Patents

Literature

49results about How to "Reduce heat storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic filter containing carbonaceous material and bonded with silica adhesive and manufacturing method thereof

The invention relates to a ceramic filter suitable for filtering metal fused mass, comprising refractory material, carbonaceous material and silica adhesive. The invention also relates to making method for the filter. The ceramic filter has the advantages of more economical making, high mechanical strength not shrinkage during sintering process, more stable performance in memory process and more safe usage.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Microcapsule preparation method of phase change material

InactiveCN102676123AImprove stabilityGood coating effectHeat-exchange elementsMicroballoon preparationBuilding energyPhase change

The invention discloses a microcapsule preparation method of a phase change material. The defects of containing of methanol, poor environment friendliness, easiness in cracking in a capsule energy storing process and poor energy storing effect exist in a phase change microcapsule prepared with the conventional method. The method comprises the following steps of: emulsifying a phase change material into a nuclear phase by adopting an interface polymerization method, wherein the phase change material accounts for 20-60 percent; preparing styryl and acrylate monomers into a shell phase; and mixing the two phases, polymerizing at the temperature of 80-160 DEG C, reacting for 2-6 hours, preserving heat for 1-4 hours, cooling and drying to obtain a phase change microcapsule. Formaldehyde is not required to be added in a preparation process, and a production process is environment-friendly; after a capsule is prepared, the capsule wall coating property is high, and reaction time is shortened; the method is low in preparation cost, has a simple and convenient process and contributes to industrial production; and the obtained product can be widely applied in the fields of building energy storage, energy saving, consumption reduction, spinning and the like.

Owner:巢启 +1

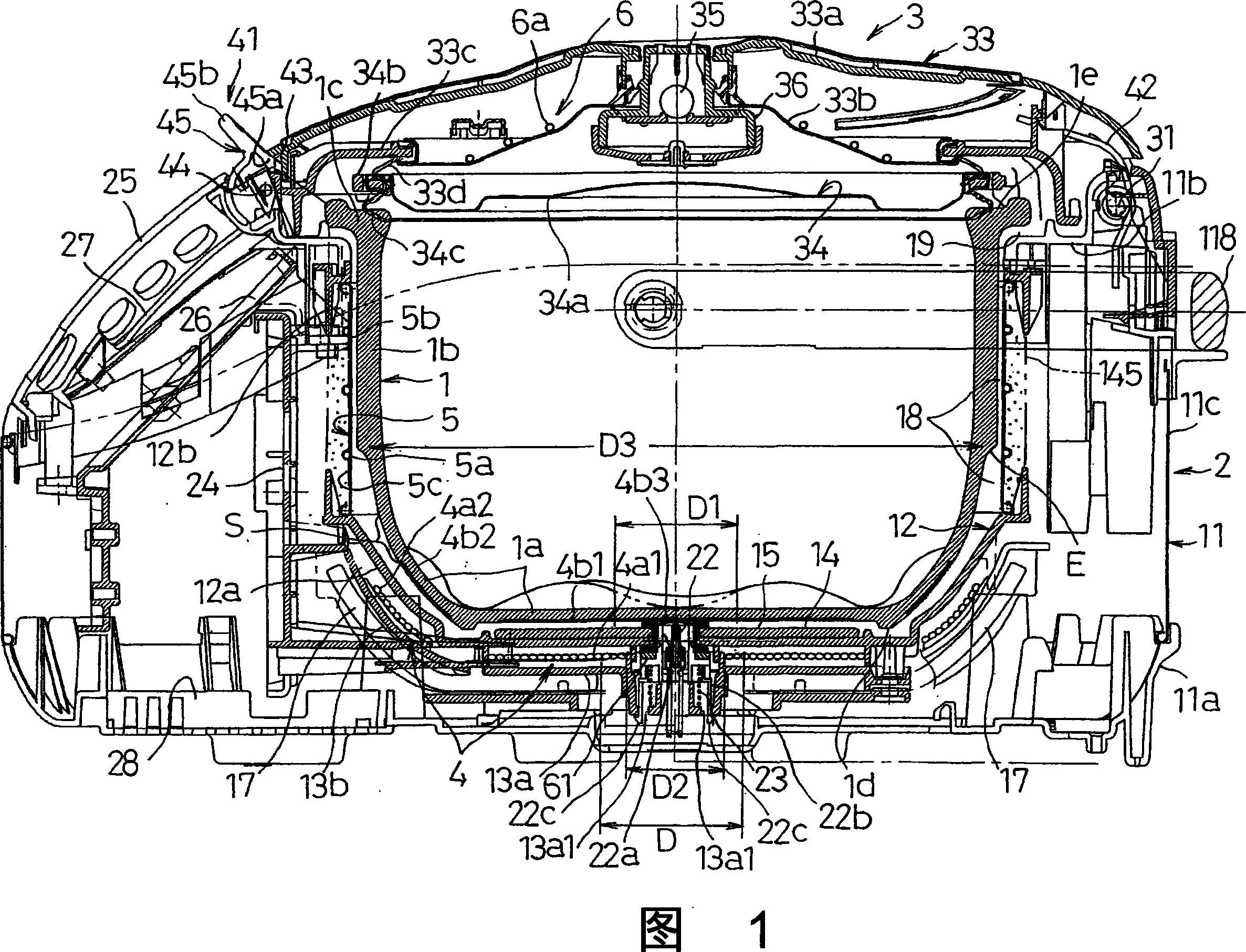

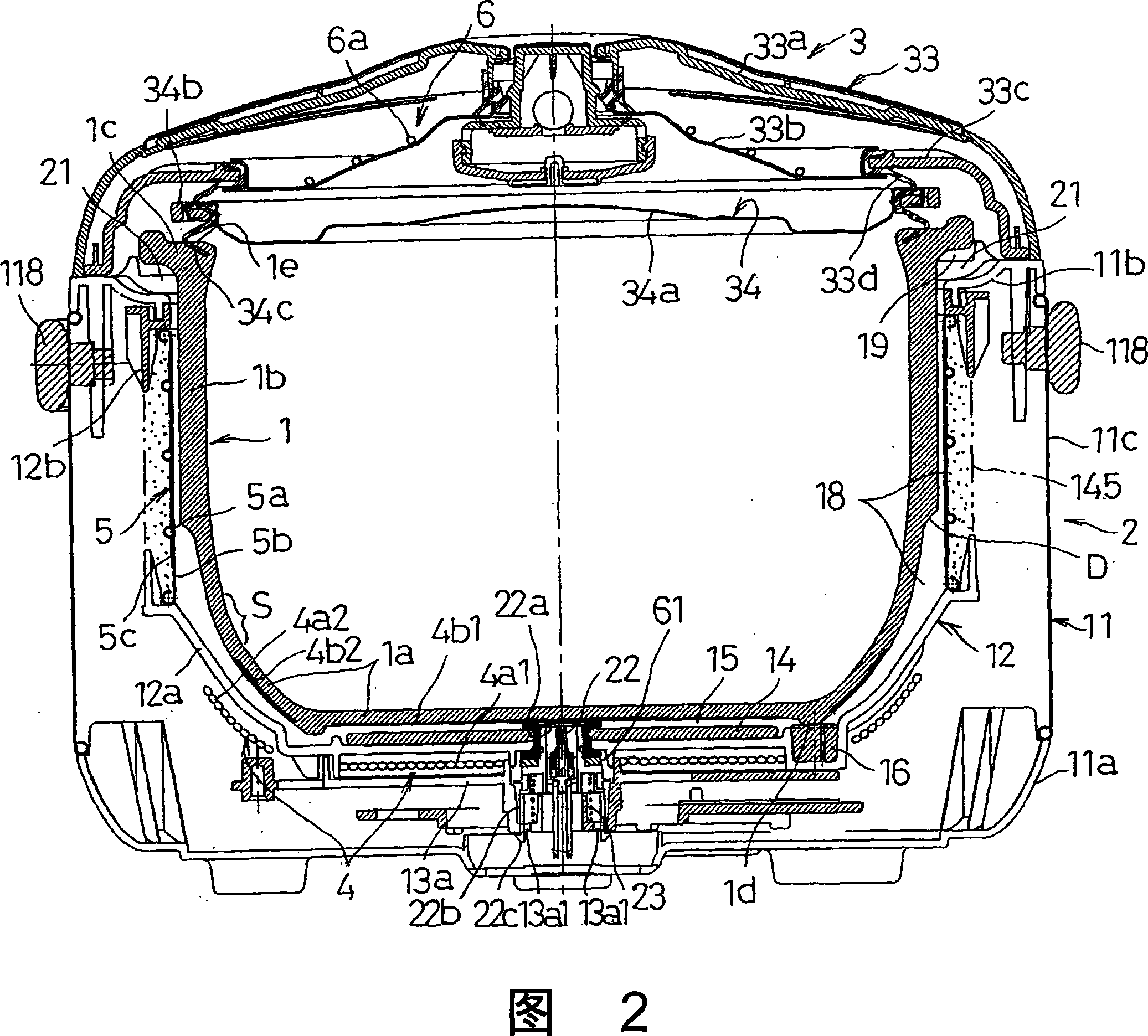

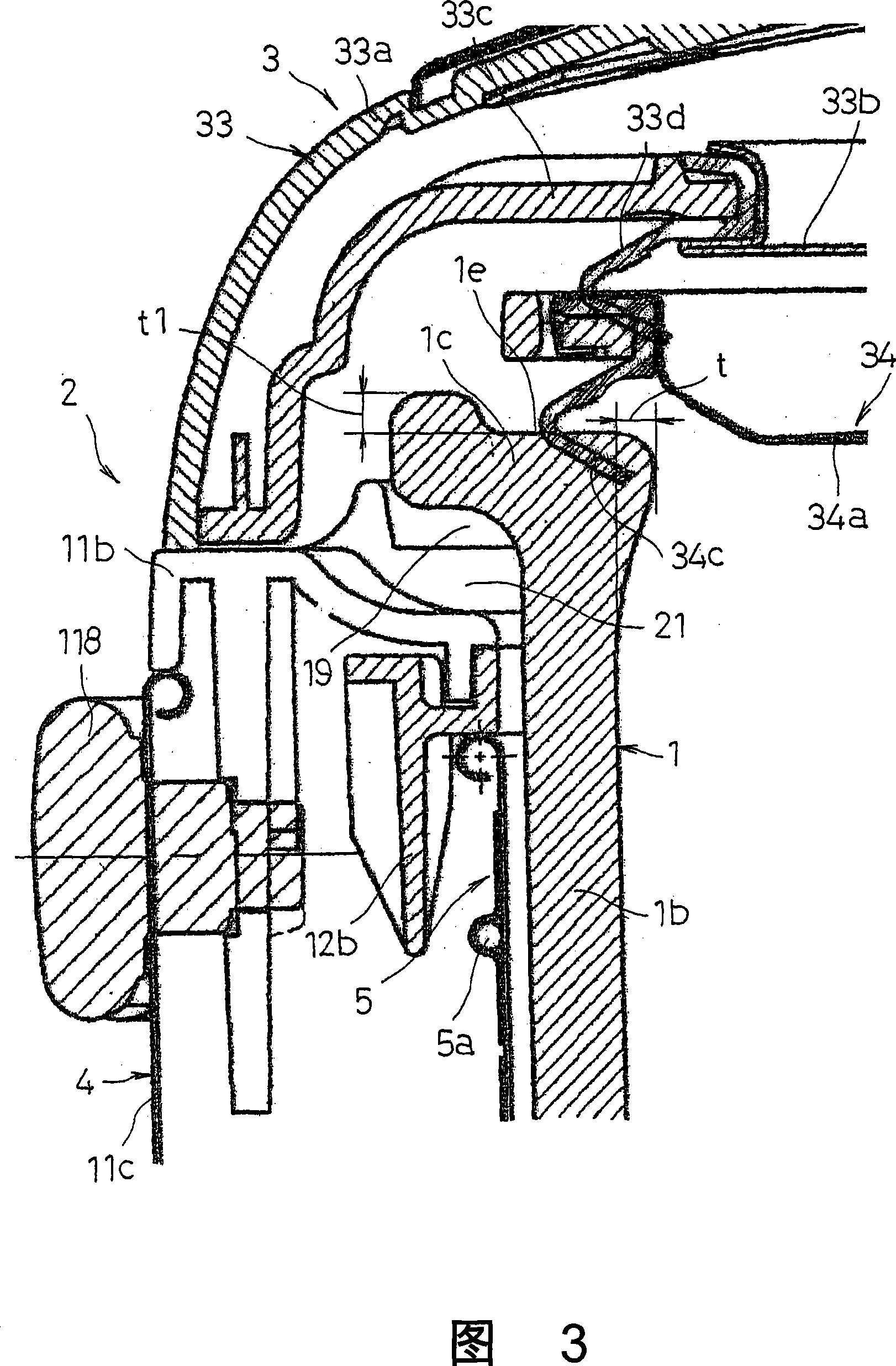

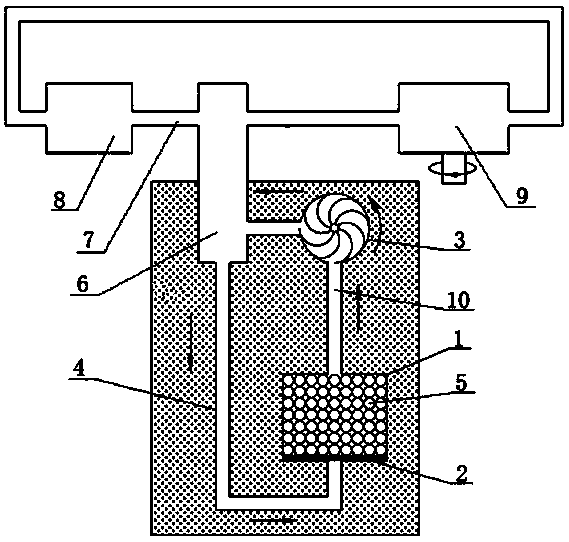

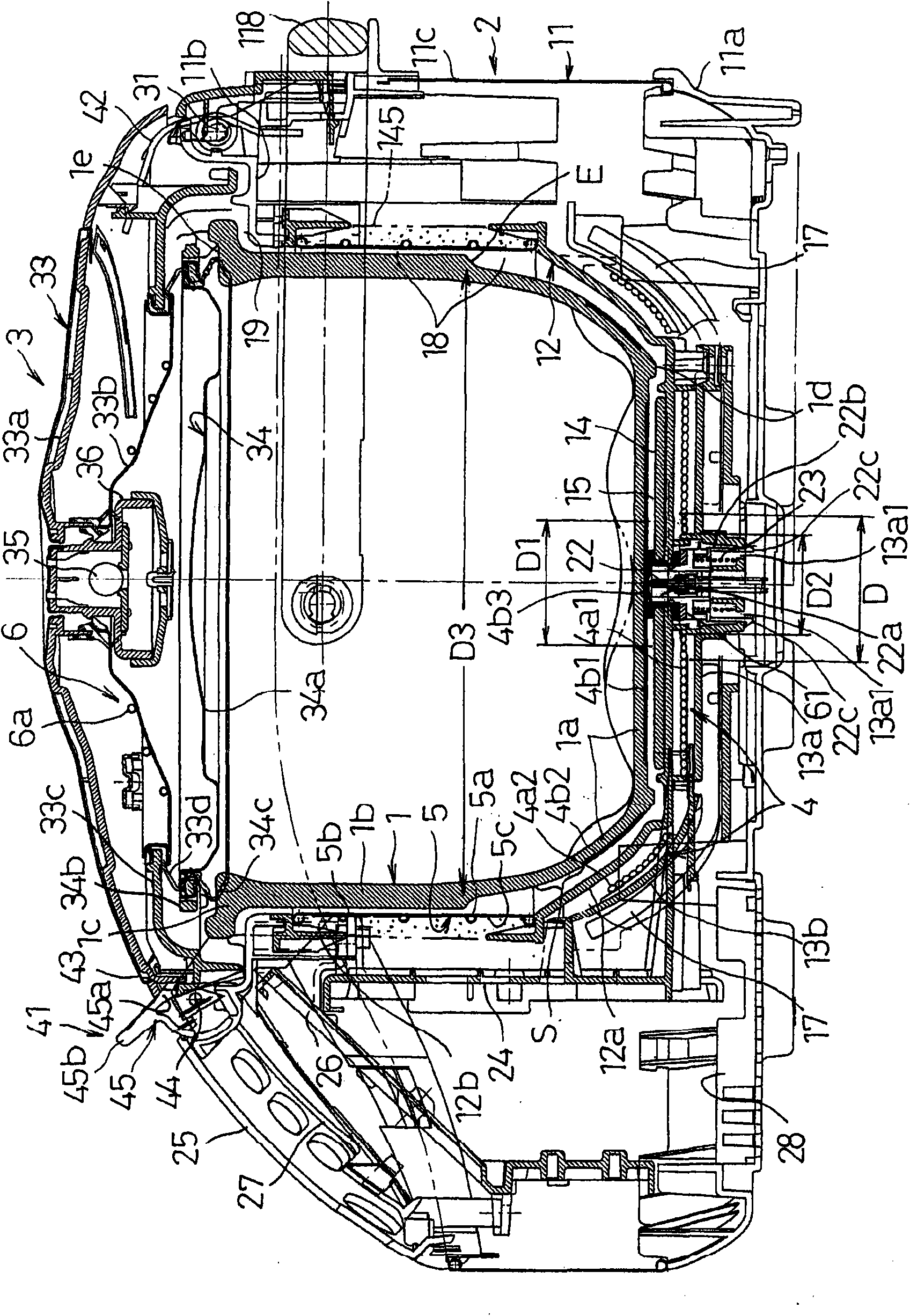

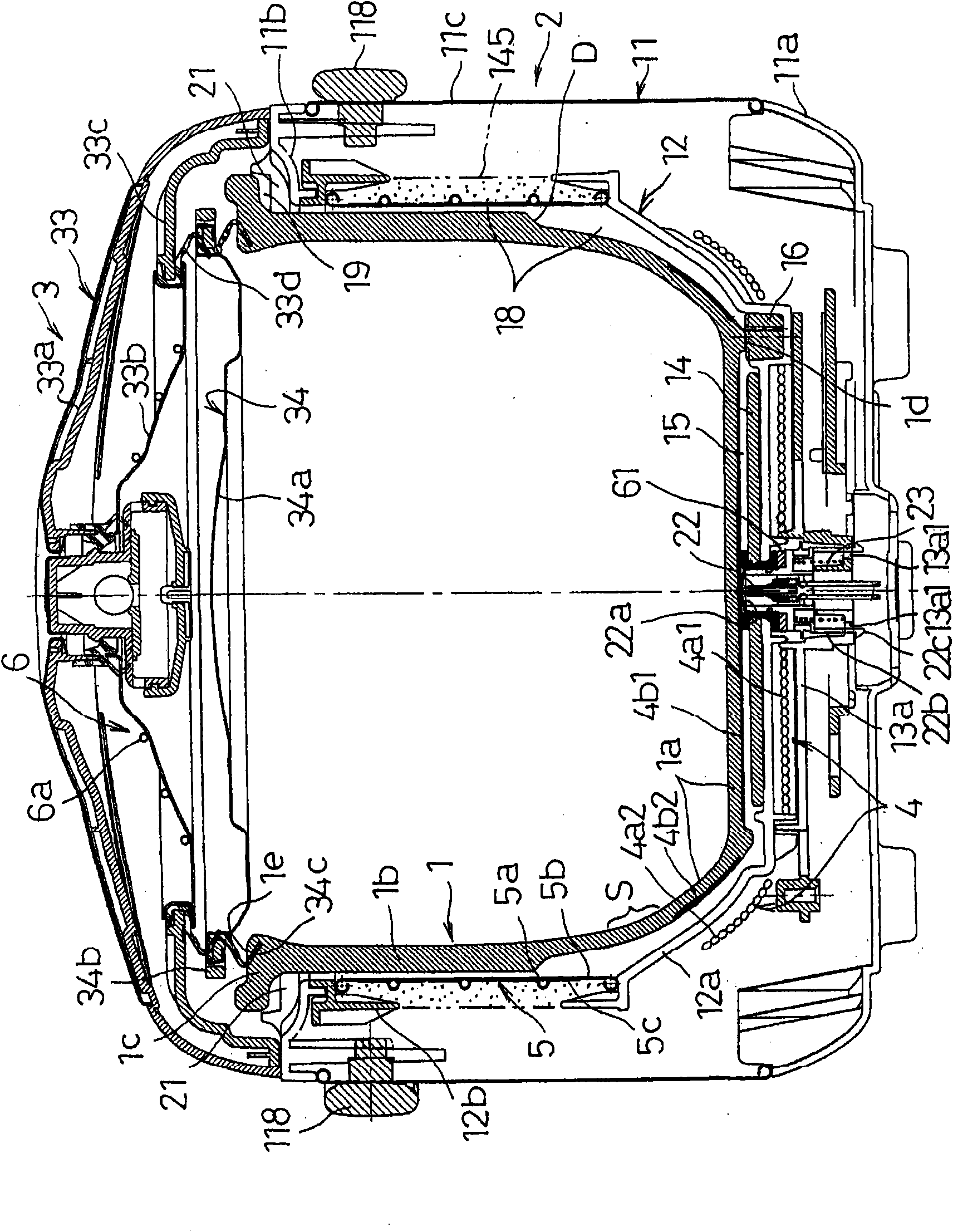

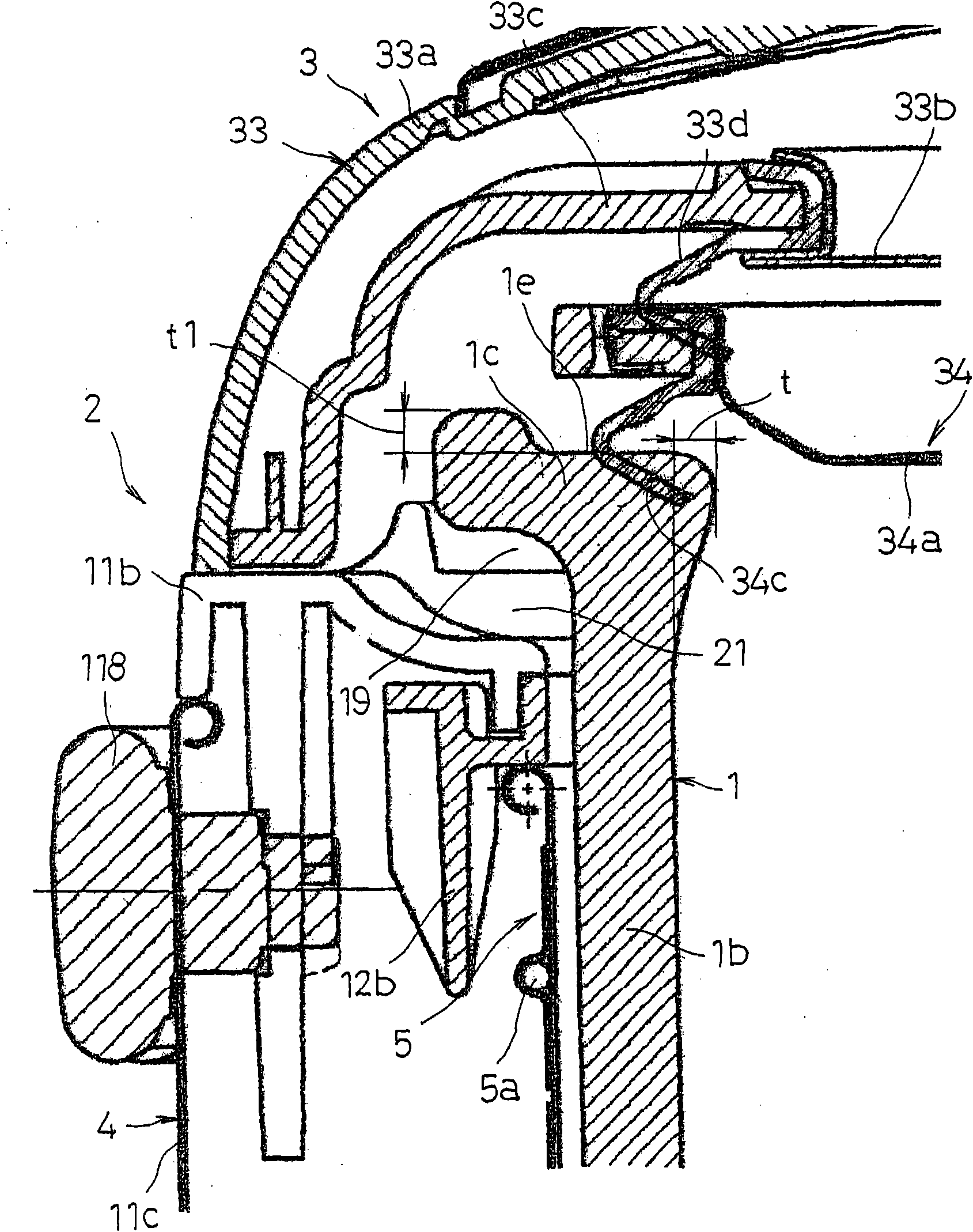

Electric cooker

ActiveCN101044953AEffective heatingSmooth movementElectric heatingCooking vesselsElectromagnetic inductionCooker

A sort of electric cooker, includes a main body(2) which accommodate the up-and-down nonmetallic pot(1) freely, and a cover component which is used to switch the main body and the nonmetallic pot, heaters(4b1,4b2) which generate heat by electromagnetic influence was set on the nonmetallic pot's surface or inner surface or inside and the heaters(4b1,4b2) is activated using the electromagnetic influence of calefaction loops(4a1,4a2) next to the main body(2),and a heat-resistant board is provided between the nonmetallic pot(1) and the heating loop(4a2),which is used to separate the heat from the nonmetallic pot(1) with the heater(4b1,4b2) to protect the heating loop(4a2) and use the reflection of the energy to reheat the nonmetallic pot(1). This character combined with the character that it is easy to obturate the heat helps to achieve the goal corresponding to this invention that makes meals with symmetrical and sufficient heating.

Owner:TIGER CORPORATION

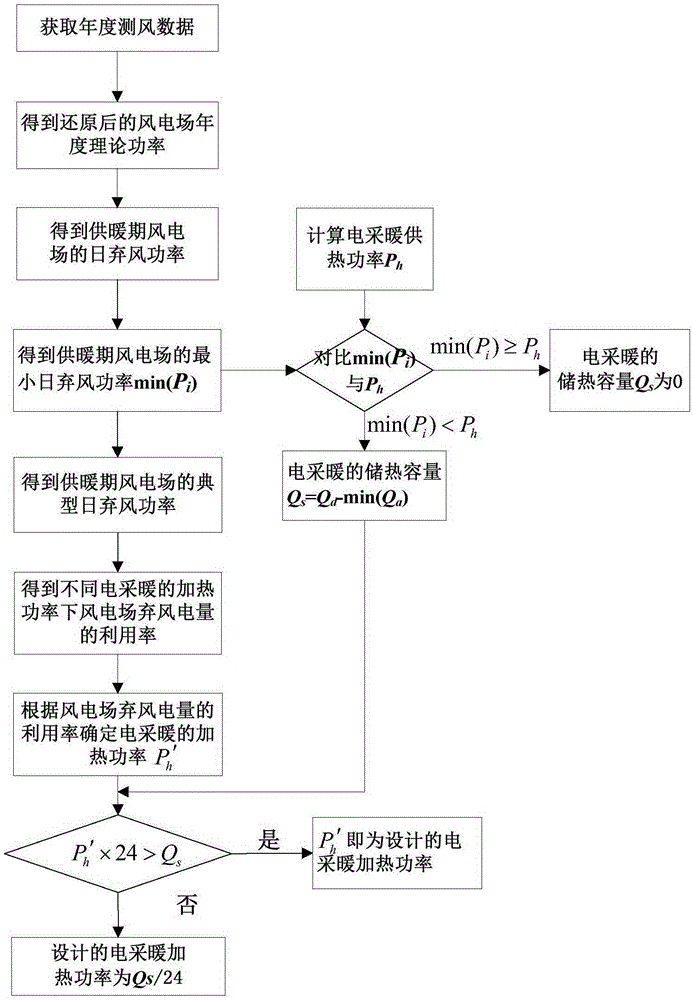

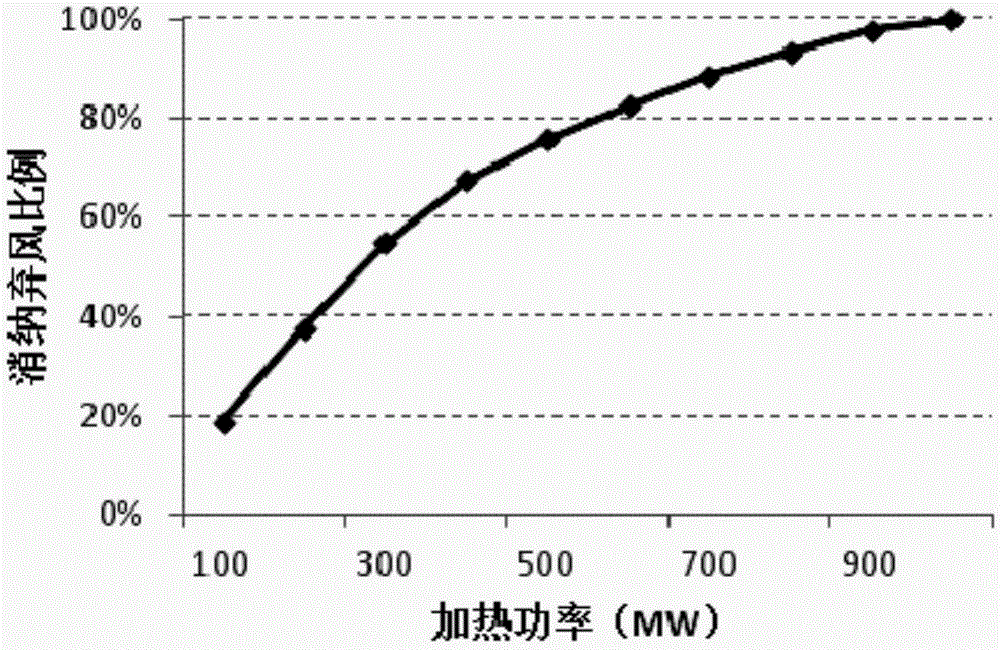

Method for designing heat storage capacity and heating power of electric heating system

ActiveCN105356452AEnsure heating qualityReduce heat storage capacityData processing applicationsMachines/enginesElectric fieldElectric heating

The invention provides a method for designing the heat storage capacity and the heating power of an electric heating system, comprising the steps of determining the daily wind curtailment power of a wind farm in the heat supply period, designing the heat supply power and the heat storage capacity of the electric heating system, and designing the heating power of the electric heating system. The heating power of the electric heating system is designed according to the wind curtailment power curve of the wind farm, and abandoned wind power can be utilized to the maximum; the heat storage capacity of the electric heating system designed by the invention takes into consideration the scenario with least wind curtailment of the wind farm, and the quality of heat supply can be ensured under the condition that abandoned wind power is utilized to the maximum; and the heat storage capacity and the heating power of the electric heating system designed by the invention are minimized under the condition of ensuring the quality of heat supply, and the investment cost of the electric heating system is reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

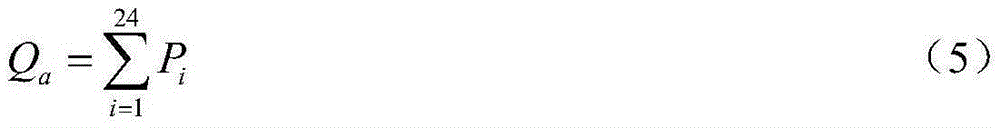

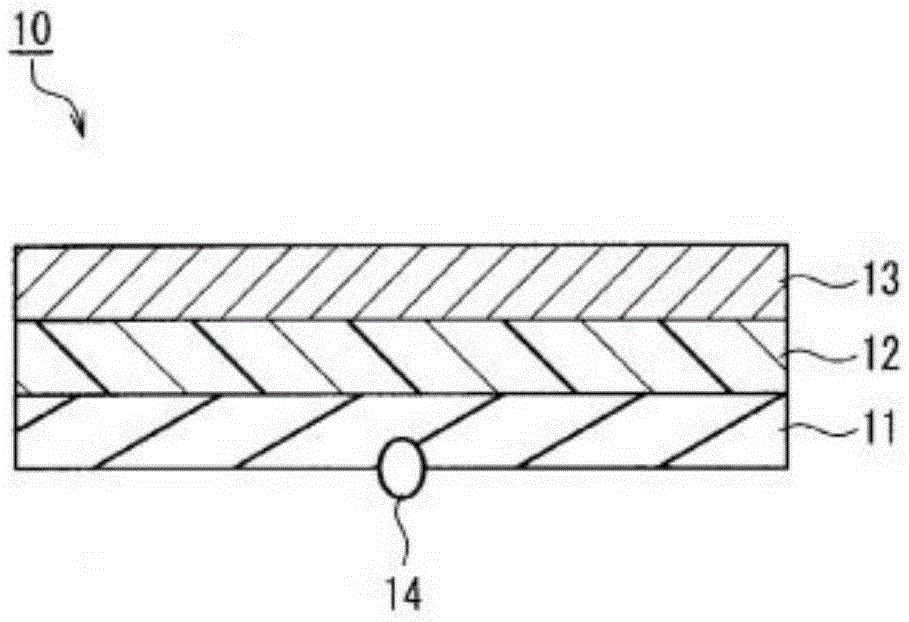

Heat-storage composition

ActiveCN105264039AImprove heat storage capacityImprove thermal conductivitySemiconductor/solid-state device detailsHeat-exchange elementsElectronThermal transmittance

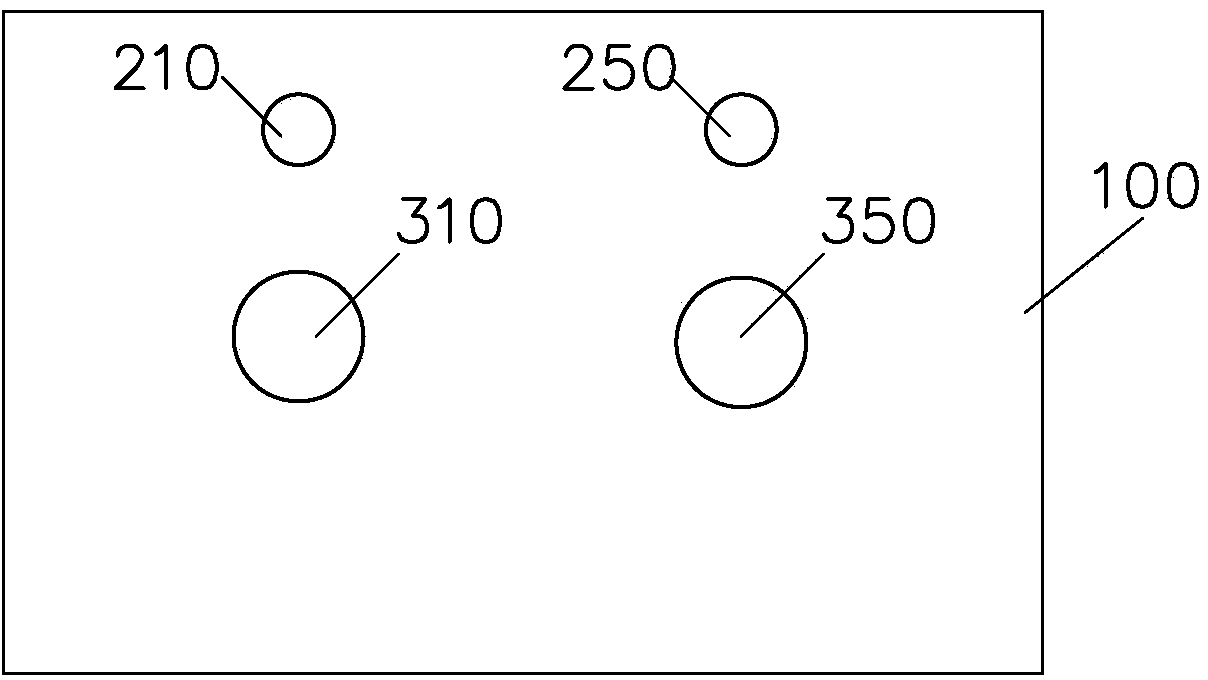

A heat-storage composition (20) according to the present invention comprises a matrix resin (21) and heat-storage inorganic particles (22), wherein each of the heat-storage inorganic particles (22) comprises a substance that can undergo electronic phase transition and can generate latent heat of 1 J / cc or more upon the occurrence of electronic phase transition, and the heat-storage inorganic particles (22) are contained in an amount of 10 to 2000 parts by weight relative to 100 parts by weight of the matrix resin. The heat-storage composition (20) has a heat conductivity of 0.3 W / mK or more. The heat-storage composition may additionally comprise heat-conductive particles (23, 24). The heat-storage inorganic particles are preferably metal oxide particles each containing vanadium as the main metal component. The composition has a high heat storage property and high heat conductivity. The heat-storage silicone material is intercalated between a heat-generating part and a housing for use. Heat coming from the heat-generating part is stored once in the heat-storage composition to delay the conductivity of the heat. During this time, the heat is diffused and therefore partial heating can be avoided. In this manner, uniform heat dissipation can be achieved.

Owner:FUJI POLYMER INDUSTRIES CO LTD +1

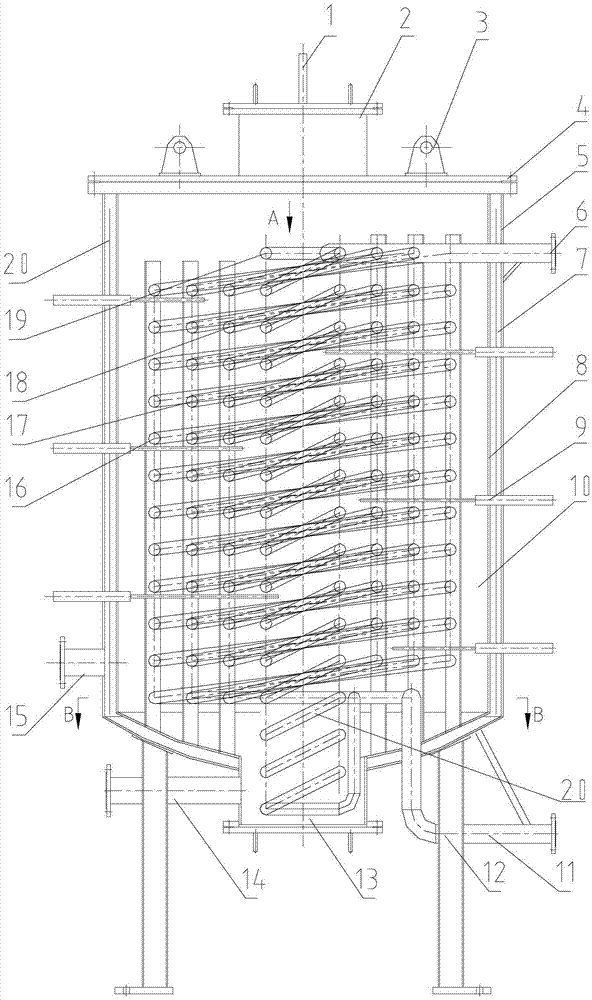

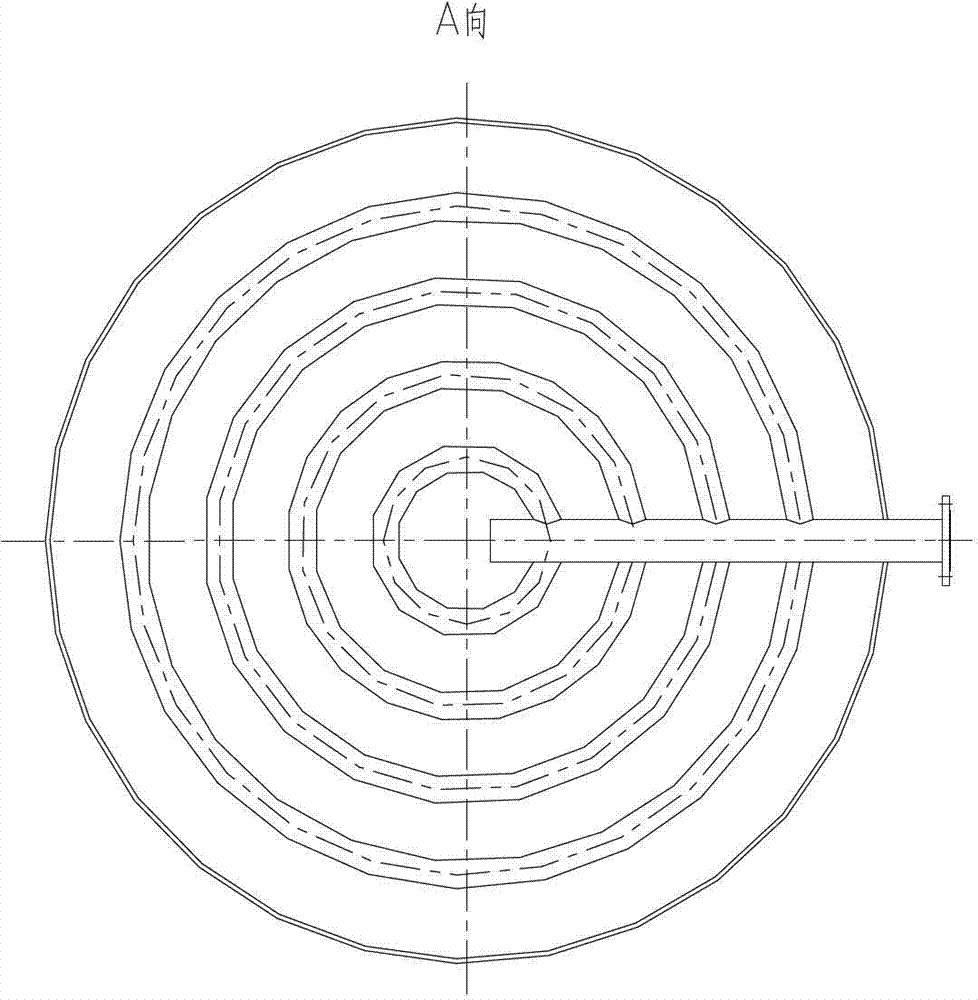

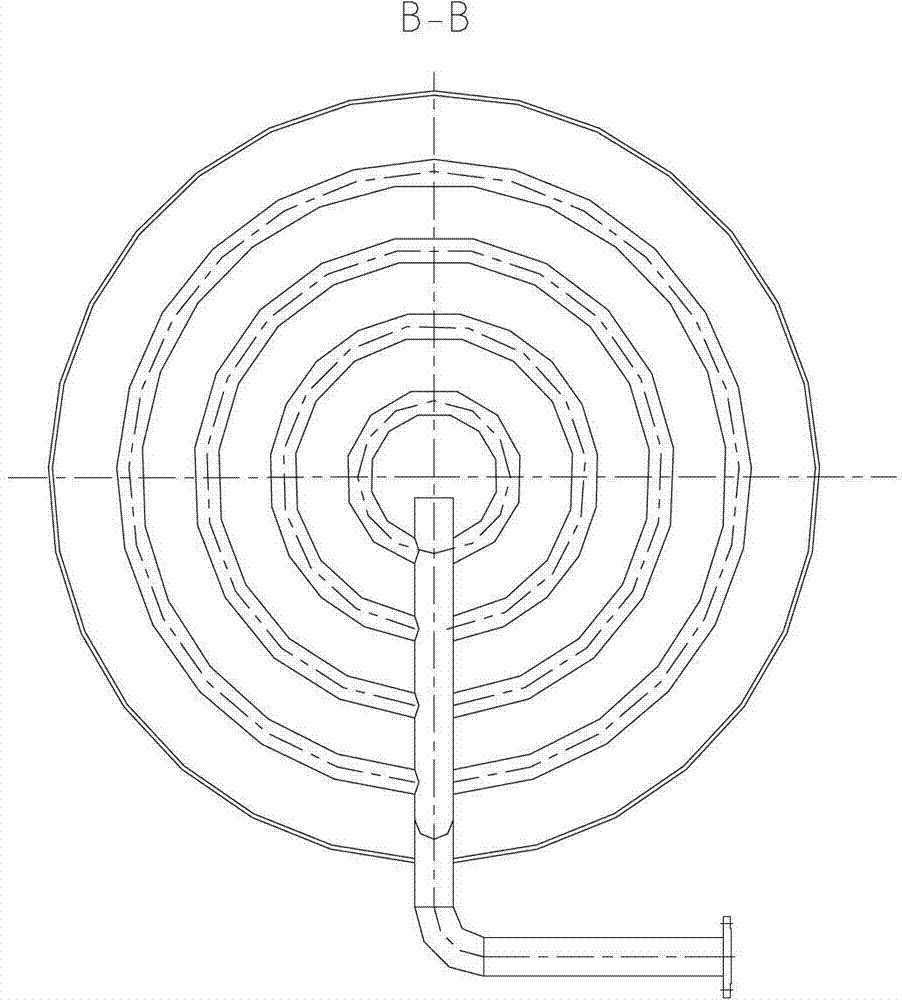

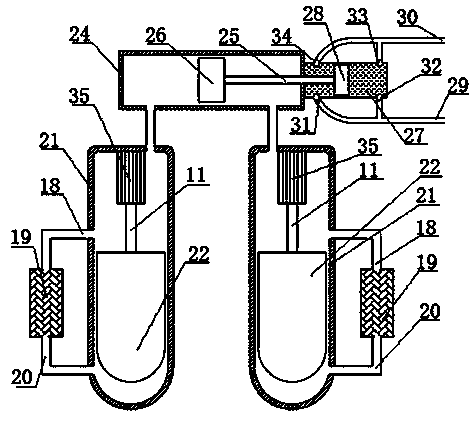

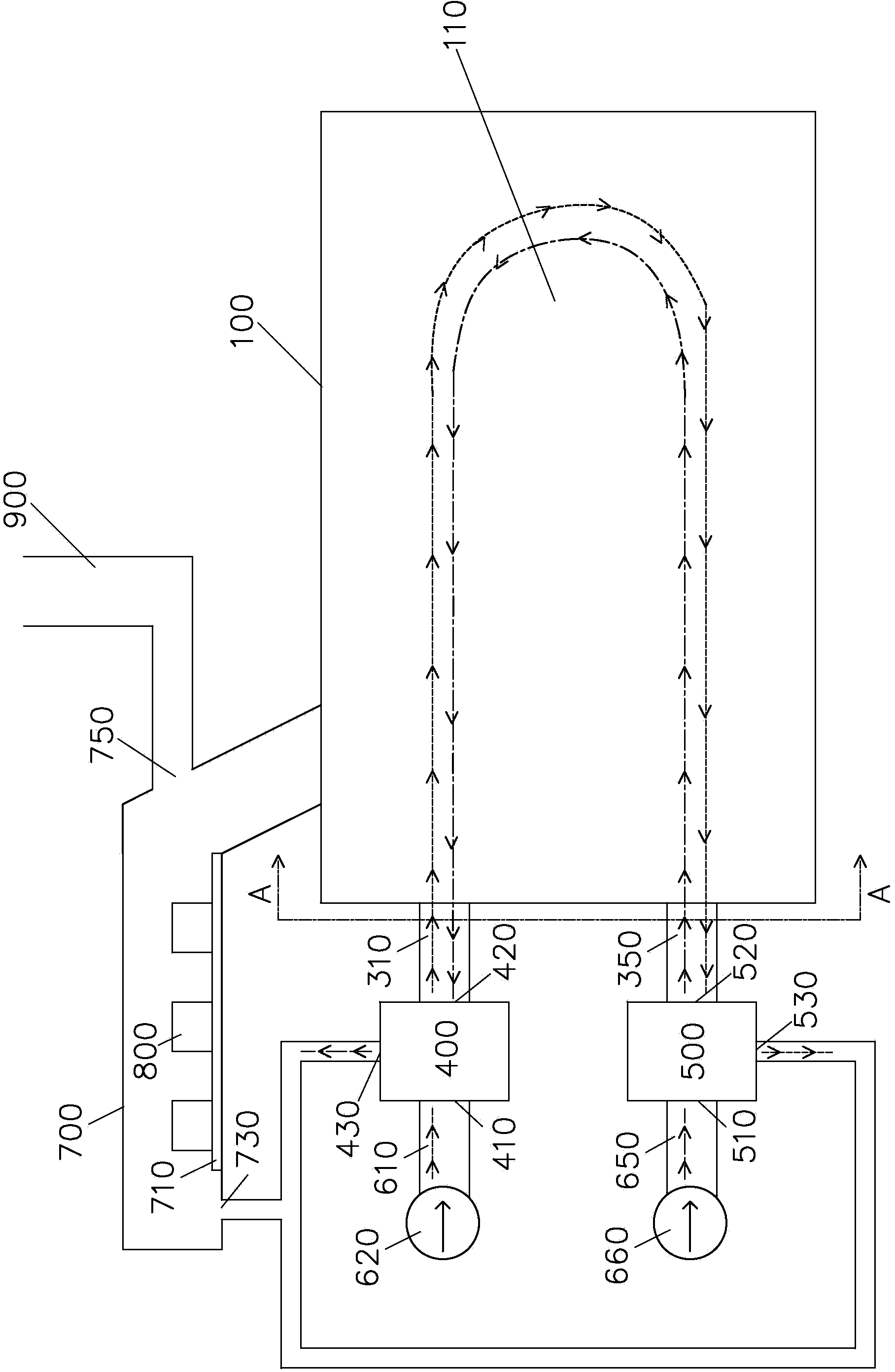

Single tank phase change thermal storage device for solar energy

InactiveCN103115443ASimple structureHigh heat storage densitySolar heating energySolar heat devicesThermal energyEngineering

The invention belongs to the field of solar energy, relates to the solar-thermal energy thermal storage technology, and in particular relates to a single tank phase change thermal storage device for solar energy. The single tank phase change thermal storage device is characterized in that a respiration port, a thermal storage medium inlet, a upper cover, a thermal storage medium outlet and a thermal storage medium discharge gate are arranged on the tank body, a polycyclic multilayer heat exchange coil is arranged in the tank body, and the polycyclic multilayer heat exchange coil is connected between a heat-transfer medium outlet pipe arranged on the upper end of the heat exchange coil and a heat-transfer medium inlet pipe arranged on the lower end of the heat exchange coil in parallel, thus forming a heat-transfer medium circulation pipeline; a thermal storage chamber of the tank body, which contains the thermal storage mediums, is enclosed by the inner wall, the upper cover and the thermal storage medium discharge gate; a sealed heat insulation sandwich is composed of the inner wall of the storage tank and the outer wall of the storage tank; and a thermometer is arranged in the tank. The device disclosed by the invention has the advantages that the phase change thermal storage technology is adopted to enable the thermal storage density to be improved greatly, and the thermal storage volume is efficiently reduced on the premise of same thermal storage capacity; and the storage and release processes of the phase change materials heat are carried out in the same device, thus simplifying the structure of thermal storage device efficiently, and reducing the cost.

Owner:兰州大成科技股份有限公司 +2

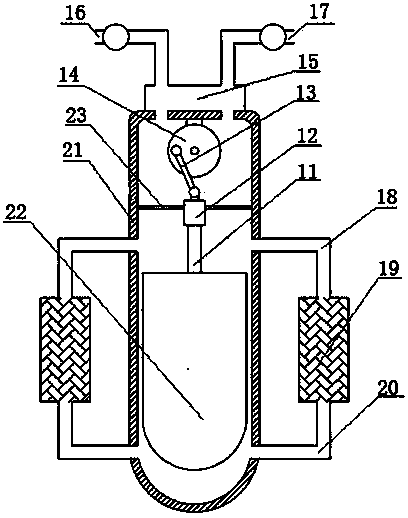

Double-action type hydraulic transmission Stirling engine taking heat storage device as heat source

InactiveCN103883425AFix the leakReduce heat storage capacityHot gas positive displacement engine plantsLiquid storage tankProcess engineering

Owner:CHENGDU UNI LINK ENERGY

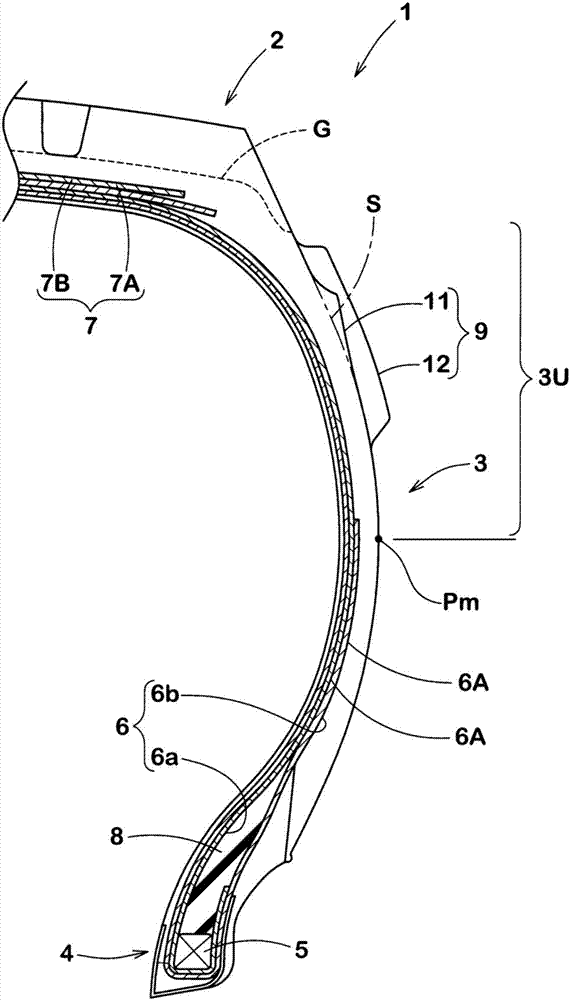

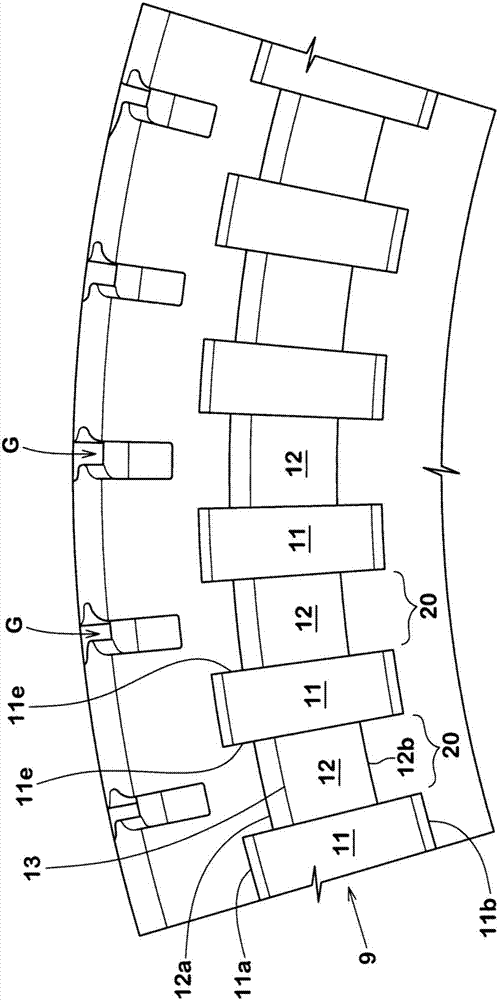

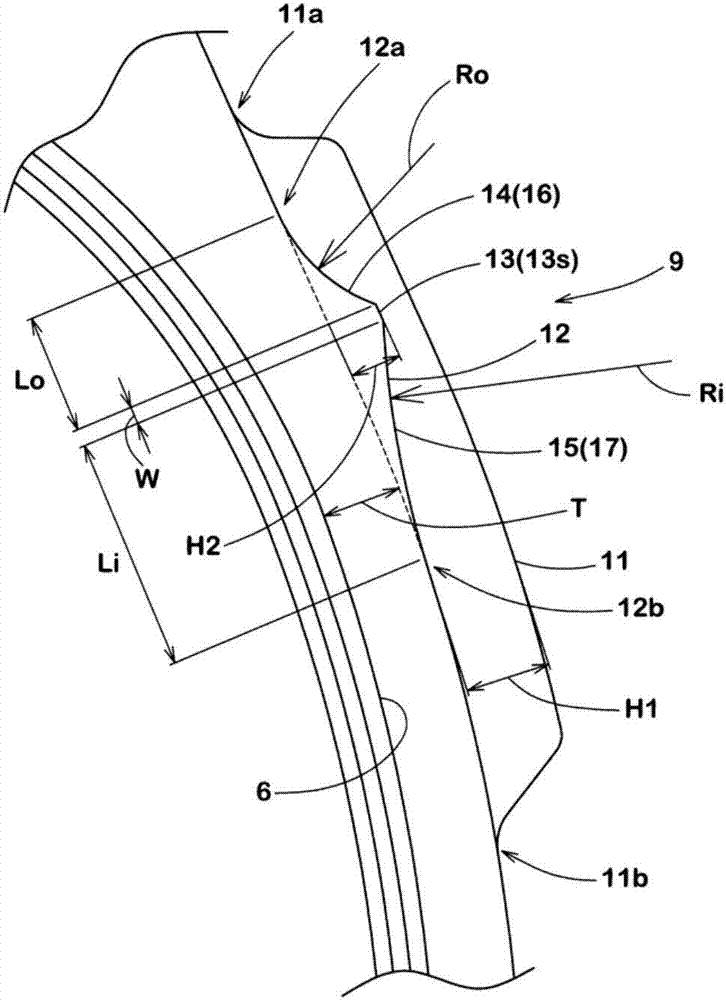

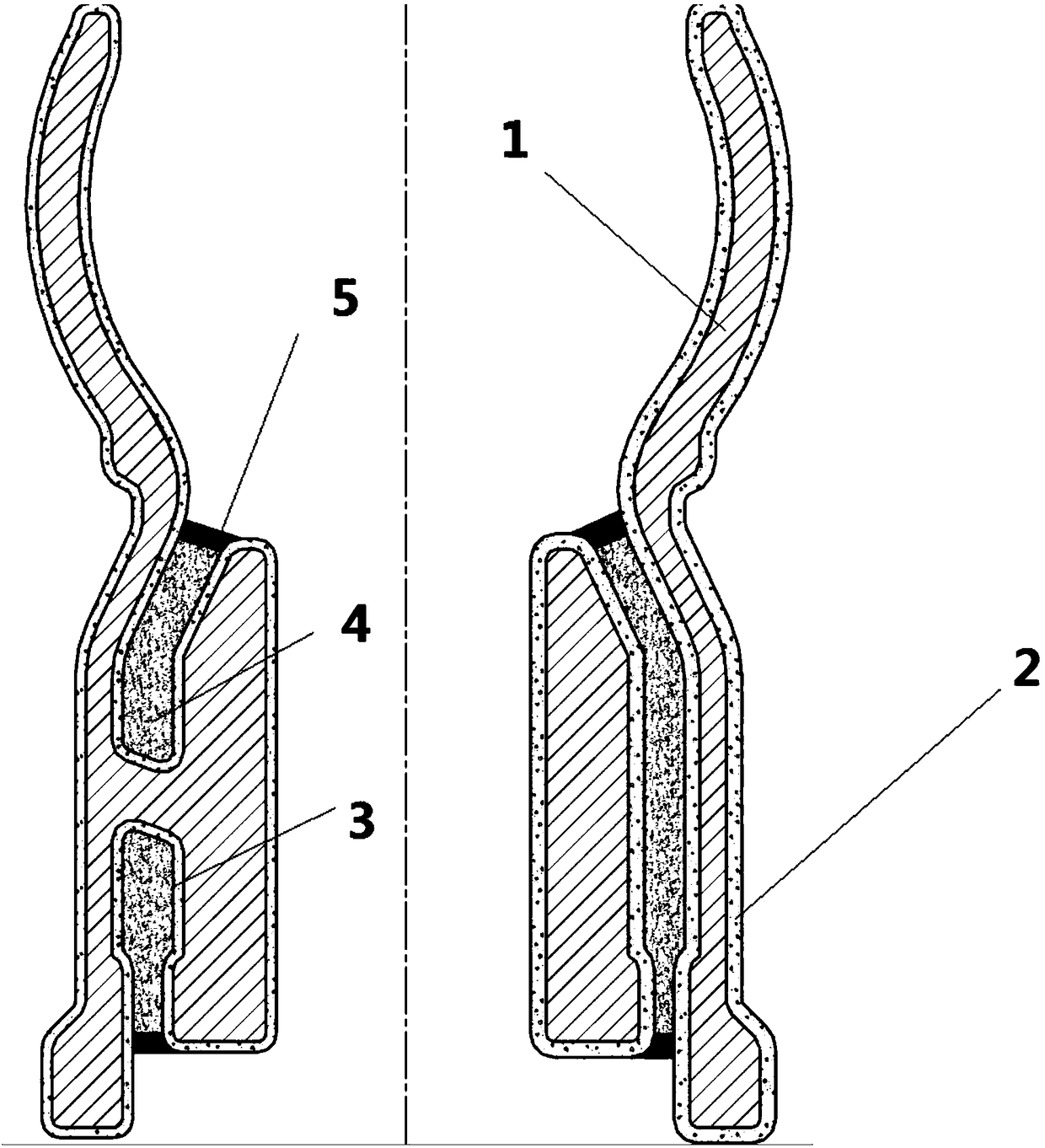

Pneumatic tire

PendingCN107187278AGuaranteed thicknessImprove cut resistanceTyre sidewallsEngineeringMechanical engineering

The present invention provides a pneumatic tire, which ensures the rock performance and improves the cutting resistance. A pneumatic tire 1 comprises a sidewall portion 3 provided with a side protector 9 protruding from a contour line S of the sidewall portion. The side protector 9 is composed of first protector blocks 11 arranged in the tire circumferential direction at intervals and second protector ribs 12 connecting therebetween. In a tire meridian section including each second protector rib 12, the second protector rib 12 has a triangular cross-sectional shape having an apex 13 at which the protruding height from the contour line S becomes maximum, and radially outer and inner oblique sides 14 and 15 extending radially outwardly and inwardly from the apex 13. Each of the radially outer and inner oblique sides 14 and 15 is a concave circular arc whose center is positioned outside the tire.

Owner:SUMITOMO RUBBER IND LTD

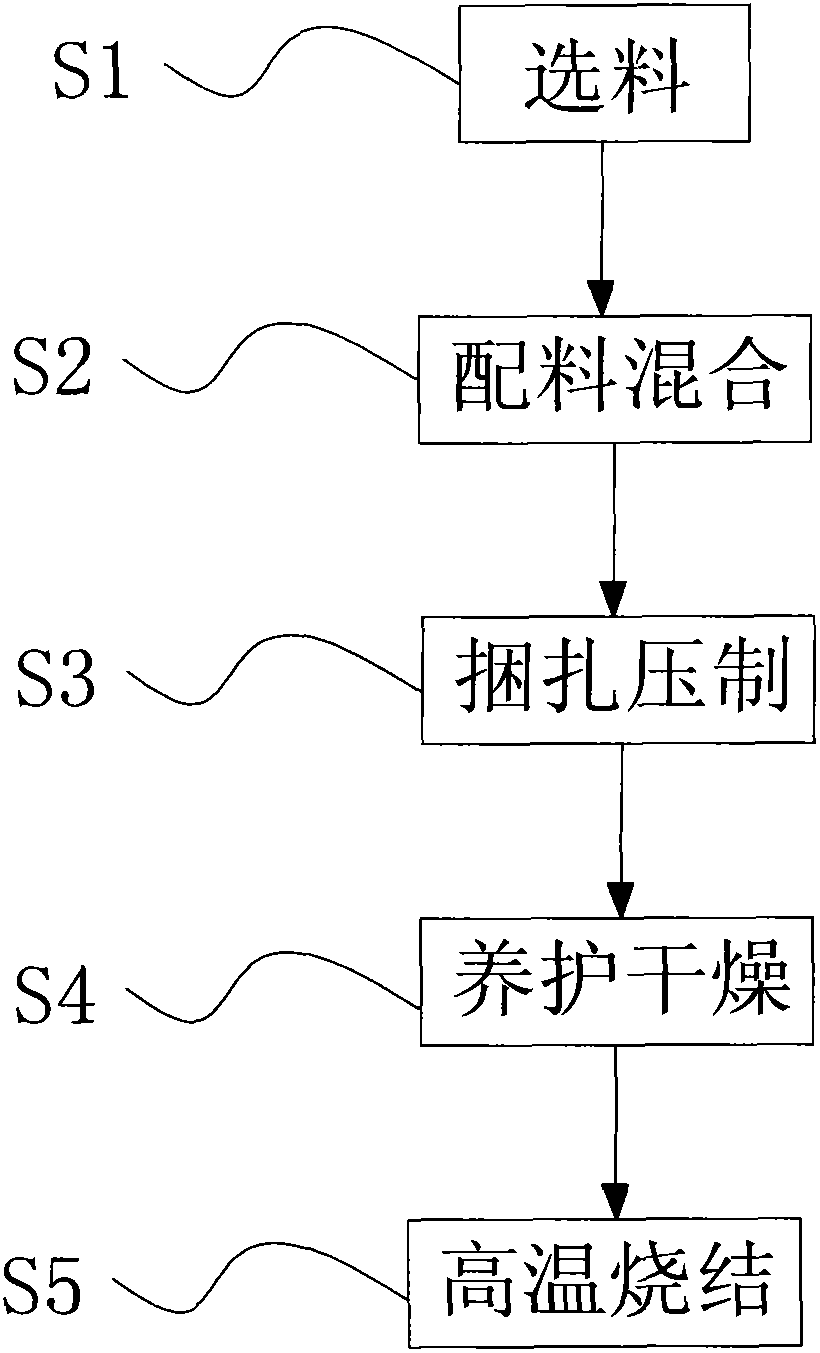

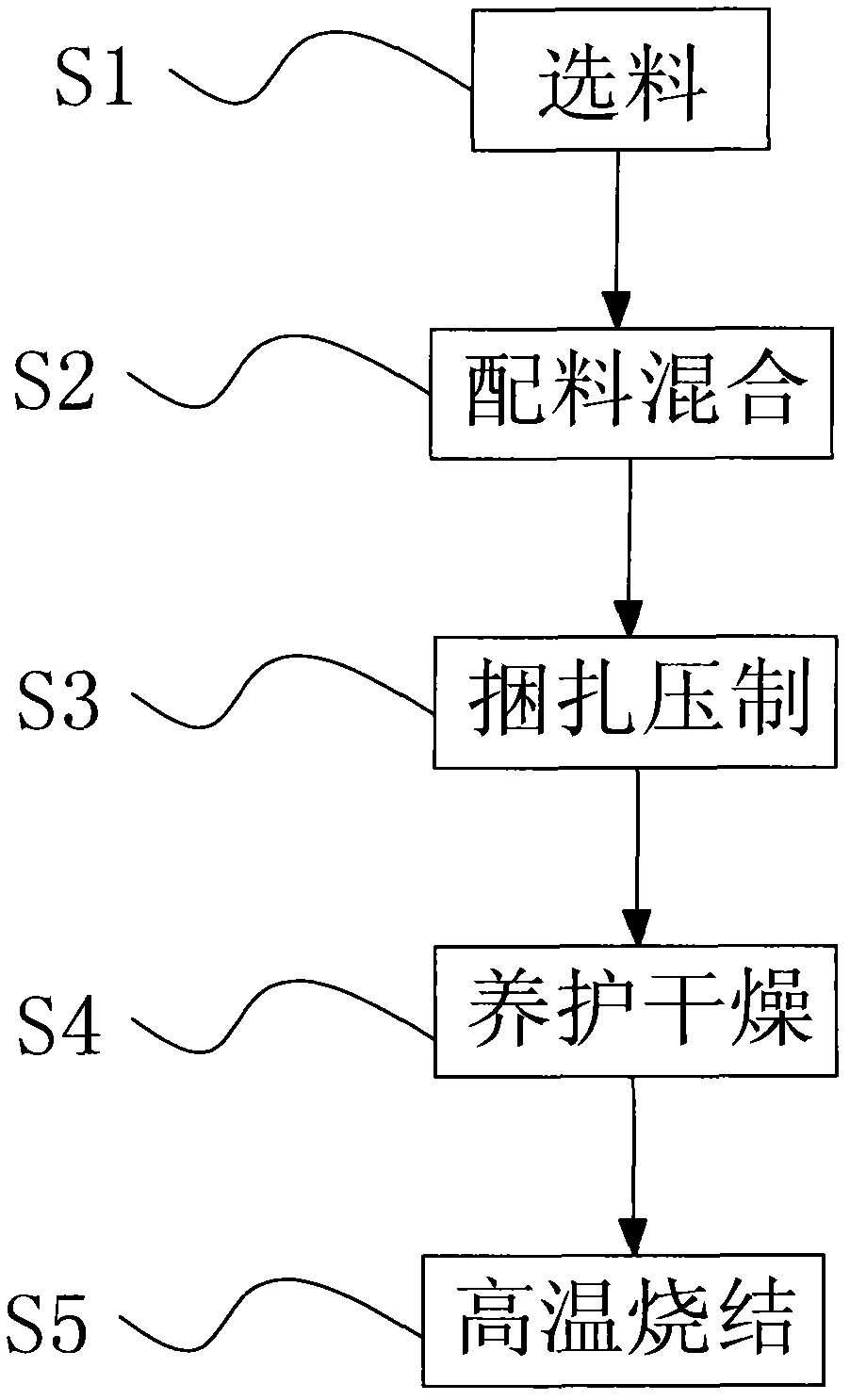

A preparation method of ultra-high temperature lightweight zirconia setter plate

The invention discloses a method for preparing an ultra-high-temperature light-weight zirconia setter plate, which comprises the following steps: (1) material selection: respectively select high-purity zirconia fiber, zirconia fine powder and high-purity zirconia sol; 2) Mixing ingredients: Weigh 30-60% of zirconia fibers with a diameter of 2-15 microns and 40-70% of zirconia fine powder with a particle size of ≤0.088mm by mass percentage; add zirconium sol binder and stir and mix; ( 3) The above-mentioned mixed and prepared raw materials are sieved through a sieve and packed into a plastic bag for bundling and storing, and then taken out and sieved twice before being pressed and formed; (4) The above-mentioned pressed and formed solid zirconia is cured and dried; (5) Sintering the solid zirconia after curing and drying at high temperature to obtain the desired high temperature resistant zirconia setter. The method of the invention is novel and effective, and the prepared zirconia light-weight setter plate has high porosity, low heat storage, good chemical stability, light weight and high temperature resistance.

Owner:韦国文 +1

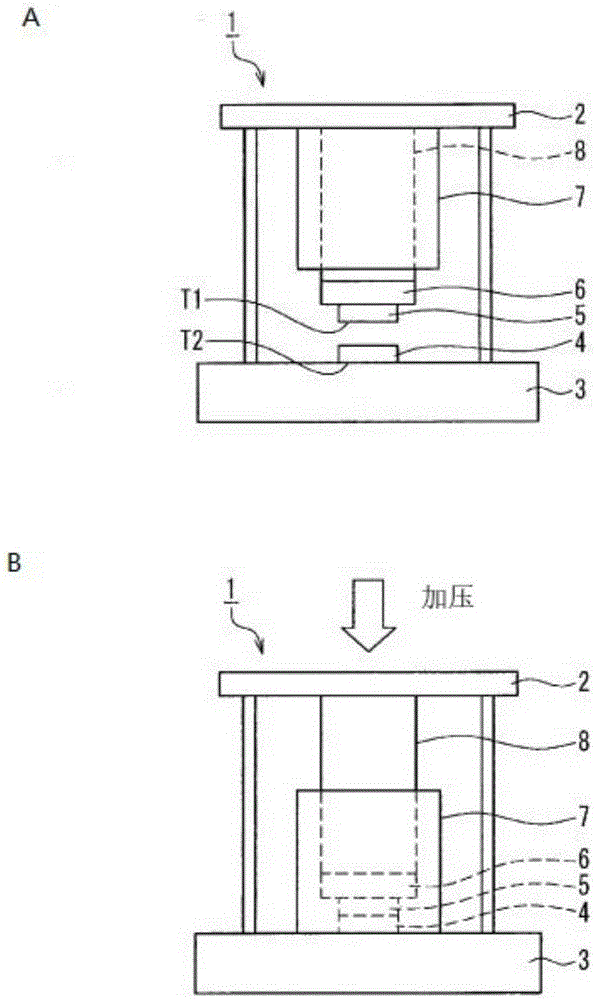

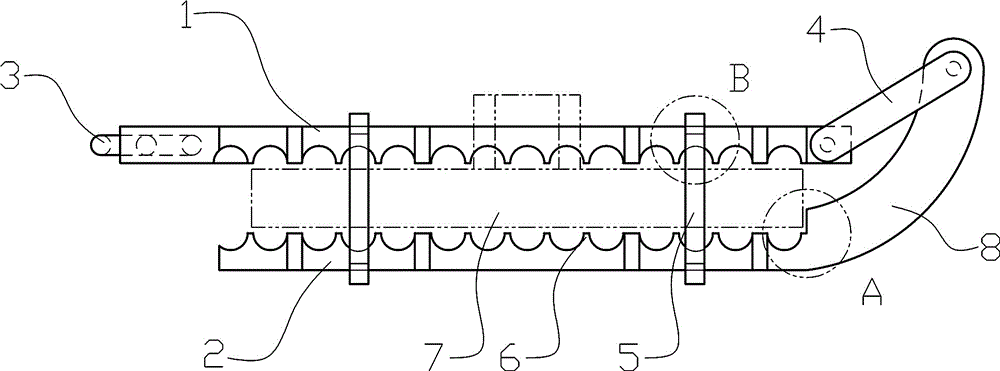

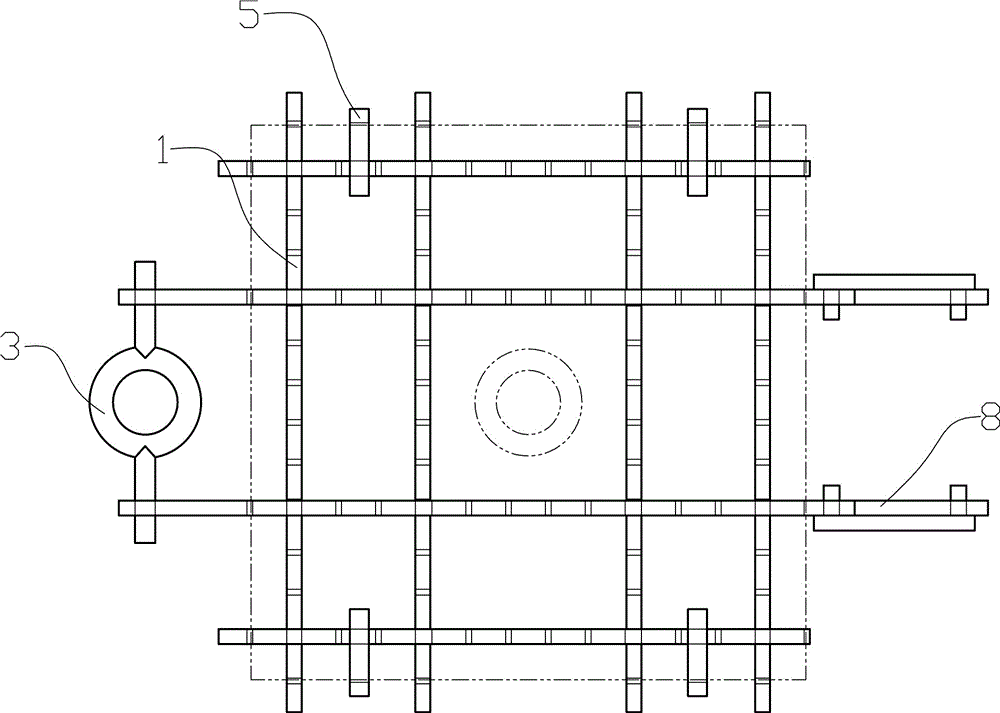

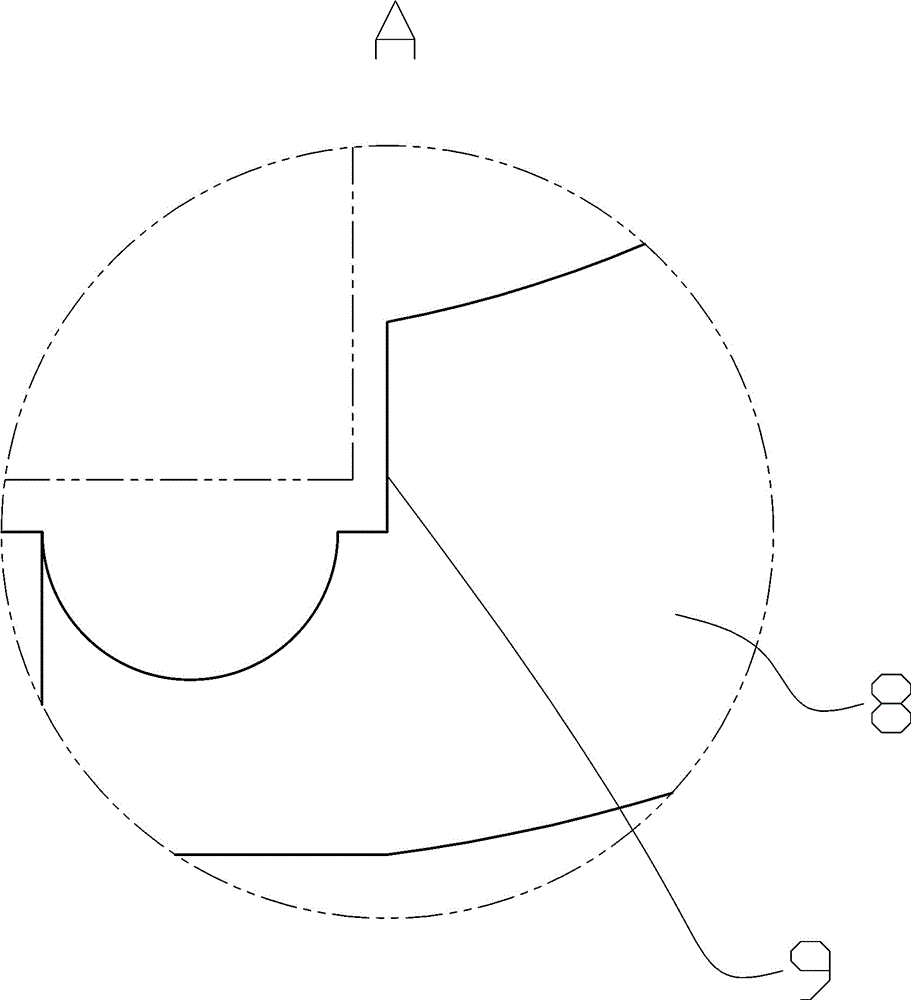

Quenching anti-deformation device and method

ActiveCN106367570AAvoid deformationControl deformationFurnace typesHeat treatment furnacesEngineeringQuenching

The invention provides a quenching anti-deformation device and method. A lower pressing frame is hinged to an upper pressing frame through a connecting rod, and a space used for pressing a workpiece is formed between the lower pressing frame and the upper pressing frame. The lower pressing frame and the upper pressing frame are connected in a pressing mode through a plurality of pressing claws. The pressing claws are in a C shape. An extending part is arranged on one side of the lower pressing frame or the upper pressing frame. A turning ring is rotationally connected with the extending part. Through the locked upper pressing frame and the lower pressing frame, enough pressing strength is achieved so that deformation during quenching of the workpiece can be prevented, the deformation amount of the workpiece can be controlled and is smaller than 5 mm, subsequent machining is well guaranteed, and the product quality is improved. Through the arrangement of the turning ring, the large-sized workpiece can be heated in the horizontal state, after heating is completed, the turning ring is hooked with a hoisting device, a workpiece (7) is hoisted vertically and placed in a quenching bath to be quenched, energy consumption is reduced, and the quenching quality is improved.

Owner:YICHANG MARINE DIESEL ENGINE

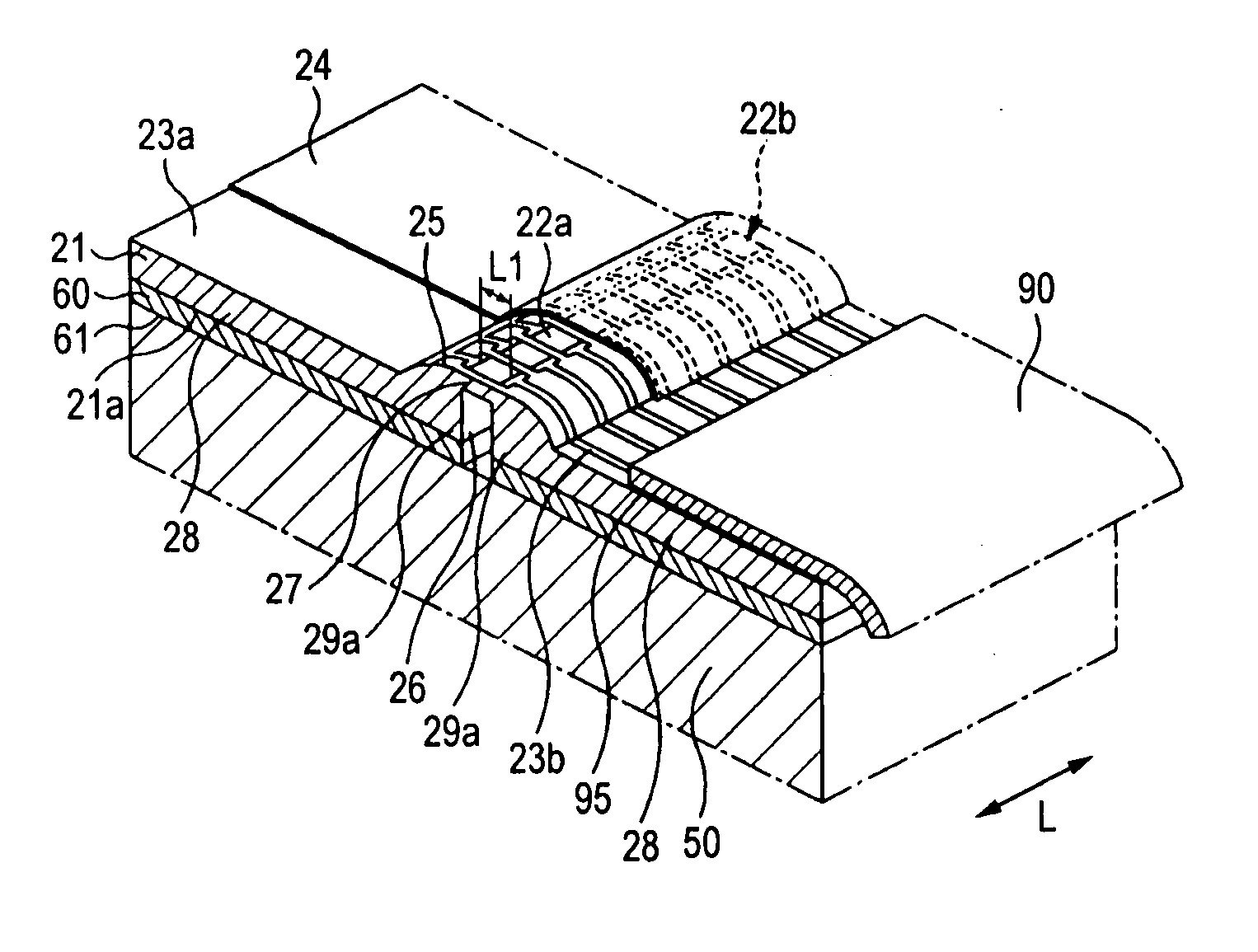

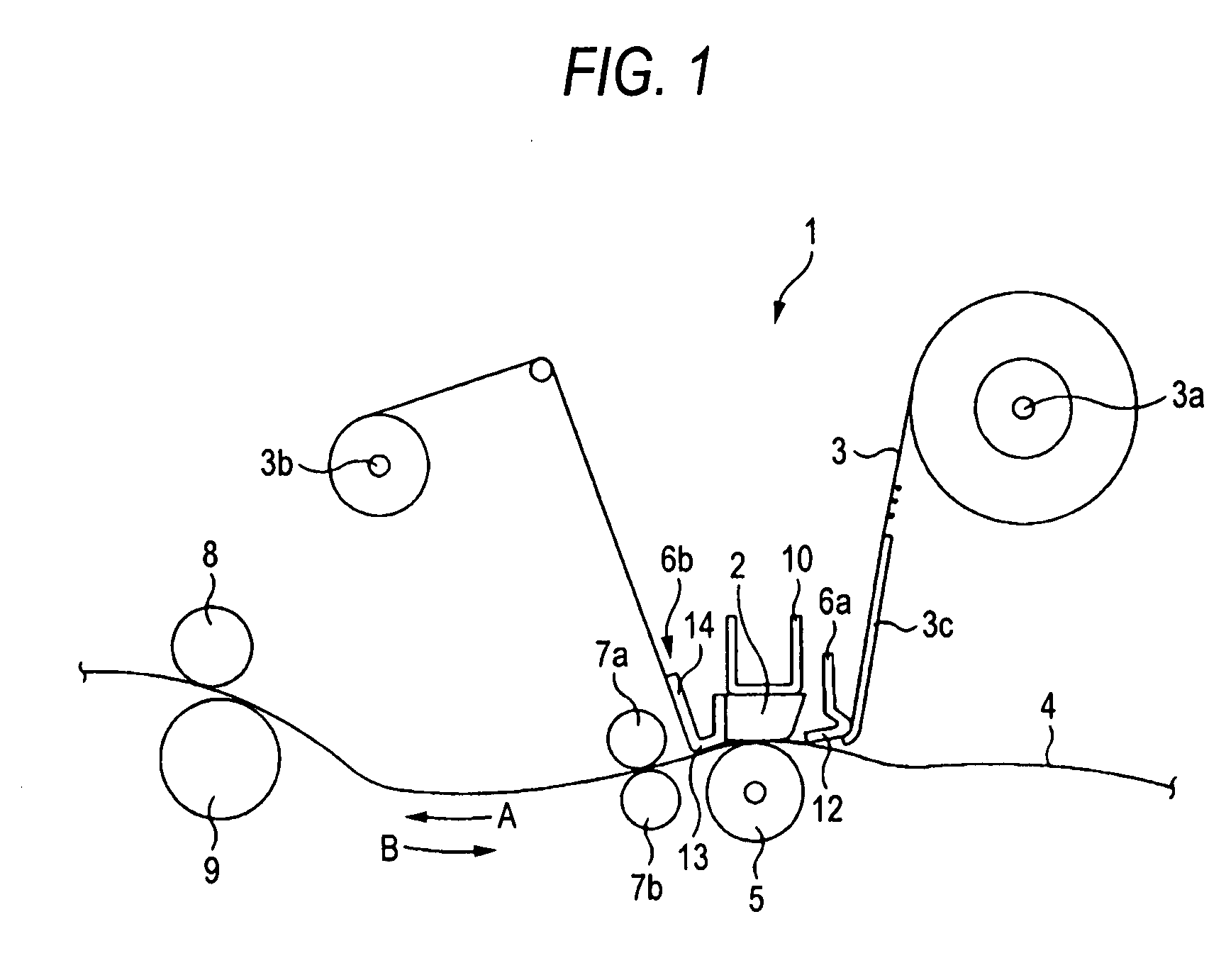

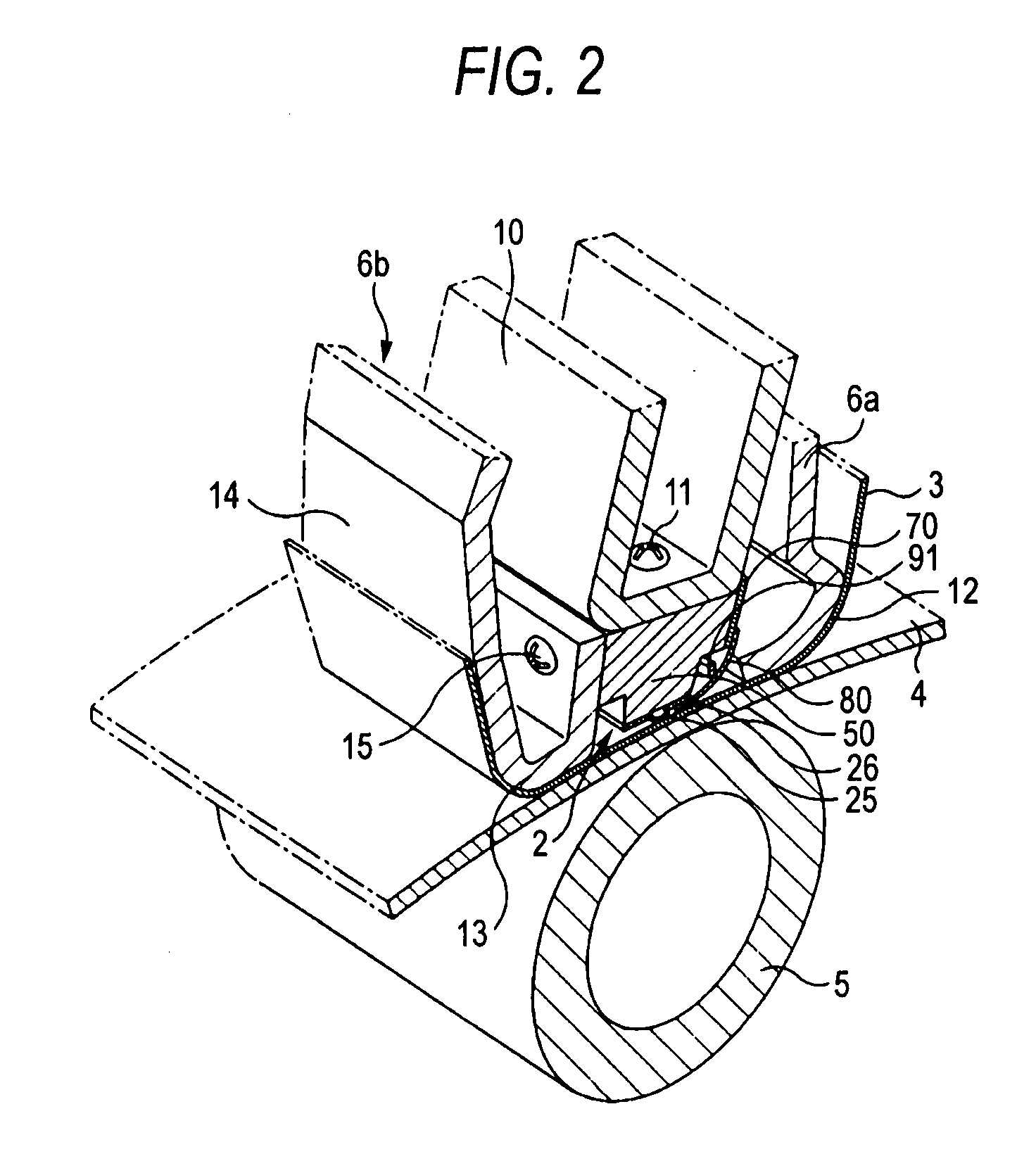

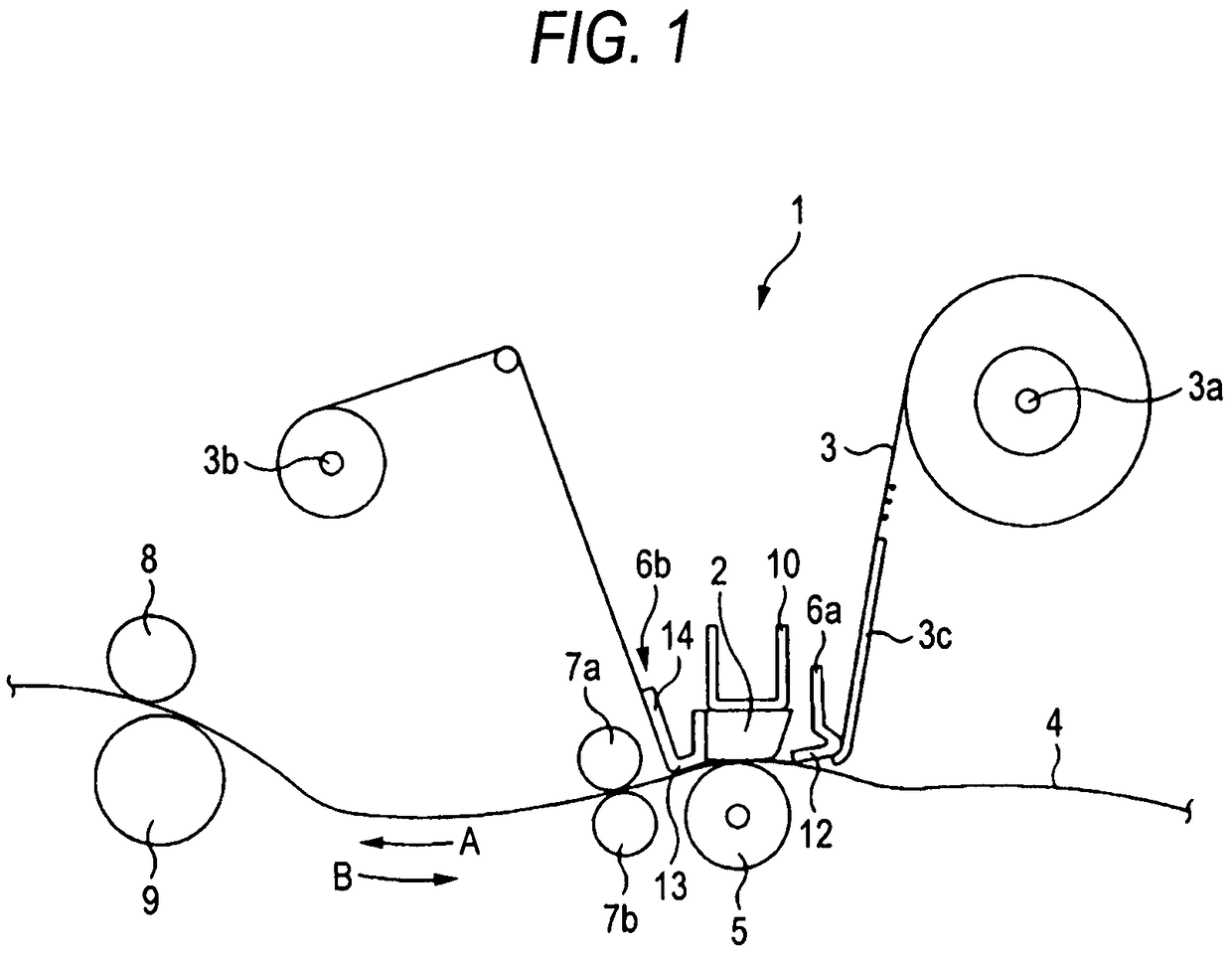

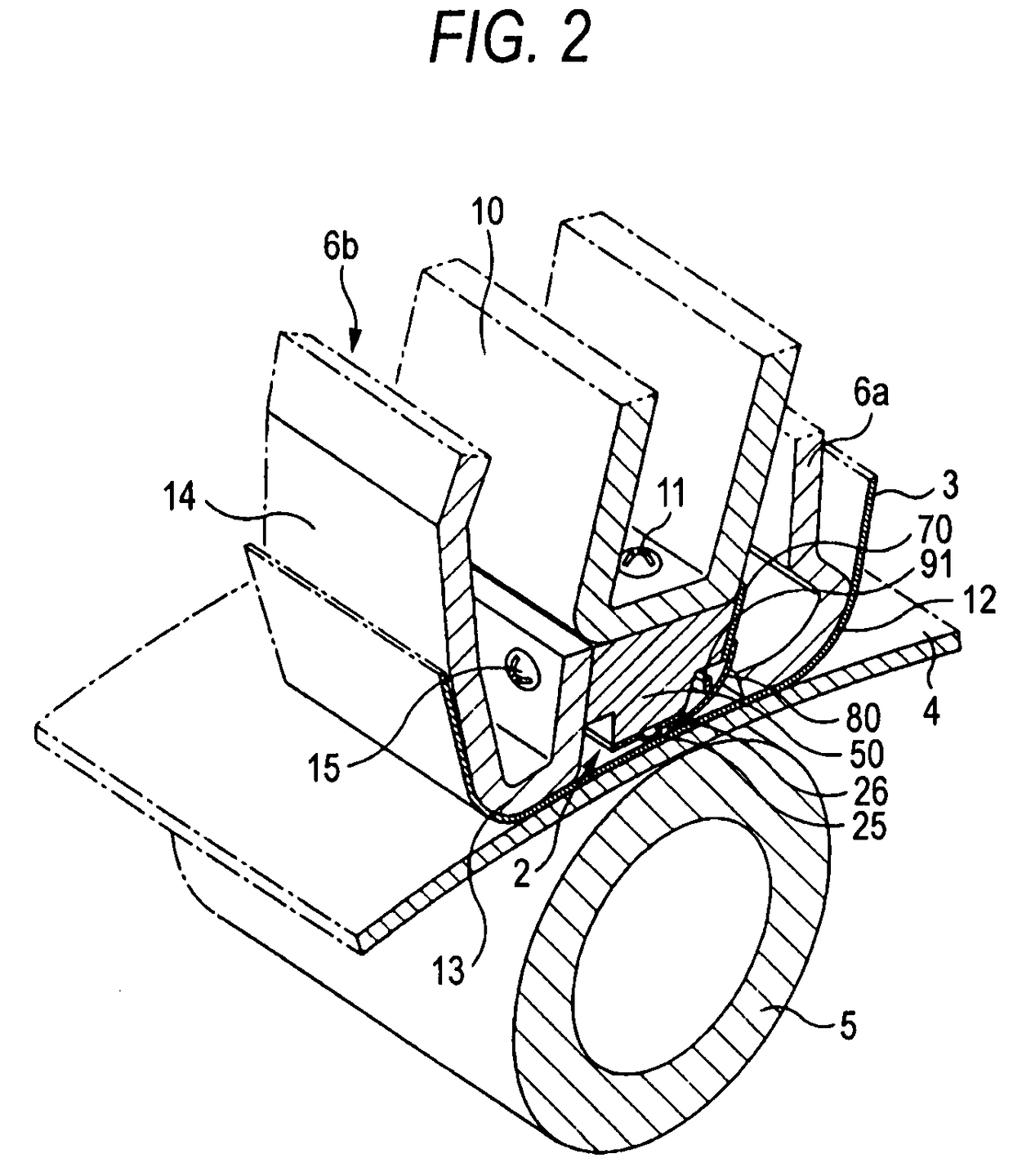

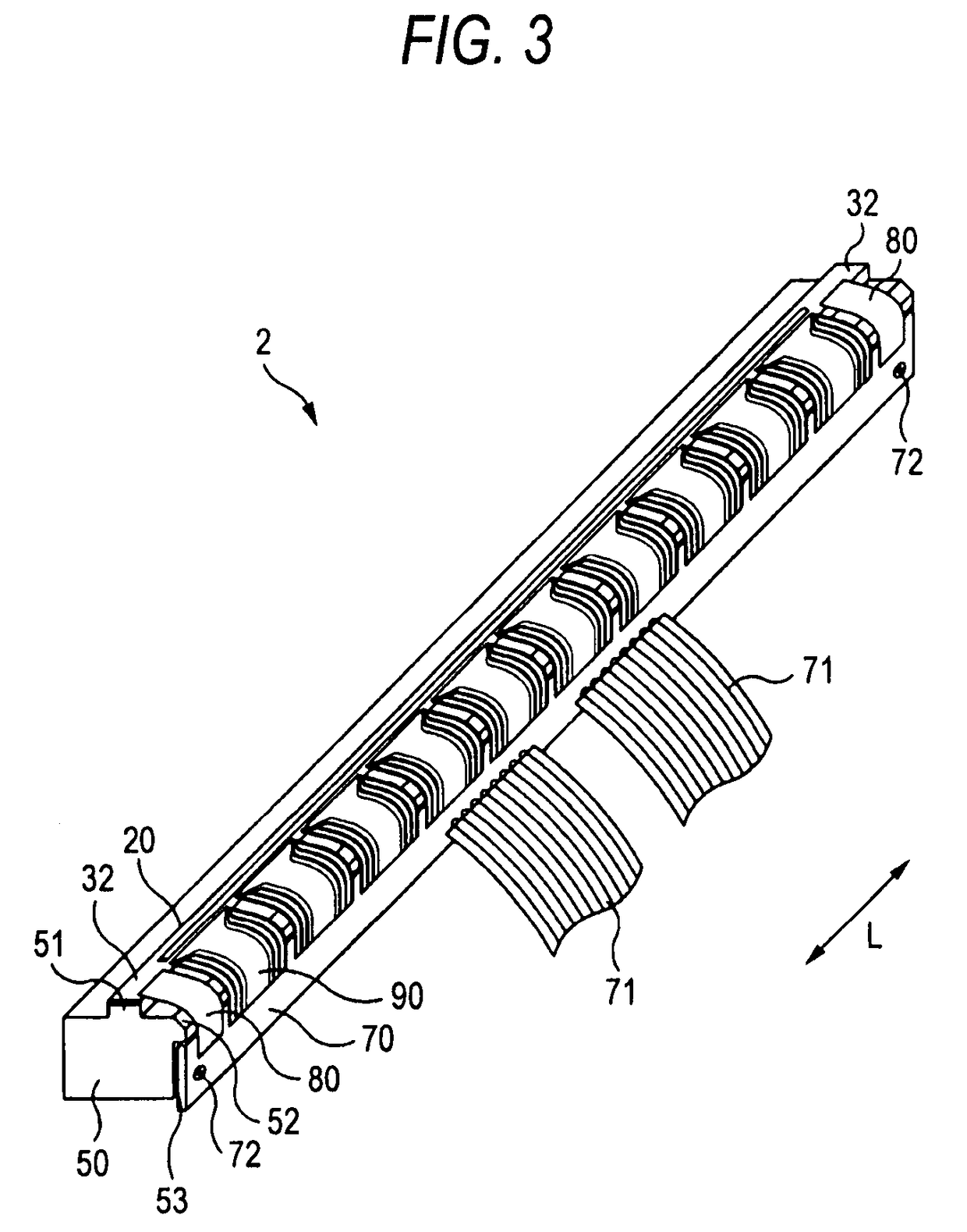

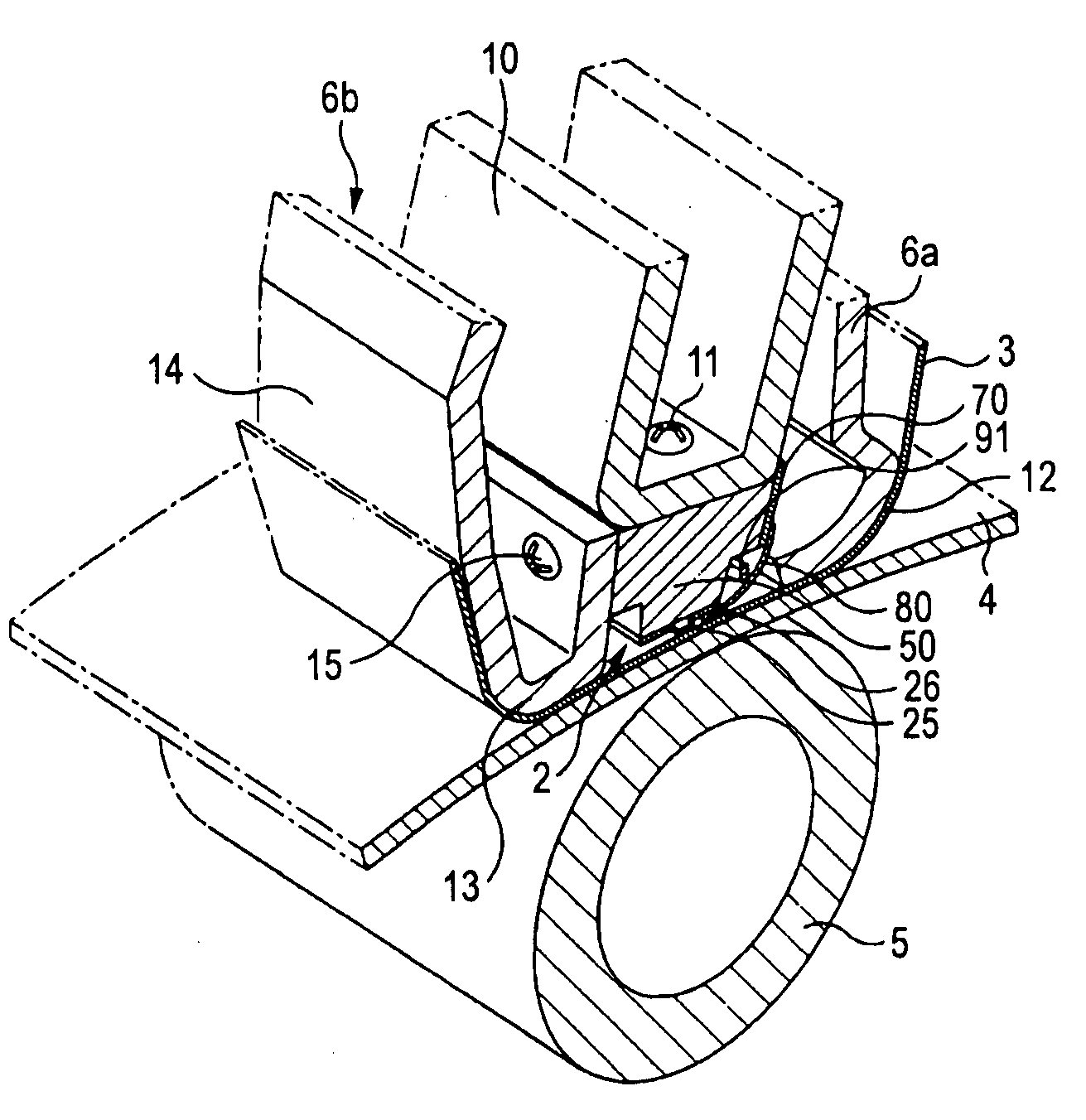

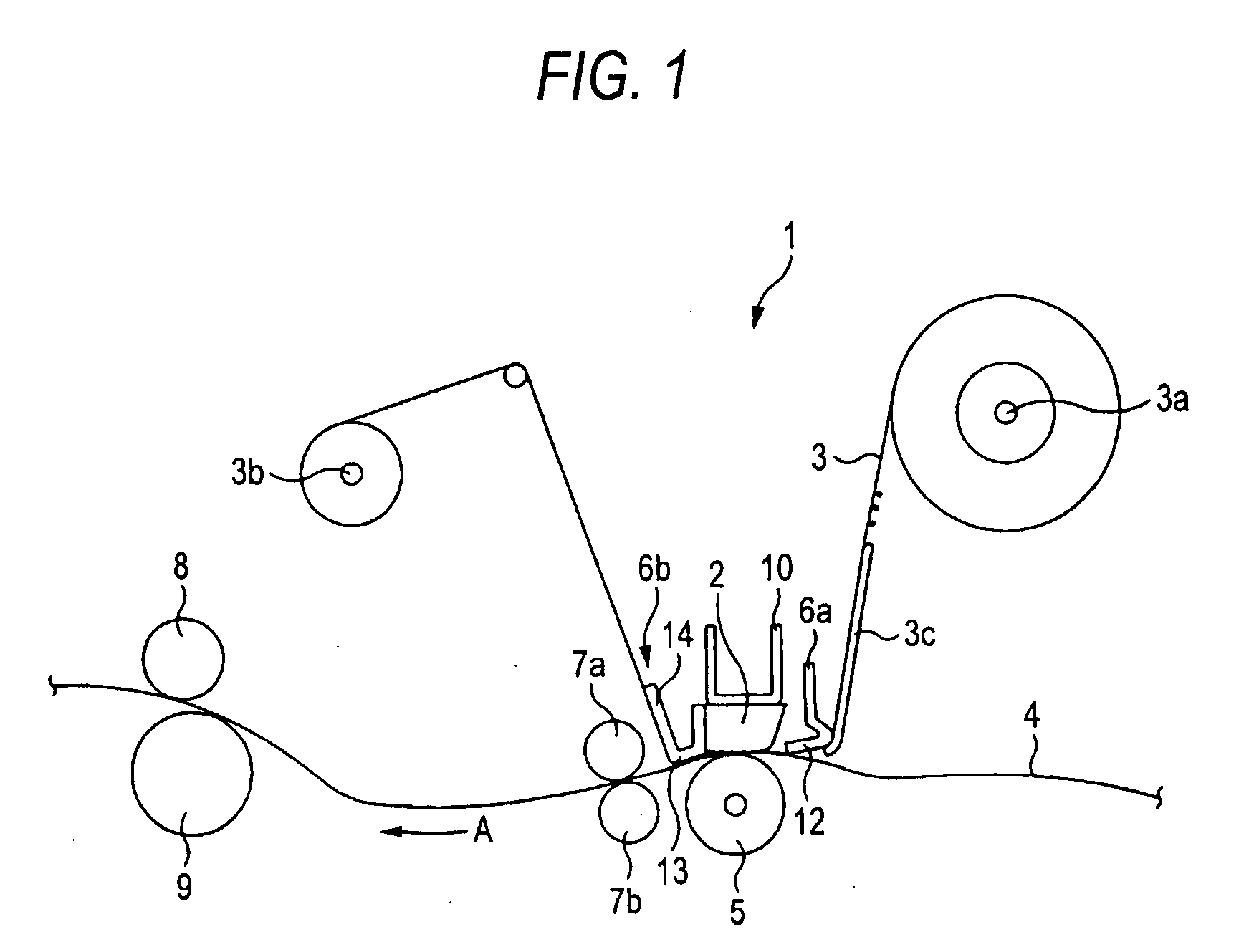

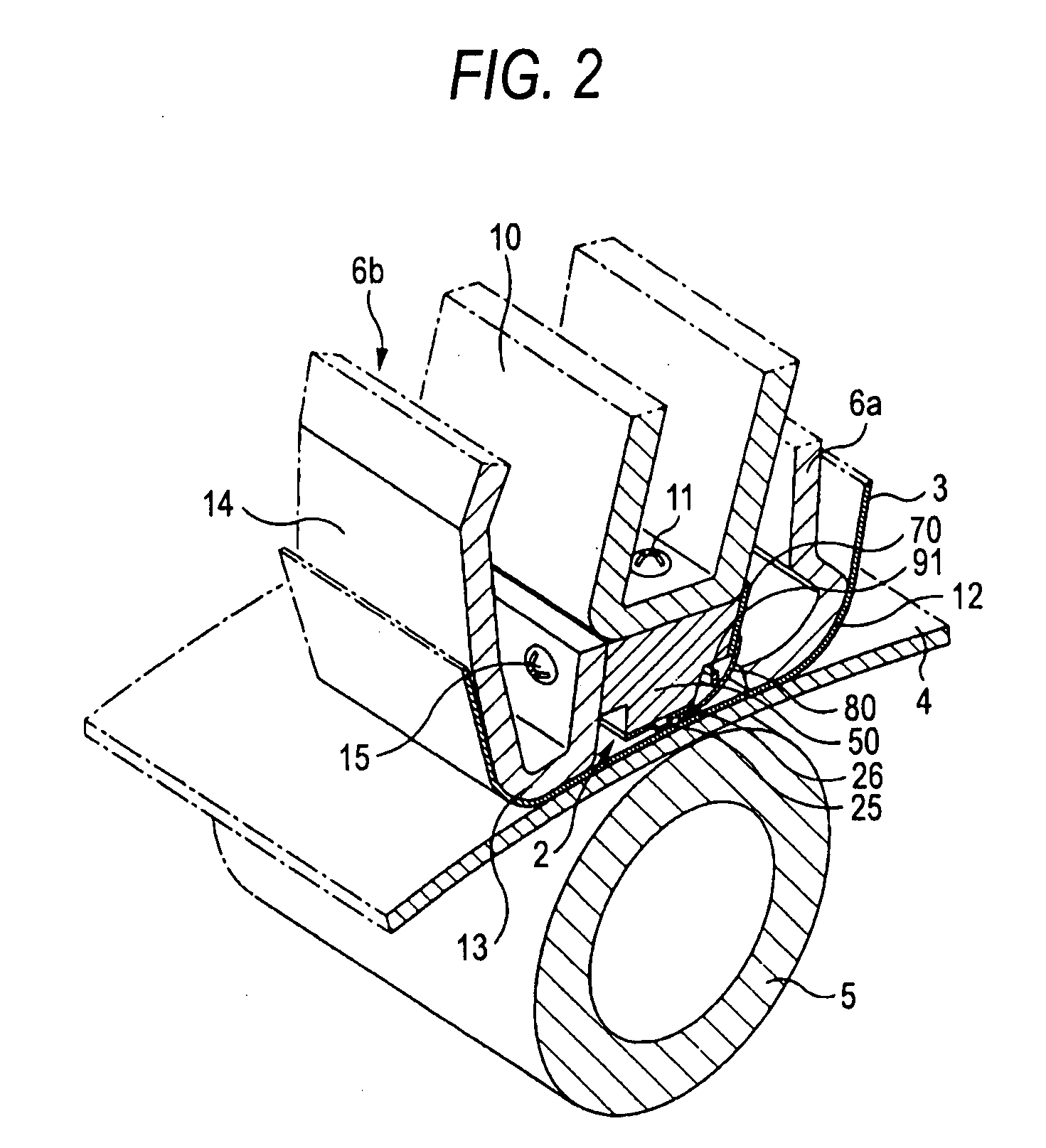

Thermal head and printing device

A thermal head includes a glass layer having a protruding section formed on one surface and a concave groove section formed on the other surface facing the protruding section, a heat generation resistor provided on the protruding section, and a pair of electrodes provided to both sides of the heat generation resistor, and a part of the heat generation resistor exposed between the pair of electrodes is defined as a heat generation section, the protruding section has a smaller curvature radius in both sides than a curvature radius in a central portion, and a width of the groove section is one of equal to and larger than a length of the heat generation section.

Owner:SONY CORP

Formwork production process for precision castings with complex deep-groove structures

InactiveCN108145095AImprove thermal conductivityReduce heat storage capacityFoundry mouldsFoundry coresSiltHeat conducting

The invention discloses a formwork production process for precision castings with complex deep-groove structures, and relates to the technical field of precision casting. According to the process, through reasonably selecting the refractory silt sand of the two front layers of formworks, the heat-conducting capacity of the formworks is improved, and the risk of loosening and hot-cracking of the castings at deep-groove parts is lowered; and through injecting dry sand into the deep-groove parts and sealing groove openings with a slurry, the problem of 'iron inclusion' brought by difficult thorough drying and insufficient strength of the formworks at the deep-groove parts is solved, and the heat storage capacity of the formworks at the deep-groove parts is weakened.

Owner:安徽应流航源动力科技有限公司

Electric cooker

InactiveCN101849765AEffective heatingSmooth movementCooking-vessel materialsElectromagnetic inductionCooker

An electric cooker has a main body (2) which can hold a non-metal pot (1) and a cover body (33) opening and closing the main body (2) and the non-metal pot (1); heaters (4b1, 4b2) for heating through electromagnetic induction are arranged on the external surface, the internal surface or inside of the non-metal pot (1); the electromagnetic induction of the heating coils (4a1, 4a2) on the main body (2) side make the heaters (4b1, 4b2) heat; a heat resisting plate (14) is disposed between the non-metal pot (1) and the heating coil (4a2); the heat resisting plate (14) isolates the heat on the side of the non-metal pot (1) having heaters (4b1, 4b2) for protecting the heating coil (4a2) and etc; the non-metal pot (1) is heated again by means of heat reflection; In the invention, the non-metal pot (1) is easy to seal heat and the electric cooker heats uniformly and completely to cook.

Owner:TIGER CORPORATION

A kind of diatomite calcium plastic composite board

A diatomite calcium plastic composite board and a production method thereof, the main points of which are that it includes the following components: PVC resin, heavy calcium carbonate, nanoscale heavy calcium carbonate, plasticizer, diatomite, straw Flour or wood flour, heat stabilizer, stearic acid, polyethylene wax, paraffin wax; after mixing and drying the above components in a certain proportion, extrude the plate structure through the extruder according to the mold, and then vacuum shape and cut , Sanding the bottom surface and the surface, the surrounding mortise and deep processing of the surface can become the finished floor. The present invention adds a small amount of nano-scale heavy calcium carbonate and diatomite to fully fill between the large particles of heavy calcium carbonate, thereby forming a complete package for PVC resin particles and increasing the specific surface area. Its reactivity increases; its hardness is high and its plasticity is strong; the nanoparticles in the nanocomposite material can prevent the formation of crystals, therefore, it can greatly reduce the weight and improve the thermal conductivity.

Owner:吉林爱尔得板材科技有限公司

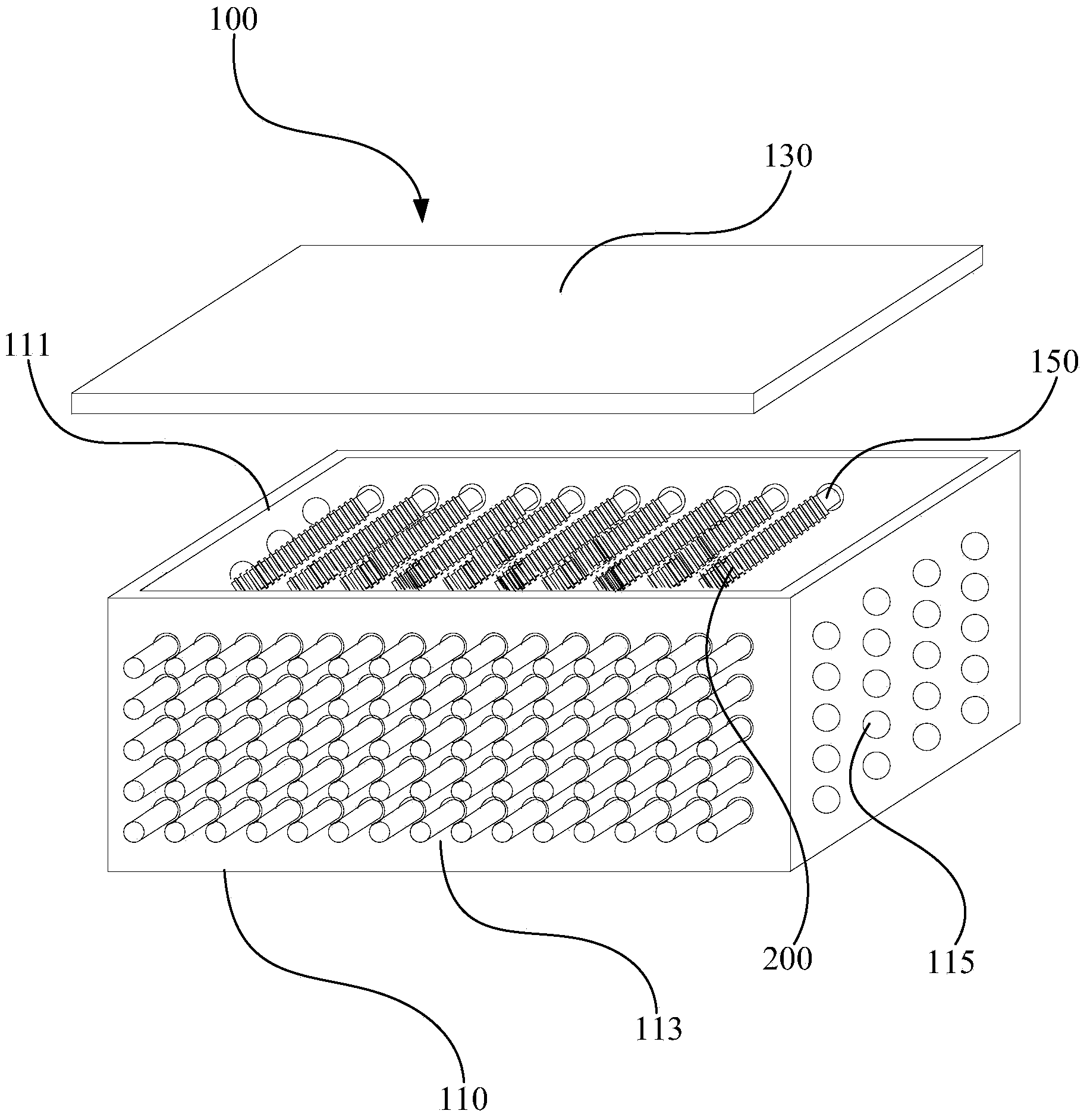

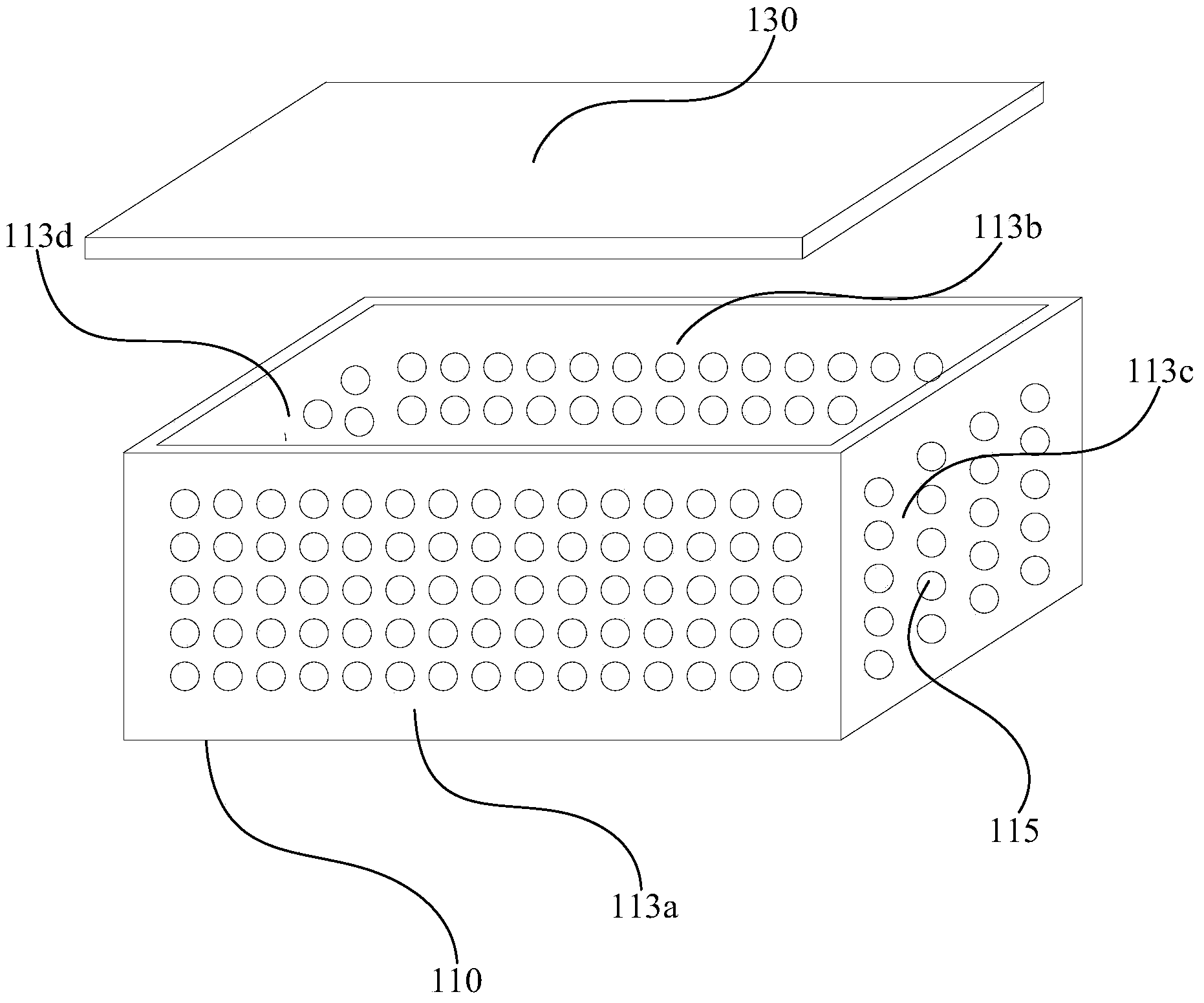

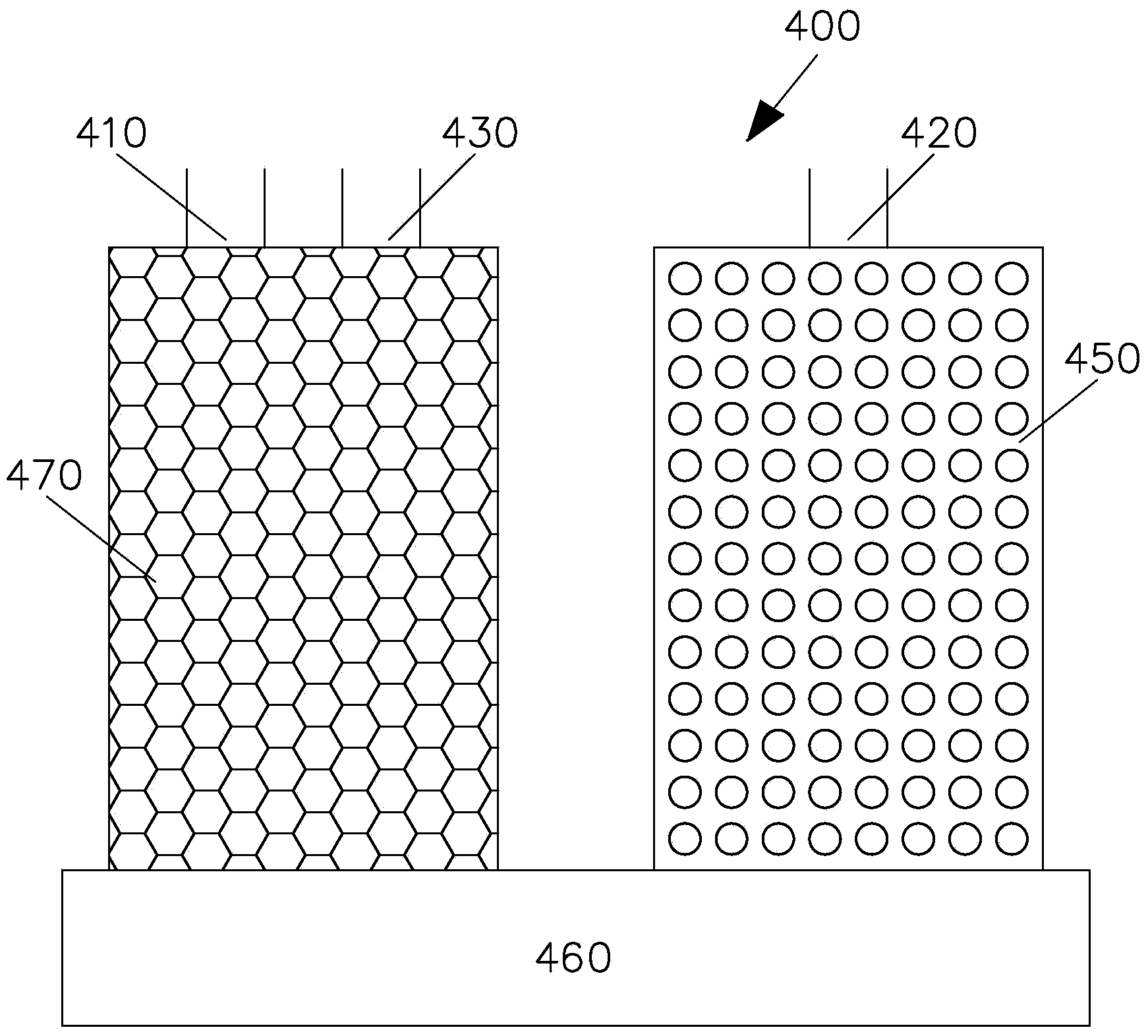

Sintering device for super-miniature annular voltage dependent resistors

ActiveCN104143401AAchieve semiconductingImprove shrinkageResistor manufactureElectrical resistance and conductanceEngineering

The invention relates to a sintering device for super-miniature annular voltage dependent resistors. The sintering device for the super-miniature annular voltage dependent resistors comprises a bottom shell, a cover body and a plurality of sintering bars. The bottom shell comprises a bottom wall and a plurality of side walls surrounding the bottom wall. The bottom shell is provided with the open end opposite to the bottom wall. The side walls are provided with a plurality of air holes. The cover body detachably covers the open end. The shell and the cover body together form a containing cavity. The sintering bars are contained in the containing cavity, horizontally hung and arranged between the two opposite side walls of the bottom shell. The sintering bars are used for being arranged in through holes in the middle of blank rings of the multiple super-miniature annular voltage dependent resistors in a penetrating mode so that the multiple blank rings can be hung on the sintering bars at intervals. According to the sintering device for the super-miniature annular voltage dependent resistors, the blank rings are not prone to deforming in the sintering process, and the requirements for the mechanical strength and the electrical property of the super-miniature annular voltage dependent resistors are met.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Cordierite kiln furniture sagger and preparation method thereof

ActiveCN110028316AExtended service lifeWill not soften and deformCharge supportsCeramic materials productionMullitePhosphoric acid

The invention discloses a cordierite kiln furniture sagger and a preparation method thereof, and belongs to the technical field of refractory materials. The cordierite kiln furniture sagger is characterized in that the raw materials are as follows by weight: 10-15 parts of mullite M47 of 3-1 mm, 10-15 parts of mullite M47 of 1-0 mm, 16-20 parts of cordierite of 2-1 mm, 7-12 parts of cordierite with the particle size less than 150 meshes, 8-13 parts of sillimanite of 0.5-0 mm, 7-13 parts of andalusite with the particle size less than 200 meshes, 4-7 parts of silicon carbide with the particle size less than 240 meshes, 5-10 parts of vice-white corundum with the particle size less than 240 meshes, 3-6 parts of aluminum oxide Ca 370C micro powder, 4-6 parts of Suzhou soil of 0.045 mm, 3.5-5.5parts of paper pulp, 0.3-0.6 part of phosphoric acid, and 0.3-0.6 part of dextrin. The high temperature load softening temperature of thecordierite kiln furniture sagger is enough, the refractorinessis higher, and the quick cooling and heating resistance property is excellent. After being repeatedly heated and cooled, the sagger still keeps certain mechanical strength and is not cracked.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

Thermal head and printing device

A thermal head includes a glass layer having a protruding section formed on one surface and a concave groove section formed on the other surface facing the protruding section, a heat generation resistor provided on the protruding section, and a pair of electrodes provided to both sides of the heat generation resistor, and a part of the heat generation resistor exposed between the pair of electrodes is defined as a heat generation section, the protruding section has a smaller curvature radius in both sides than a curvature radius in a central portion, and a width of the groove section is one of equal to and larger than a length of the heat generation section.

Owner:SONY CORP

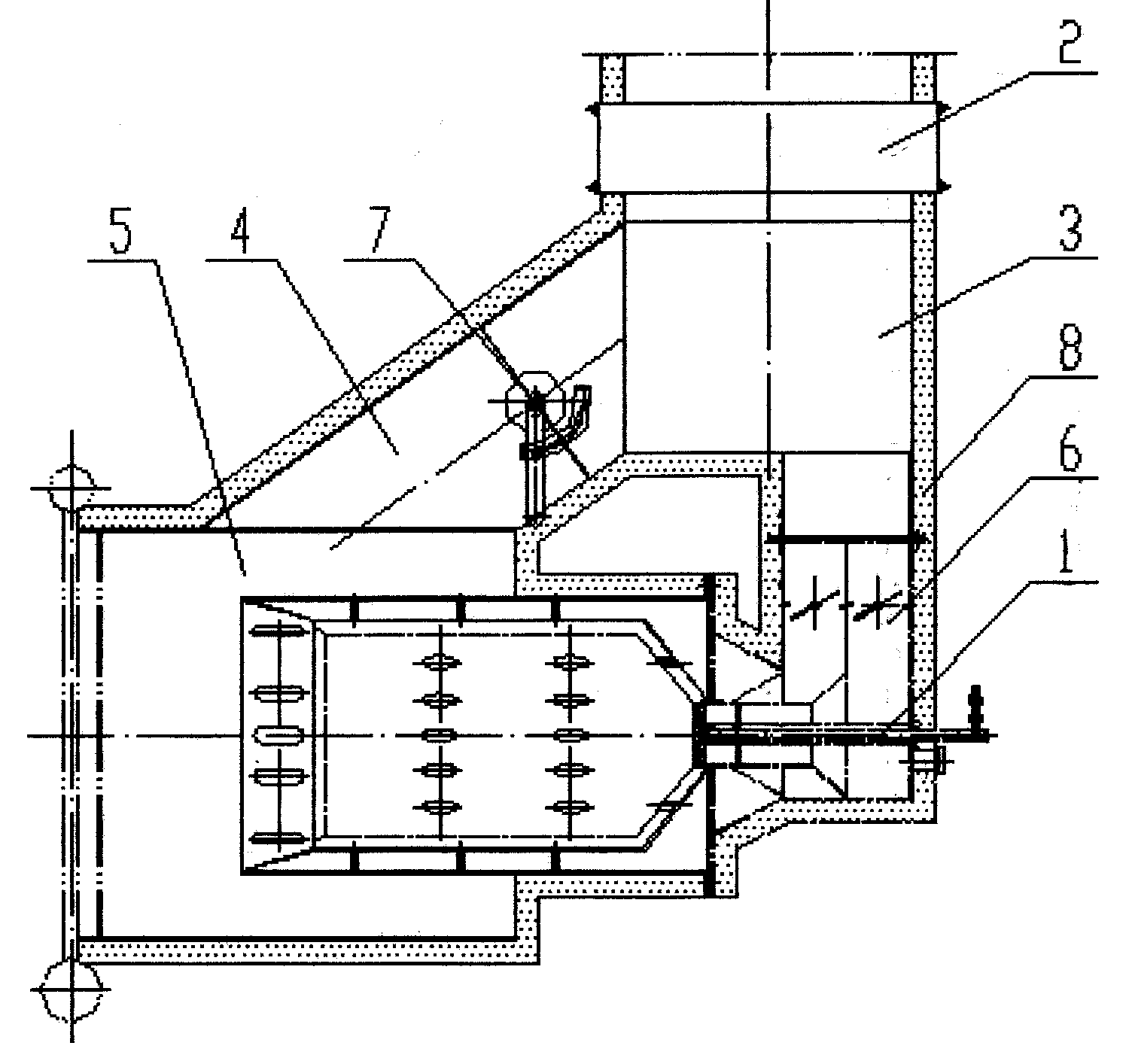

Device with annular cold air low-heat-storage quick start ignition and combustion system

InactiveCN103438443AReduce heat storage capacityFully mixed combustionFluidized bed combustionCombustion ignitionCold airCombustion system

The invention relates to a device with an annular cold air low-heat-storage quick start ignition and combustion system. The device is characterized in that an ignition and combustion device is composed of a combustor body and an ignition device of which an ignition end extends into the combustor body, wherein the ignition and combustion device is arranged in a combustion air duct; the combustion air duct is connected with an air supplementing duct and an air distribution duct; the air supplementing duct is provided with an adjusting damper; a communicating chamber is provided with an expansion joint; a thermal fire-proof layer is arranged outside the device with the annular cold air low-heat-storage quick start ignition and combustion system. In an ignition starting process of a boiler, primary hot air volumes of the air supplementing duct and the air distribution duct are adjusted through the adjusting damper, so that hot air and fuel are fully mixed and combusted and the combustion efficiency is improved; the purposes of low oil consumption and quick start of a circulating fluidized bed boiler are reached by reducing the lengths of the ducts, reducing the using amount of the thermal fire-proof material and reducing the heat storage capacity of the ducts.

Owner:鞍山锅炉厂有限公司

Thermal head and printing device equipped with the same

InactiveUS20070216731A1Improve production efficiencyImprove thermal efficiencyPrintingThermal HeadResistor

A thermal head includes a base layer having a predetermined thickness and provided with a substantially semicylindrical protruding section integrally formed on one surface of the base layer, a heat generation resistor formed on the protruding section, and a pair of electrodes formed on both sides of the heat generation resistor, wherein a part of each of the heat generation resistors exposed between the pair of electrodes is defined as a heat generation section, and the base layer is provided with a groove section formed on the opposite side of the protruding section and having opening on the other surface of the base layer.

Owner:SONY CORP

Packaging machine for packs of beverage containers and related conveying device

ActiveUS20100126122A1Run energy savingReduce capacityWrappers shrinkageConveyorsThin membraneEngineering

A conveying device and a packaging machine for beverage containers are disclosed. The beverage containers are grouped as packs and wrapped with film, comprising a horizontal conveying device including an endlessly circulating conveyor chain whose movable members and / or meshes each have a supporting structure and contact areas for the packs and / or coatings that include significant portions of PTFE plastic. The contact areas of plastic have a thickness corresponding to at least 10% of the thickness of the supporting structure covered and / or coated therewith

Owner:KRONES AG

Ceramic filter containing carbonaceous material and bonded with silica adhesive and manufacturing method thereof

The invention relates to a ceramic filter suitable for filtering metal fused mass, comprising refractory material, carbonaceous material and silica adhesive. The invention also relates to making method for the filter. The ceramic filter has the advantages of more economical making, high mechanical strength not shrinkage during sintering process, more stable performance in memory process and more safe usage.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Preparation method of temperature-resistant ultrathin external wall insulation coating

InactiveCN106147469AHigh compressive strengthHigh melting pointChemical industryAnti-corrosive paintsRare earthTemperature resistance

The invention discloses a preparation method of a temperature-resistant ultrathin external wall insulation coating. The temperature-resistant ultrathin external wall insulation coating is used for thermal insulation of crude oil, heavy oil and residual oil storage tanks and building external walls and is prepared from 70-300 parts of a resin emulsion, 20-50 parts of pigments, 30-80 parts of filler, 0.1-1 part of a rare earth oxide, 13-40 parts of an aid and 100-300 parts of water. According to the preparation method, by means of the high flowability and the film-forming property of special monomer modified self-crosslinked acrylate copolymers as well as the high stability, the low heat conductivity and the heat storage property of rare earth oxide, high-temperature resistance, elasticity and anti-ageing resistance are formed, the temperature-resistant ultrathin insulation coating is prepared and has a thin coating layer only about 1-3 mm thick, the heat efficiency of a heating furnace can be improved by 1.5% or above, the heat dissipation loss of the outer surface of a furnace body is decreased by not less than 40%, the coating can resist 150 DEG C after being cured, and the temperature-resistant ultrathin external wall insulation coating is high in adhesive force and good in ductility and corrosion resistance and can be widely applied to thermal insulation of the crude oil, heavy oil and residual oil storage tanks and the building external walls.

Owner:泉州市合创涂料科技有限公司

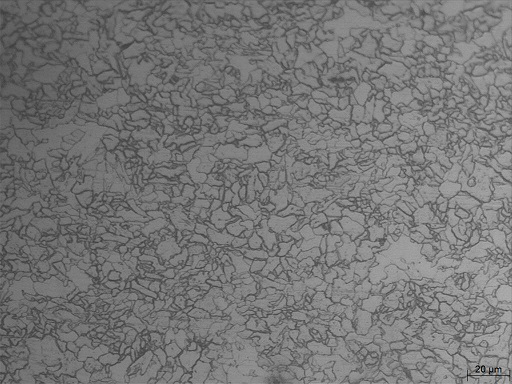

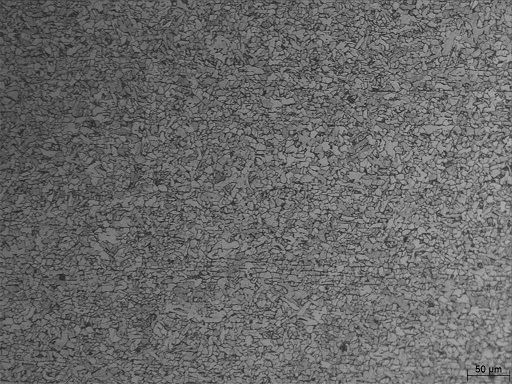

Thin SAPH 440 strip steel and production method thereof

ActiveCN111979478AReduce heat storage capacityImprove hardenabilityProcess efficiency improvementSteelmakingRefining (metallurgy)

The invention relates to thin SAPH 440 strip steel and a production method thereof, and belongs to the technical field of metallurgy. The strip steel comprises the following chemical components: by mass, C: 0.05-0.10%, Si <= 0.12%, Mn: 1.0-1.2%, P <= 0.020%, S <= 0.020%, Als: 0.02-0.05%, Ti: 0.005-0.015%, B: 0.001-0.002%, N <= 0.0045%, and the balance Fe and inevitable impurities. The production method comprises the steps of molten iron pretreatment, converter steelmaking, LF refining, slab continuous casting, hot rolling, cooling, leveling and pickling; and in the hot rolling process, finishrolling temperature is 870-930 DEG C, and laminar flow cooling adopts a latter 1 / 4 section cooling mode. Through microalloy component design and the matching hot rolling process, the finished strip steel is good in plasticity and small in strength performance fluctuation.

Owner:HANDAN IRON & STEEL GROUP +1

High-heat-storage-density tin alloy with working temperature less than 100 DEG C and technology thereof

The invention discloses a high-heat-storage-density tin alloy with working temperature less than 100 DEG C and a technology thereof. The alloy is prepared from the following components in percentage by weight: 15.0 to 18.0 weight percent of Cd, 6.0 to 6.5 weight percent of Pb, 8.4 to 8.6 weight percent of Bi, 1.2 to 1.5 weight percent of Sb, 2.0 to 2.5 weight percent of Ga, 0.2 to 0.3 weight percent of Y, 0.1 to 0.2 weight percent of Cu, 0.4 to 0.5 weight percent of Sr and the balance of tin. The material provided by the invention provides the tin alloy with the working temperature less than 100 DEG C for storing energy for the field of energy storage of alloys; a melt has excellent oxidization-resisting performance, thermophysical performance and thermal cycling performance. The difficulties of a current heat storage field can be overcome, and extremely great social value and market value also can be obtained while technical problems in the field of energy-storage alloys are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Air conditioners, air conditioning system and control method thereof

ActiveCN111322699AAchieve continuous coolingImprove cooling effectMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringAir conditioning

The invention discloses air conditioners, an air conditioning system and a control method thereof. The air conditioning system comprises the first air conditioner and the second air conditioner. Whenthe first air conditioner is in a refrigeration operation mode, an evaporator end of the first air conditioner absorbs heat, and a condenser end of the first air conditioner releases heat. If the temperature of a heat storage agent is higher than a first preset value, it is represented that the heat storage agent absorbs enough heat from the condenser, the first air conditioner sends a first signal to the second air conditioner, and moves to a preset position to dissipate heat after receiving a second signal, responding to the first signal, sent by the second air conditioner if it is determined that the second air condition is in a ready state, the first preset position is the position where the second air conditioner is located, the second air conditioner moves to the original position ofthe first air conditioner to replace the first air conditioner to continue to carry out refrigeration, and therefore the cold capacity is continuously supplied.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

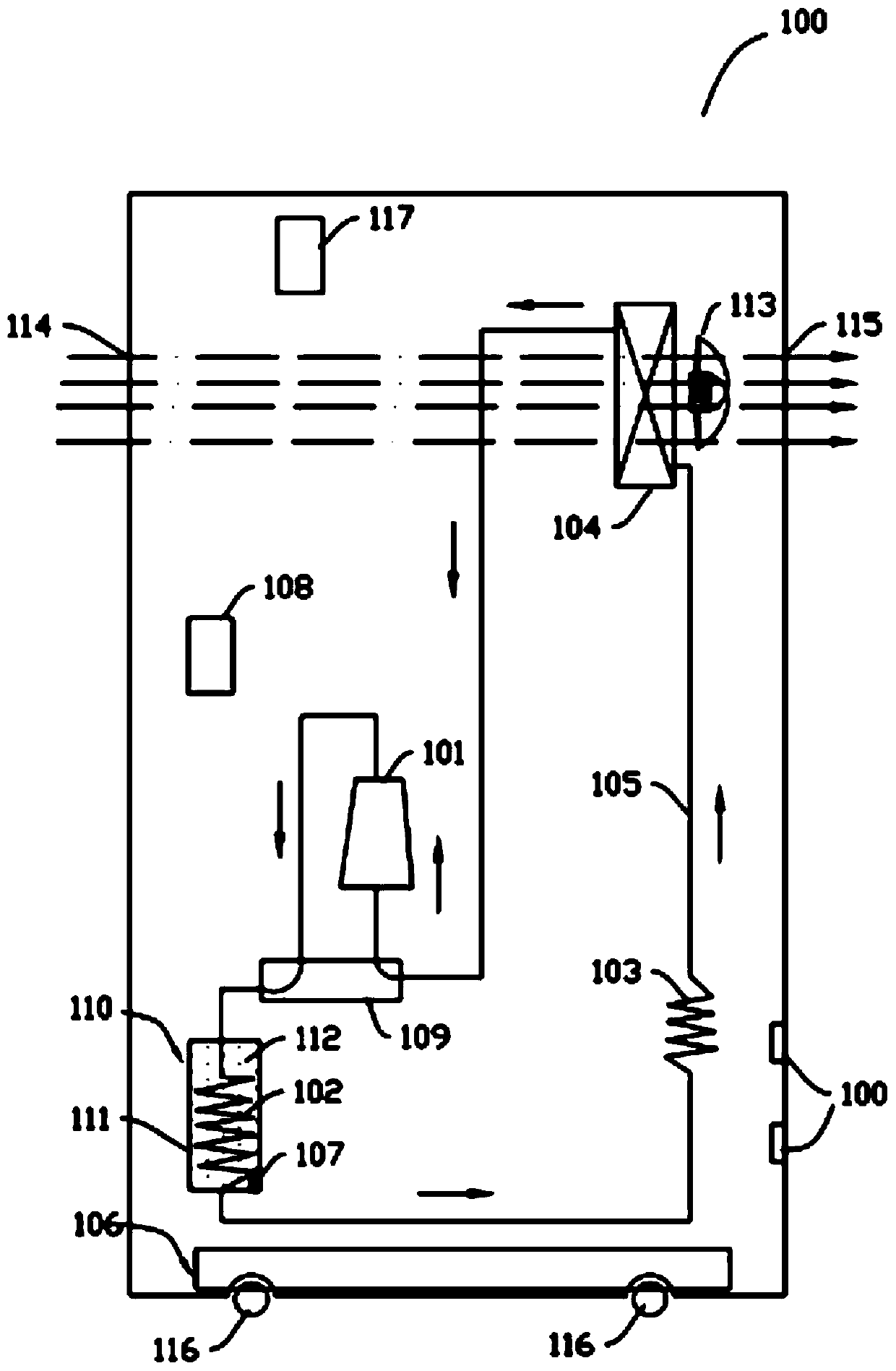

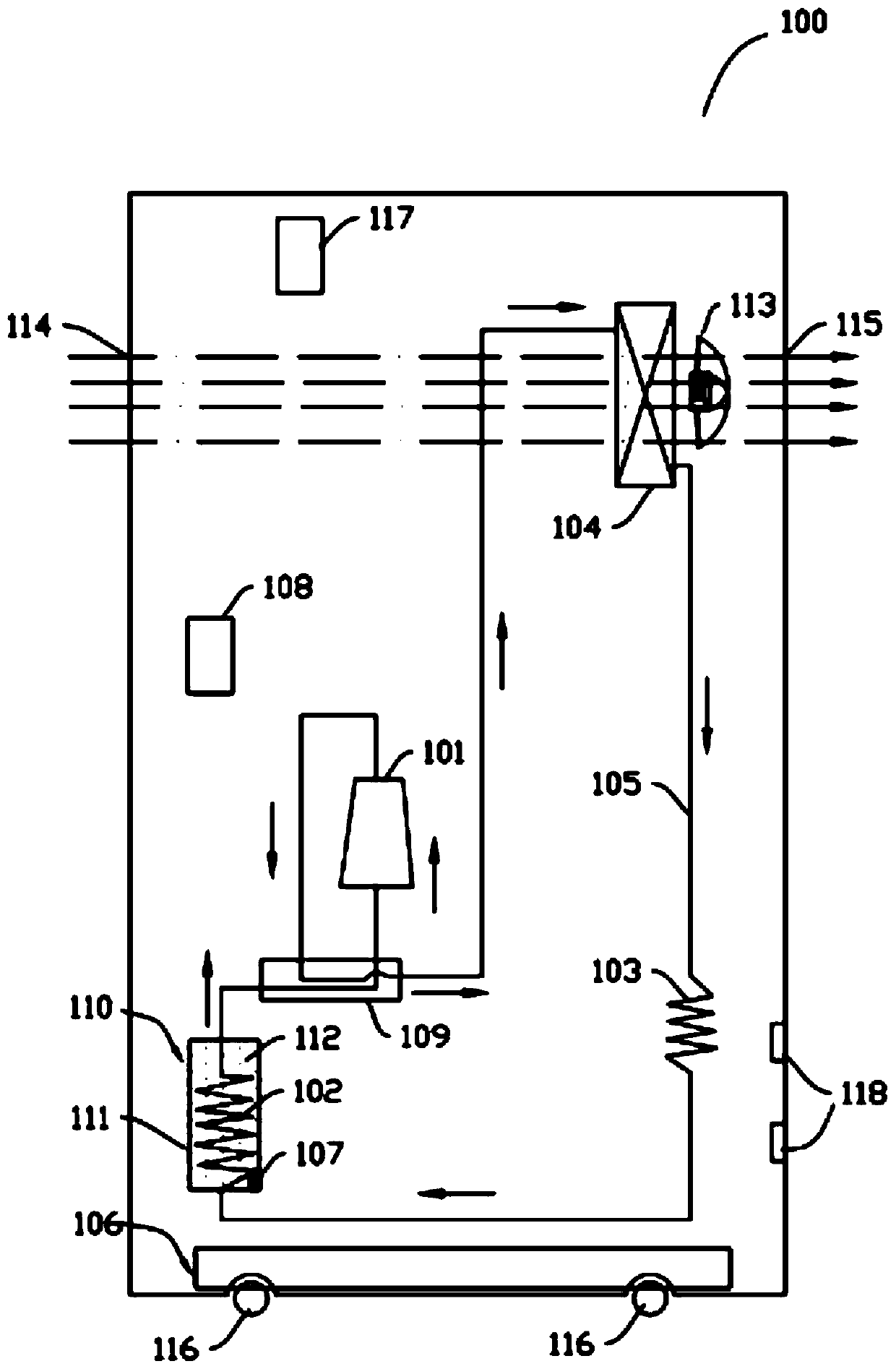

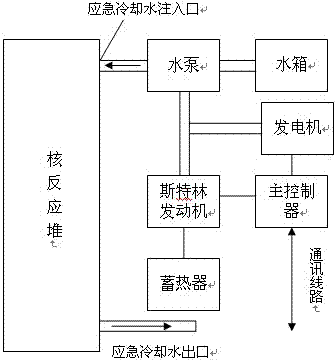

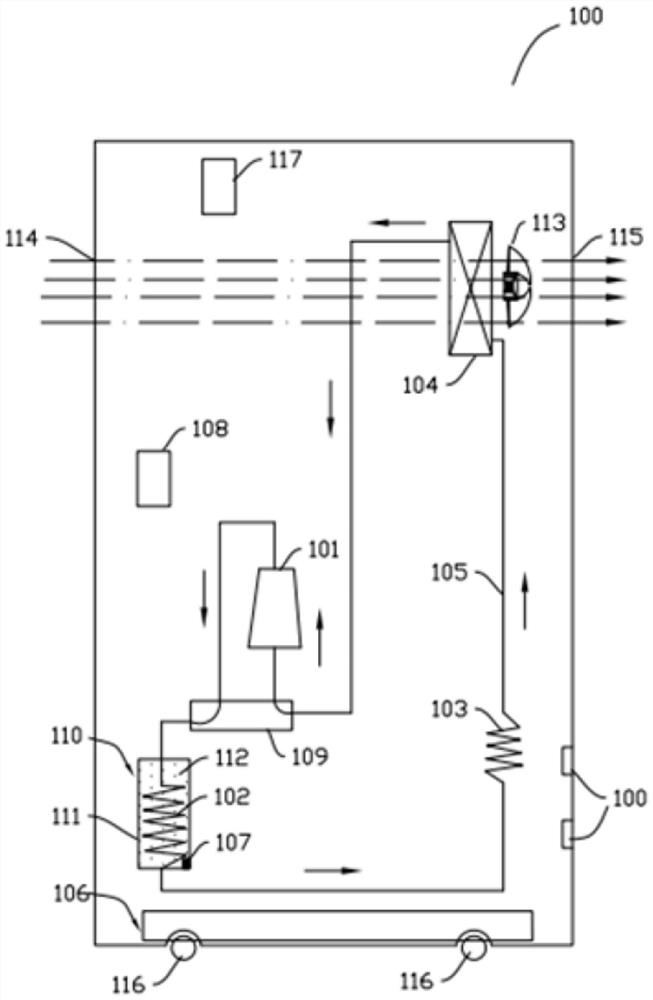

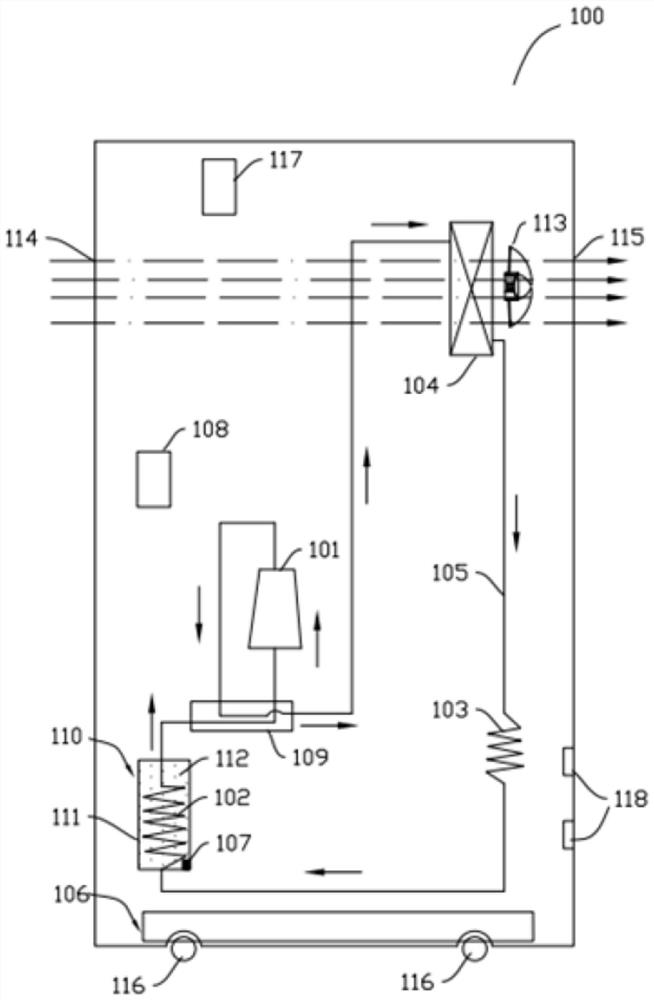

Emergent cooling system of nuclear power station based on heat accumulating type Stirling engine

InactiveCN103050159ASimple structureGuaranteed normal operationNuclear energy generationCooling arrangementNuclear powerReactor safety

The invention discloses an emergent cooling system of a nuclear power station based on a heat accumulating type Stirling engine. The system comprises a nuclear reactor, a water pump, a water tank, a Stirling engine, a generator, a heat accumulator and a main controller, wherein the water tank is connected with a water inlet of the water tank; a water outlet of the water tank is connected to the nuclear reactor; power of the Stirling engine is output to power output ends of the generator and the water pump; an electric energy output end of the generator is connected with the main controller; the main controller is connected with the Stirling engine; a heater in the Stirling engine is connected with the heat accumulator; the heat accumulator is further connected with the main controller; and the heat accumulator is made of a high-temperature resistant material with higher specific heat capacity. The system has the advantages of high reliability, capability of guaranteeing operation safety of the nuclear reactor and the like.

Owner:CHENGDU UNI LINK ENERGY

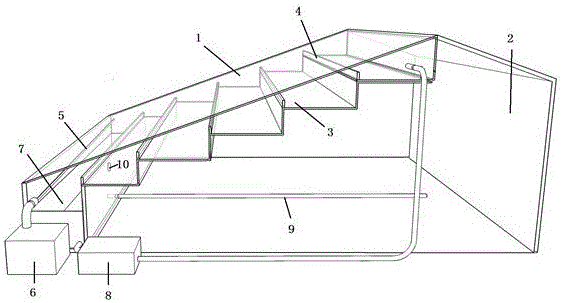

Sunroom with water purification function

InactiveCN106069368ALow costImprove insulation effectClimate change adaptationSaving energy measuresWater storage tankEngineering

The invention discloses a sunroom with a water purification function. The sunroom is characterized in that a structure that a roof inclines toward the south is adopted; the roof is a flat-shaped upper glass layer; walls are connected around the upper glass layer; a stepped lower glass layer is arranged below the upper glass layer; a water baffle is arranged on the edge of each step; a water purification trough is fixed on the north-facing wall of the wall at the south side; the lower end of the water purification trough is connected with a water purification tank by a pipeline; a water storage tank is arranged on the ground, close to the south end, in the sunroom and is connected with a pump station by a pipeline; the pump station is connected to the uppermost space of an interlayer between the upper and lower glass layers by a pipeline. The sunroom has various functions of water purification, lighting, heat storage, and the like, has a simple structure, is low in cost, saves energy, land and water and has great popularization potential.

Owner:NANJING SUOLEYOU ENERGY SAVING TECH CO LTD

Fast switchover heat accumulating type aluminum smelting furnace

InactiveCN103528368AReduce energy consumptionAvoid cloggingCrucible furnacesWaste heat treatmentEngineeringSmelting

The invention discloses a fast switchover heat accumulating type aluminum smelting furnace which comprises a furnace body, a first fuel spray nozzle, a second fuel spray nozzle, a first vent pipe, a second vent pipe, a first heat reservoir, a second heat reservoir, a first air inlet pipe and a second air inlet pipe. The first vent pipe and the second vent pipe are arranged on the end wall of one side of the furnace body at intervals and are communicated with a combustion chamber, and the first vent pipe and the second vent pipe are located below the first fuel spray nozzle and the second fuel spray nozzle respectively. The first heat reservoir comprises a first port, a second port and a third port. The first port of the first heat reservoir is communicated with the first air inlet pipe, the second port of the first heat reservoir is communicated with the first vent pipe, and the third port of the first heat reservoir is communicated to a chimney through a pipeline. The second heat reservoir comprises a first port, a second port and a third port. The first port of the second heat reservoir is communicated with the second air inlet pipe, the second port of the second heat reservoir is communicated with the second vent pipe, and the third port of the second heat reservoir is communicated to the chimney through a pipeline. The first heat reservoir and the second heat reservoir are alternatively switched and run between a preheating working state and a heat accumulating working state.

Owner:横琴东方智睿科技有限公司

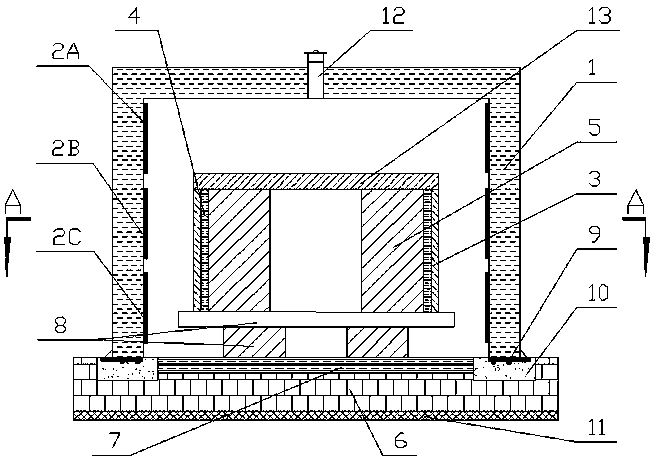

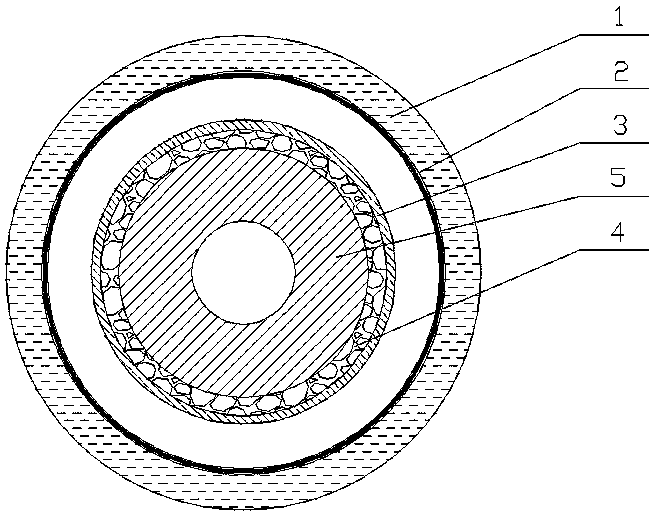

Non-oxidation differential temperature quenching heat treatment equipment for abrasion-resisting cement roller shell

ActiveCN109576479APrevent oxidationHeating fastFurnace typesHeat treatment furnacesSurface oxidationAntioxidant

The invention discloses non-oxidation differential temperature quenching heat treatment equipment for an abrasion-resisting cement roller shell and relates to the technical field of roller shell differential temperature heat treatment. The non-oxidation differential temperature quenching heat treatment equipment for the abrasion-resisting cement roller shell comprises a cylindrical protective shield, an antioxidant, a protective cover, a cylindrical profiled furnace shield, a heating element and a trolley, wherein the protective shield surrounds the cement roller shell, the protective shield and the cement roller shell are coaxially arranged, the antioxidant is arranged between the protective shield and the cement roller shell and makes contact with the outer surface of the side wall of the cement roller shell, the cement roller shell is covered with the protective cover, the profiled furnace shield surrounds the protective shield, the profiled furnace shield and the cement roller shell are coaxially arranged, the heating element is arranged on the internal side wall of the profiled furnace cover, and the profiled furnace shield, the cement roller shell and the protective cover aresupported by the trolley; and the height of the cement roller shell is identical with that of the protective shield, and a certain space is arranged between the protective shield and the profiled furnace shield. The equipment which can prevent cement roller shell surface oxidation and can also achieve differential temperature heat treatment of the cement roller shell is provided for the defects of an ordinary trolley furnace treating the abrasion-resisting cement roller shell.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Air conditioner, air conditioning system and control method thereof

ActiveCN111322699BAchieve continuous coolingImprove cooling effectMechanical apparatusSpace heating and ventilation safety systemsAir conditioningCooling capacity

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com