Pneumatic tire

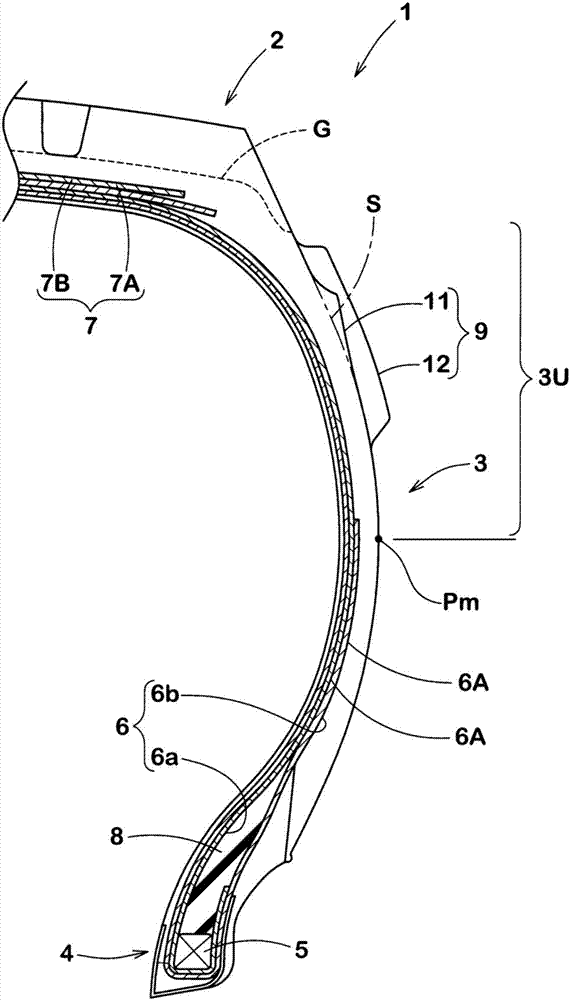

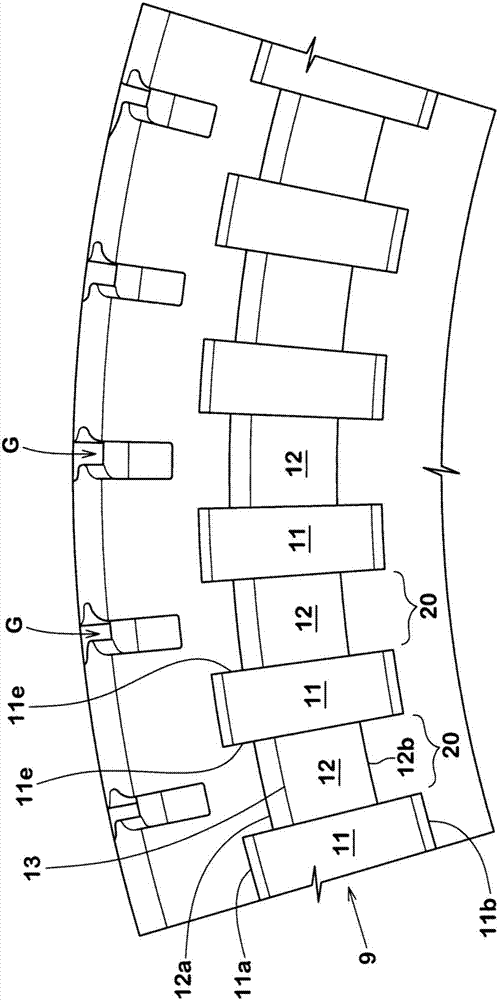

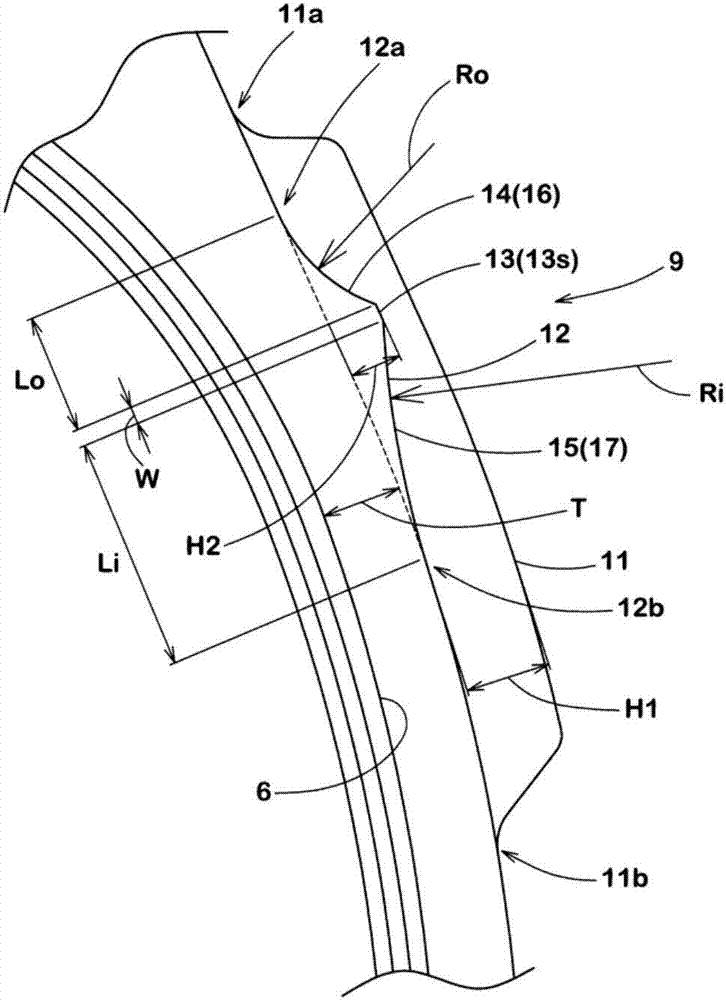

A technology of pneumatic tires and tires, applied in tire parts, tire sidewalls, transportation and packaging, etc., can solve problems such as deterioration, small rubber thickness, cut resistance and cutting resistance, and maintain riding comfort and reduce rubber. volume, the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] In order to confirm the effect of the present invention, a pneumatic tire (LT265×70R17) for a four-wheel drive vehicle having side protectors of the specifications in Table 1 was trial-manufactured, and rock performance, cutting resistance performance, heat storage performance, and ride comfort performance were tested. . All the test tires have substantially the same specifications except for the side bead.

[0051]

[0052] Under the conditions of rim (17×7.5) and internal pressure (100kPa), install each trial tire on all wheels of a four-wheel drive vehicle (2500cc), and test it on rocky roads including rocky mountains, etc. through the driver's senses The traction performance (rock performance) when running on a runway was evaluated. The results are represented by an index with Comparative Example 1 as 100. The larger the value, the better the rock performance.

[0053]

[0054] After running for about 50 km on the above-mentioned rocky road surface, the cuts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com