can solve the problems of complicated process, multiple raw materials, easy to pollute the environment, etc., and achieve the effect of simple and convenient method, less material consumption and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

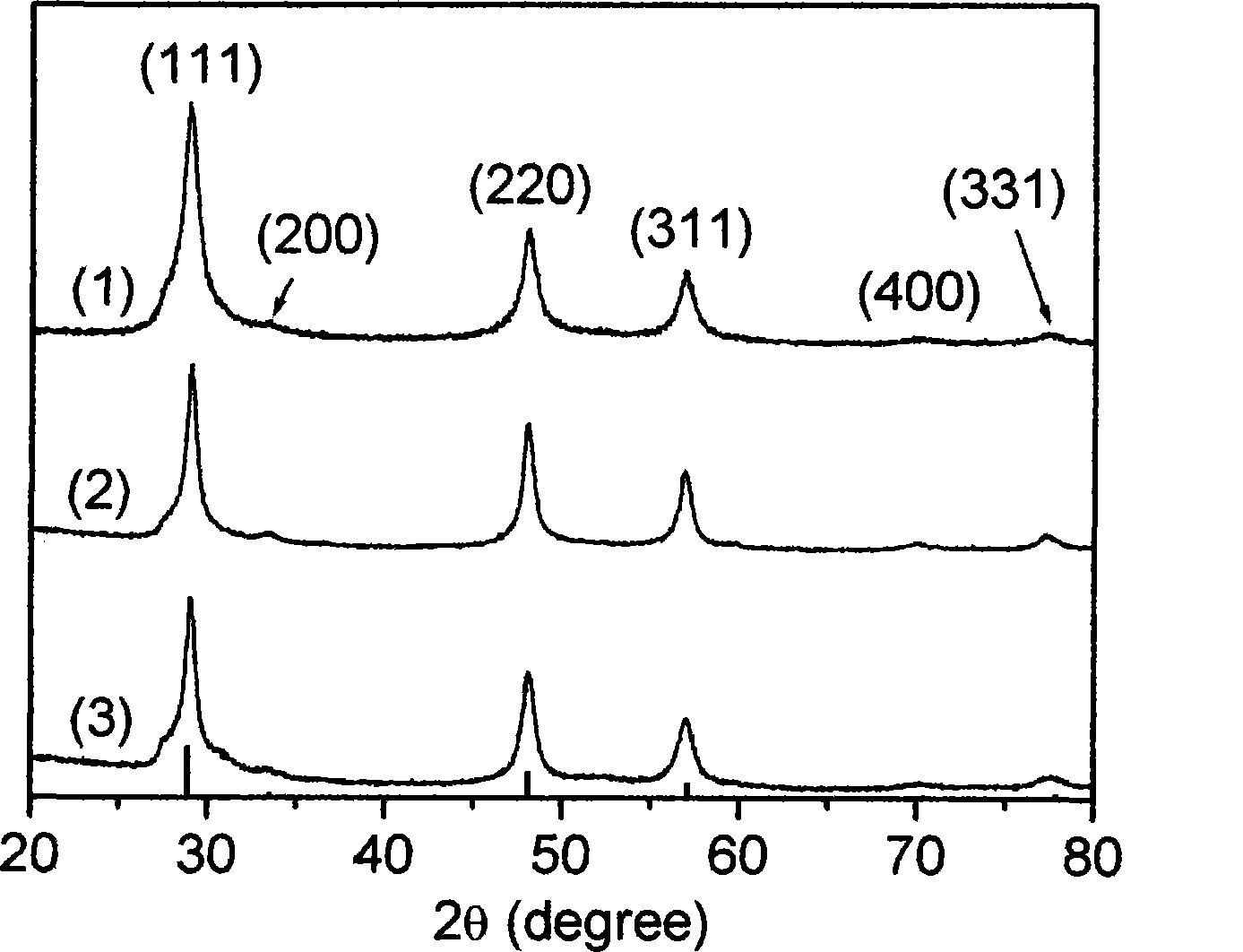

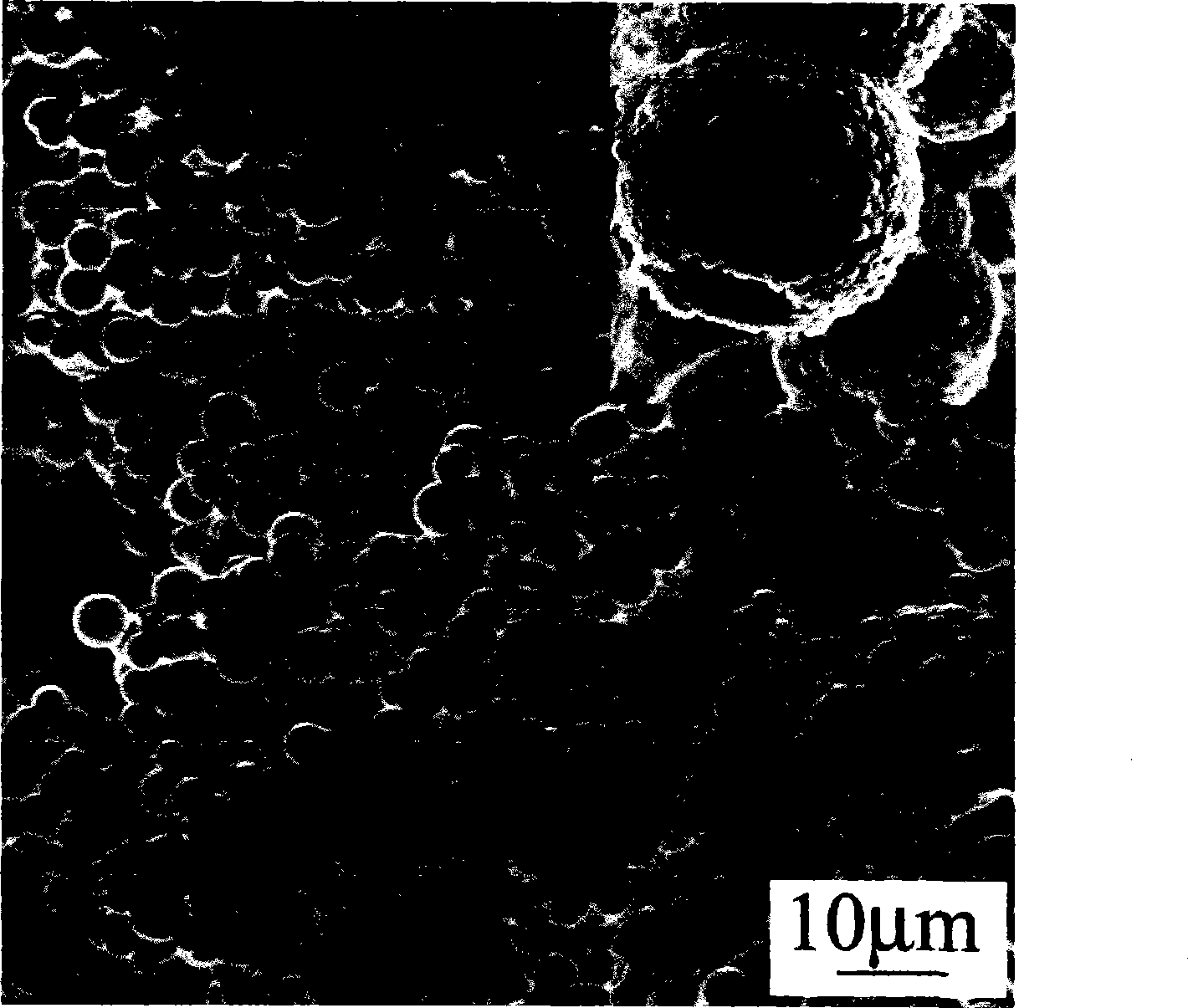

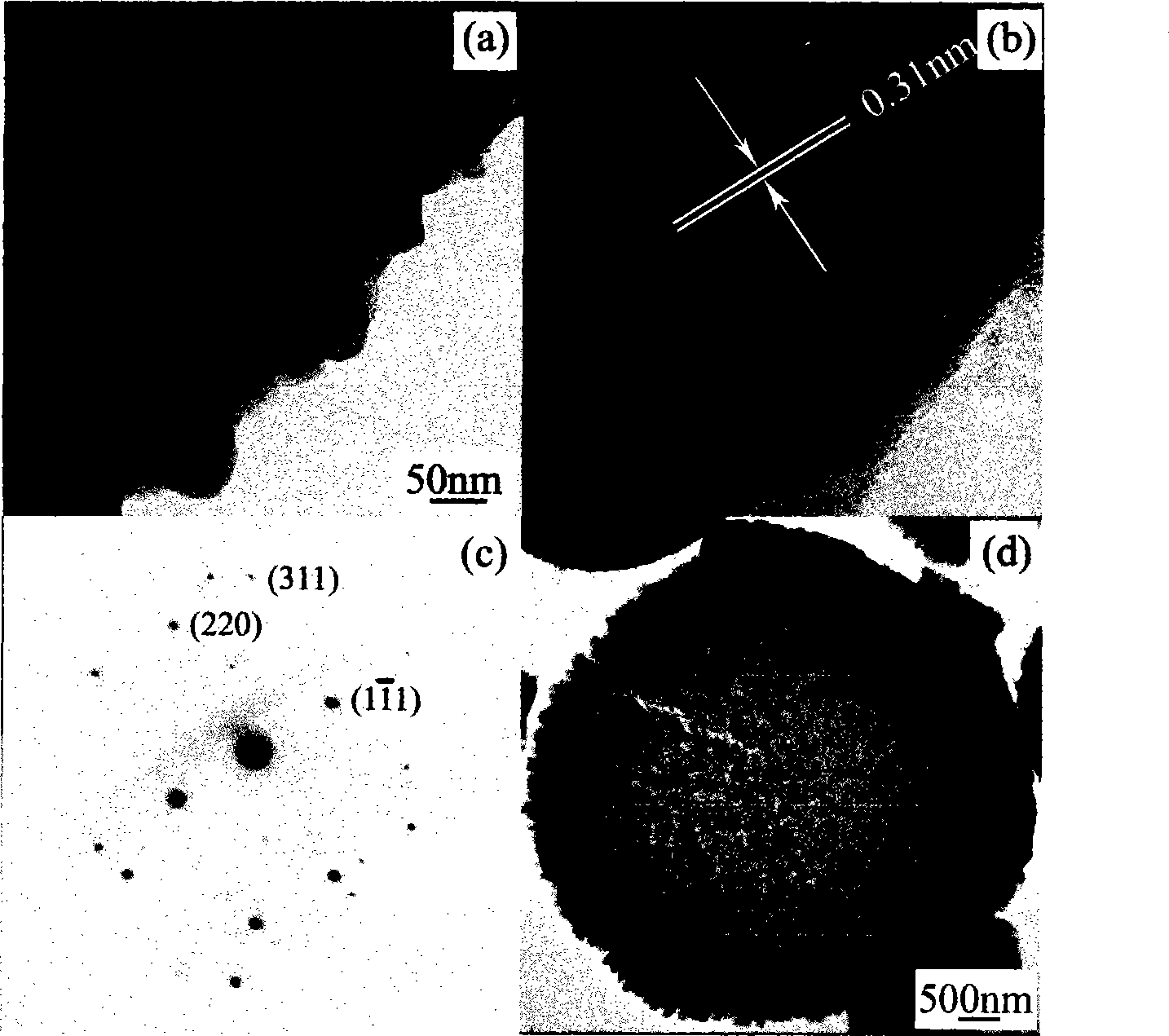

Embodiment 1

[0019] Embodiment 1: Complete the preparation in sequence according to the following steps: the first step, mix zinc nitrate, thioacetamide and water to obtain a precursor solution, the weight between zinc nitrate, thioacetamide and water in the precursor solution The ratio is 0.4:0.3:20; wherein, the water is deionized water. In the second step, the precursor solution is placed under a pressure of 5×10 5 Pa, react at 180°C for 15 hours to obtain a precipitated product, and then wash the precipitated product with a solvent and dry it in vacuum; wherein, after the reaction of the precursor solution is completed, the precipitated product is obtained by centrifugation at a speed of 4000rpm / min. The washing time is 5min, the washing solvent is deionized water, the number of washing is 3 times, and the vacuum degree during vacuum drying is 1×10 -5 Pa, the drying treatment is vacuum heating at 50°C for 4h. made as Figure 4 a, and if figure 1 The curve in (3), Figure 5 The cur...

Embodiment 2

[0020] Embodiment 2: complete the preparation in sequence according to the following steps: the first step, zinc nitrate, thioacetamide and water are mixed to obtain a precursor solution, the weight between zinc nitrate, thioacetamide and water in the precursor solution The ratio is 0.45:0.25:23; wherein, the water is distilled water. After that, polyethylene glycol is added to the precursor solution under stirring, wherein the weight ratio between polyethylene glycol and zinc nitrate is 0.2:0.45, the molecular weight of polyethylene glycol is 4000mol / g, polyethylene glycol The stirring speed of adding to the precursor solution is 100rpm / min, and the stirring time is 30min. In the second step, the precursor solution is placed under a pressure of 6×10 5 Pa, react at 190°C for 13 hours to obtain a precipitated product, then wash the precipitated product with a solvent and dry it in vacuum; wherein, after the reaction of the precursor solution is completed, the precipitated prod...

Embodiment 3

[0021] Embodiment 3: Complete the preparation in sequence according to the following steps: the first step, mix zinc nitrate, thioacetamide and water to obtain a precursor solution, the weight between zinc nitrate, thioacetamide and water in the precursor solution The ratio is 0.5:0.2:25; wherein, the water is deionized water. Afterwards, polyethylene glycol is added to the precursor solution under stirring, wherein the weight ratio between polyethylene glycol and zinc nitrate is 0.3:0.5, the molecular weight of polyethylene glycol is 4000mol / g, polyethylene glycol The stirring speed of adding to the precursor solution is 200rpm / min, and the stirring time is 25min. In the second step, the precursor solution is placed under a pressure of 7×10 5 Pa, react at 200°C for 12 hours to obtain a precipitated product, then wash the precipitated product with a solvent and dry it in vacuum; wherein, after the reaction of the precursor solution is completed, the precipitated product is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com