Ventilation heating system for tunnels in high-altitude and cold regions as well as ventilation heating construction method

A technology for ventilation in alpine regions and tunnels. It is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc. It can solve the problems of insufficient heating demand and poor heating effect, and achieve high practical value, convenient installation and layout, and low investment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

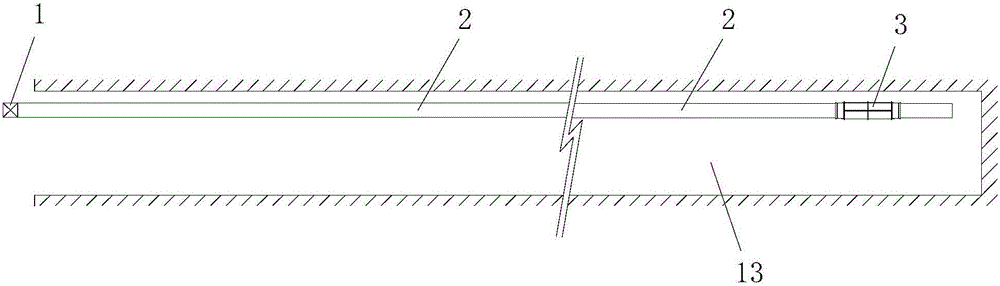

[0059] Such as figure 1 A ventilation and heating system for tunnels in high-altitude and cold regions is shown, which includes an axial flow fan 1 that supplies air to the tunnel hole 13 of the constructed tunnel, an air duct 2 arranged in the tunnel hole 13 of the constructed tunnel and The ventilation heating pipe 3 for heating the cold air sent into the construction tunnel by the axial flow fan 1 , the air pipe 2 is located at the front side of the axial flow fan 1 . The ventilation heating pipe 3 is installed on the air pipe 2 and connected with the air pipe 2 to form a ventilation pipe connected with the air outlet of the axial flow fan 1 .

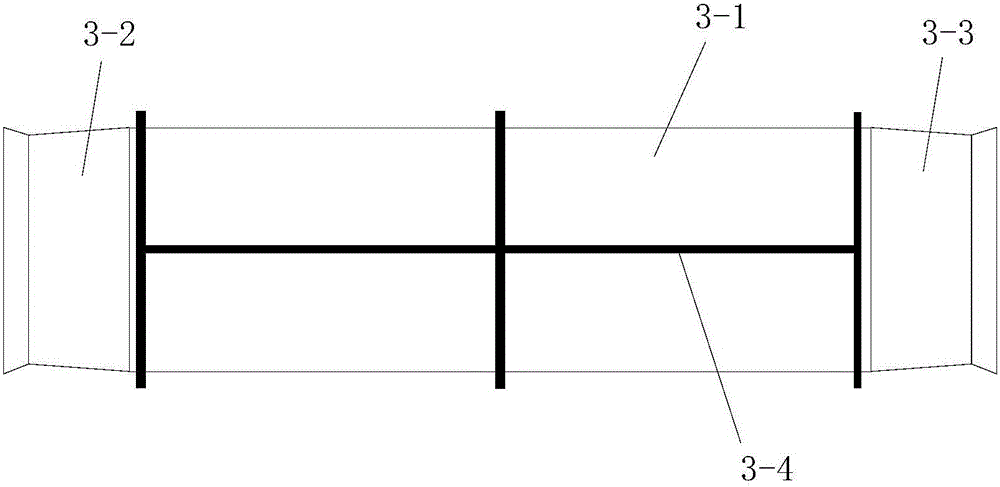

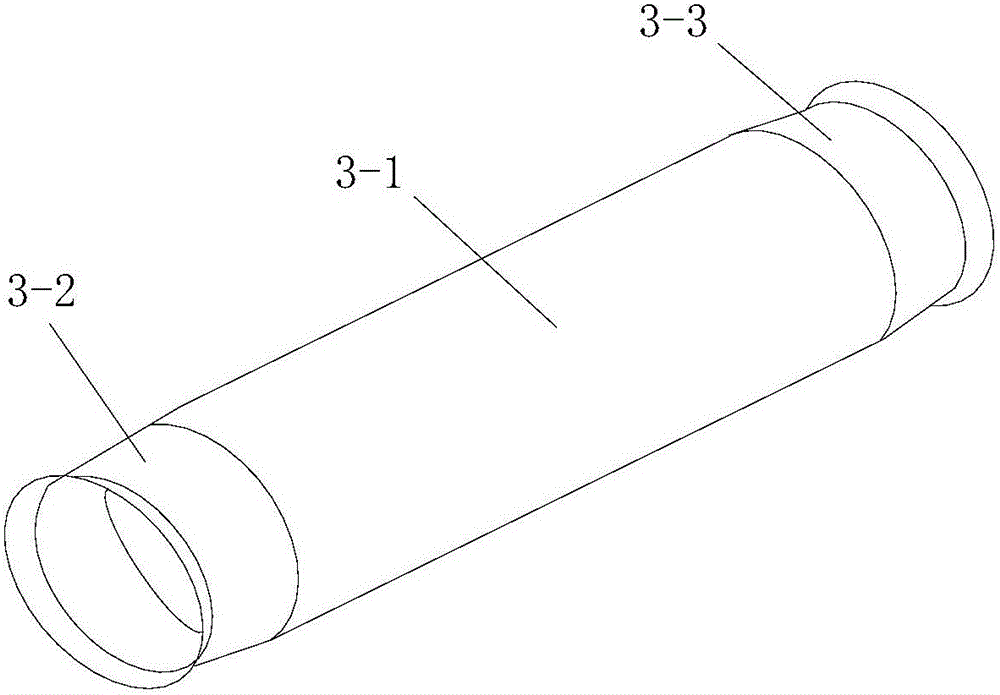

[0060] Such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the ventilation heating pipe 3 includes a circular heating pipe 3-1 and an air outlet 3-3 and an air inlet 3-2 respectively installed at the front and rear ends of the circular heating pipe 3-1; the circular heating pipe 3- 1 including the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com