Electric cooker

A technology of electric rice cooker and conductive layer, which is applied in special materials of cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of difficult bottom side heating, inability to cook, overheating of pot side, etc., and achieve the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

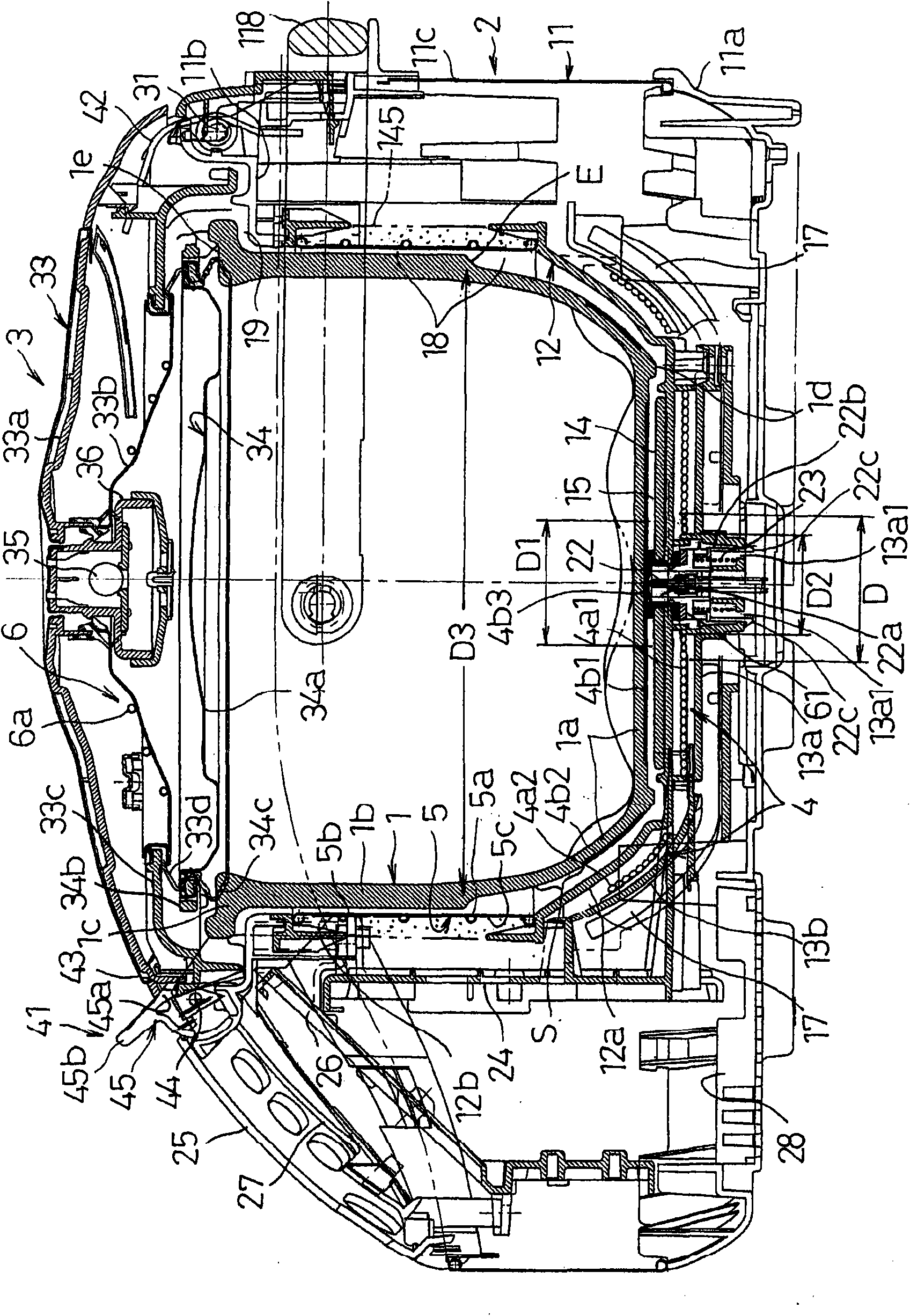

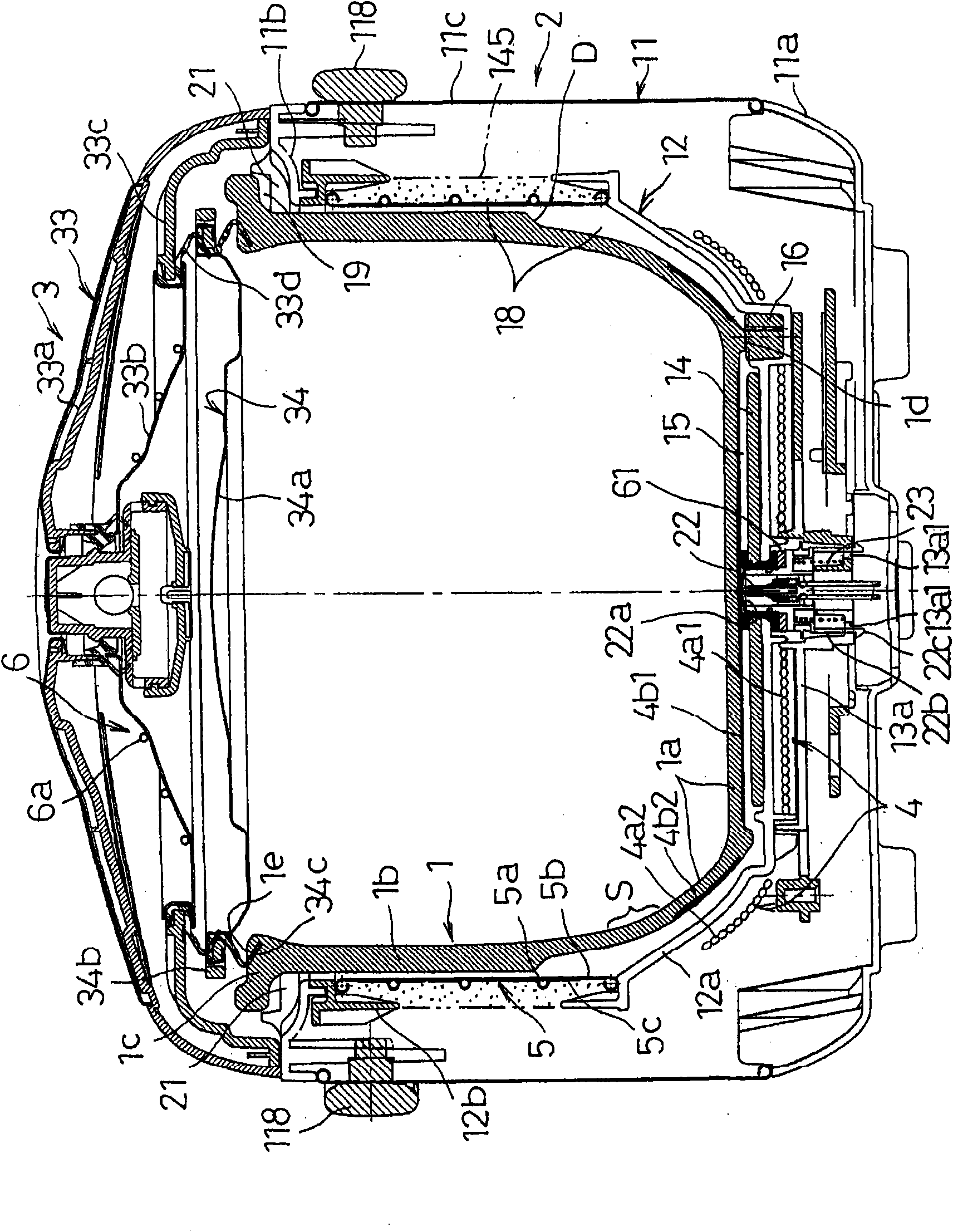

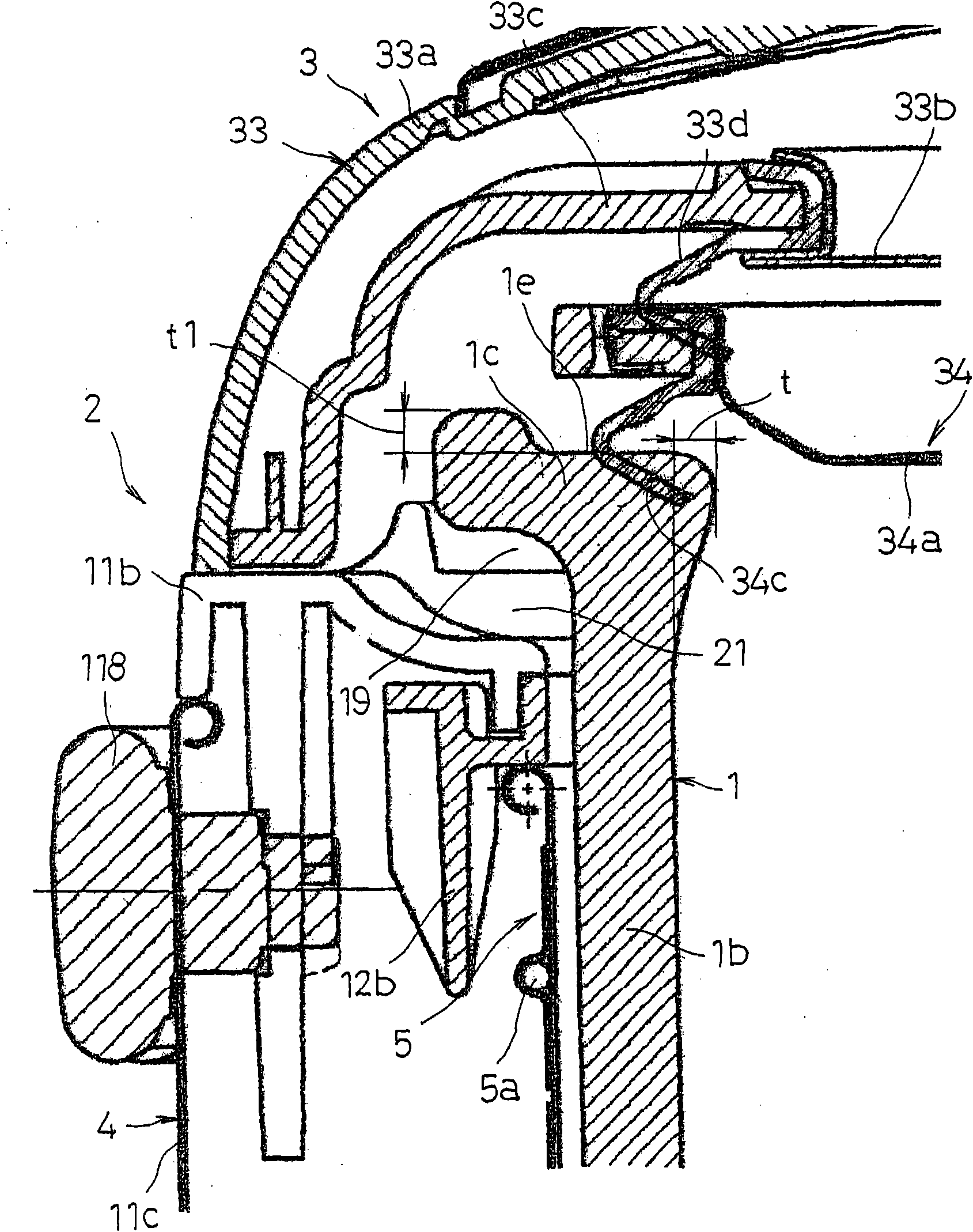

[0051] Below, refer to Figure 1 to Figure 21 Embodiments of the rice cooker of the present invention will be explained in detail for understanding of the present invention.

[0052] Such as Figure 1 ~ Figure 3 As shown, the electric rice cooker of this embodiment has: a non-metallic pot 1; a body 2 that accommodates the non-metallic pot 1 that can be put in and out; The temperature detection performed by the temperature sensor 22 that is in contact with the non-metallic pot 1 from the main body 2 side controls the energization to the heating coils 4a1, 4a2, and utilizes the alternating magnetic field from the heating coils 4a1, 4a2 to make the non-metallic pots 1 The conductive layers 4b1, 4b2 at the bottom generate heat for cooking. Here, the heating coils 4a1, 4a2 and the conductive layers 4b1, 4b2 mainly constitute the bottom heating source 4 for imparting heat for cooking, and the side heating source 5 and heater are also provided for mainly imparting heat to the cooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com