Non-oxidation differential temperature quenching heat treatment equipment for abrasion-resisting cement roller shell

A heat treatment equipment and differential temperature quenching technology, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of affecting the use effect of wear-resistant cement roller sleeves, unable to achieve differential temperature heat treatment, heating and heating speed limits, etc. Simplify the process of anti-oxidation, avoid uneven heating, and prevent the effect of lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

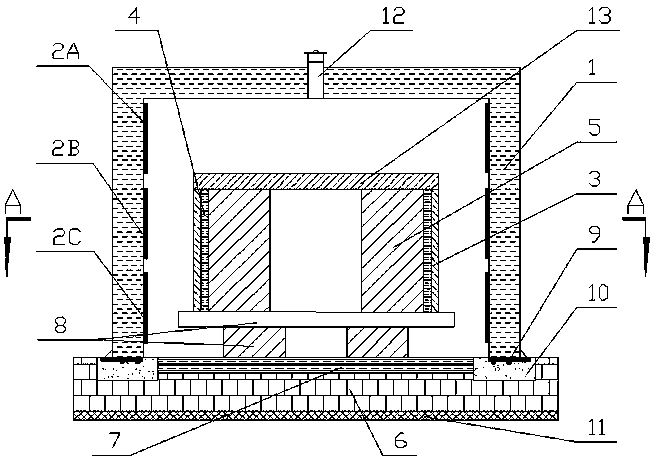

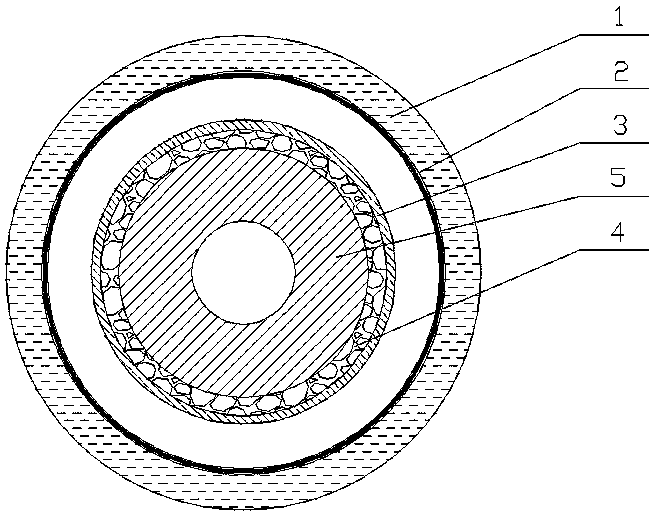

[0028] Such as figure 1 with figure 2 As shown, a wear-resistant cement roller sleeve non-oxidation differential temperature quenching heat treatment equipment includes a trolley 6, a profiling furnace cover 1, a heating element 2, a protective cover 3, an anti-oxidant 4, a protective cover 13 and a sealing element, the sealing The components include a heat-resistant plate 9 and a ceramic fiber soft seal 10 . The cement roller cover 5 to be processed is placed on the trolley 6, the cement roller cover 5 is cylindrical, the wall thickness of the cement roller cover 5 is thicker, and the cement roller cover 5 outer surface is provided with decorative pattern. Both the protective cover 13 and the profiling furnace cover 1 are cylindrical, and the cement roller cover 5 is covered with a protective cover 3, and an anti-oxidation 4 is arranged between the cement roller cover 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com