Device with annular cold air low-heat-storage quick start ignition and combustion system

A rapid start-up and combustion system technology, applied in the direction of combustion ignition, combustion method, combustion type, etc., can solve problems affecting the normal start-up of circulating fluidized bed boilers, oil dripping, and low reliability of atomization of atomizing sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

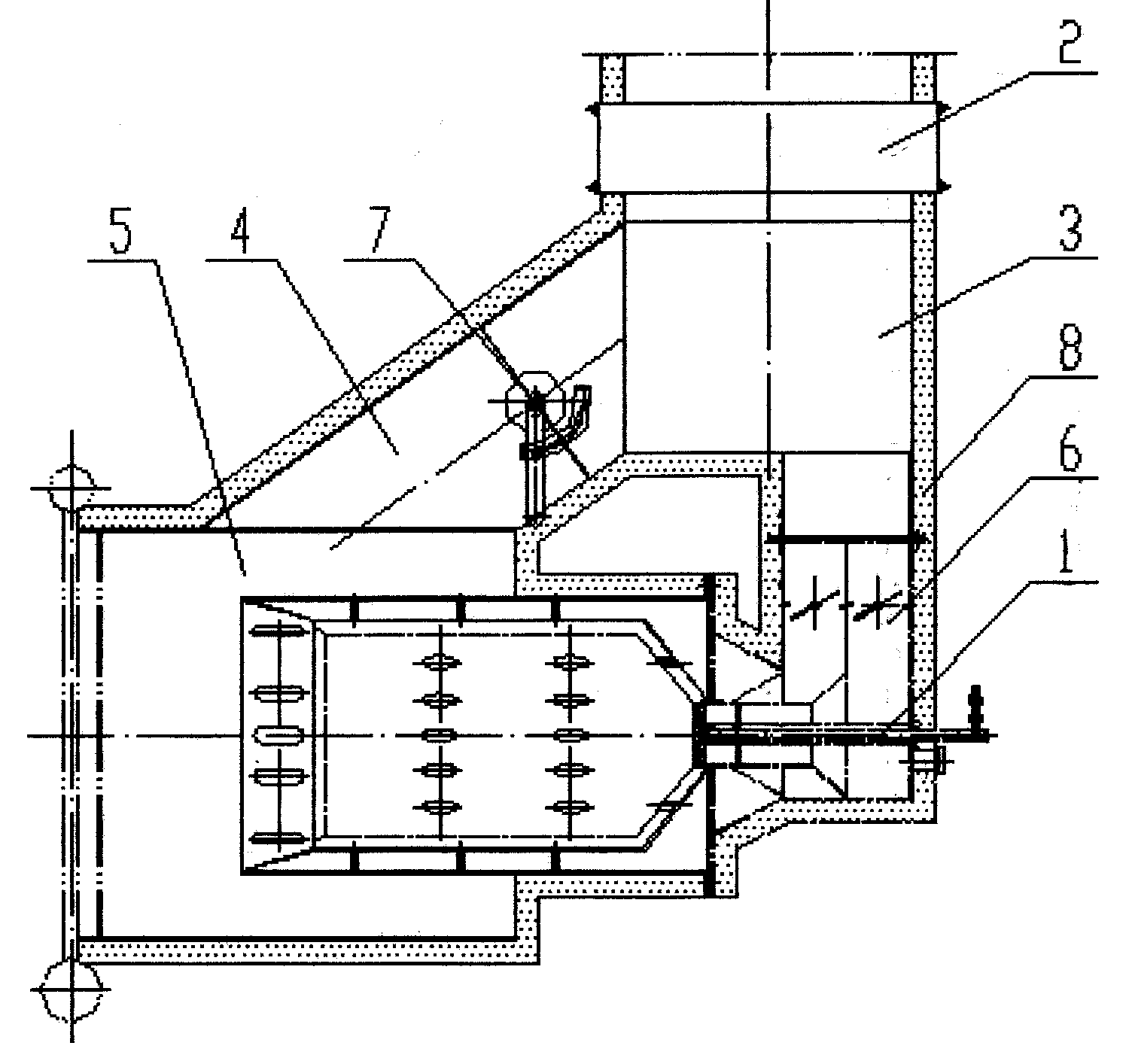

[0009] The present invention is equipped with the ring-cooled air low heat storage quick-start ignition combustion system device is realized in this way, and will be described in detail below in conjunction with the accompanying drawings.

[0010] See figure 1 , the present invention has ring-cooled air low thermal storage quick-start ignition combustion system device, which is composed of: ignition burner 1, expansion joint 2, communication chamber 3, supplementary air duct 4, combustion air duct 5, air distribution duct 6, Regulating damper 7 and thermal insulation refractory layer 8 are made up, and ignition burner 1 is made up of the ignition device that burner body and ignition end extend into burner body; Ignition burner 1 is arranged in combustion air channel 5, and combustion air channel 5 and The supplementary air duct 4 is connected to the air distribution duct 6, and the supplementary air duct 4 is provided with an adjusting damper 7 to adjust the ratio of supplemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com