Cyclone burning method and device for reburning fuel in cyclone drum for denitration

A cyclone combustion and cyclone technology, which is applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., which can solve the heat release of the cyclone Reduce the threat of normal operation of the cyclone furnace, the limited degree of fuel classification, etc., and achieve the effect of solving the burnout problem, convenient implementation, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

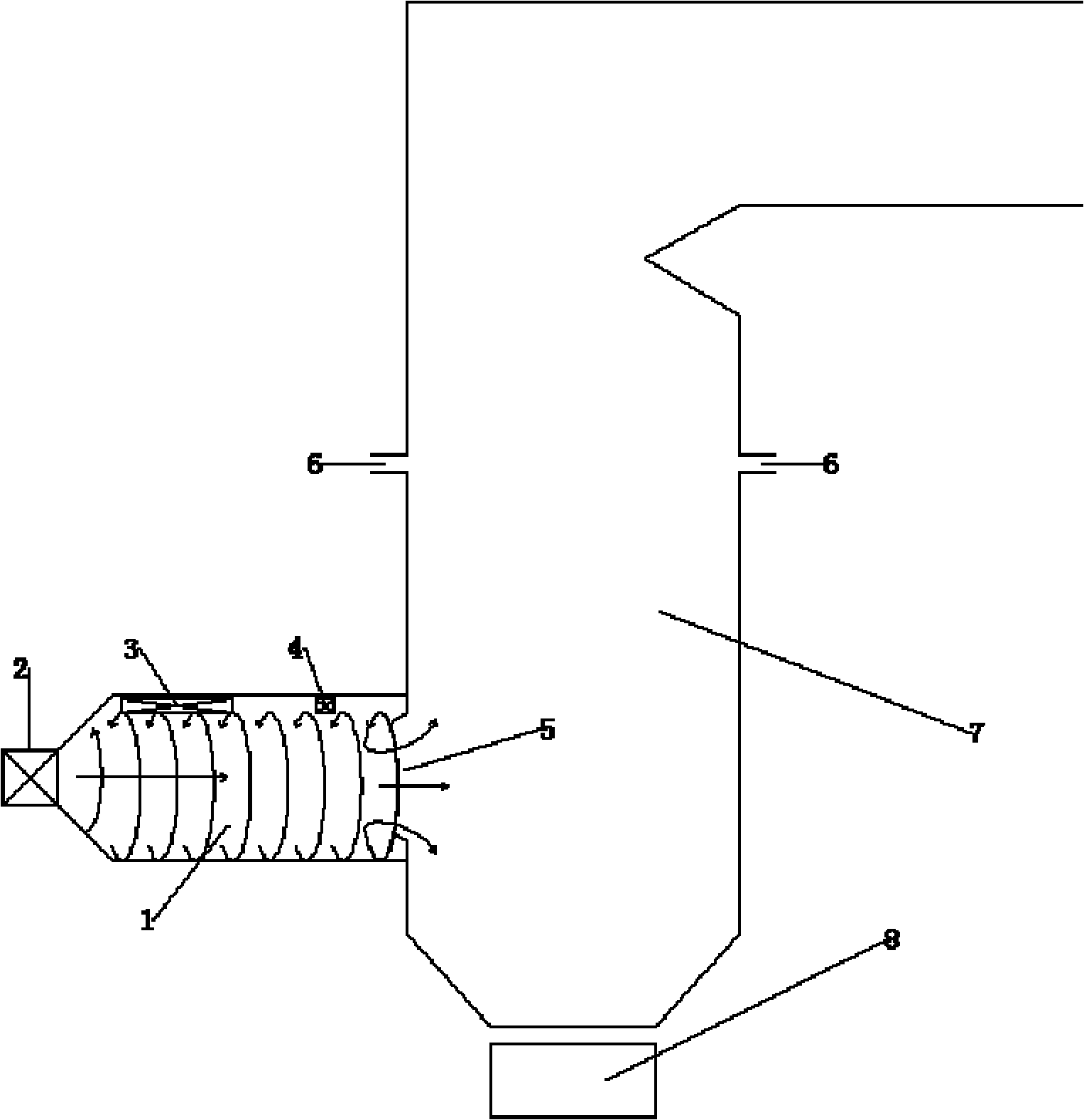

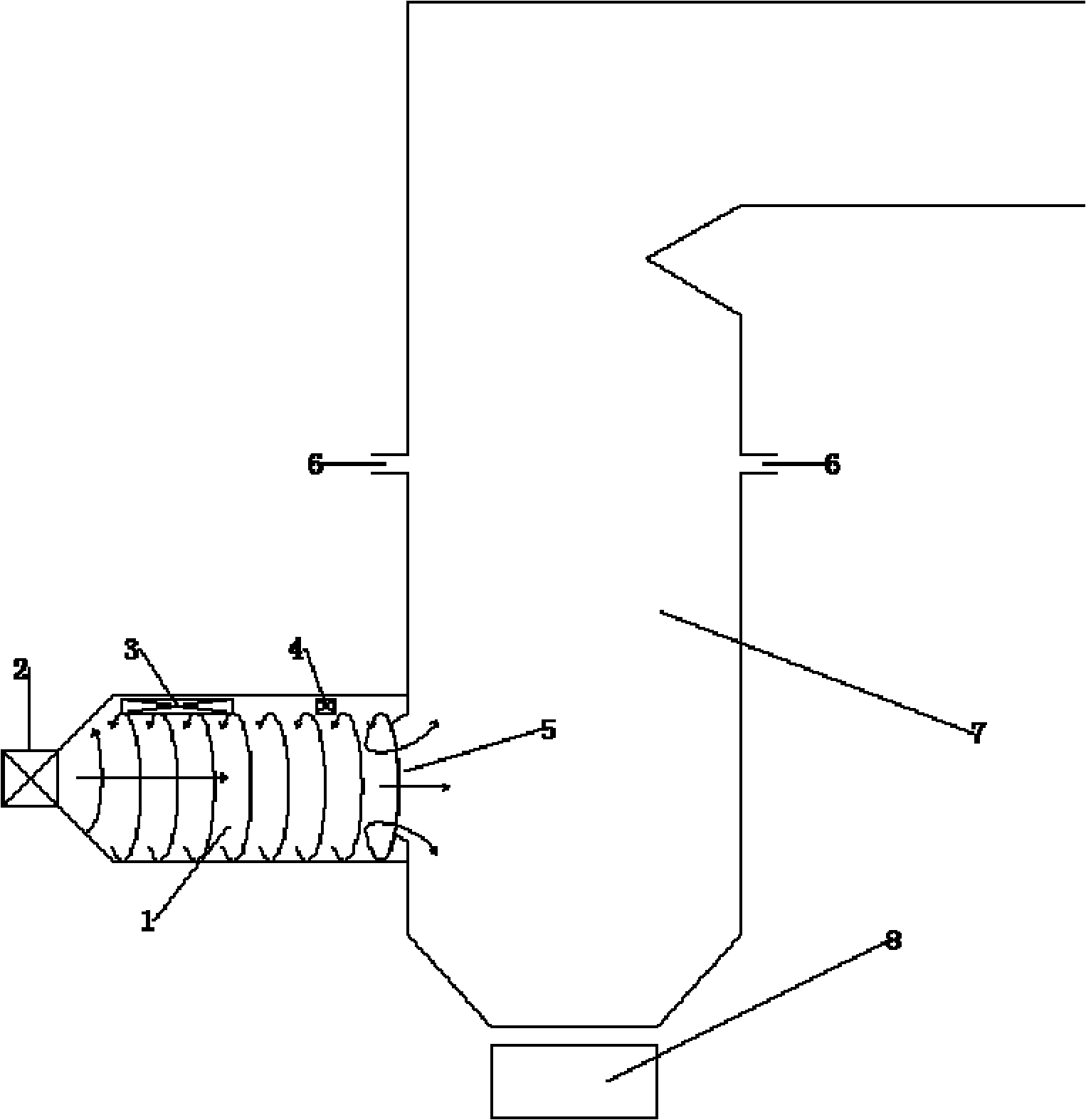

[0019] see figure 1 , a cyclone combustion method and device for achieving fuel reburning and denitrification in a cyclone proposed by the present invention, the schematic diagram of the device structure is shown in the figure. The device mainly includes cyclone, main fuel and primary air inlet, secondary air inlet, reburning fuel inlet, cyclone concave outlet, burn-out air nozzle, boiler main furnace and liquid slag granulation water tank.

[0020] The cyclone combustion method for realizing fuel reburning and denitrification in a cyclone proposed by the present invention specifically refers to: (1) the main fuel airflow sent in by the main fuel and the primary air inlet, and the high-pressure airflow sent in by the secondary air inlet The high-speed air (or "oxygen-enriched" air) is strongly mixed and combusted, forming the so-called main combustion zone in the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com