Double-action type hydraulic transmission Stirling engine taking heat storage device as heat source

A Stirling engine and hydraulic transmission technology, which is applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve the problems of high failure rate of complex systems, limited use of secondary batteries, low voltage of single batteries, etc. problems, to achieve the effect of wide adaptability, low cost and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

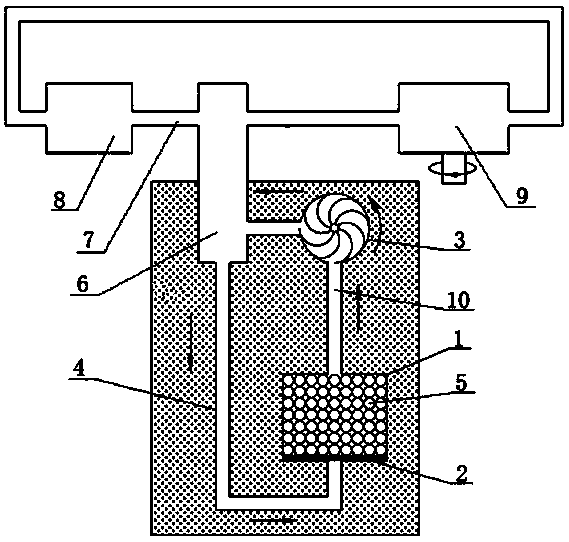

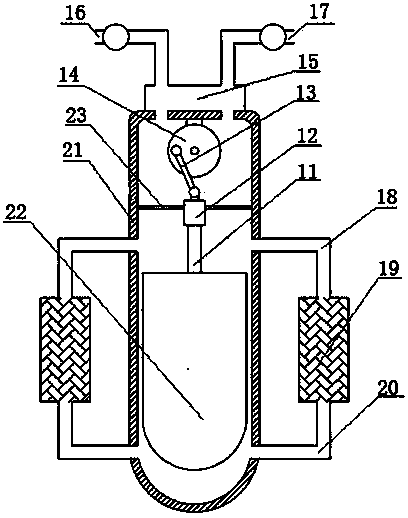

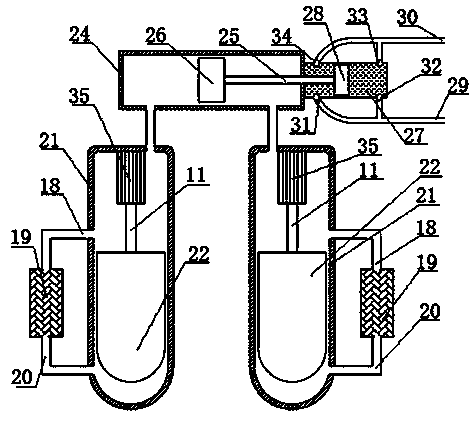

[0032] Such as figure 1 As shown, a double-acting hydraulic transmission Stirling engine with a heat accumulator as a heat source, which includes a heat accumulator shell 1, a heating element 2, a heat exchange system 3, an air inlet pipe 4, a heat storage body 5, a hydraulic pressure Transmission Stirling engine 6, hydraulic pipeline 7, hydraulic system liquid storage tank 8, hydraulic motor 9 and hot air pipeline 10, heat storage body 5 is a ceramic heat storage ball, located in the heater shell 1, and the heating element 2 is located in the heater Inside the shell 1 and in contact with the ceramic heat storage ball, the hot air pipe 10 communicates with the cold chamber of the hydraulic transmission Stirling engine 6 and the heater shell 1 through the heat exchange system 3. The heat exchange system 3 is a high-temperature hot air system, and the air inlet pipe 1 communicates with The thermal cavity of the hydraulic transmission Stirling engine 6 and the heater shell 1, th...

Embodiment 2

[0041] Such as figure 1 As shown, a double-acting hydraulic transmission Stirling engine with a heat accumulator as a heat source is characterized in that it includes a heat accumulator shell 1, a heating element 2, a heat exchange system 3, an air inlet duct 4, a heat storage Body 5, hydraulic transmission Stirling engine 6, hydraulic pipeline 7, hydraulic system liquid storage tank 8, hydraulic motor 9 and hot air pipeline 10, heat storage body 5 is ceramic heat storage ball, located in heater shell 1, heating element 2 is located in the heater shell 1 and is in contact with the ceramic heat storage ball. The hot air pipe 10 communicates with the cold chamber of the hydraulic transmission Stirling engine 6 and the heater shell 1 through the heat exchange system 3. The heat exchange system 3 is a high-temperature hot air system. The air duct 1 communicates with the hot chamber of the hydraulic transmission Stirling engine 6 and the heater shell 1, and the hydraulic Stirling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com