Preparation method for lithium ion battery pole piece

A technology for lithium-ion batteries and pole pieces, which is applied in the field of preparation of lithium-ion battery pole pieces, can solve the problems of low efficiency and low consistency in the adhesive tape process, improve uniformity and consistency, reduce workload, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

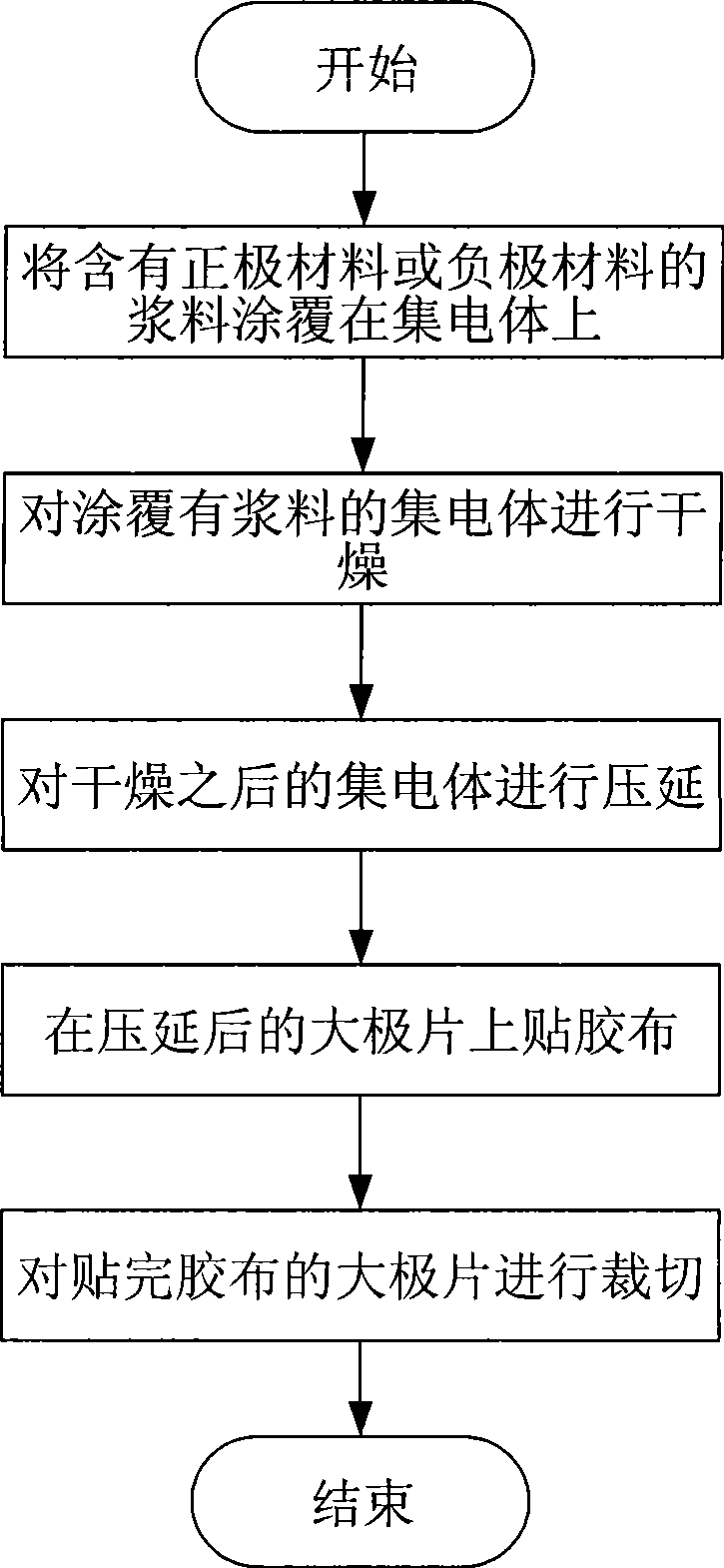

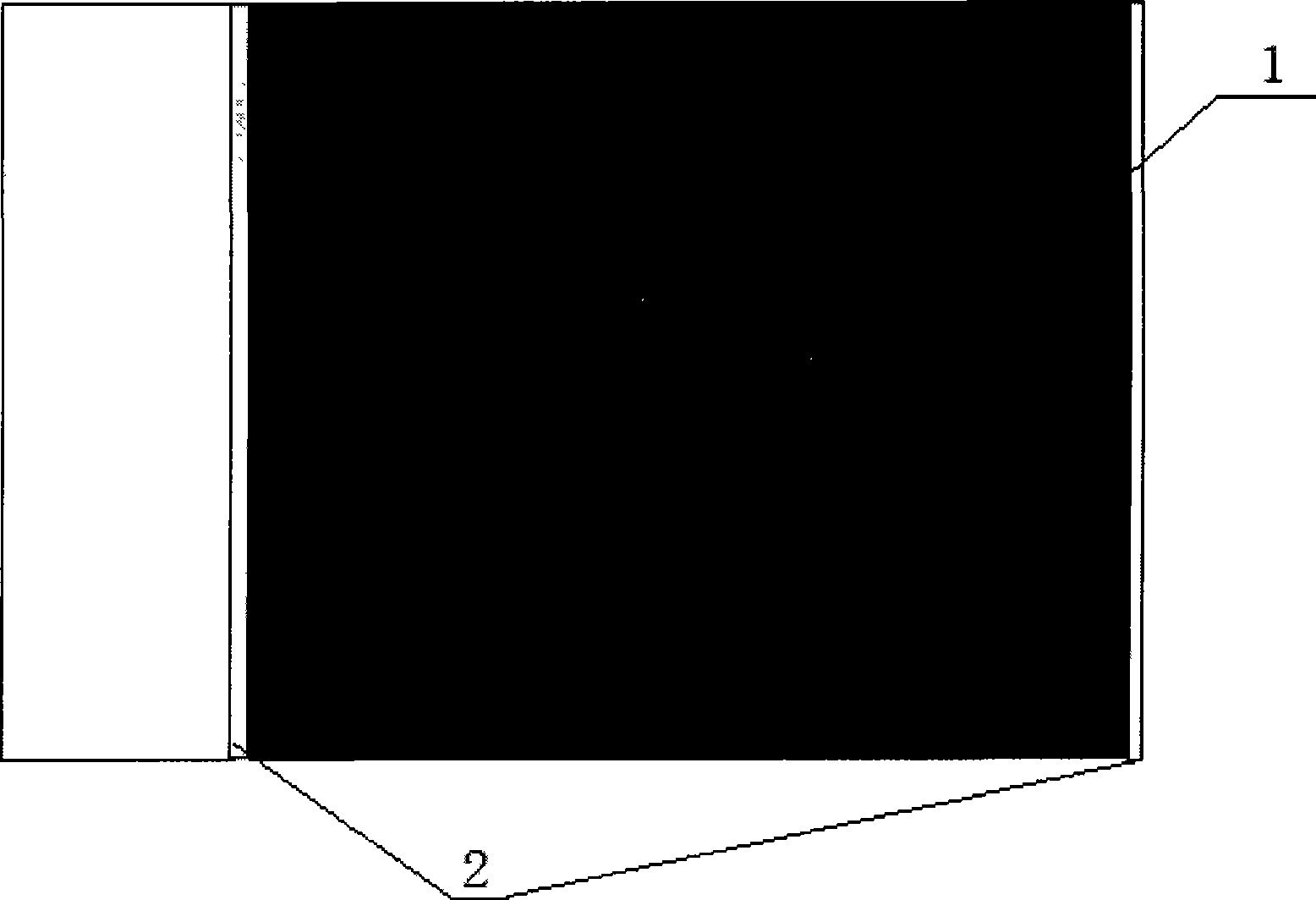

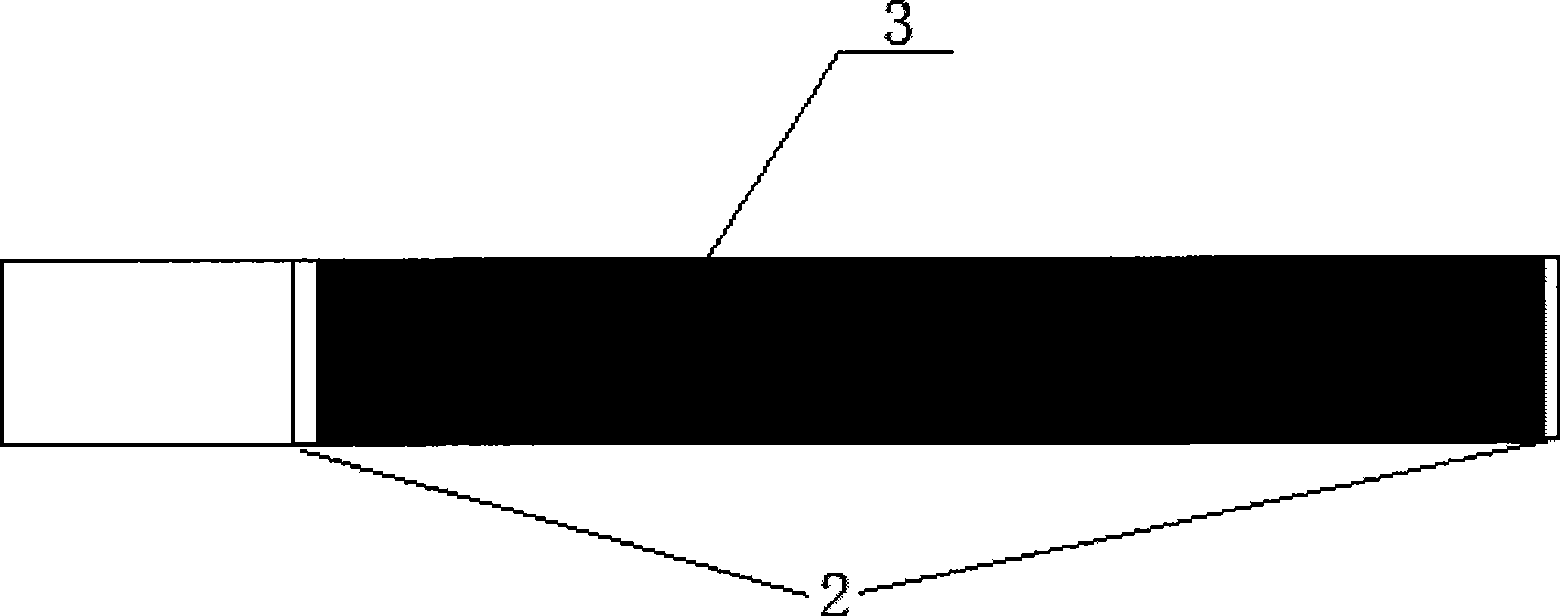

[0015] figure 1 The flow chart of the preparation method of the lithium battery pole piece provided by the present invention, such as Figure 1-3 As shown, the method for preparing lithium ion battery pole pieces provided by the present invention includes: coating a slurry containing a positive electrode material or a negative electrode material on a current collector; drying and rolling the current collector coated with the slurry, Thus the large pole piece 1 is produced; wherein the method further includes applying tape 2 on the transition area where the dressing area and the non-dressing area of at least one end of the large pole piece 1 after calendering; along the length of the tape 2 The large pole piece 1 is cut in the direction perpendicular to the direction, so that the pole piece 3 is obtained.

[0016] Since both ends of the pole piece 3 are prone to burrs and material loss after being pressed, it is preferable that the dressing area and the non-dressing area at bot...

Embodiment

[0025] This embodiment is used to manufacture a lithium ion battery using the positive electrode sheet and the negative electrode sheet prepared by the preparation method provided by the present invention.

[0026] 100 parts by weight of LiFePO 4 , 2 parts by weight of vinylidene fluoride polymer containing carboxyl group (from the copolymerization of methacrylic acid monomer and vinylidene fluoride monomer in a weight ratio of 1:30, the number average molecular weight is 8×10 5 -1×10 6 ), 1 part by weight polyacrylonitrile (number average molecular weight is 5×10 4 ~1×10 5 ) And 4 parts by weight of acetylene black are added to 60 parts by weight of NMP, and stirred to obtain positive electrode slurry.

[0027] Coat the positive electrode slurry evenly on the aluminum foil, then dry it at 150°C and roll it. After rolling, the dressing area and the non- dressing area on both sides of the large pole piece are both Paste the tape, the width of the tape in the dressing area and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com